SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 1269 of 1463

POWER STEERING SYSTEM 6A-9

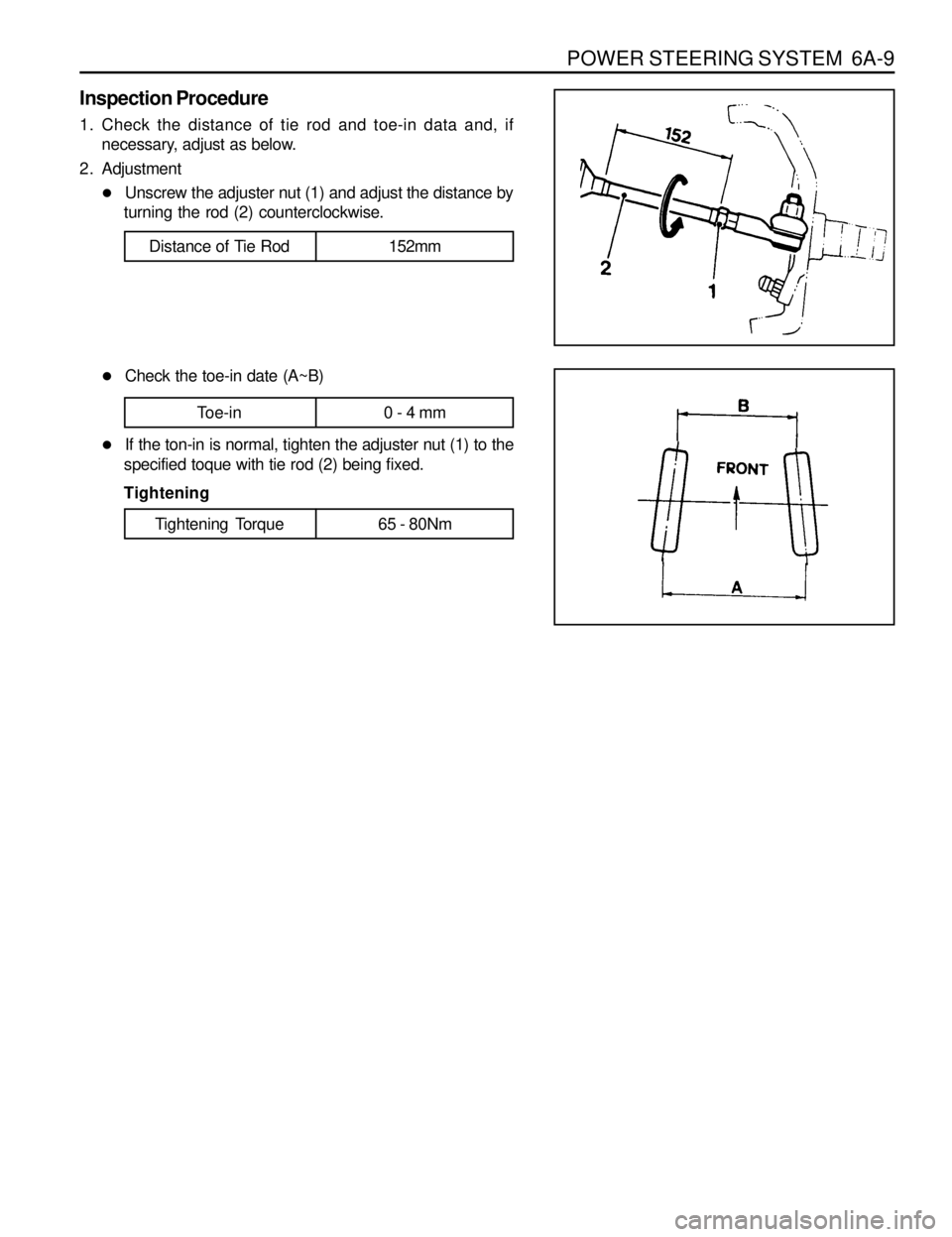

Inspection Procedure

1. Check the distance of tie rod and toe-in data and, if

necessary, adjust as below.

2. Adjustment

lUnscrew the adjuster nut (1) and adjust the distance by

turning the rod (2) counterclockwise.

Distance of Tie Rod152mm

Toe-in 0 - 4 mm

Tightening Torque 65 - 80Nm

lCheck the toe-in date (A~B)

lIf the ton-in is normal, tighten the adjuster nut (1) to the

specified toque with tie rod (2) being fixed.

Tightening

Page 1272 of 1463

STEERING WHEEL AND COLUMN 6E-3

Removal & Installation Procedure

1. Remove the horn pad from the steering wheel and

disconnect the connectors .

2. Place an alignment marks on the column shaft end and

fixing nut and then remove the fixing nut.

Installation Notice

3. Remove the steering wheel.

4. Remove the combination switch upper cover .

Tightening Torque 50 - 80 Nm

5. Release the crash pad panel.

Notice

Remove the hood release wire and the other switch

connectors.

Page 1273 of 1463

6E-4 STEERING WHEEL AND COLUMN

6. Disconnect each connectors.

7. Remove the vacuum hose from the ignition switch(Diesel

only) .

9. Remove the lower shaft by removing the bolt of the steering

column shaft.

Installation Notice

Tightening Torque 9 - 14 Nm

8. Remove the combination switch assembly.

10. Remove the dash panel mounting bolts.

Installation Notice

Tightening Torque 30 - 40 Nm

Page 1274 of 1463

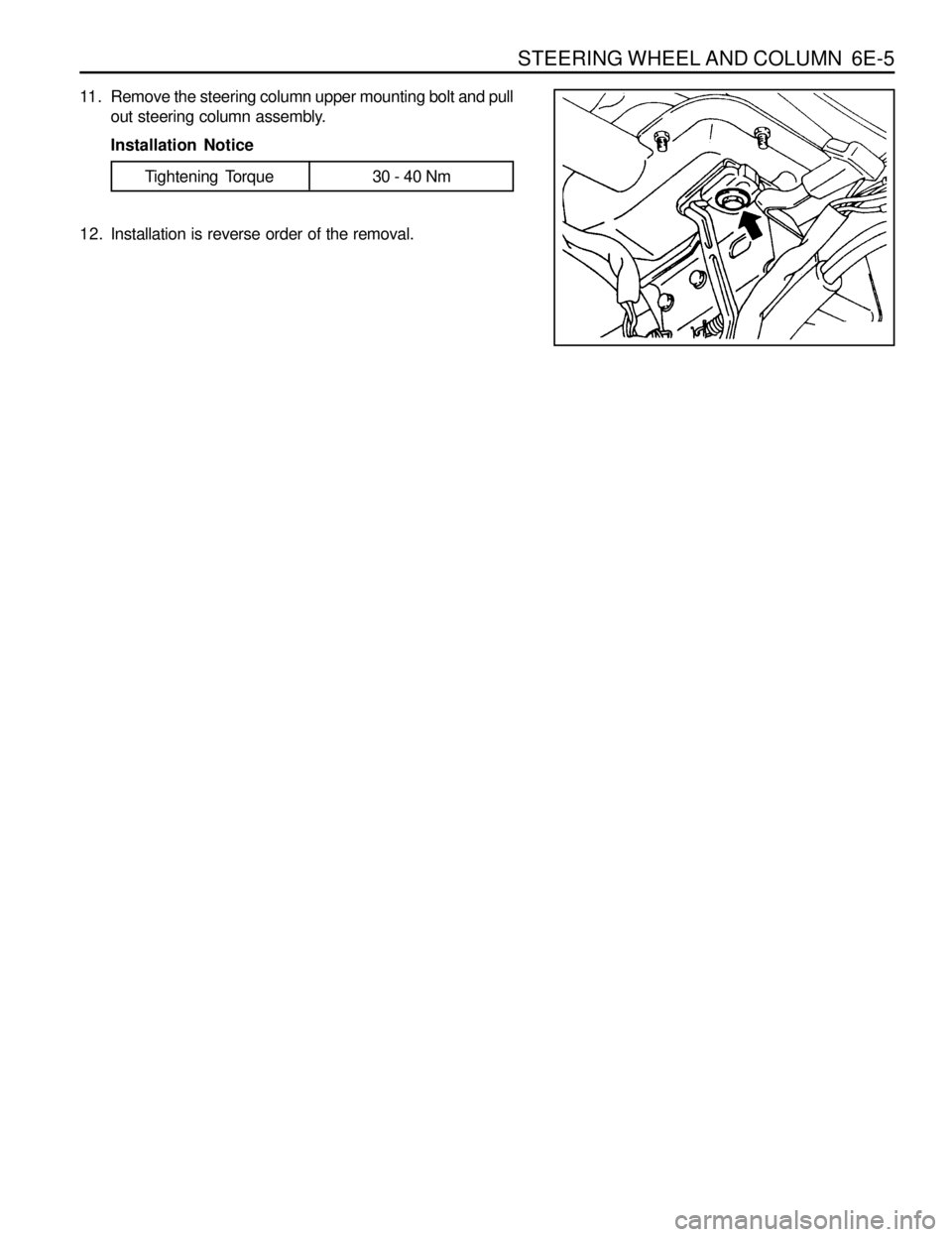

STEERING WHEEL AND COLUMN 6E-5

Tightening Torque 30 - 40 Nm 11. Remove the steering column upper mounting bolt and pull

out steering column assembly.

Installation Notice

12. Installation is reverse order of the removal.

Page 1287 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-13

Replacement of Refrigerant Connection (O-ring

Type)

1. When connecting a O-ring type, apply compressor oil to

portions shown in illustration. Be careful not to apply oil to

threaded portion.

Notice

Use specified compressor oil.

2. O-rings must be closely attached to inflated portion of pipe

and always replace used O-rings.

3. After inserting the pipe to the union, tighten the nut by hand

as much as possible and tighten the nut to specified torque.

4. When connecting liquid pipe(B) and low pressure hose(A)

to evaporate pipe, apply compressor oil to the O-ring.

5. When tightening, set the center of pipe and tighten fully.

6. Tighten the nut by specified wrench.

Installation Notice

Tightening Torque Inlet Side to 12 - 15Nm

Low Pressure Hose (A) 30 - 35 Nm

Page 1293 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-19

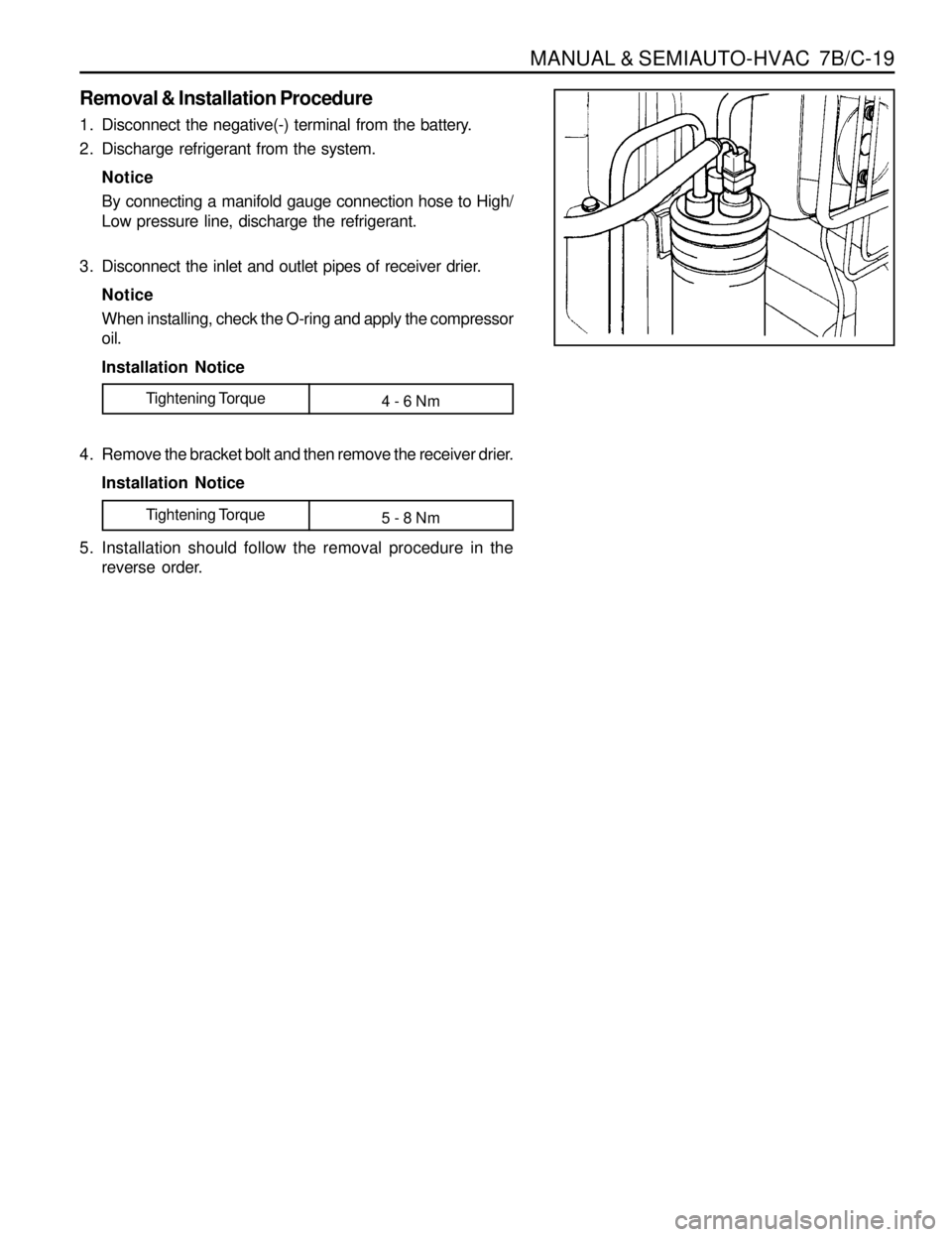

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the inlet and outlet pipes of receiver drier.

Notice

When installing, check the O-ring and apply the compressor

oil.

Installation Notice

4. Remove the bracket bolt and then remove the receiver drier.

Installation Notice

Tightening Torque

4 - 6 Nm

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

5 - 8 Nm

Page 1296 of 1463

7B/C-22 MANUAL & SEMIAUTO-HVAC

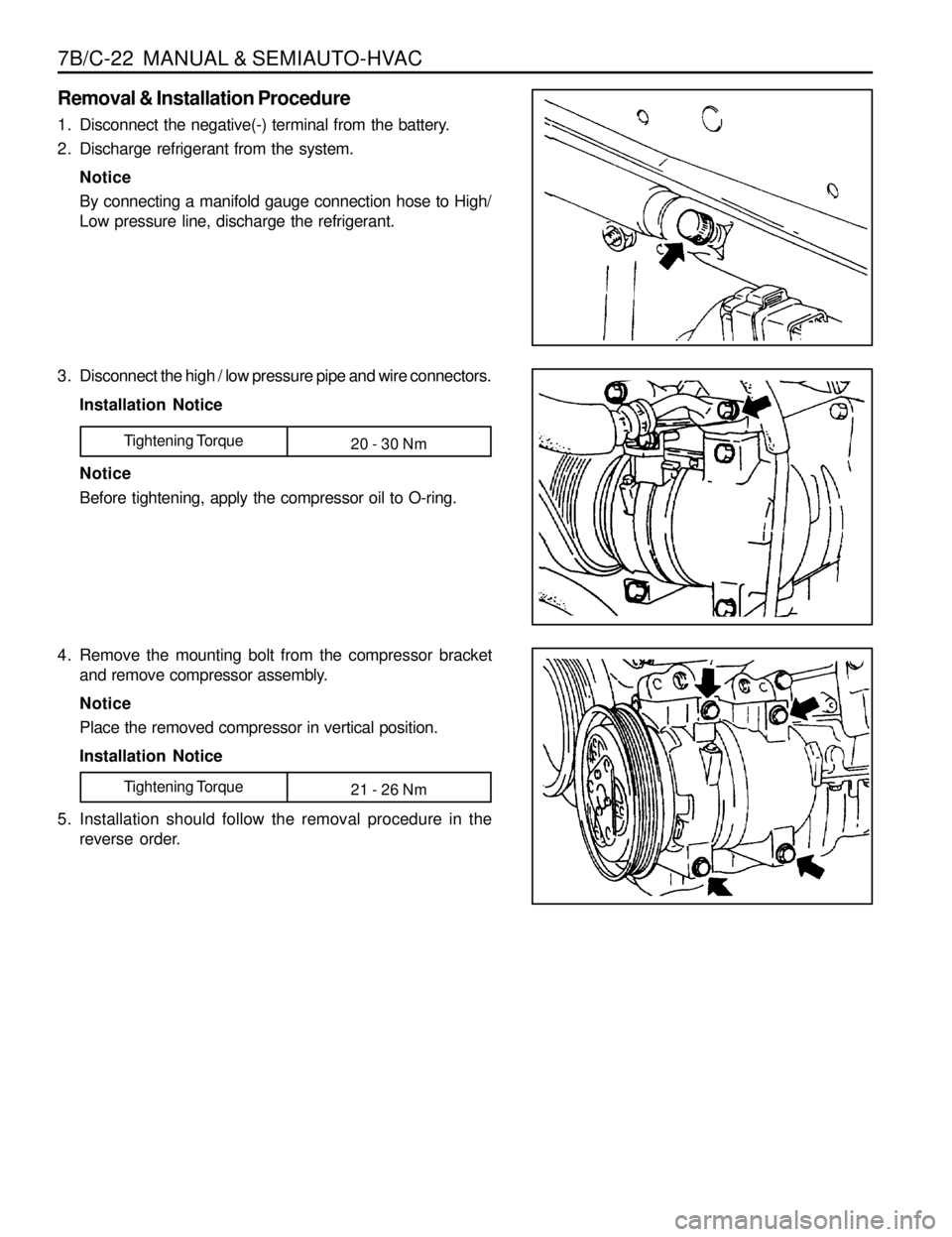

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the battery.

2. Discharge refrigerant from the system.

Notice

By connecting a manifold gauge connection hose to High/

Low pressure line, discharge the refrigerant.

3. Disconnect the high / low pressure pipe and wire connectors.

Installation Notice

Notice

Before tightening, apply the compressor oil to O-ring.

Tightening Torque

20 - 30 Nm

4. Remove the mounting bolt from the compressor bracket

and remove compressor assembly.

Notice

Place the removed compressor in vertical position.

Installation Notice

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

21 - 26 Nm

Page 1322 of 1463

8B-18 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

AIR BAG MODULE

Removal & Installation Procedure

1. Remove the steering wheel rid (LH,RH) with a screwdriver.

Installation Notice

Each position mark (LH,RH) is stamped on the inner surface

of the rids.

Tightening Torque 7 - 11 Nm

3. Disconnect the connectors and remove the air bag module.

4. Installation should follow the removal procedure in the

reverse order. 2. Unscrew the bolts from both sides.

Installation Notice

Page 1398 of 1463

9L-8 GLASS AND MIRRORS

Tightening Torque 7.7 Nm 4. Before installation, ensure that the stay bolt washer is

inserted.

5. Using suction holders, install the side glass within 5minutes

after application of sealant.

Page 1409 of 1463

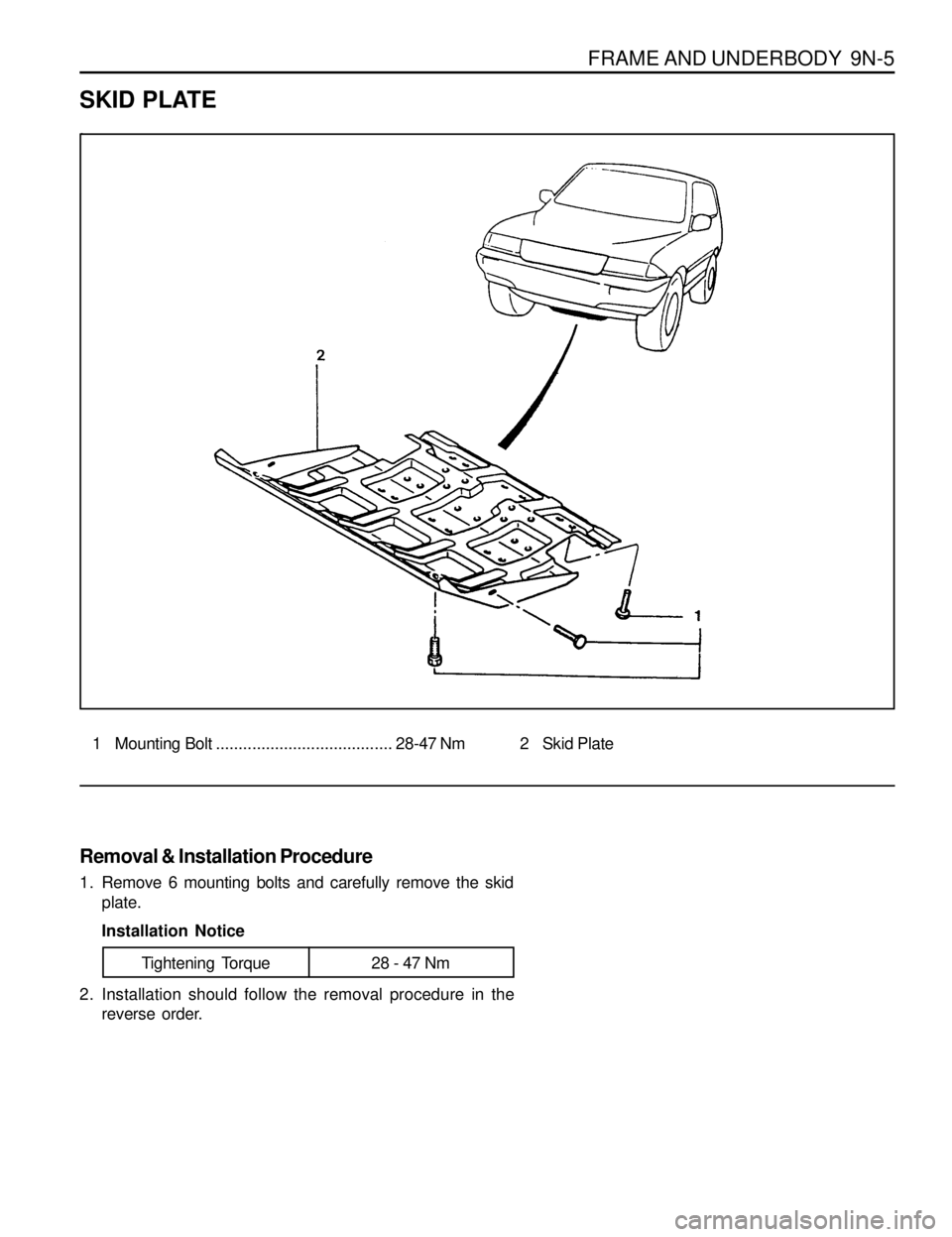

FRAME AND UNDERBODY 9N-5

1 Mounting Bolt.......................................28-47 Nm

SKID PLATE

.

2 Skid Plate

Removal & Installation Procedure

1. Remove 6 mounting bolts and carefully remove the skid

plate.

Installation Notice

2. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 28 - 47 Nm