SSANGYONG MUSSO 1998 Workshop Owner's Guide

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Owner's Guide

Page 366 of 1463

1B3-64 OM600 ENGINE MECHANICAL

8. Remove the guide pulley bracket (24).

Tools Required

116 589 03 07 00 Socket Wrench

Removal Procedure

1. Remove the fan clutch and cooling fan belt pulley.

2. Drain the engine oil completely.

3. Remove the oil dipstick tube bracket bolts.

4. Remove the crankshaft pulley.

5. Loosen the bolt (1) and then remove the cylinder head cover

(2) and gasket.

6. Remove the vacuum pump.

7. Detach the closing cover (20). Remove the bolts(21) and

then remove the guide pulley (22).

Page 372 of 1463

1B3-70 OM600 ENGINE MECHANICAL

15. Install the guide pulley (22) and fit the closing cover (20).

16. Replace the gasket (3) and install the cylinder head cover

(2).

17. Install the cooling fan belt pulley and fan clutch.

18. Install the belt tensioning device and then install the belt.

19. Install the cooling fan.

20. Fill the engine oil and check oil leaks by running the engine.

Tightening Torque 23 Nm

Tightening Torque 10 Nm

Page 376 of 1463

1B3-74 OM600 ENGINE MECHANICAL

VIBRATION DAMPER AND HUB

Preceding Work : Removal of the cooling fan

Removal of poly V-belt

1 Bolt............................................................10Nm

2 Cooling Fan Belt Pulley

3 Socket Bolt................................................23Nm

4 Crankshaft Belt Pulley

5 Vibration Damper6 Bolt................................................200Nm + 90°

7 Washer

8 Straight Pin

9 Hub

10 Oil Pan

Page 378 of 1463

1B3-76 OM600 ENGINE MECHANICAL

Removal Procedure

1. Remove the starter motor and install the engine lock into

the wheel ring gear.

Engine Lock 602 589 00 40 00

2. Remove the poly V-belt.

3. Remove the cooling fan.

Notice

Keep the fan in vertical position.

4. Remove the cooling fan belt pulley (2).

5. Place alignment marks (arrow) on the vibration damper (5)

and crankshaft belt pulley (4).

6. Remove the timing sensor bracket.

Notice

Remove if necessary.

Page 381 of 1463

OM600 ENGINE MECHANICAL 1B3-79

5. Install the timing sensor bracket.

Notice

See the ‘TDC setting’.

6. Install the cooling fan pulley.

Tightening Torque 10 Nm

7. Install the cooling fan.

8. Install the fan belt.

9. Remove the engine lock.

Page 419 of 1463

OM600 ENGINE MECHANICAL 1B3-117

Tools Required

000 589 10 53 00 Reamer (for Exhaust)

000 589 10 68 00 Cylinder Brush

000 589 21 53 00 Reamer (for Intake)

102 589 00 23 00 GO / NO GO Gauge (for Intake)

103 589 02 15 00 Drift (for Exhaust)

103 589 03 15 00 Drift (for Intake)

117 589 03 25 00 GO / NO GO Gauge (for Exhaust)

346 589 00 63 00 Super Cooling Box

601 589 02 23 00 GO/NO GO Gauge

601 589 05 15 00 Drift (for Intake)

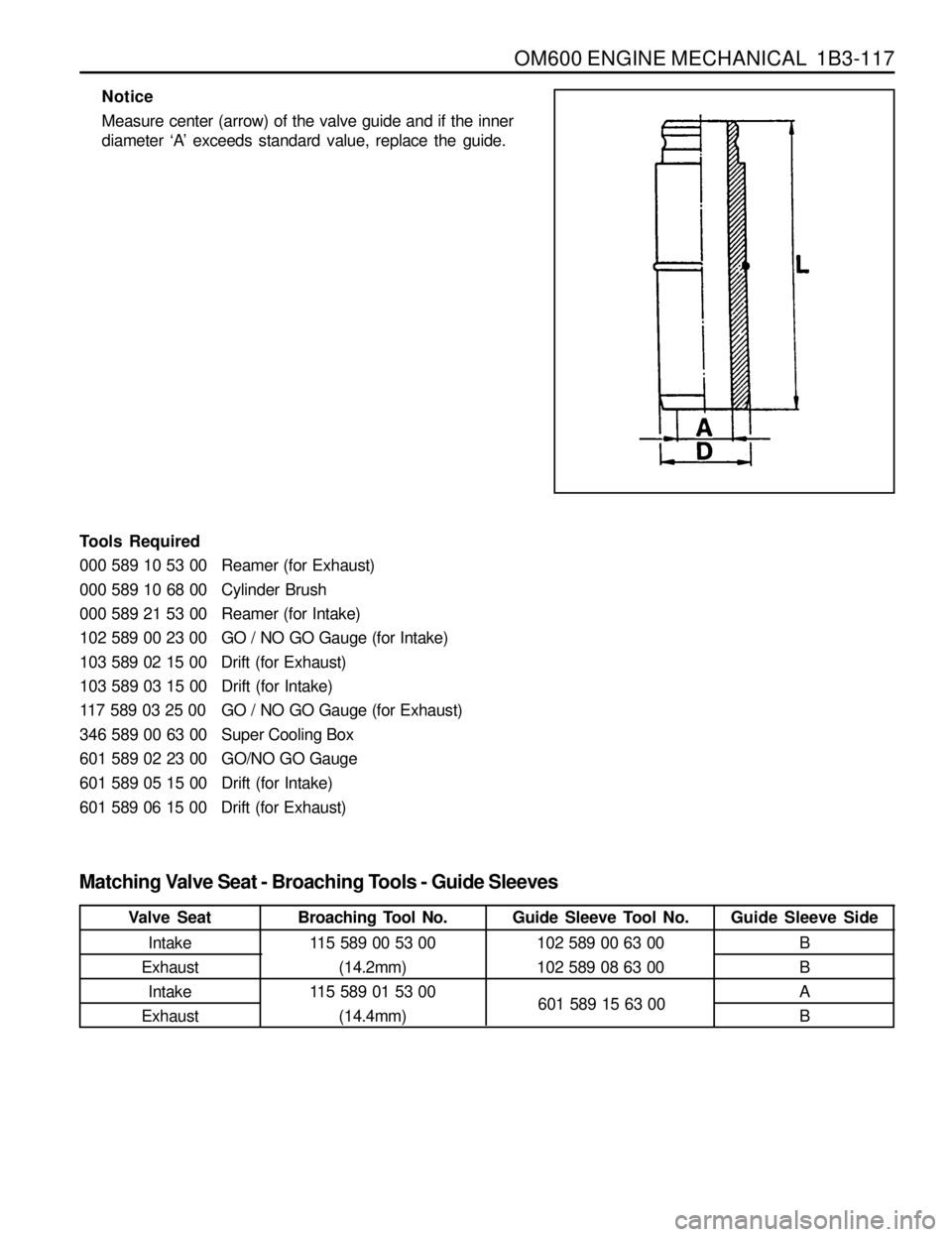

Notice

Measure center (arrow) of the valve guide and if the inner

diameter ‘A’ exceeds standard value, replace the guide.

601 589 06 15 00 Drift (for Exhaust)

Matching Valve Seat - Broaching Tools - Guide Sleeves

Valve Seat

Intake

Exhaust

Intake

ExhaustBroaching Tool No.

115 589 00 53 00

(14.2mm)

115 589 01 53 00

(14.4mm)Guide Sleeve Tool No.

102 589 00 63 00

102 589 08 63 00Guide Sleeve Side

B

B

A

B

601 589 15 63 00

Page 422 of 1463

1B3-120 OM600 ENGINE MECHANICAL

8. Check the valve guide bore with GO / NO GO gauge (9).

The GO side (marked ‘0’) should just still drop. If the GO

side cannot be inserted, the bore of valve guide should be

reamed.

Notice

Perform the check only on cooled down cylinder head.

GO / NO GO Gauge (for Intake) 102 589 00 23 00

GO / NO GO Gauge (for Exhaust) 117 589 03 23 00

6. Cool down the new valve guide (2) with liquid nitrogen.

Notice

Do not touch the cooled valve guide by hand.

Super Cooling box 346 589 00 63 00

7. Drive in new valve guide with drift (8) until the wire ring makes

contact.

Notice

The valve guide must be driven in from the cylinder head

cover.

Drift (for Intake) 601 589 05 15 00

Drift (for Exhaust) 601 589 06 15 00

5. Heat the cylinder head (1) in a wear tank to approx. 80°C.

Page 428 of 1463

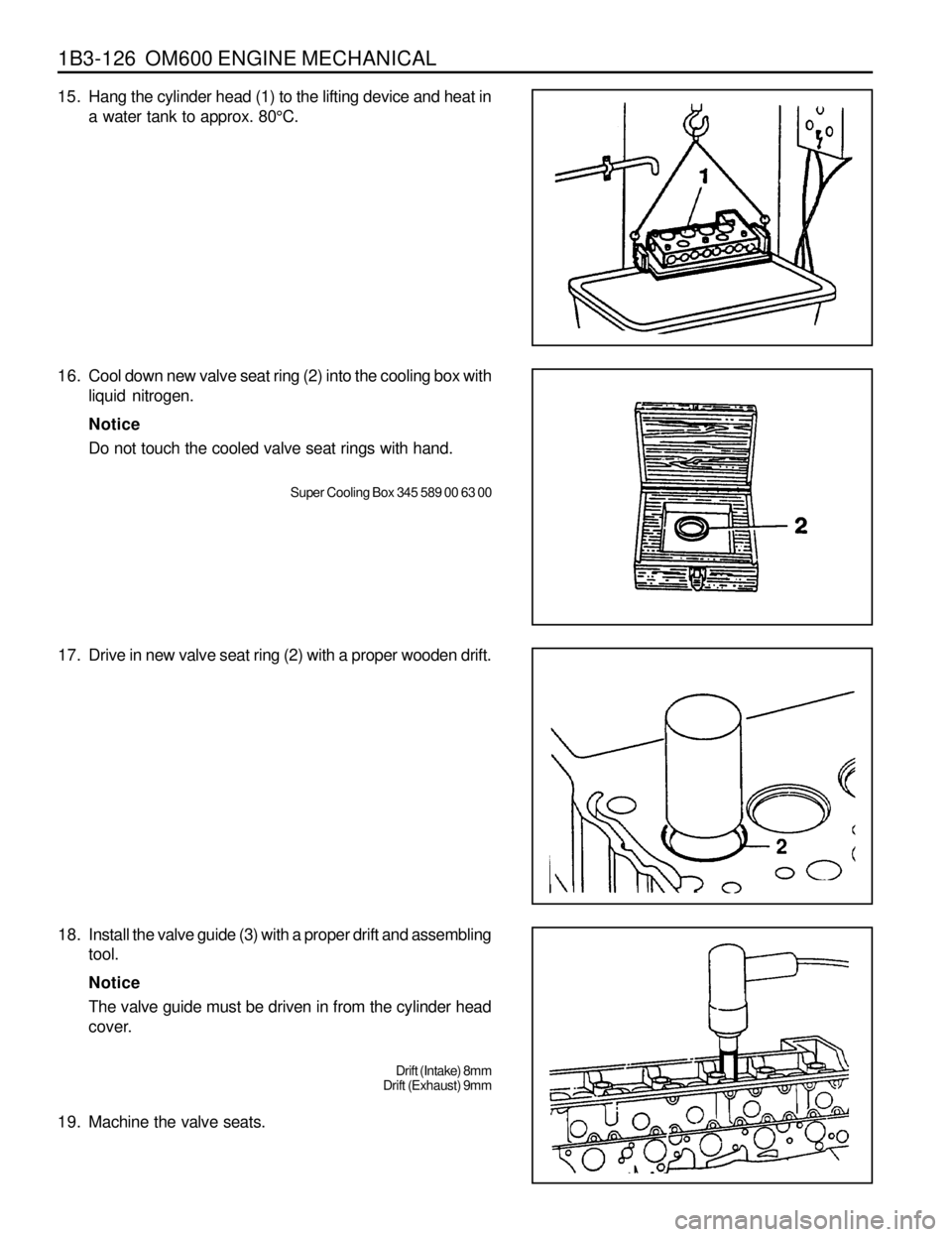

1B3-126 OM600 ENGINE MECHANICAL

17. Drive in new valve seat ring (2) with a proper wooden drift.

18. Install the valve guide (3) with a proper drift and assembling

tool.

Notice

The valve guide must be driven in from the cylinder head

cover.

Drift (Intake) 8mm

Drift (Exhaust) 9mm

19. Machine the valve seats.

15. Hang the cylinder head (1) to the lifting device and heat in

a water tank to approx. 80°C.

16. Cool down new valve seat ring (2) into the cooling box with

liquid nitrogen.

Notice

Do not touch the cooled valve seat rings with hand.

Super Cooling Box 345 589 00 63 00

Page 449 of 1463

OM600 ENGINE MECHANICAL 1B3-147

TIMING CHAIN

Preceding Work : Removal of glow plug

Removal of chain tensioner

Removal of cooling fan

Removal of cylinder head cover

1 Chain Link

2 Timing Chain

3 Camshaft Sprocket

4 Outer Plate

Page 454 of 1463

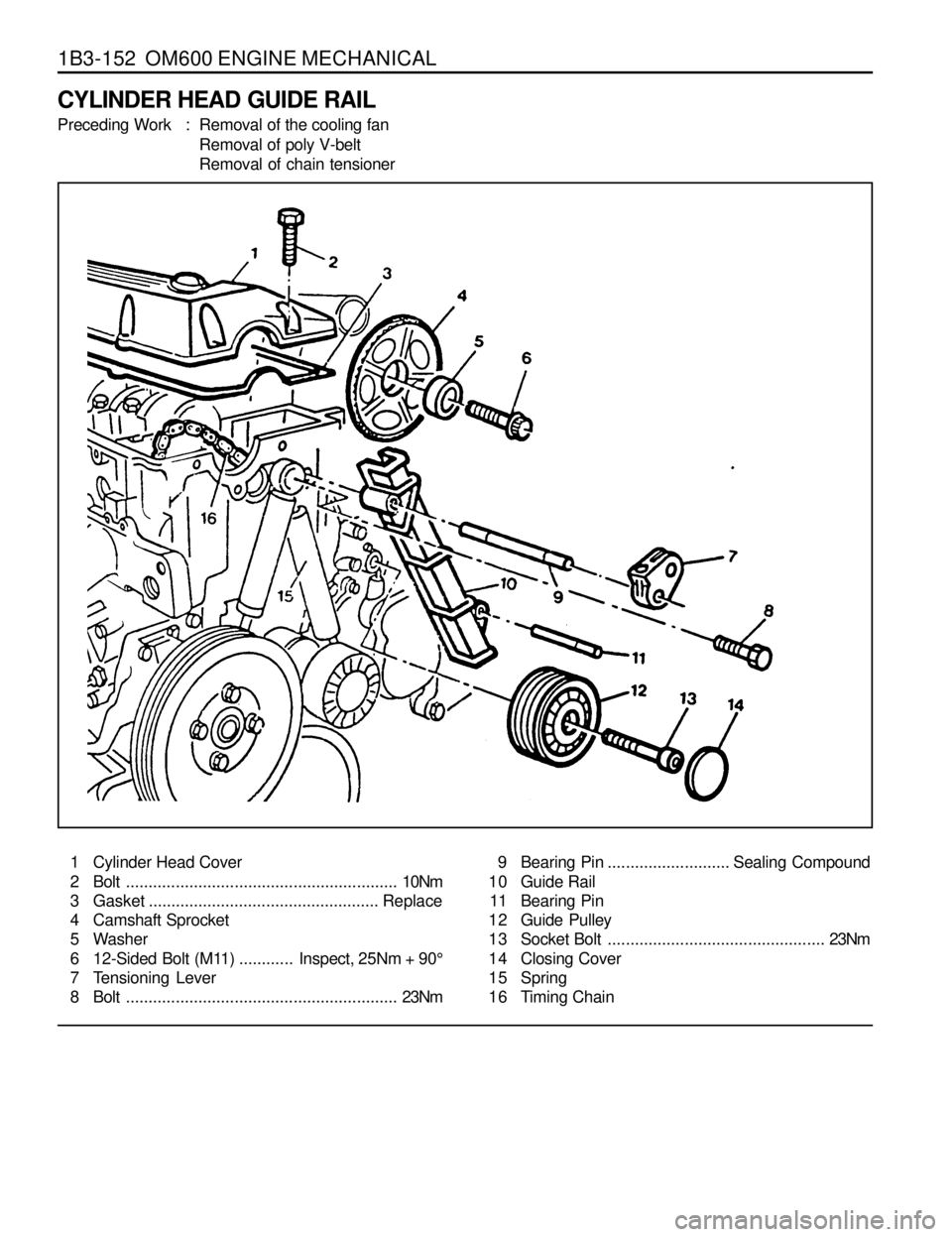

1B3-152 OM600 ENGINE MECHANICAL

CYLINDER HEAD GUIDE RAIL

Preceding Work : Removal of the cooling fan

Removal of poly V-belt

Removal of chain tensioner

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace

4 Camshaft Sprocket

5 Washer

6 12-Sided Bolt (M11)............Inspect, 25Nm + 90°

7 Tensioning Lever

8 Bolt............................................................23Nm9 Bearing Pin...........................Sealing Compound

10 Guide Rail

11 Bearing Pin

12 Guide Pulley

13 Socket Bolt................................................23Nm

14 Closing Cover

15 Spring

16 Timing Chain