coolant temperature SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 687 of 1463

1F2-38 M161 ENGINE CONTROLS

Engine Connector

Pin No.Abbreviation

Description

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80-

-

EV1

EV4

EV2

EV3

M+

M-

TM.31

-

ZSB23

ZSA14

NWS

EGR

-

SLP

-

MT

GND

LT -

-

Injector-cylinder 1

Injector-cylinder 2

Injector-cylinder 3

Injector-cylinder 4

E-GAS motor plus

E-GAS motor minus

Power ground TM.31

-

Ignition coil cylinder 2+3

Ignition coil cylinder 1+4

Camshaft control

EGR (Exhaust Gas Recirculation)

-

Second air pump relay

-

Engine coolant temperature

Intake air temperature ground

Intake air temperature

Page 691 of 1463

1F2-42 M161 ENGINE CONTROLS

Pin No.

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Abbreviation Description

-

-

Injector-cylinder 1

Injector-cylinder 2

Injector-cylinder 3

Injector-cylinder 4

E-GAS motor plus

E-GAS motor minus

Power ground TM.31

-

Ignition coil cylinder 2+3

Ignition coil cylinder 1+4

Camshaft control

-

Second air pump relay

-

Engine coolant temperature

Temperature ground

Intake air temperature

Hot film air mass signal

-

-

E-GAS potentiometer ground

E-GAS potentiometer 2 signal

-

E-GAS potentiometer 1 signal

-

-

-

-

-

EV1

EV4

EV2

EV3

M+

M-

TM.31

-

ZSB23

ZSA14

NWS

-

-

SLP

-

MT

GND

LT

HFM

-

-

-

IP2S

-

IP1S

-

-

--

-

l

l

l

l

l

l

l

-

l

l

l

-

-

¡

-

l

l

l

l

-

-

l

l

-

l

-

-

-

-

-

l

l

l

l

l

l

l

-

l

l

l

-

-

¡

-

l

l

l

l

-

-

l

l

-

l

-

-

-

E23 ENG,

4speed A/T E23 ENG,

5speed A/T

Page 711 of 1463

1F2-62 M161 ENGINE CONTROLS

PURGE SWITCHOVER VALVE

1 Purge Control valve

2 Line to engine

3 Line to canister

4 Canister

Functions

The fuel vaporization control system is installed to inhibit the

fuel vaporized gas from discharging into the atmosphere. The

fuel vaporized gas that is accumulated in the canister abstracts

through the purge switchover valve purification during the

engine combustion (except the decreasing mode) and coolant

temperature of over 80°C. For this reason, the ECU transacts

the engine speed, air inflow quantity, coolant temperature, and

intake temperature.

The purge switchover valve is activated by the ECU frequency

according with the engine rotating speed to adjust the

purification rate. The purification rate is determined by the

continuous valve opening interval.

The purge switchover valve is activated by the ECU for the

following conditions :

lCoolant temperature of over 80°C

lEngine speed of over 1000rpm

l2 Minutes after starting

lWhen the fuel cut-off mode is not activated

Page 721 of 1463

1F2-72 M161 ENGINE CONTROLS

If the measured value is not within the specified value, the

possible cause may be in cable or HFM sensor in itself.

Perform the 5V power supply inspection procedures.

HFM Sensor 5V Power Supply Inspection

1. Measure the voltage between the HFM sensor No.108(+) and

No.105(-) after removing the HFM sensor connector.

HFM Sensor Input Voltage Inspection

1. Measure the HFM sensor signal voltage between the ECU

terminal No.81 and No.105.

Specified Value (coolant temperature is over 70°C)

If the measured value is not within the specified value, the

possible cause may be in cable or ECU coupling.

Iginition"ON” 0.9 - 1.1 V

Engine at idle 1.3 - 1.7 V

Specified Value 4.7 - 5.2 V

2. Measure the voltage between the HFM sensor wining

connector terminal No.3 pin and No.102(+) after removing

the HFM sensor connector.

Specified Value

If the measured value is not within the specified value, the

possible cause may be in cable or over voltage protection

relay.

Perfrom the 12V power supple inspection procedures.

Specified Value 4.7 - 5.2 V

HFM Sensor 12V Power Supply Inspection

1. Measure the voltage between the HFM sensor wining

connector 1G No.2 pin(+) and No.3 after removing the HFM

sensor connector.

If the measured value is not within the specified value, the

possible cause may be in cable or over voltage protection

relay.

Specified Value 11 - 14 V

Page 723 of 1463

1F2-74 M161 ENGINE CONTROLS

Oxygen Sensor Signal Voltage Inspection

1. Measure the oxygen sensor signal voltage between the ECU

terminal No.11 and No.9. Maintain the engine speed ia at

idle while the coolant temperature is over 80°C.

If the measured value is not within the specified value, the

possible cause may be in cable, oxygen sensor or ECU.

Oxygen Sensor Heating Voltage Inspection

1. Measure the oxygen sensor heating voltage between the

ECU terminal No.11 and No.9. Maintain the engine speed ia

at idle while the coolant temperature is over 80°C.

If the measured value is not within the specified value, the

possible cause may be in cable, oxygen sensor or ECU.

Oxygen Sensor Heating Current Consumption

Inspection

1. Measure the oxygen sensor heating current consumption

between the ECU terminal No.9 and sensor heating(+) line

while the ignition switch is in "ON" position.

If the measured value is not within the specified value, the

possible cause may be in cable, oxygen sensor or ECU.

Specified Value 0.2 - 2.0 A

Specified Value -0.2 - 1.0 V

Specified Value 11 - 14

Page 725 of 1463

1F2-76 M161 ENGINE CONTROLS

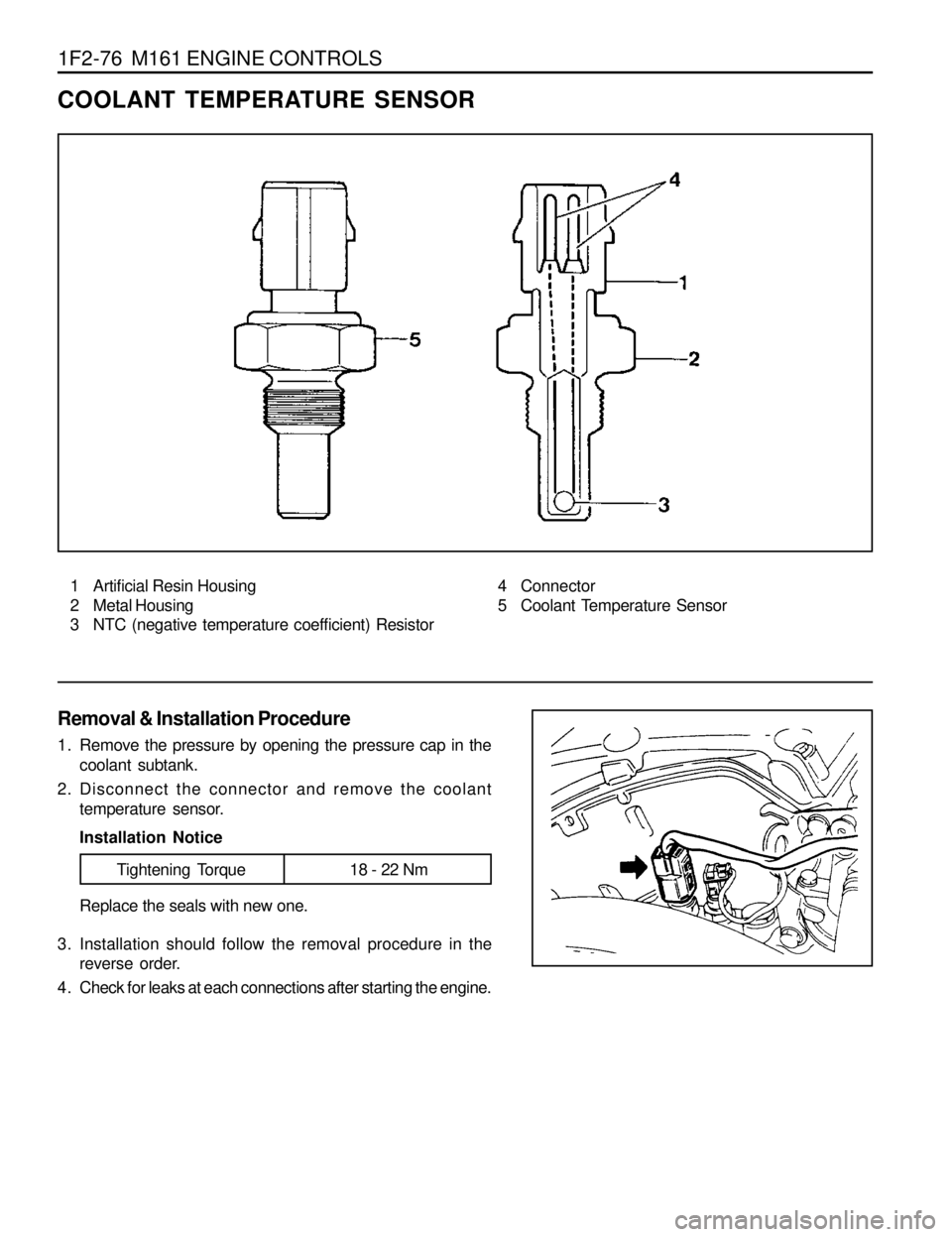

COOLANT TEMPERATURE SENSOR

1 Artificial Resin Housing

2 Metal Housing

3 NTC (negative temperature coefficient) Resistor

Removal & Installation Procedure

1. Remove the pressure by opening the pressure cap in the

coolant subtank.

2. Disconnect the connector and remove the coolant

temperature sensor.

Installation Notice

Replace the seals with new one.

3. Installation should follow the removal procedure in the

reverse order.

4. Check for leaks at each connections after starting the engine.4 Connector

5 Coolant Temperature Sensor

Tightening Torque 18 - 22 Nm

Page 726 of 1463

M161 ENGINE CONTROLS 1F2-77

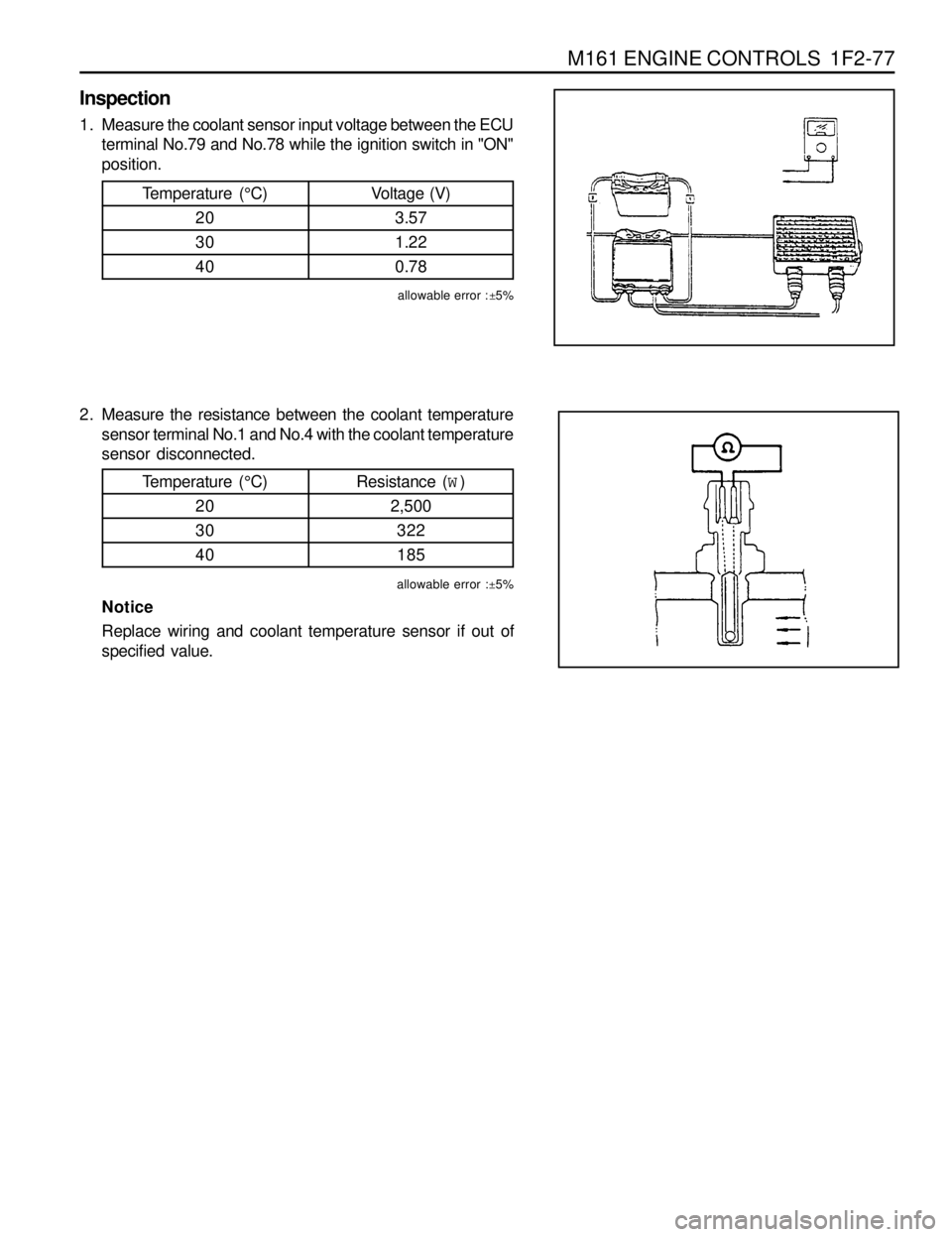

2. Measure the resistance between the coolant temperature

sensor terminal No.1 and No.4 with the coolant temperature

sensor disconnected.

Inspection

1. Measure the coolant sensor input voltage between the ECU

terminal No.79 and No.78 while the ignition switch in "ON"

position.

Notice

Replace wiring and coolant temperature sensor if out of

specified value.

allowable error :±5%

allowable error :±5%

Voltage (V)

3.57

1.22

0.78 Temperature (°C)

20

30

40

Resistance (W)

2,500

322

185 Temperature (°C)

20

30

40

Page 727 of 1463

1F2-78 M161 ENGINE CONTROLS

Service Data

Resistance characteristic curve according to the coolant

temperature

Temperature(°C) Resistance(W) Voltage(V) Temperature(°C) Resistance(W) Voltage(V)

-40 48,550 4.8991 60 594 1.8632

-30 27,000 4.8214 70 434 1.5132

-20 15,670 4.7001 80 322 1.2179

-10 9,450 4.5215 90 243 0.9775

0 5,890 4.4273 100 185 0.7806

10 3,790 3.9562 110 143 0.6255

20 2,500 3.5714 120 111.6 0.5020

30 1,692 3.1426 130 88.0 0.4044

40 1,170 2.6959 140 71.2 0.3323

50 826 2.2618 - - -

Page 736 of 1463

OM600 ENGINE CONTROLS 1F3-7

Vacuum 500 mbar

Lines and connections leaking.

Faulty PLA vacuum unit.

Test step 1

Connect vacuum pump (14) with Y adapter to PLA

vacuum unit (5). Run engine at idle speed.

YES

NO

(Remove the connection hose from vacuum pump)

Connect vacuum pump (14) direct to PLA vacuum unit

(5) and pressurize with vacuum.

Vacuum is built up and idle speed increases approx.

150-200 rpm

YESNO

Faulty PLA vacuum unit

(Coolant Temperature 30°C)

Stop the engine Seal the air admission line with plug.

Connect the vacuum pump to line to thermovalve and

pressurize the line with vacuum.

Vacuum is built up.

YESNO

Lines and connectors leaking.

Faulty thermovalve.

= >

Page 1376 of 1463

INSTRUMENTATION/DRIVER INFORMATION 9E-3

COMBINATION METER

COMPONENT LOCATOR

1. Speedometer

2. Odometer

3. Trip odometer

4. Tachometer

5. Coolant temperature gauge

6. Fuel gauge

7. Low fuel level warning light

8. Turn signal indicator (left)

9. Turn signal indicator (right)

10. Outside rearview mirror & tailgate heating switch

11. Reset button

12. Auto shift indicator*

13. Door open warning light

14. TCS indicator (equipped with ABD)*

21. ABS warning light*22. EBD warning light*

23. ECS / SPORT warning light*

24. 4 - wheel warning light*

25. 4 - wheel high indicator

26. 4 - wheel low indicator

27. WINTER indicator

28. POWER indicator

29. High beam indicator

15. Alternator warning light

16. Engine oil pressure warning light

17. Brake system warning light

18. Glow indicator light (For Diesel engine)

19. Airbag warning light*

20. Seat belt reminder