Vacuum SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 746 of 1463

OM600 ENGINE CONTROLS 1F3-17

6. After adjustment, tighten the locking nut and place the

position marking with different color of paint.

Notice

If there are no changes in idle speed with PLA unit

adjustment, perform the service at a BOSCH Service Center.

7. Connect the vacuum pump to the PLA vacuum unit and

build up vacuum approx. 500mbar. If engine rpm increases

by approx. 100rpm, It is normal.

Vacuum Pump 001 589 73 21 00

8. Connect the vacuum line (4).

9. Switch on all ancillaries and check the idle speed.

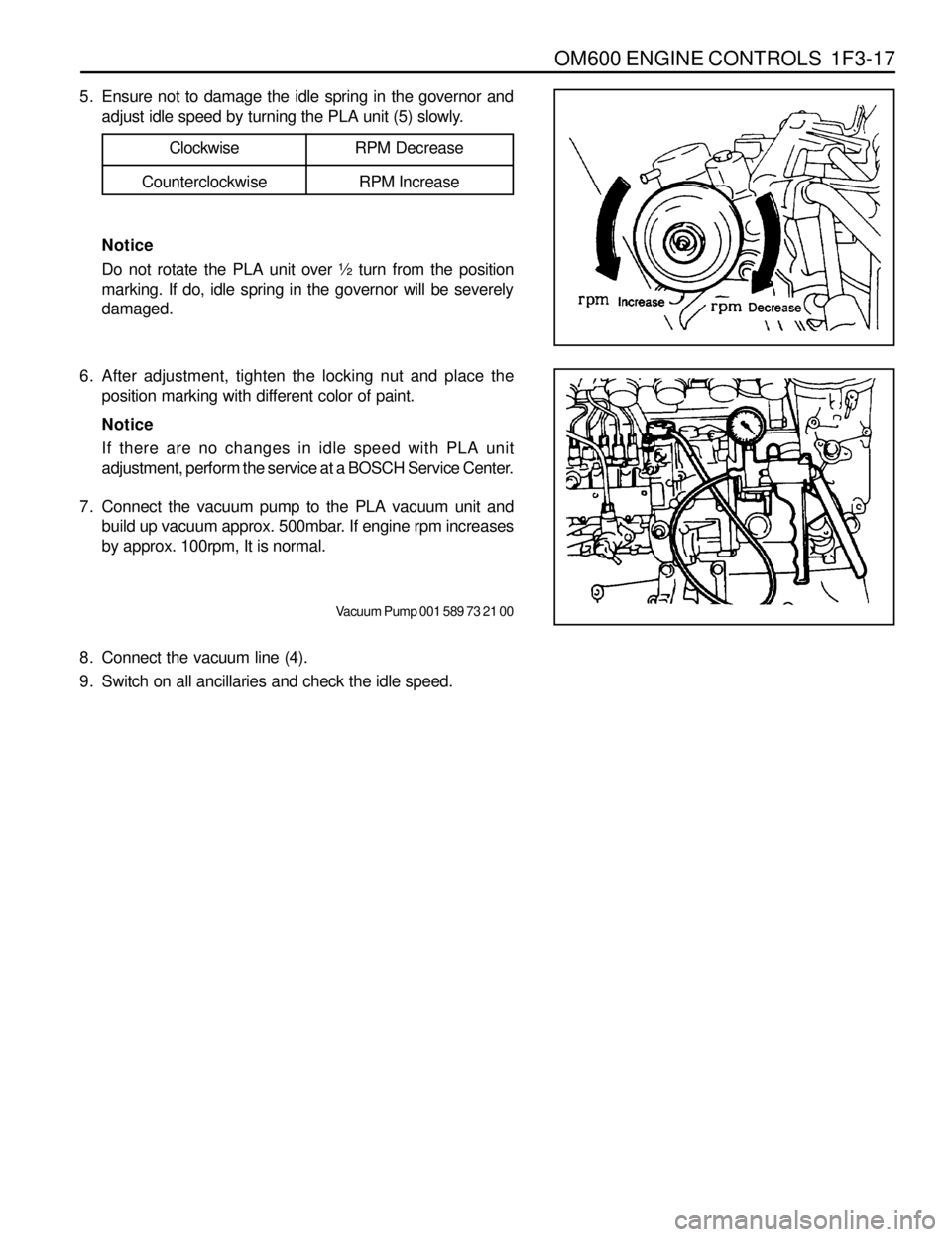

5. Ensure not to damage the idle spring in the governor and

adjust idle speed by turning the PLA unit (5) slowly.

Notice

Do not rotate the PLA unit over ½ turn from the position

marking. If do, idle spring in the governor will be severely

damaged.Clockwise

Counterclockwise

RPM Decrease

RPM Increase

Page 747 of 1463

1F3-18 OM600 ENGINE CONTROLS

Min. volume 150cm for 30 seconds

FUEL PUMP TEST

Notice

Before test, replace the fuel filter cartridge and fuel prefilter.

Fuel Feed Test

1. Disconnect the fuel return line (1) and seal up it with plug.

2. Insert the plastic hose (5) and put the end into the measuring

beaker (6).

3. Disconnect the vacuum line (4) from vacuum unit (engine

stop) (5) and connect the vacuum pump (7) to the vacuum

unit.

4. To avoid the engine starting, build up vacuum (approx. 500

mbar).

5. Operate the starter motor for exactly 30 seconds and

measure fuel volume in the beaker.

3

Page 759 of 1463

1F3-30 OM600 ENGINE CONTROLS

REMOVAL AND INSTALLATION OF INJECTION TIMING DEVICE

Preceding Work : Removal of vacuum pump

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace

4 Fuel Injection Pump

5 Seal....................................................... Replace

6 Screw Plug.................................................30Nm

7 Oil Pan

8 Locking Pin

9 Injection Timing Device10 Washer

11 Bolt (Left-Hand Thread).............................46Nm

12 Camshaft Sprocket

13 Washer

14 12-Sided Stretch Bolt............Check, 25Nm + 90°

15 Timing Chain

1 6 Seal

17 Chain Tensioner.........................................80Nm

Page 775 of 1463

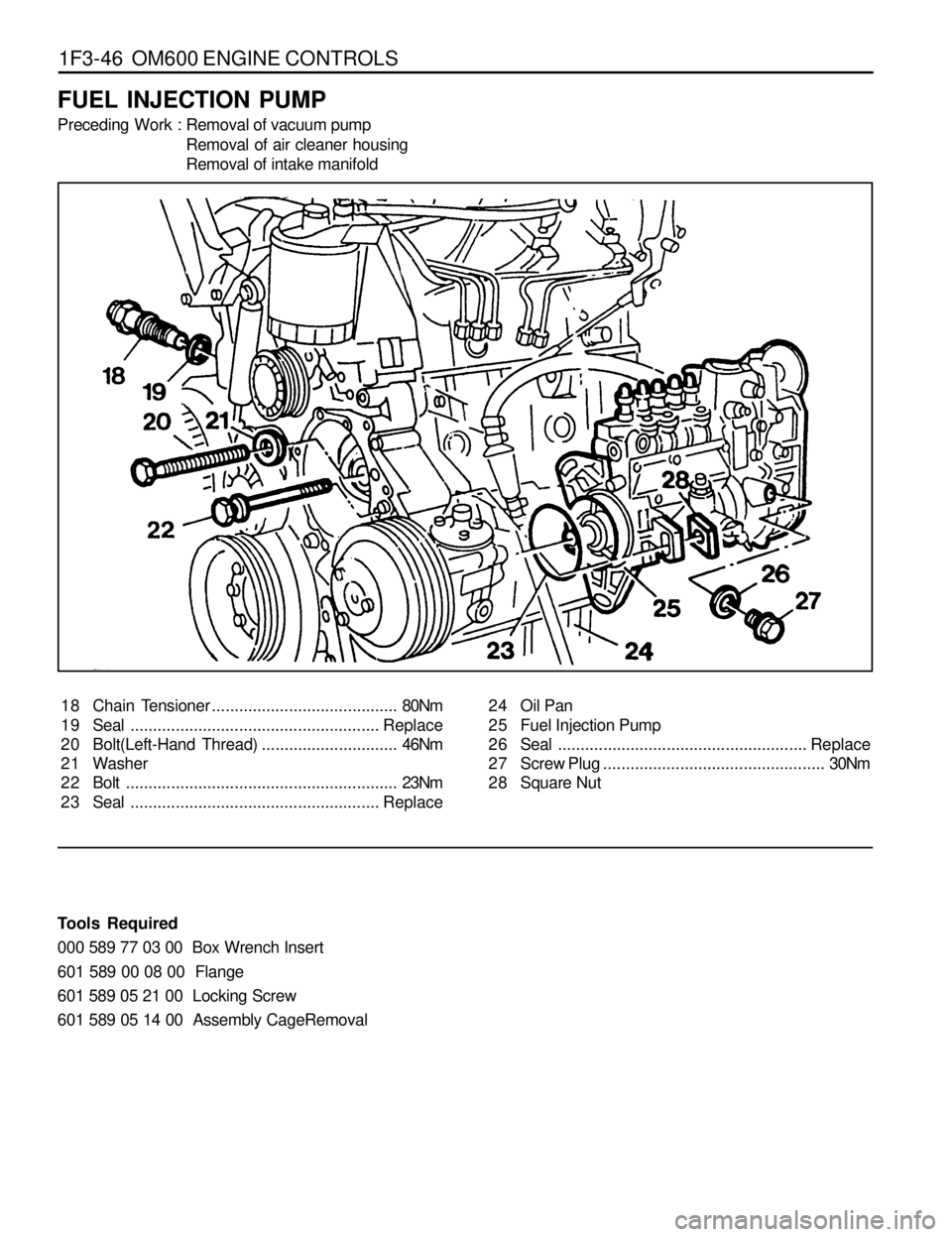

1F3-46 OM600 ENGINE CONTROLS

Tools Required

000 589 77 03 00 Box Wrench Insert

601 589 00 08 00 Flange

601 589 05 21 00 Locking Screw

601 589 05 14 00 Assembly CageRemoval

FUEL INJECTION PUMP

Preceding Work : Removal of vacuum pump

Removal of air cleaner housing

Removal of intake manifold

18 Chain Tensioner.........................................80Nm

1 9 Seal....................................................... Replace

20 Bolt(Left-Hand Thread)..............................46Nm

21 Washer

2 2 Bolt............................................................23Nm

2 3 Seal....................................................... Replace24 Oil Pan

25 Fuel Injection Pump

2 6 Seal....................................................... Replace

27 Screw Plug.................................................30Nm

28 Square Nut

Page 776 of 1463

OM600 ENGINE CONTROLS 1F3-47

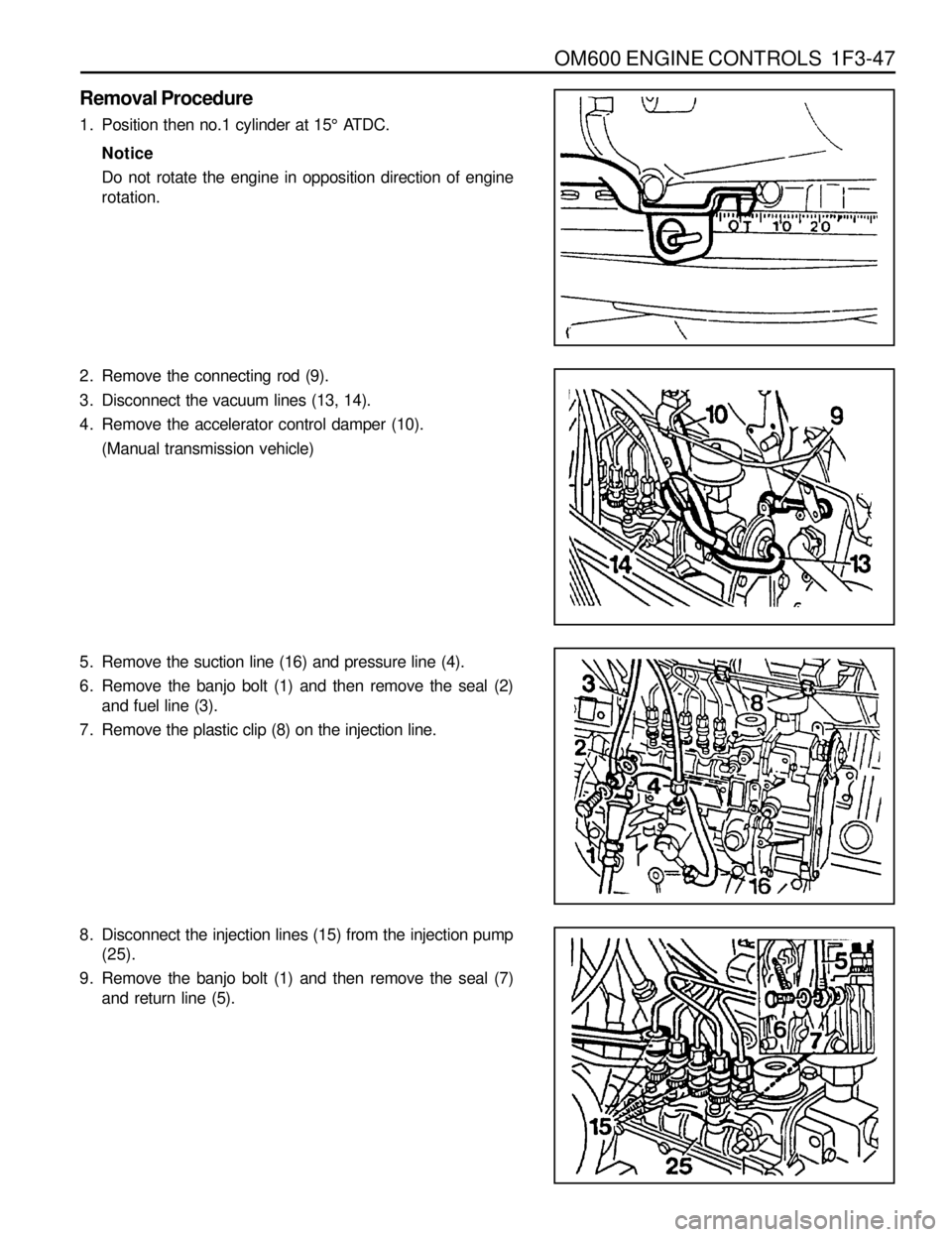

2. Remove the connecting rod (9).

3. Disconnect the vacuum lines (13, 14).

4. Remove the accelerator control damper (10).

(Manual transmission vehicle)

5. Remove the suction line (16) and pressure line (4).

6. Remove the banjo bolt (1) and then remove the seal (2)

and fuel line (3).

7. Remove the plastic clip (8) on the injection line.

Removal Procedure

1. Position then no.1 cylinder at 15° ATDC.

Notice

Do not rotate the engine in opposition direction of engine

rotation.

8. Disconnect the injection lines (15) from the injection pump

(25).

9. Remove the banjo bolt (1) and then remove the seal (7)

and return line (5).

Page 780 of 1463

OM600 ENGINE CONTROLS 1F3-51

12. Connect the vacuum line (13, 14).

13. Connect the connecting rod (9).

14. Connect the accelerator control damper (10).

(Manual transmission vehicle)

15. Install the chain tensioner.

16. Install the vacuum pump.

17. Check the start of delivery.

18. Adjust the idle speed.

11. Assemble the plastic clip (8).

Page 786 of 1463

1G1-6 M162 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

lUpper Intake Manifold

1. Disconnect the vacuum hose (8,9).

2. Loosen the clip (22).

3. Remove the upper intake manifold (5) after unscrewing the

bolt (6).

Installation Notice

Notice

Check the gasket and replace it if necessary.

4. Installation should follow the removal procedure in the

reverse order.

lLower Intake Manifold

Preceding work : removal of upper intake manifold

1. Remove the hose of brake booster vacuum line and idle

speed connector.

2. Disconnect the hot water inlet pipe from the bottom of lower

intake manifold.

3. Unscrew the bolt (17) and remove the lower intake manifold

(16).

Installation Notice

4. Start the engine and check for leaks at each connection

part.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 787 of 1463

M162 ENGINE INTAKE & EXHAUST 1G1-7

RESONANCE FLAP

1 Soft Cap (2)

2 Bolt (M6 x 25, 4 pieces)......................... 9-11 Nm

3 O-ring

Removal & Installation Procedure

1. Remove the 2 soft caps (1).

2. Remove the upper resonance flap coupling after removing

4 bolts (2).

Notice

Connect carefully the vacuum hose (4) for installation.

3. Check the O-ring (3) and replace it if necessary.

4. Remove the lower resonance flap (5).

5. Replace the gasket (6).

6. Installation should follow the removal procedure in the

reverse order.4 Vacuum Hose

5 Resonance Flap

6 Gasket ................................................... Replace

Page 799 of 1463

1G2-8 M161 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

1. Disconnect the battery ground cable.

2. Remove idle speed control plug connector (arrow).

3. Disconnect the brake booster vacuum line and other

vacuum lines.

4. Disconnector the rod from bearing bracket assembly and

remove the connection piece (8).

Installation Notice

Tightening Torque 36 - 44 Nm

5. Unscrew the three bolts (4) and remove the idle regulator

and intermediate flange (6).

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

6. Unscrew the two bolts (M8 X 16) and remove the support

assembly (arrow).

Installation Notice

7. Unscrew the intake manifold assembly mounting bolts (1)

and remove the intake manifold and gasket.

Installation Notice

Notice

Replace the gasket with new one.

8. Installation should follow the removal procedure in the

reverse order.

9. Start the engine and check for leaks in each connection.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 869 of 1463

M/T

M/T

A/T (MB)

M/T

A/T (BTRA)

M/T

A/T (BTRA)

M/T

A/T (MB)

M/T

A/T (MB)

A/T (BTRA)

M/T

A/T (MB)

A/T (BTRA)

SECTION 3A

FRONT DRIVE AXLE

TABLE OF CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 3A-1

General Specifications . . . . . . . . . . . . . . . . . . 3A-1

Fastener Tightening Specifications . . . . . . . . . 3A-2

Component Locator . . . . . . . . . . . . . . . . . . . 3A-3

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-3

Auto-Locking Hub . . . . . . . . . . . . . . . . . . . . . . 3A-4

Vacuum Circuit . . . . . . . . . . . . . . . . . . . . . . . . 3A-5

Maintenance and Repair . . . . . . . . . . . . . . . 3A-6

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 3A-6

Vacuum Line . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-6

Steering Knuckle and Drive Shaft . . . . . . . . . . 3A-8

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-14

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 3A-16

Axle Housing . . . . . . . . . . . . . . . . . . . . . . . . . 3A-16

Application

Drive Shaft Type

Axle Housing Type

Differential Type

Differential Gear

CV Joint

Build - up

Conventional

Hypoid Gear

4.56

4.56

3.73

4.56

5.38

4.27

4.89

4.89

4.55

4.55

4.55

5.86

3.73

3.73

4.89

1.4 L

SAE 80W/90, API GL - 5

Description

661NA

662NA

661LA

662LA

E20

E23

E32 Reduction Ratio

Oil Capacity

Oil Specification