clutch SSANGYONG MUSSO 1998 Workshop Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1005 of 1463

5A-28 AUTOMATIC TRANSMISSION

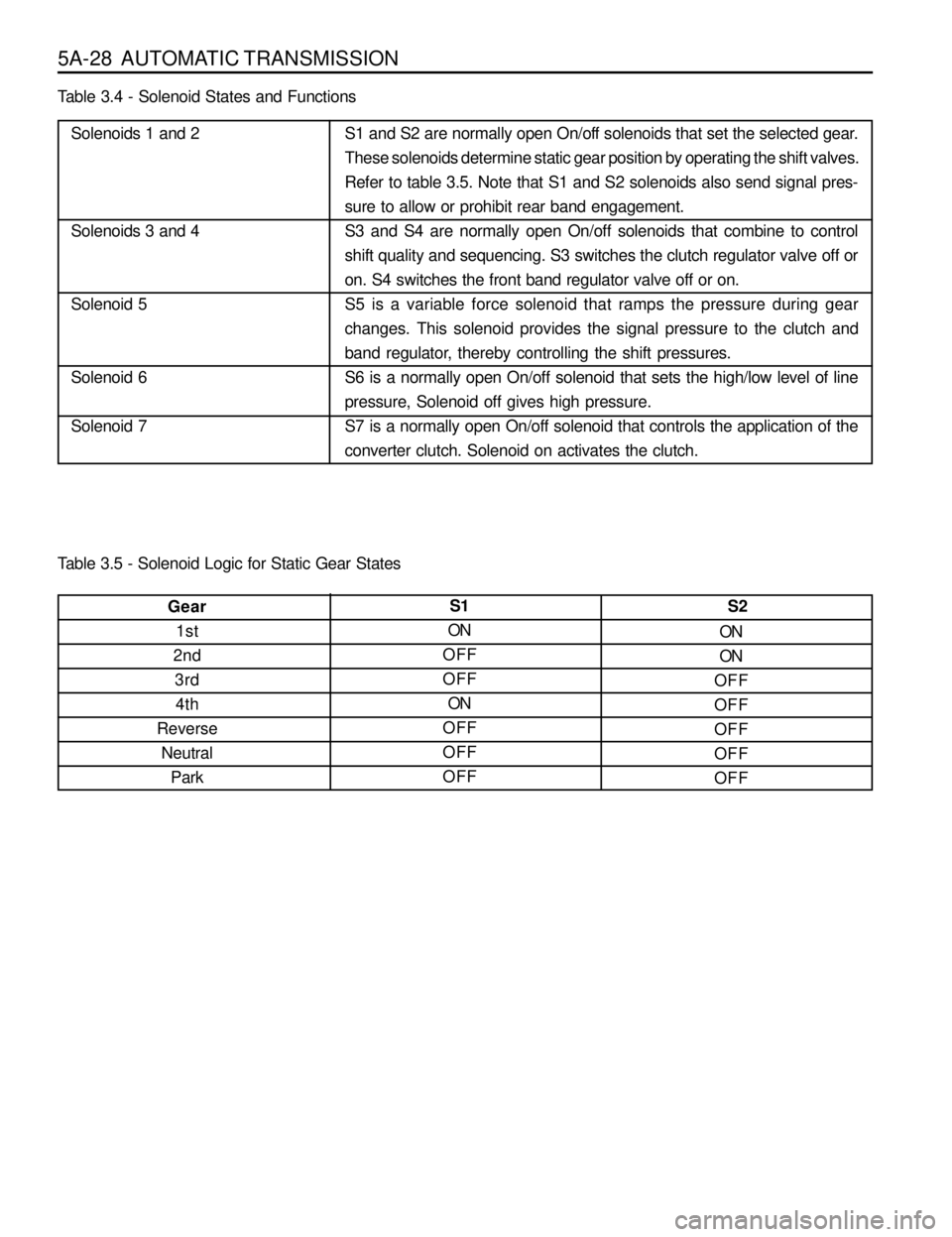

Table 3.4 - Solenoid States and Functions

Table 3.5 - Solenoid Logic for Static Gear States

Solenoids 1 and 2

Solenoids 3 and 4

Solenoid 5

Solenoid 6

Solenoid 7S1 and S2 are normally open On/off solenoids that set the selected gear.

These solenoids determine static gear position by operating the shift valves.

Refer to table 3.5. Note that S1 and S2 solenoids also send signal pres-

sure to allow or prohibit rear band engagement.

S3 and S4 are normally open On/off solenoids that combine to control

shift quality and sequencing. S3 switches the clutch regulator valve off or

on. S4 switches the front band regulator valve off or on.

S5 is a variable force solenoid that ramps the pressure during gear

changes. This solenoid provides the signal pressure to the clutch and

band regulator, thereby controlling the shift pressures.

S6 is a normally open On/off solenoid that sets the high/low level of line

pressure, Solenoid off gives high pressure.

S7 is a normally open On/off solenoid that controls the application of the

converter clutch. Solenoid on activates the clutch.

S2

ON

ON

OFF

OFF

OFF

OFF

OFFS1

ON

OFF

OFF

ON

OFF

OFF

OFF Gear

1st

2nd

3rd

4th

Reverse

Neutral

Park

Page 1006 of 1463

AUTOMATIC TRANSMISSION 5A-29

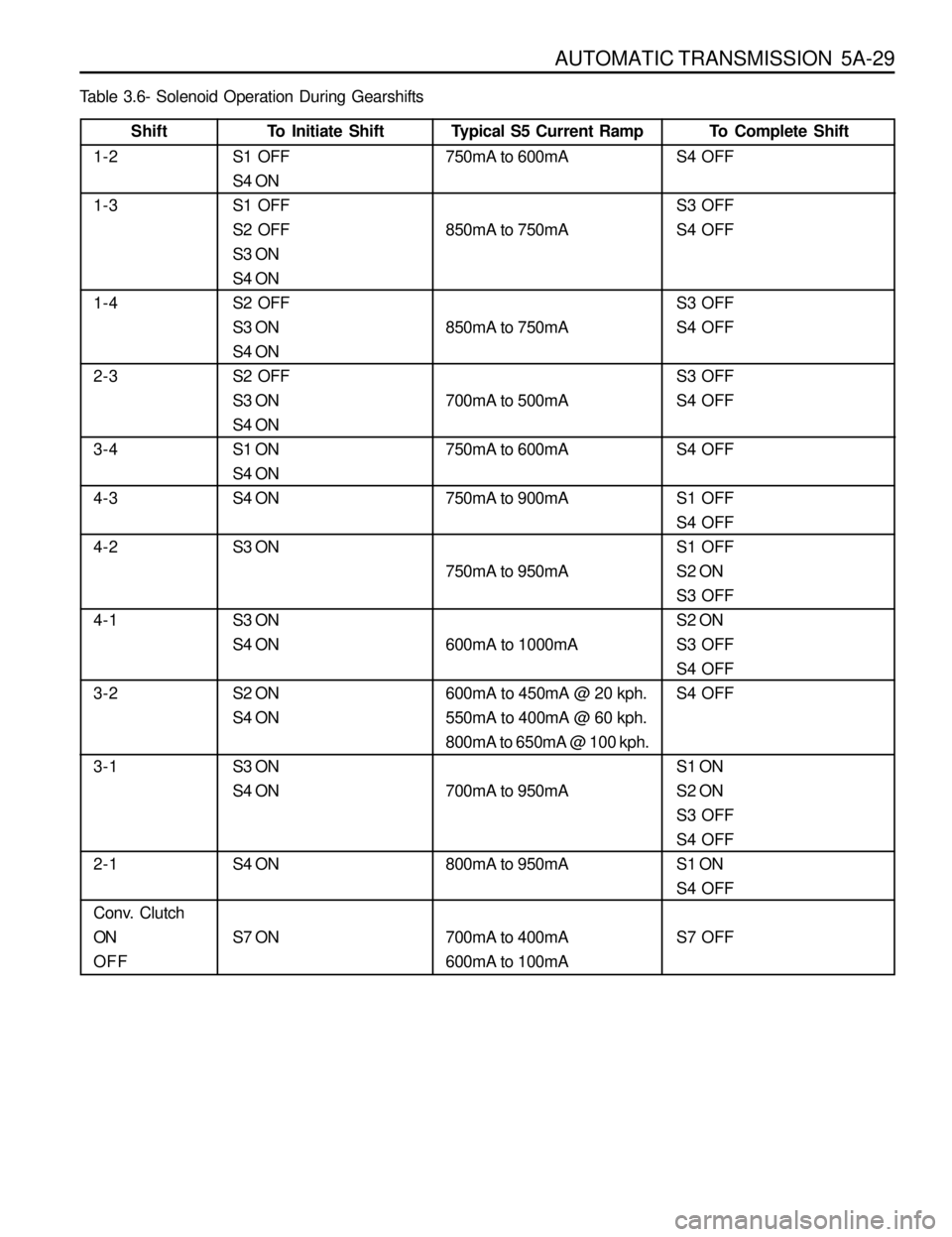

Table 3.6- Solenoid Operation During Gearshifts

To Initiate Shift

S1 OFF

S4 ON

S1 OFF

S2 OFF

S3 ON

S4 ON

S2 OFF

S3 ON

S4 ON

S2 OFF

S3 ON

S4 ON

S1 ON

S4 ON

S4 ON

S3 ON

S3 ON

S4 ON

S2 ON

S4 ON

S3 ON

S4 ON

S4 ON

S7 ONTo Complete Shift

S4 OFF

S3 OFF

S4 OFF

S3 OFF

S4 OFF

S3 OFF

S4 OFF

S4 OFF

S1 OFF

S4 OFF

S1 OFF

S2 ON

S3 OFF

S2 ON

S3 OFF

S4 OFF

S4 OFF

S1 ON

S2 ON

S3 OFF

S4 OFF

S1 ON

S4 OFF

S7 OFFTypical S5 Current Ramp

750mA to 600mA

850mA to 750mA

850mA to 750mA

700mA to 500mA

750mA to 600mA

750mA to 900mA

750mA to 950mA

600mA to 1000mA

600mA to 450mA @ 20 kph.

550mA to 400mA @ 60 kph.

800mA to 650mA @ 100 kph.

700mA to 950mA

800mA to 950mA

700mA to 400mA

600mA to 100mA Shift

1-2

1-3

1-4

2-3

3-4

4-3

4-2

4-1

3-2

3-1

2-1

Conv. Clutch

ON

OFF

Page 1007 of 1463

5A-30 AUTOMATIC TRANSMISSION

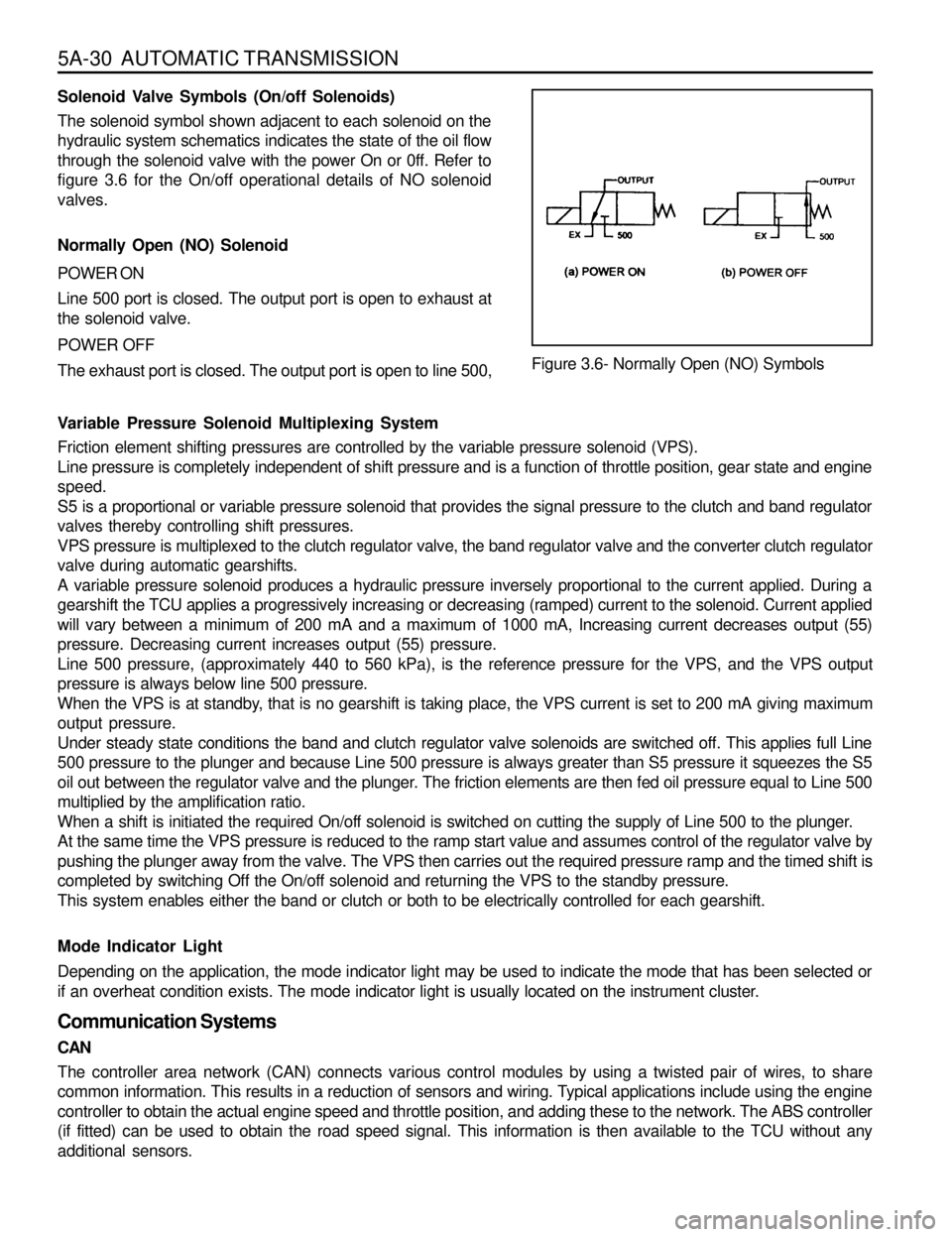

Solenoid Valve Symbols (On/off Solenoids)

The solenoid symbol shown adjacent to each solenoid on the

hydraulic system schematics indicates the state of the oil flow

through the solenoid valve with the power On or 0ff. Refer to

figure 3.6 for the On/off operational details of NO solenoid

valves.

Normally Open (NO) Solenoid

POWER ON

Line 500 port is closed. The output port is open to exhaust at

the solenoid valve.

POWER OFF

The exhaust port is closed. The output port is open to line 500,Figure 3.6- Normally Open (NO) Symbols

Variable Pressure Solenoid Multiplexing System

Friction element shifting pressures are controlled by the variable pressure solenoid (VPS).

Line pressure is completely independent of shift pressure and is a function of throttle position, gear state and engine

speed.

S5 is a proportional or variable pressure solenoid that provides the signal pressure to the clutch and band regulator

valves thereby controlling shift pressures.

VPS pressure is multiplexed to the clutch regulator valve, the band regulator valve and the converter clutch regulator

valve during automatic gearshifts.

A variable pressure solenoid produces a hydraulic pressure inversely proportional to the current applied. During a

gearshift the TCU applies a progressively increasing or decreasing (ramped) current to the solenoid. Current applied

will vary between a minimum of 200 mA and a maximum of 1000 mA, Increasing current decreases output (55)

pressure. Decreasing current increases output (55) pressure.

Line 500 pressure, (approximately 440 to 560 kPa), is the reference pressure for the VPS, and the VPS output

pressure is always below line 500 pressure.

When the VPS is at standby, that is no gearshift is taking place, the VPS current is set to 200 mA giving maximum

output pressure.

Under steady state conditions the band and clutch regulator valve solenoids are switched off. This applies full Line

500 pressure to the plunger and because Line 500 pressure is always greater than S5 pressure it squeezes the S5

oil out between the regulator valve and the plunger. The friction elements are then fed oil pressure equal to Line 500

multiplied by the amplification ratio.

When a shift is initiated the required On/off solenoid is switched on cutting the supply of Line 500 to the plunger.

At the same time the VPS pressure is reduced to the ramp start value and assumes control of the regulator valve by

pushing the plunger away from the valve. The VPS then carries out the required pressure ramp and the timed shift is

completed by switching Off the On/off solenoid and returning the VPS to the standby pressure.

This system enables either the band or clutch or both to be electrically controlled for each gearshift.

Mode Indicator Light

Depending on the application, the mode indicator light may be used to indicate the mode that has been selected or

if an overheat condition exists. The mode indicator light is usually located on the instrument cluster.

Communication Systems

CAN

The controller area network (CAN) connects various control modules by using a twisted pair of wires, to share

common information. This results in a reduction of sensors and wiring. Typical applications include using the engine

controller to obtain the actual engine speed and throttle position, and adding these to the network. The ABS controller

(if fitted) can be used to obtain the road speed signal. This information is then available to the TCU without any

additional sensors.

Page 1008 of 1463

AUTOMATIC TRANSMISSION 5A-31

K-Line

The K-line is typically used for obtaining diagnostic information from the TCU. A computer with a special interface is

connected to the TCU and all current faults, stored faults, runtime parameters are then available. The stored fault

codes can also be cleared.

The K-line can be used for vehicle coding at the manufacturer’s plant or in the workshop. This allows for one TCU

design to be used over different vehicle models. The particular code is sent to the microprocessor via the K line and

this results in the software selecting the correct shift and VPS ramp parameters.

HYDRAULIC CONTROL SYSTEM

The hydraulic controls are located in the valve body, pump body and main case.

The valve body contains the following:

lManual valve,

lThree shift valves,

lSequence valve,

lsolenoid supply pressure regulator valve,

lline pressure control valve,

lclutch apply regulator valve,

lband apply regulator valve,

lS1 to S6, and

lReverse lockout valve.

lThe pump body contains the following:

lPrimary regulator valve for line pressure,

lconverter clutch regulator valve,

lconverter clutch control valve,

lS7,and

lC1 bias valve.

The main case contains the following:

lB1R exhaust valve

The hydraulic control system schematic is shown at figure 3.7.

All upshifts are accomplished by simultaneously switching on a shift valve(s), switching VPS pressure to the band

and/or clutch regulator valve, and then sending the VPS a ramped current. The shift is completed by switching the

regulators off and at the same time causing the VPS to reach maximum . pressure. All downshifts are accomplished

by switching VPS pressure to the band and/or clutch regulator valve and sending a ramped current to the VPS. The

shift is completed by simultaneously switching the regulators off, switching the shift valves and at the same time

causing the VPS to return to stand-by pressure.

The primary regulator valve is located in the pump cover and supplies four line pressures; high and low for forward

gears, and high and low for reverse. This pressure has no effect on shift quality and merely provides static clutch

capacity during steady state operation. Low pressure can be obtained by activating an On/off solenoid with high line

pressure being the default mode.

Torque converter lock-up is initiated by toggling the converter clutch control valve with an On/off solenoid. The actual

apply and release of the clutch is regulated by the VPS via the converter clutch regulator valve. As an additional

safety feature, the lock-up is hydraulically disabled in first and second gear by the bias valve which only supplies oil

to the lock-up solenoid when C1 is applied in third and fourth gears. This prevents the vehicle from being rendered

immobile in the unlikely event of S7 becoming stuck.

The solenoid supply valve provides reference pressure for all the solenoids.

Page 1011 of 1463

5A-34 AUTOMATIC TRANSMISSION

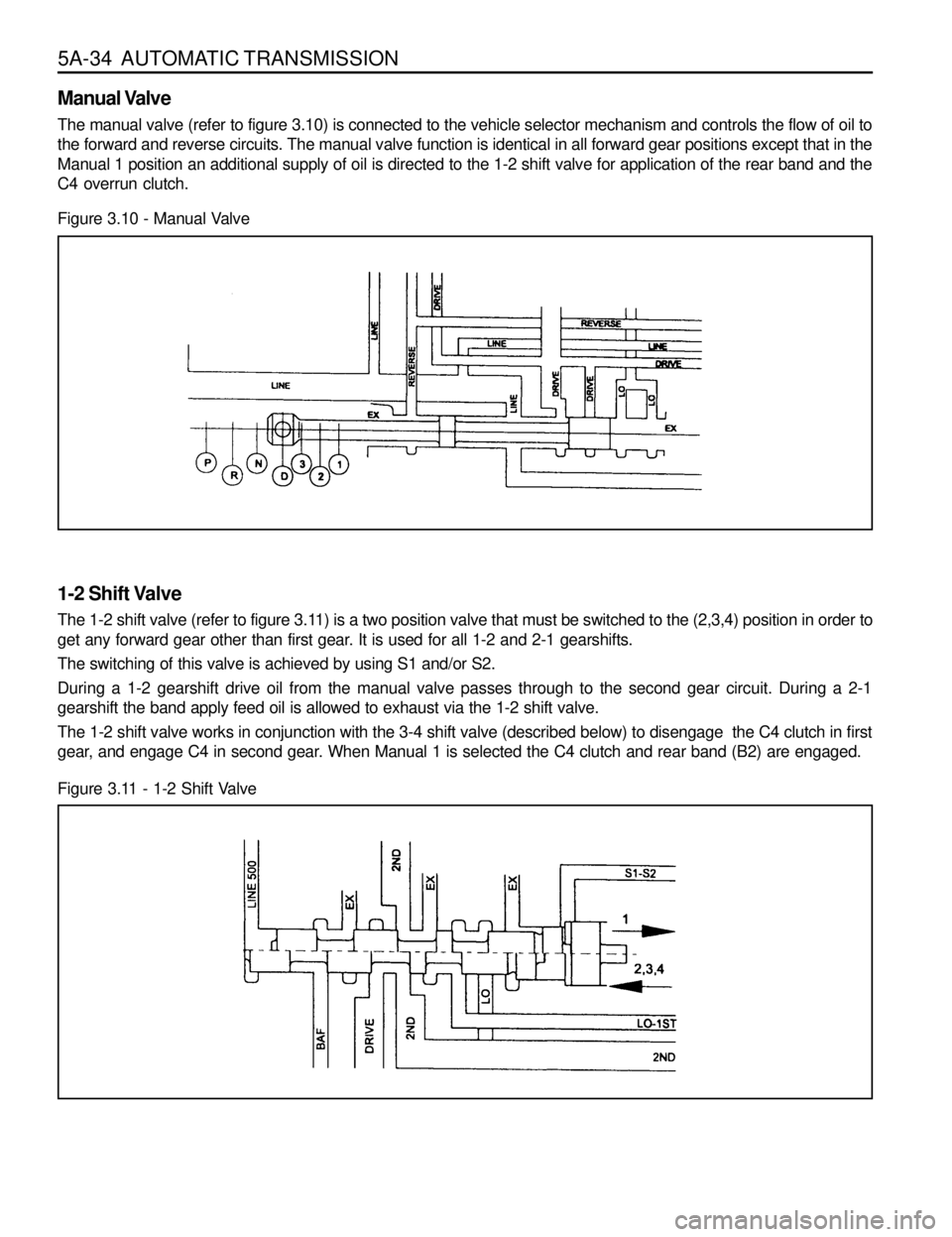

Figure 3.10 - Manual Valve

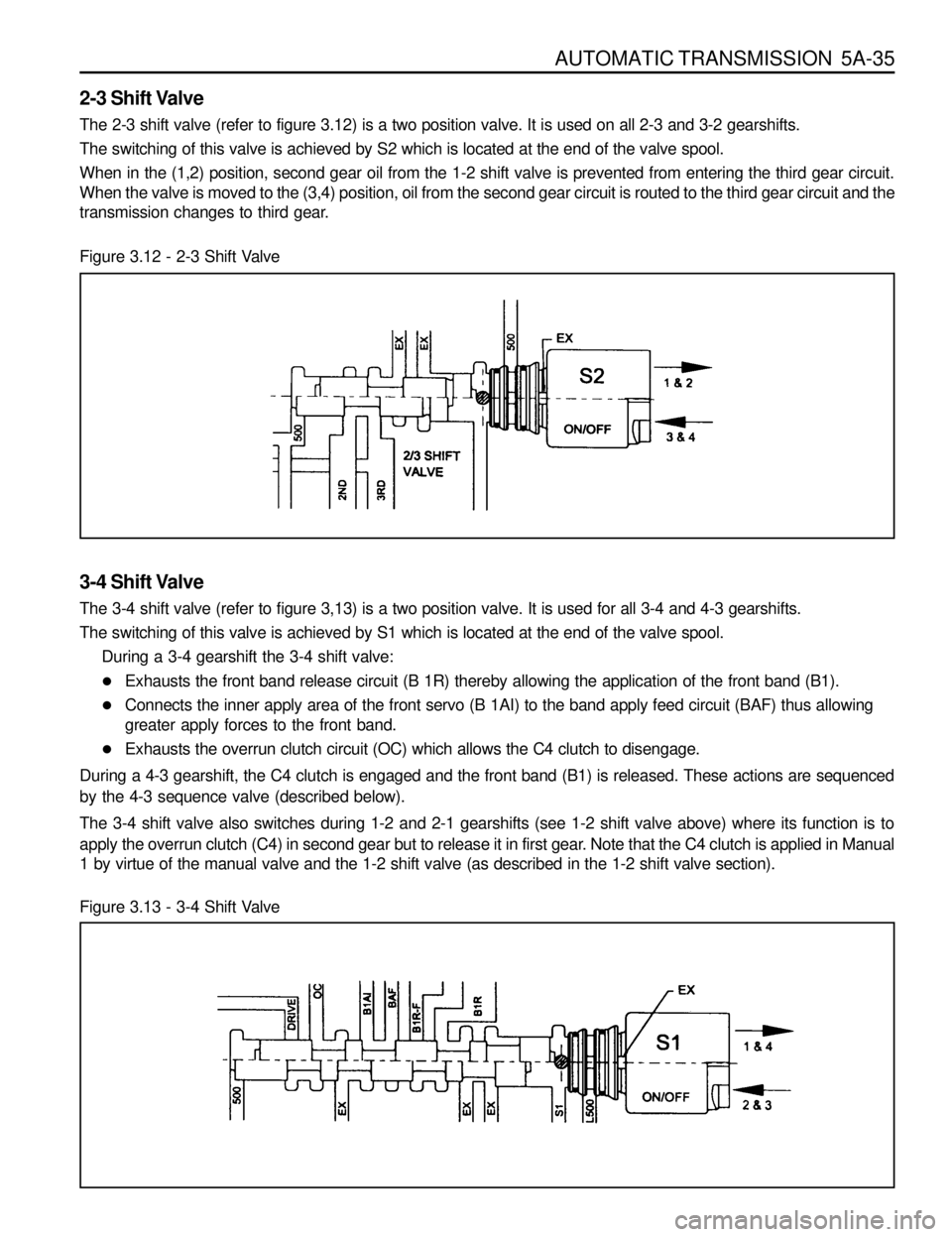

1-2 Shift Valve

The 1-2 shift valve (refer to figure 3.11) is a two position valve that must be switched to the (2,3,4) position in order to

get any forward gear other than first gear. It is used for all 1-2 and 2-1 gearshifts.

The switching of this valve is achieved by using S1 and/or S2.

During a 1-2 gearshift drive oil from the manual valve passes through to the second gear circuit. During a 2-1

gearshift the band apply feed oil is allowed to exhaust via the 1-2 shift valve.

The 1-2 shift valve works in conjunction with the 3-4 shift valve (described below) to disengage the C4 clutch in first

gear, and engage C4 in second gear. When Manual 1 is selected the C4 clutch and rear band (B2) are engaged.

Figure 3.11 - 1-2 Shift Valve

Manual Valve

The manual valve (refer to figure 3.10) is connected to the vehicle selector mechanism and controls the flow of oil to

the forward and reverse circuits. The manual valve function is identical in all forward gear positions except that in the

Manual 1 position an additional supply of oil is directed to the 1-2 shift valve for application of the rear band and the

C4 overrun clutch.

Page 1012 of 1463

AUTOMATIC TRANSMISSION 5A-35

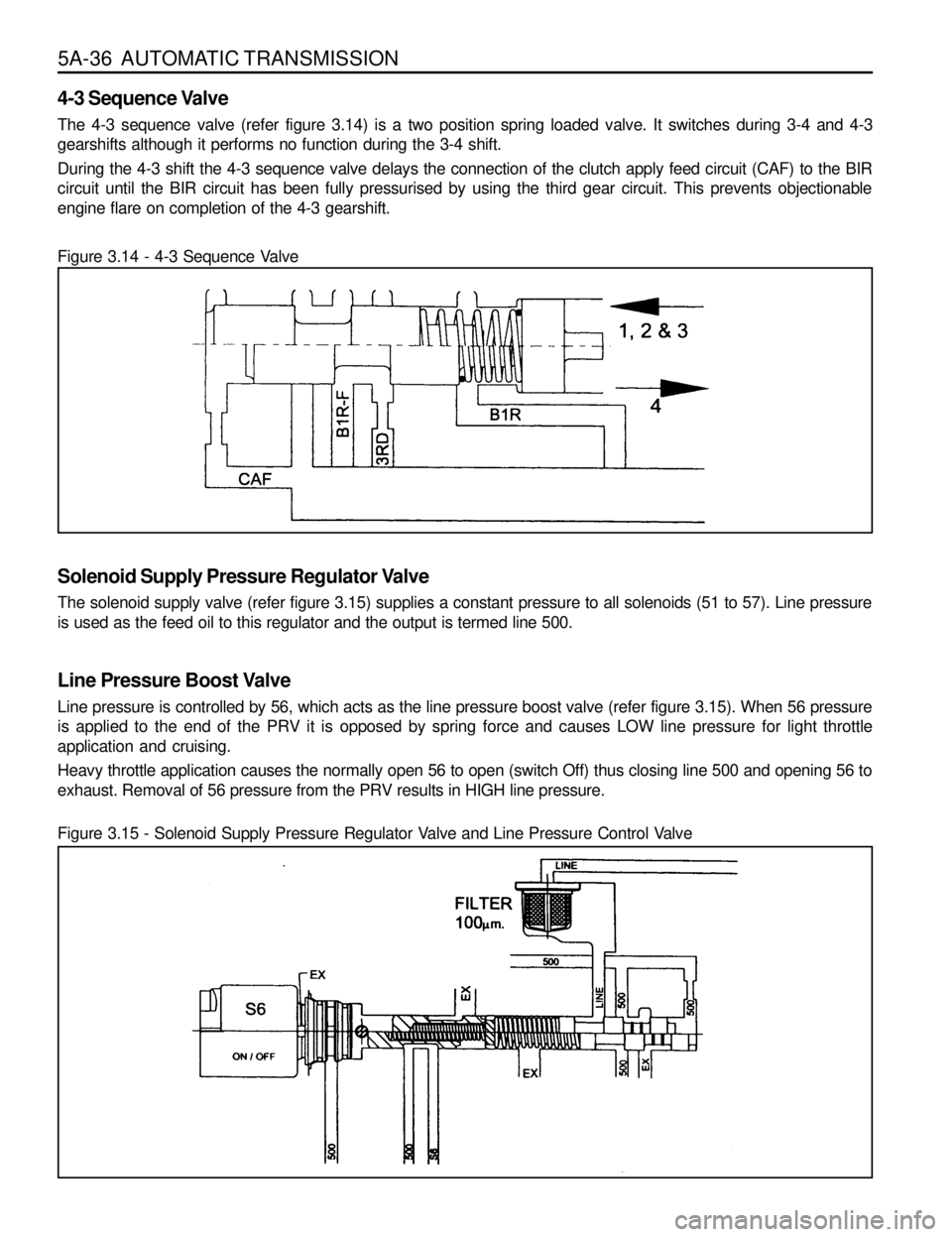

2-3 Shift Valve

The 2-3 shift valve (refer to figure 3.12) is a two position valve. It is used on all 2-3 and 3-2 gearshifts.

The switching of this valve is achieved by S2 which is located at the end of the valve spool.

When in the (1,2) position, second gear oil from the 1-2 shift valve is prevented from entering the third gear circuit.

When the valve is moved to the (3,4) position, oil from the second gear circuit is routed to the third gear circuit and the

transmission changes to third gear.

Figure 3.12 - 2-3 Shift Valve

3-4 Shift Valve

The 3-4 shift valve (refer to figure 3,13) is a two position valve. It is used for all 3-4 and 4-3 gearshifts.

The switching of this valve is achieved by S1 which is located at the end of the valve spool.

During a 3-4 gearshift the 3-4 shift valve:

lExhausts the front band release circuit (B 1R) thereby allowing the application of the front band (B1).

lConnects the inner apply area of the front servo (B 1AI) to the band apply feed circuit (BAF) thus allowing

greater apply forces to the front band.

lExhausts the overrun clutch circuit (OC) which allows the C4 clutch to disengage.

During a 4-3 gearshift, the C4 clutch is engaged and the front band (B1) is released. These actions are sequenced

by the 4-3 sequence valve (described below).

The 3-4 shift valve also switches during 1-2 and 2-1 gearshifts (see 1-2 shift valve above) where its function is to

apply the overrun clutch (C4) in second gear but to release it in first gear. Note that the C4 clutch is applied in Manual

1 by virtue of the manual valve and the 1-2 shift valve (as described in the 1-2 shift valve section).

Figure 3.13 - 3-4 Shift Valve

Page 1013 of 1463

5A-36 AUTOMATIC TRANSMISSION

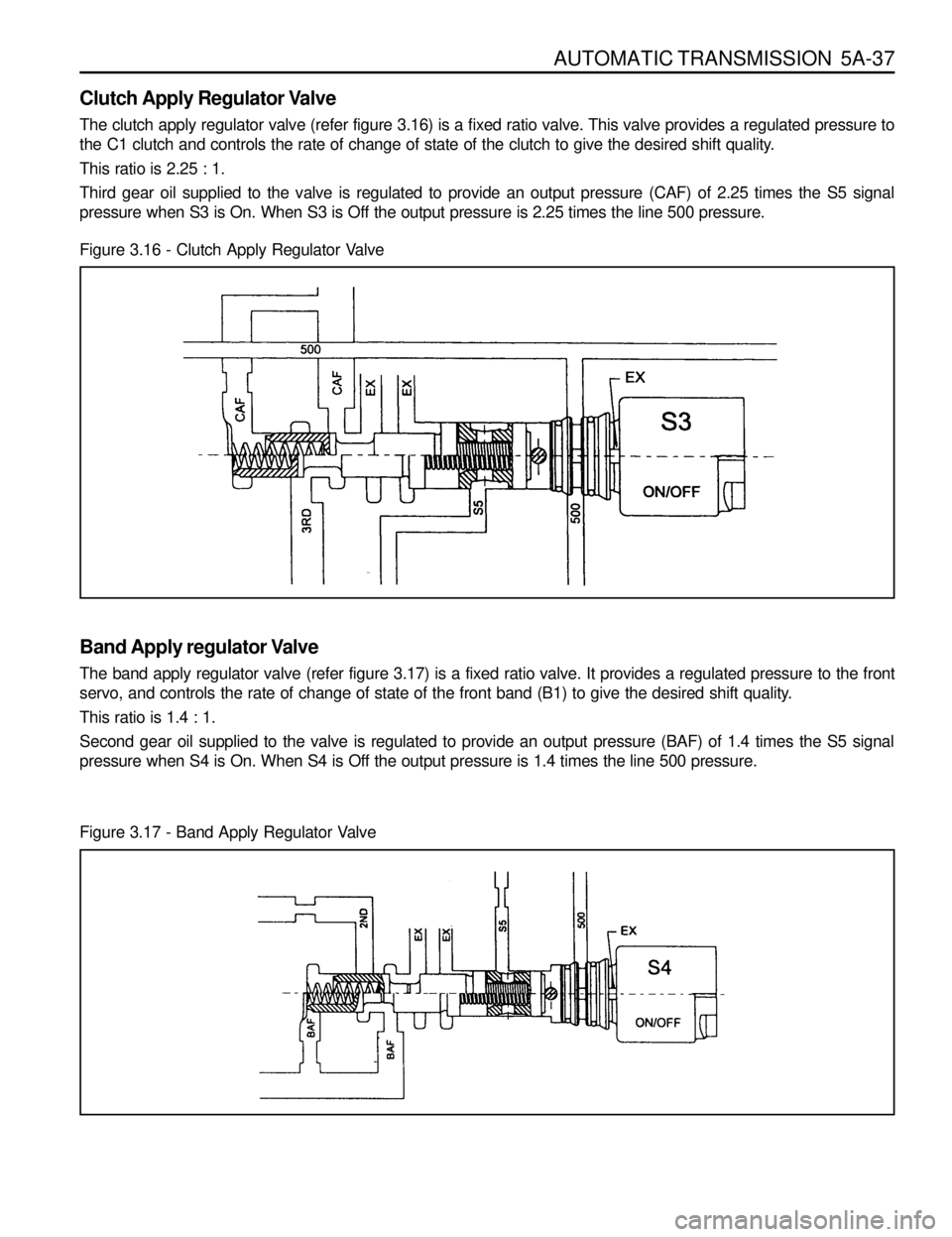

4-3 Sequence Valve

The 4-3 sequence valve (refer figure 3.14) is a two position spring loaded valve. It switches during 3-4 and 4-3

gearshifts although it performs no function during the 3-4 shift.

During the 4-3 shift the 4-3 sequence valve delays the connection of the clutch apply feed circuit (CAF) to the BIR

circuit until the BIR circuit has been fully pressurised by using the third gear circuit. This prevents objectionable

engine flare on completion of the 4-3 gearshift.

Figure 3.14 - 4-3 Sequence Valve

Figure 3.15 - Solenoid Supply Pressure Regulator Valve and Line Pressure Control Valve

Solenoid Supply Pressure Regulator Valve

The solenoid supply valve (refer figure 3.15) supplies a constant pressure to all solenoids (51 to 57). Line pressure

is used as the feed oil to this regulator and the output is termed line 500.

Line Pressure Boost Valve

Line pressure is controlled by 56, which acts as the line pressure boost valve (refer figure 3.15). When 56 pressure

is applied to the end of the PRV it is opposed by spring force and causes LOW line pressure for light throttle

application and cruising.

Heavy throttle application causes the normally open 56 to open (switch Off) thus closing line 500 and opening 56 to

exhaust. Removal of 56 pressure from the PRV results in HIGH line pressure.

Page 1014 of 1463

AUTOMATIC TRANSMISSION 5A-37

Figure 3.16 - Clutch Apply Regulator Valve

Clutch Apply Regulator Valve

The clutch apply regulator valve (refer figure 3.16) is a fixed ratio valve. This valve provides a regulated pressure to

the C1 clutch and controls the rate of change of state of the clutch to give the desired shift quality.

This ratio is 2.25 : 1.

Third gear oil supplied to the valve is regulated to provide an output pressure (CAF) of 2.25 times the S5 signal

pressure when S3 is On. When S3 is Off the output pressure is 2.25 times the line 500 pressure.

Band Apply regulator Valve

The band apply regulator valve (refer figure 3.17) is a fixed ratio valve. It provides a regulated pressure to the front

servo, and controls the rate of change of state of the front band (B1) to give the desired shift quality.

This ratio is 1.4 : 1.

Second gear oil supplied to the valve is regulated to provide an output pressure (BAF) of 1.4 times the S5 signal

pressure when S4 is On. When S4 is Off the output pressure is 1.4 times the line 500 pressure.

Figure 3.17 - Band Apply Regulator Valve

Page 1016 of 1463

AUTOMATIC TRANSMISSION 5A-39

Primary Regulator Valve

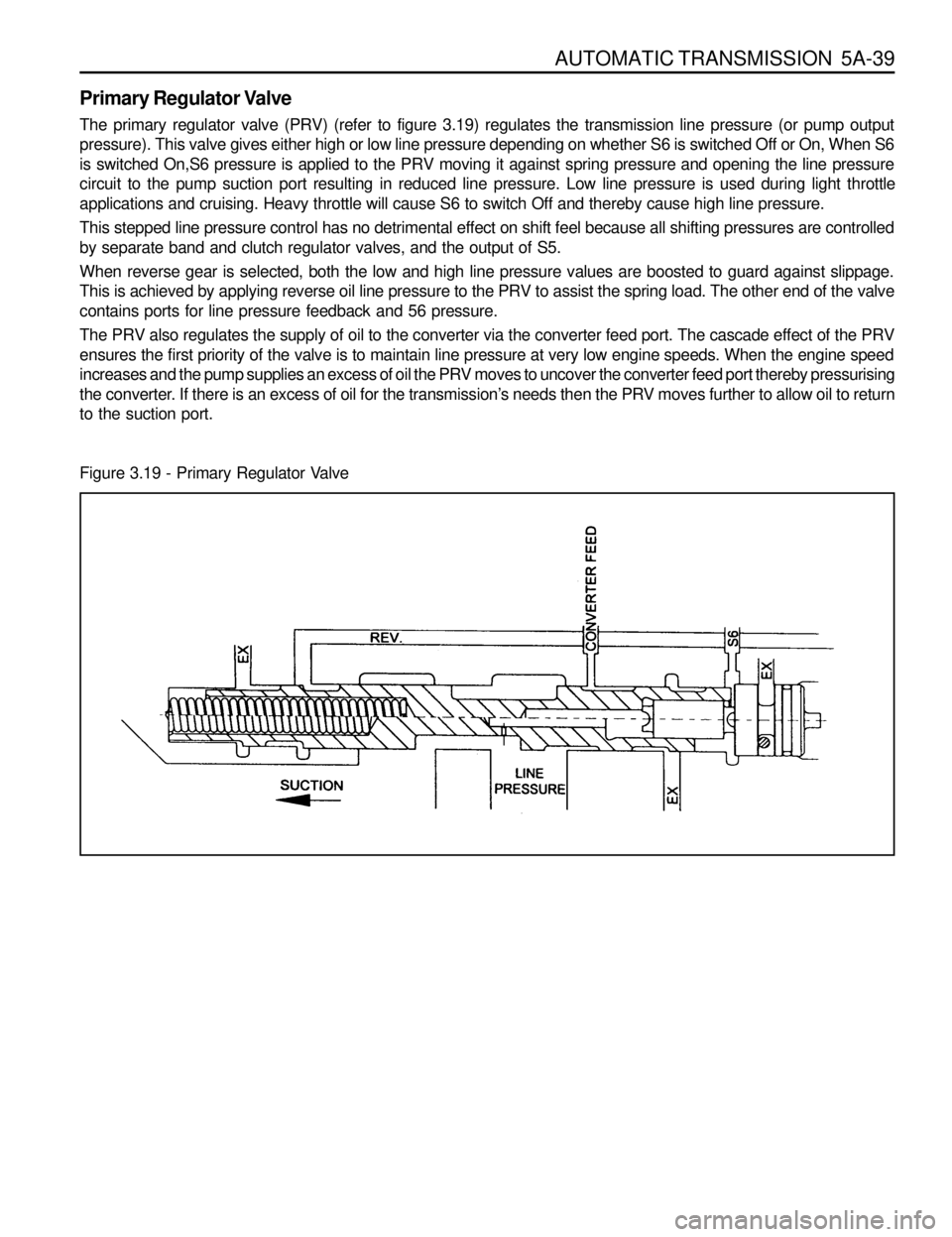

The primary regulator valve (PRV) (refer to figure 3.19) regulates the transmission line pressure (or pump output

pressure). This valve gives either high or low line pressure depending on whether S6 is switched Off or On, When S6

is switched On,S6 pressure is applied to the PRV moving it against spring pressure and opening the line pressure

circuit to the pump suction port resulting in reduced line pressure. Low line pressure is used during light throttle

applications and cruising. Heavy throttle will cause S6 to switch Off and thereby cause high line pressure.

This stepped line pressure control has no detrimental effect on shift feel because all shifting pressures are controlled

by separate band and clutch regulator valves, and the output of S5.

When reverse gear is selected, both the low and high line pressure values are boosted to guard against slippage.

This is achieved by applying reverse oil line pressure to the PRV to assist the spring load. The other end of the valve

contains ports for line pressure feedback and 56 pressure.

The PRV also regulates the supply of oil to the converter via the converter feed port. The cascade effect of the PRV

ensures the first priority of the valve is to maintain line pressure at very low engine speeds. When the engine speed

increases and the pump supplies an excess of oil the PRV moves to uncover the converter feed port thereby pressurising

the converter. If there is an excess of oil for the transmission’s needs then the PRV moves further to allow oil to return

to the suction port.

Figure 3.19 - Primary Regulator Valve

Page 1017 of 1463

5A-40 AUTOMATIC TRANSMISSION

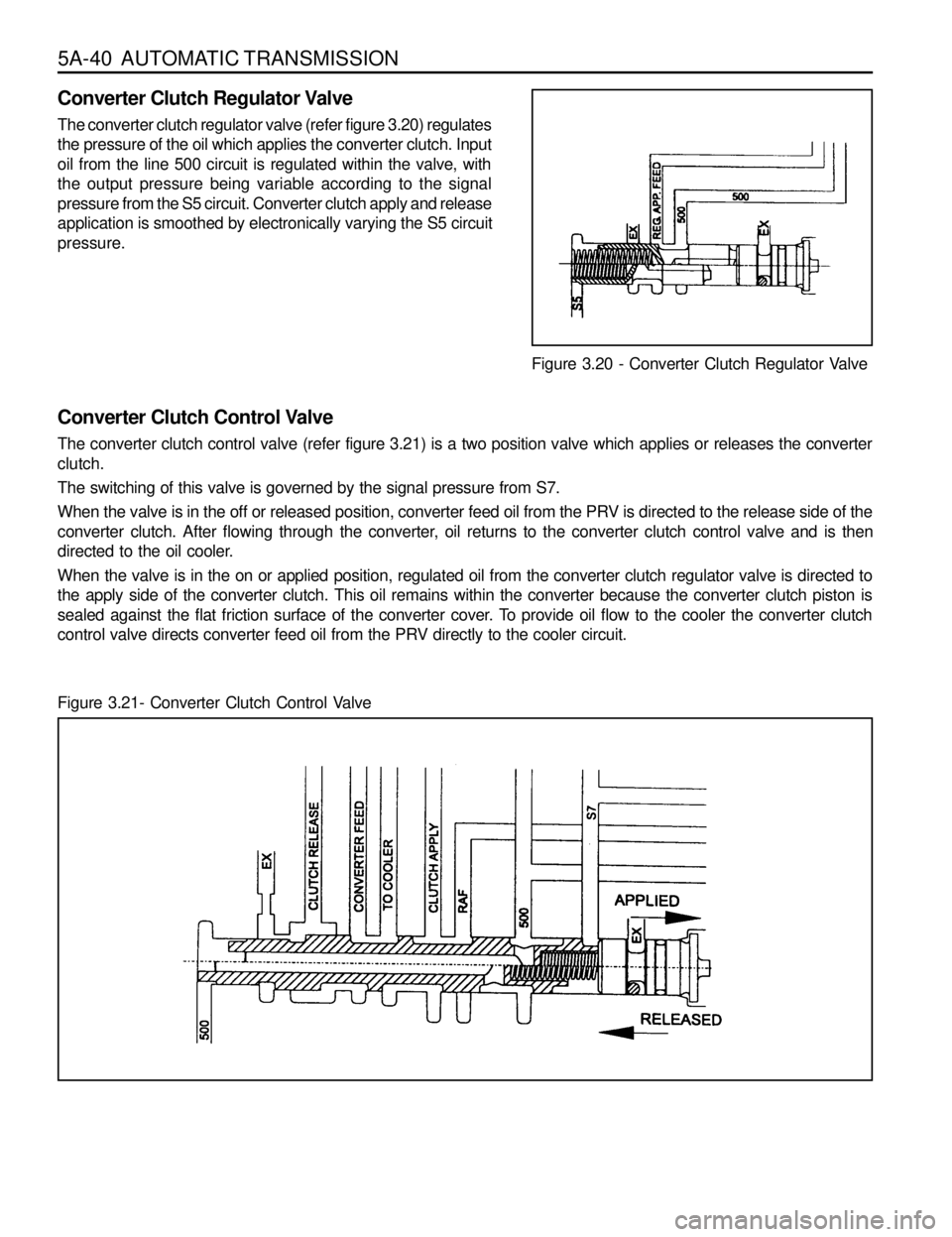

Converter Clutch Regulator Valve

The converter clutch regulator valve (refer figure 3.20) regulates

the pressure of the oil which applies the converter clutch. Input

oil from the line 500 circuit is regulated within the valve, with

the output pressure being variable according to the signal

pressure from the S5 circuit. Converter clutch apply and release

application is smoothed by electronically varying the S5 circuit

pressure.

Converter Clutch Control Valve

The converter clutch control valve (refer figure 3.21) is a two position valve which applies or releases the converter

clutch.

The switching of this valve is governed by the signal pressure from S7.

When the valve is in the off or released position, converter feed oil from the PRV is directed to the release side of the

converter clutch. After flowing through the converter, oil returns to the converter clutch control valve and is then

directed to the oil cooler.

When the valve is in the on or applied position, regulated oil from the converter clutch regulator valve is directed to

the apply side of the converter clutch. This oil remains within the converter because the converter clutch piston is

sealed against the flat friction surface of the converter cover. To provide oil flow to the cooler the converter clutch

control valve directs converter feed oil from the PRV directly to the cooler circuit.

Figure 3.21- Converter Clutch Control ValveFigure 3.20 - Converter Clutch Regulator Valve