torque SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1104 of 1463

AUTOMATIC TRANSMISSION 5A-127

Torque Converter and Housing Assembly

To assemble the torque converter and housing assembly,

proceed as follows.

1. Locate the torque converter housing on the transmission

main case.

2. Install and tighten the securing bolts to specification.

Notice

All the hardware must be correctly installed and torqued to

specification.

3. Fit the converter ensuring that the tangs are engaged in

the pump gear. Ensure that the tangs do not contact the

pump seal.

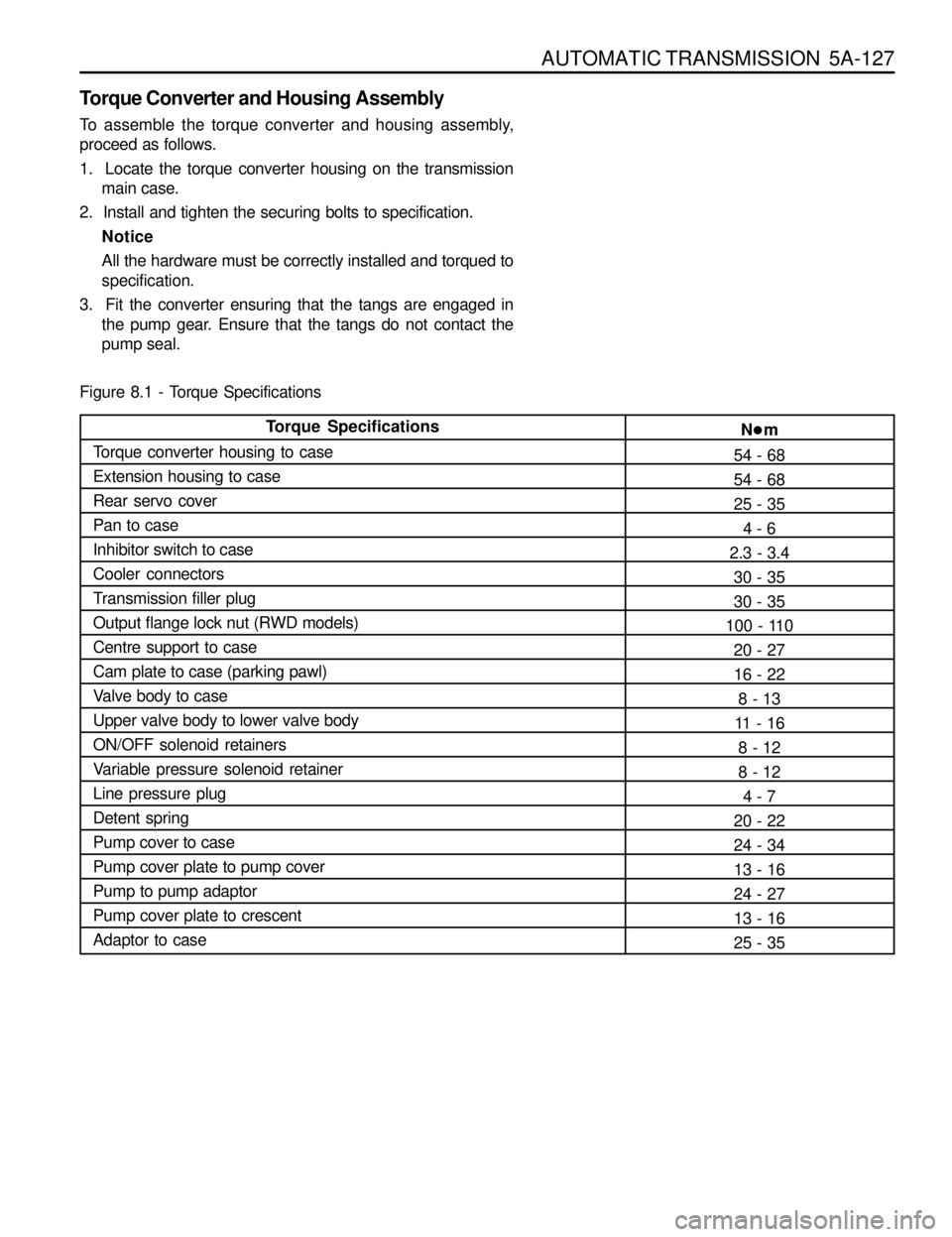

Figure 8.1 - Torque Specifications

Torque Specifications

Torque converter housing to case

Extension housing to case

Rear servo cover

Pan to case

Inhibitor switch to case

Cooler connectors

Transmission filler plug

Output flange lock nut (RWD models)

Centre support to case

Cam plate to case (parking pawl)

Valve body to case

Upper valve body to lower valve body

ON/OFF solenoid retainers

Variable pressure solenoid retainer

Line pressure plug

Detent spring

Pump cover to case

Pump cover plate to pump cover

Pump to pump adaptor

Pump cover plate to crescent

Adaptor to caseNlm

54 - 68

54 - 68

25 - 35

4 - 6

2.3 - 3.4

30 - 35

30 - 35

100 - 110

20 - 27

16 - 22

8 - 13

11 - 16

8 - 12

8 - 12

4 - 7

20 - 22

24 - 34

13 - 16

24 - 27

13 - 16

25 - 35

Page 1122 of 1463

MANUAL TRANSMISSION 5B-15

Removal & Installation Procedure

1. Disconnect the negative terminal from the battery.

2. Lift up the vehicle and fix it safely.

3. Remove the drain plug from the transmission housing and

drain the oil. Reinstall the drain plug.

Installation Notice

Tightening Torque

25 Nm

4. Disconnect the back-up switch connector.

5. Remove the breather hose.

6. Remove the speedometer connector and other wiring

harnesses and connectors.

Page 1123 of 1463

5B-16 MANUAL TRANSMISSION

7. Remove the front and rear propeller shafts from the

transfercase.

Installation Notice

Tightening Torque81 - 89 Nm

70 - 90 NmFront

Rear

8. Support the transmission on an suitable jack.

Unscrew the center mounting nuts and each sides

mounting bolts and remove the cross member.

Installation Notice

9. Remove the transmission mounting bolts.

Installation Notice

Tightening Torque (1)

Tightening Torque (2)21 - 35 Nm

62 - 93 Nm

10. Move the transmission jack backward careful and

disengage the transmission input shaft from the engine.

Remove the transmission.

11. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 77 - 87 Nm

Page 1130 of 1463

MANUAL TRANSMISSION 5B-23

Assembly Procedure

1. Using a hydraulic press and a supporting tool, press the

counter shaft rear bearing into the case. Be sure that the

supporting tool inside of the case should support the counter

shaft.

2. Without the shim, install the retainer and counter shaft rear

bearing outer race. Tighten the 4 retainer bolts.

3. Place a dial indicator on the case and measure counter

shaft end play by moving up and down.

4. Select a shim which is the same thickness as the indicator

rearing (up to 0.004 inch) and assemble it.

5. When the end play is correctly adjusted, remove the counter

shaft rear bearing retainer and outer race.

6. Using a pin punch and rubber hammer, install the reverse

idler shaft, gear and O-ring.

Tightening Torque 20 Nm

Page 1131 of 1463

5B-24 MANUAL TRANSMISSION

7. Install the counter shaft rear bearing outer race, shim and

retainer.

Tightening Torque

39 - 52 Nm

lUsing a punch and hammer, bend the lock tabs on the

retainer.

8. Install the following parts :

lInstall the main shaft into case.

lInstall the main shaft rear bearing outer race into the

rear of the case.

lInstall the 4th speed blocking ring onto the front of the

main shaft.

lInstall the input shaft onto the front of the main shaft.

lInstall the input bearing retainer without shim onto the

front of the case.

lUsing a torque wrench, tighten the 4 bolts.

9. Install the 5th speed drive gear and blocking ring on the

counter shaft.

10. Install the 5th synchronizer and rail/fork.

11. Install the 5th synchronizer snap ring and oiling funnel.

12. Align the slots of the lever with the rollers of the reverse

fork and 5th shift rail. Apply sealer on the 5-R lever pivot

bolt and install it into the case.

Tightening Torque 28 Nm

13. Using a needle nose pliers, install the 5-R lever clip.

Page 1163 of 1463

5C-10 CLUTCH

Removal & Installation Procedure

1. Remove the starter motor. Install the special tool to the

flywheel through the starter motor mounting holes.

Tightening Torque

47 Nm

Engine Lock 602 589 00 40 00

2. Unscren the release cylinder mounting bolts and remove

the release cylinder.

Installation Notice

3. Unscrew the clutch housing bolts and remove the clutch

housing, release fork and release bearing.

Installation Notice

4. Insert the centering pin into the clutch spline.

Loosen the clutch cover bolts 1/2 turn in crisscross sequence

until the spring tension is released.

Notice

Do not remove the bolts at a time, or clutchcover can be

damaged or deformed.

Centering Pin 661 589 00 15 00

Tightening Torque

30 - 40 Nm

Page 1164 of 1463

CLUTCH 5C-11

5. Unscrew the bolts and remove the clutch cover, pressure

plate and clutch disc.

Notice

Be careful not to drop the pressure plate and clutch disc.

Installation Notice

Tightening Torque 21 - 27 Nm

6. Installation should follow the removal procedure in the

reverse order.

Notice

lBefore installation, clean oil and grease on the

flywheel surface.

lDo not clean the clutch disc and release bearing in

solvent.

Page 1167 of 1463

5C-14 CLUTCH

Removal & Installation Procedure

1. Draw out the fluid.

2. Pull out the snap pin and clevis pin from the clutch pedal

connection.

3. Remove the clutch tube.

Installation Notice

Tightening Torque 15 - 18 Nm

Notice

Be careful not the fluid contact a painted surface.

4. Remove the master cylinder mounting nuts and pull off the

master cylinder.

Installation Notice

Tightening Torque 8 - 18 Nm

5. Check the clutch pedal operation.

6. Bleed the clutch system.

Page 1180 of 1463

5D1-10 TRANSFER CASE (PART TIME 4408)

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

MAINTENANCE OF TRANSFER CASE

LUBRICANT

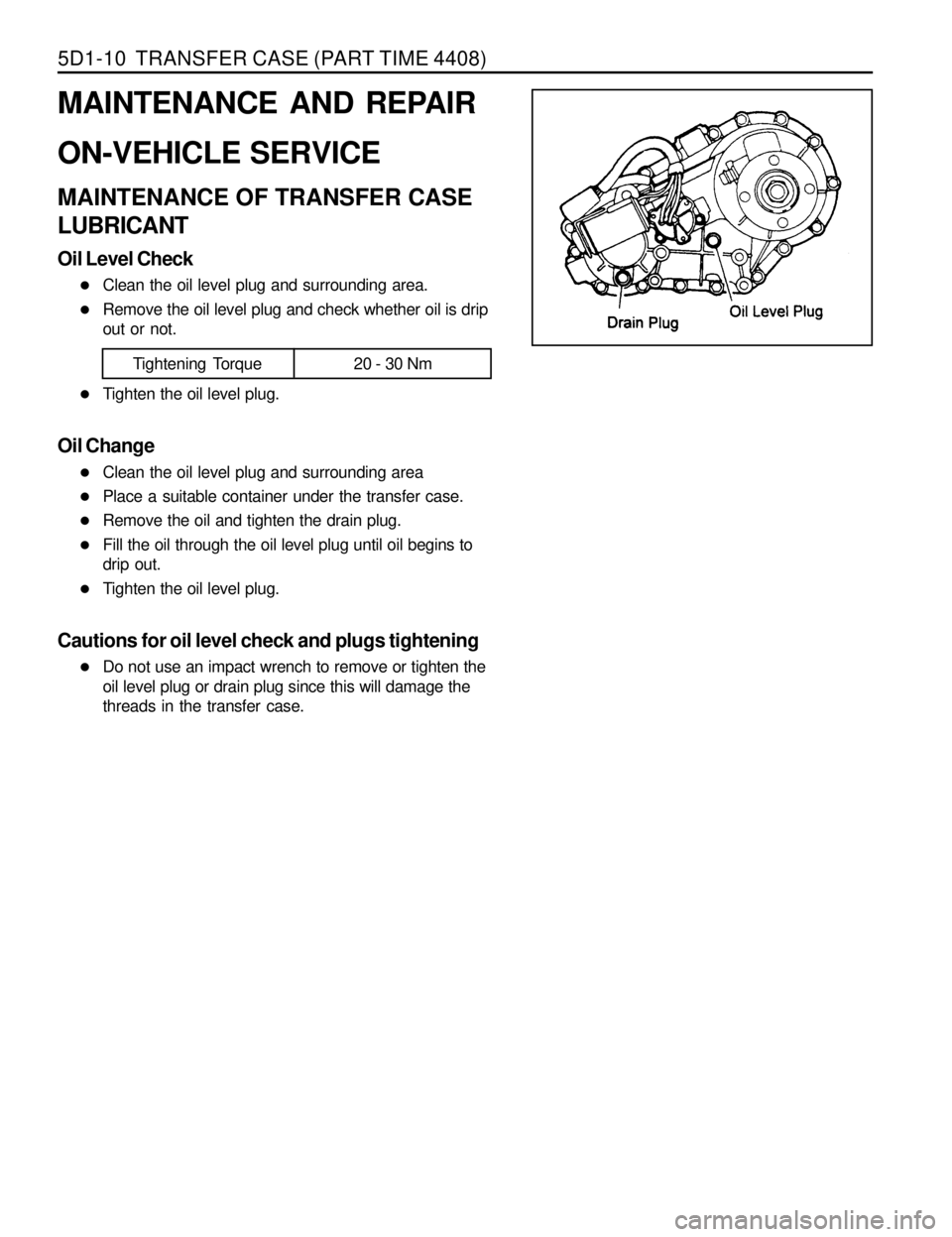

Oil Level Check

lClean the oil level plug and surrounding area.

lRemove the oil level plug and check whether oil is drip

out or not.

lTighten the oil level plug.

Oil Change

lClean the oil level plug and surrounding area

lPlace a suitable container under the transfer case.

lRemove the oil and tighten the drain plug.

lFill the oil through the oil level plug until oil begins to

drip out.

lTighten the oil level plug.

Cautions for oil level check and plugs tightening

lDo not use an impact wrench to remove or tighten the

oil level plug or drain plug since this will damage the

threads in the transfer case.

Tightening Torque 20 - 30 Nm

Page 1182 of 1463

5D1-12 TRANSFER CASE (PART TIME 4408)

Removal & Installation Procedure

1. Disconnect the negative terminal from the battery.

2. Lift up the vehicle and fix it safely.

3. Remove the drain plug and drain the oil.

Reinstall the drain plug.

* If planar damper is installed, unscrew 4 bolts and remove

the planar damper.

Installation Notice

Tightening Torque 19 - 30 Nm

4. Remove the breather hose.

5. Disconnect the speedometer cable connector and other

cable connectors and wiring harnesses.

6. Support the transfer case with jack and remove the front

and rear propeller shafts from the transfer case.

Installation Notice

Front

Rear81 - 89 Nm

70 - 80 NmTightening Torque