Vacuum SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 872 of 1463

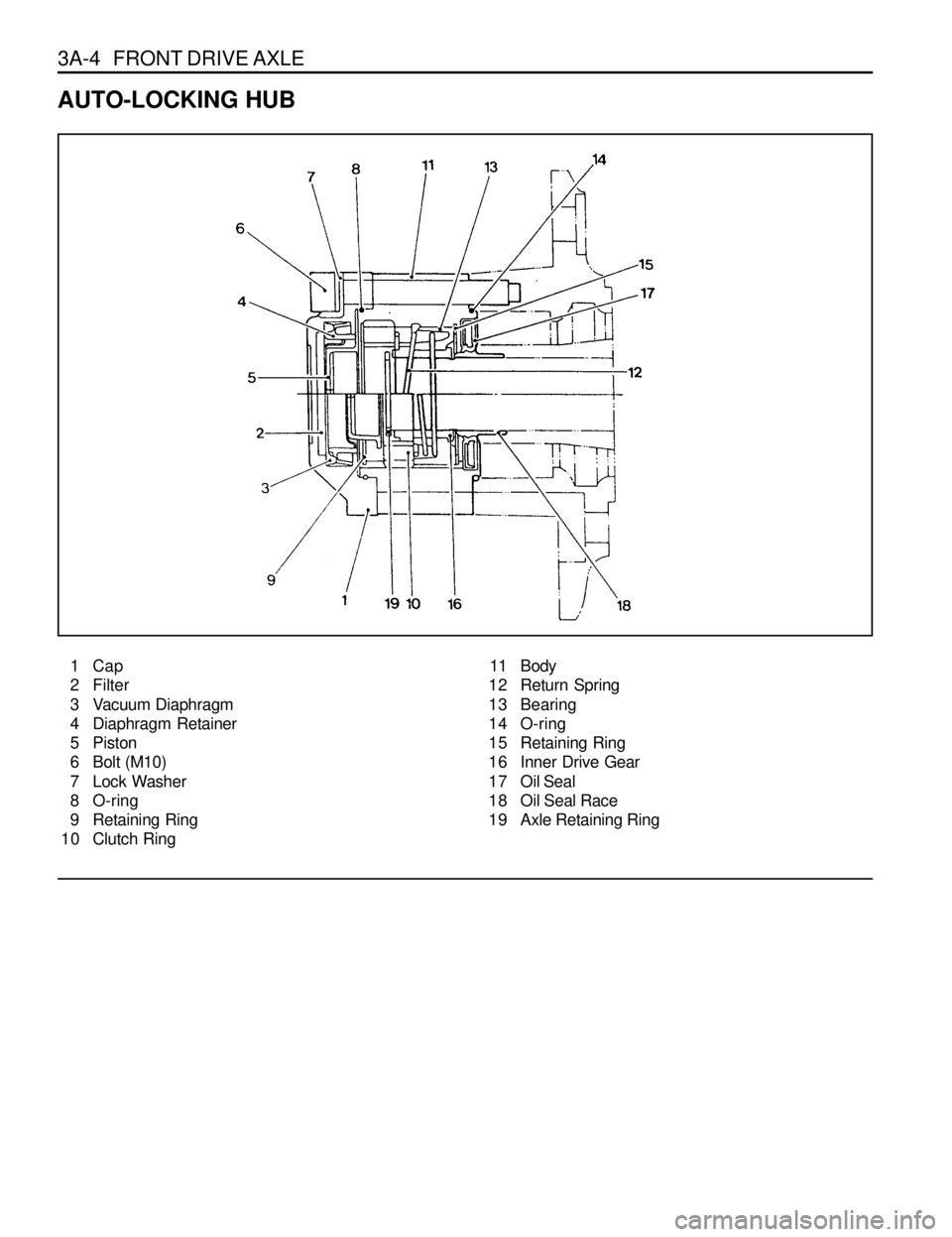

3A-4 FRONT DRIVE AXLE

AUTO-LOCKING HUB

1 Cap

2 Filter

3 Vacuum Diaphragm

4 Diaphragm Retainer

5 Piston

6 Bolt (M10)

7 Lock Washer

8 O-ring

9 Retaining Ring

10 Clutch Ring11 Body

12 Return Spring

13 Bearing

14 O-ring

15 Retaining Ring

16 Inner Drive Gear

17 Oil Seal

18 Oil Seal Race

19 Axle Retaining Ring

Page 873 of 1463

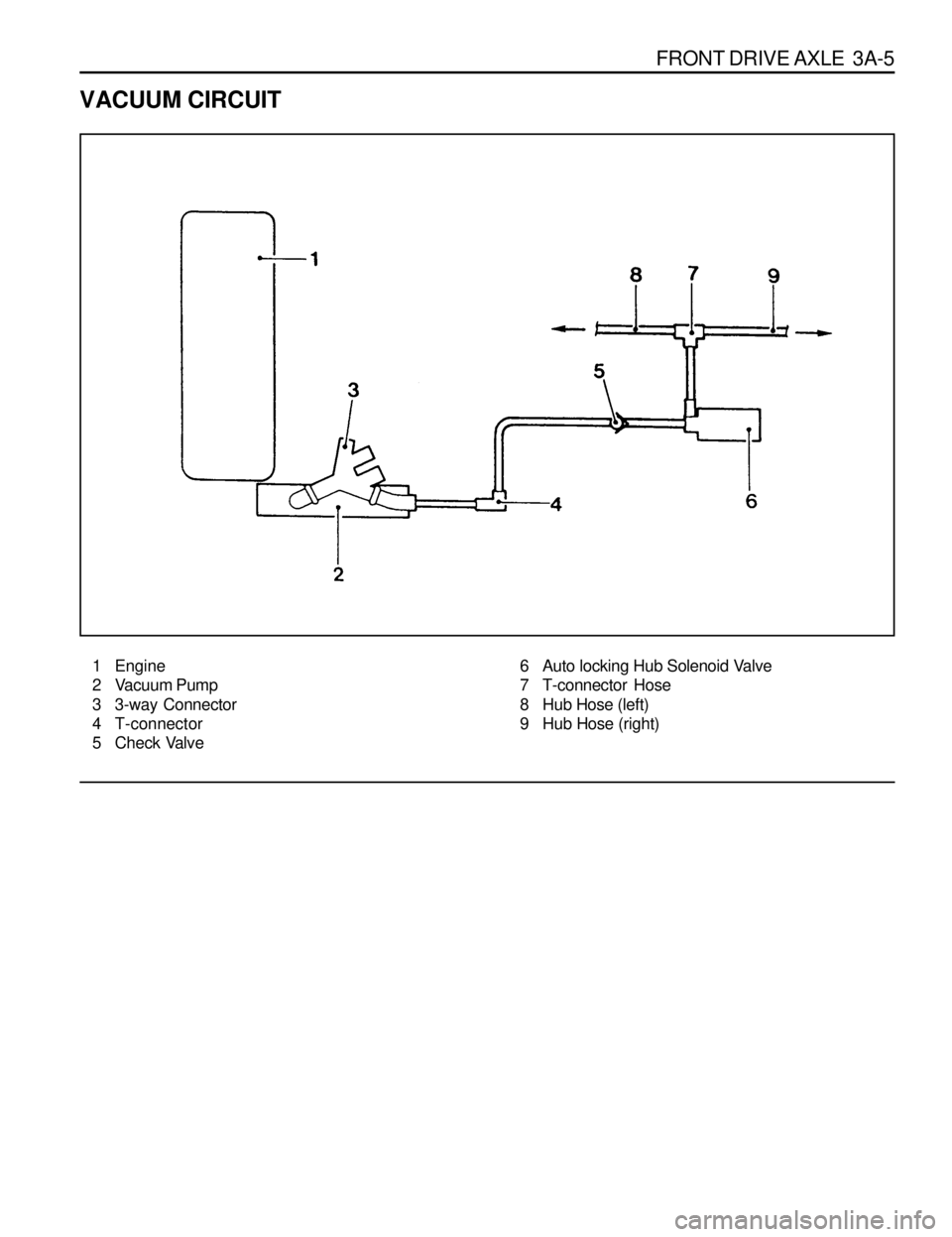

FRONT DRIVE AXLE 3A-5

VACUUM CIRCUIT

1 Engine

2 Vacuum Pump

3 3-way Connector

4 T-connector

5 Check Valve6 Auto locking Hub Solenoid Valve

7 T-connector Hose

8 Hub Hose (left)

9 Hub Hose (right)

Page 874 of 1463

3A-6 FRONT DRIVE AXLE

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

VACUUM LINE

1 Vacuum Auto-locking Hub Assembly

2 Bolt......................................................50-60 Nm

3 Cam Washer

4 Auto-locking Hub Cap

5 Retainer Ring

6 Shim

7 Locking Hub

8 Band

9 Hose (L : 400)

10 T-connector

11 Hose (L : 250, white)12 Check Valve

13 Hose (L :100, green)

14 Auto Locking Hub Solenoid Valve

1 5 Bolt

16 Hose (L :100, green)

17 T-connector

18 Hose (L : 720, yellow)

19 Hose (L :2, 360 , red)

20 Corrugated Tube

2 1 Clip

2 2 Clip

Page 877 of 1463

FRONT DRIVE AXLE 3A-9

Removal & Installation Procedure

1. Remove the tire.

Installation Notice

Steel Wheel

Aluminum WheelTightening Torque80 - 120 Nm

110 - 130 Nm

2. Remove the autolocking hub vacuum hose.

3. With ABS

Remove the wheel speed sensor from the steering knuckle.

Installation Notice

4. Remove the mounting bolts and pull off the caliper assembly.

Installation Notice

Tightening Torque 6 - 8 Nm

Hose Bolt

Mounting BoltTightening Torque25 - 35 Nm

85 - 105 Nm

Notice

Be careful not to damage the brake hose.

Page 916 of 1463

SECTION 4A

HYDRAULIC BRAKES

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4A-1

General Specifications . . . . . . . . . . . . . . . . . . 4A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Noise or Vehicle Vibration When Applied

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Pulls to One Side When Braking . . . . . . . . . . . 4A-2

Poor Braking . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Increasing Pedal Stroke (Pedal Goes to

Floor) or Brake Dragging . . . . . . . . . . . . . . . 4A-3

Poor Braking of Parking Brake . . . . . . . . . . . . 4A-3

TABLE OF CONTENTS

Component Locator . . . . . . . . . . . . . . . . . . . 4A-4

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-4

ABS / ABD . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-5

Non-ABS / ABD . . . . . . . . . . . . . . . . . . . . . . . . 4A-6

Maintenance and Repair . . . . . . . . . . . . . . . 4A-7

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 4A-7

Bleeding the Brakes . . . . . . . . . . . . . . . . . . . . 4A-7

Brake Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-9

LCRV (Load Conscious Reducing Valve) . . . 4A-12

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Type

Pedal Ratio

Pedal Stroke

Pedal Freeplay

Type

Inner Diameter

Type

Ratio

Type

I.D. of Caliper Cylinder

Thickness of Brake Pad

Thickness of Disc Plate

Type

I.D. of Caliper Cylinder

Thickness of Brake Pad

Thickness of Disc Plate

Type

Operation

SpecificationPBR Brake

4.3 : 1

132 mm

f23.81 mm

5.0 : 1

f60.4 mm

¬

f40.5 mm

9.5 mm

¬ Suspended

1 - 4 mm

Tandem Type with Lever Sensor

Vacuum Booster Type

Ventilated Disc

10 mm

24 mm

Rear Wheel Internal Expansion Type

Mechanical

SAE J1703, DOT3

SPECIFICATIONS

GENERAL SPECIFICATIONS

Brake Pedal

Master Cylinder

Brake Booster

Front Brake

Rear Brake

Parking Brake

Brake FluidMANDO Brake

4.3 : 1

138 mm

f25.4 mm

5.6 : 1

f60 mm

Solid Disc

f38.2 mm

10.0 mm

10.4 mm

Application

Page 926 of 1463

HYDRAULIC BRAKES 4A-11

Adjustment Procedure

1. Pedal Height

Notice

If pedal height is not in specified value, loosen the stop

lamp nut (B) and adjust the pedal height.

2. Pedal Stroke

Height (A) 150 mm (From the carpet)

Notice

If pedal stroke is not in specified value, loosen the stop bolt

and lock nut (F) and adjust the pedal stroke.

3. Free Play

Stroke (C)Mando : 138 mm

PBR : 132mm

Notice

To adjust, depress the brake pedal several times until there

is no more vacuum left in the vacuum line.

To adjust, loosen the lock nut (D) of the push rod and turn

the rod.

Free Play (E)1 - 4 mm

Inspection Procedure

1. Inspect the wear of bushing.

2. Inspect the warp and bend of brake pedal.

3. Inspect the return spring of brake pedal.

4. Inspect the conductivity when connecting the tester to the

stop lamp switch connector.

Page 932 of 1463

MASTER CYLINDER 4B-3

Removal & Installation Procedure

1. Remove the oil level sensor connector.

2. Remove the tube from the master cylinder.

Installation Notice

Notice

lBe careful not to drop the oil when removing the tube.

lIf the oil is dropped, promptly sweep up.

3. Remove the booster vacuum hose.

Notice

lConnect fully to the end of vacuum hose when installing.

4. Loosen the nut of master cylinder.

Installation Notice

5. Remove the clevis pin and disconnect the pedal and brake

booster push rod.

Notice

lInstall in the upper hole when PBR brake.

lConnect the snap pin in the hole of clevis pin fully.

lApply the grease around the hole of clevis pin.

Tightening Torque 14 - 22 Nm

Tightening Torque 15 - 19 Nm

Page 934 of 1463

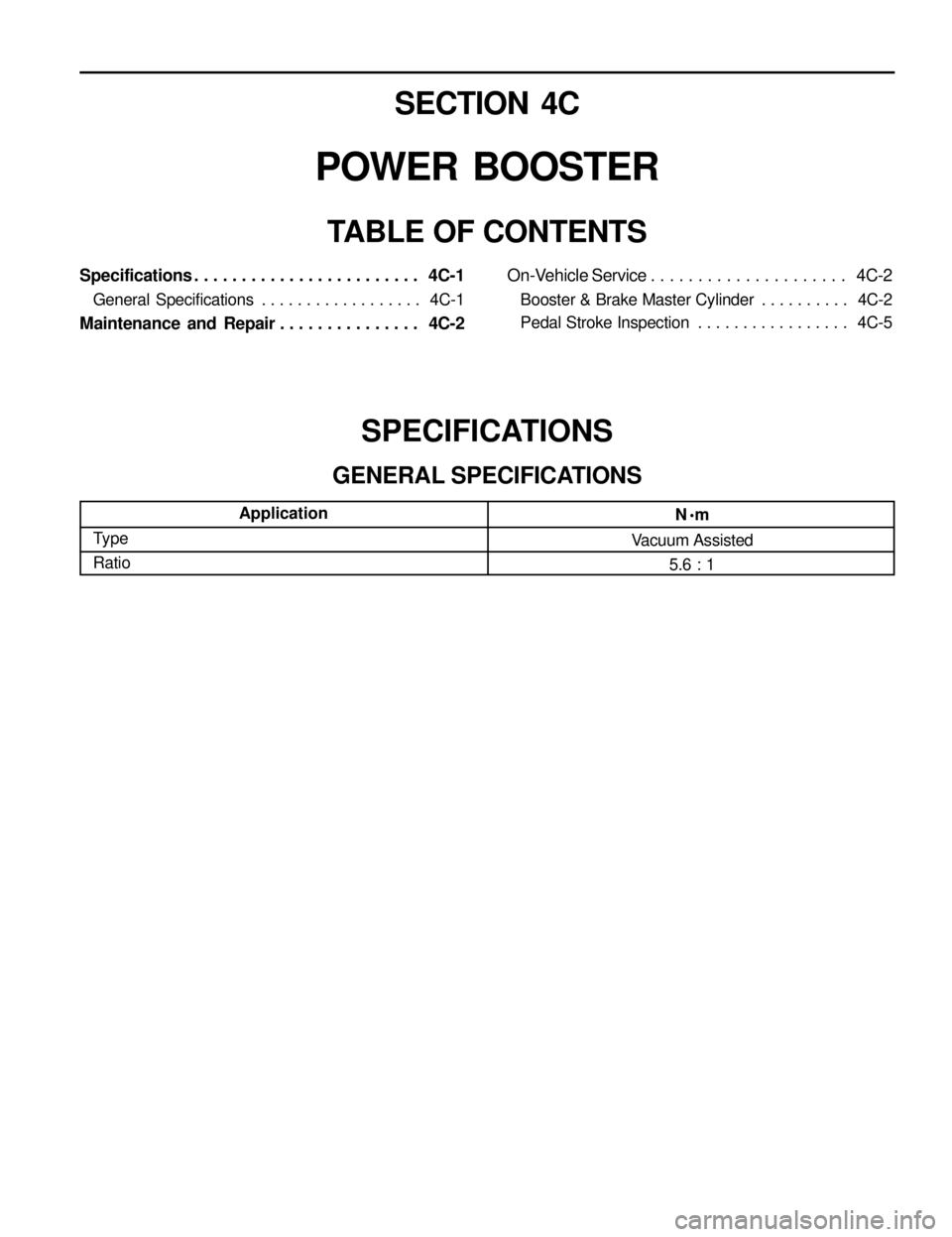

SECTION 4C

POWER BOOSTER

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4C-1

General Specifications . . . . . . . . . . . . . . . . . . 4C-1

Maintenance and Repair . . . . . . . . . . . . . . . 4C-2

TABLE OF CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Type

RatioN

· ·· ·

·m

Vacuum Assisted

5.6 : 1

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 4C-2

Booster & Brake Master Cylinder . . . . . . . . . . 4C-2

Pedal Stroke Inspection . . . . . . . . . . . . . . . . . 4C-5

Page 936 of 1463

POWER BOOSTER 4C-3

Removal & Installation Procedure

1. Remove the oil level sensor connector.

2. Remove the tube from the master cylinder.

Installation Notice

Notice

lBe careful not to drop the oil when removing the tube.

lIf the oil is dropped, promptly sweep up.

3. Remove the booster vacuum hose.

Notice

lConnect fully to the end of vacuum hose when installing.

4. Loosen the nut of master cylinder.

Installation Notice

5. Remove the clevis pin and disconnect the pedal and brake

booster push rod.

Notice

lInstall in the upper hole when PBR brake.

lConnect the snap pin in the hole of clevis pin fully.

lApply the grease around the hole of clevis pin.

Tightening Torque 14 - 22 Nm

Tightening Torque 15 - 19 Nm

Page 1273 of 1463

6E-4 STEERING WHEEL AND COLUMN

6. Disconnect each connectors.

7. Remove the vacuum hose from the ignition switch(Diesel

only) .

9. Remove the lower shaft by removing the bolt of the steering

column shaft.

Installation Notice

Tightening Torque 9 - 14 Nm

8. Remove the combination switch assembly.

10. Remove the dash panel mounting bolts.

Installation Notice

Tightening Torque 30 - 40 Nm