lock SSANGYONG MUSSO 1998 Workshop Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 730 of 1463

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1

Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15Idle Speed Adjustment . . . . . . . . . . . . . . . . 1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of

Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test

(Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut

Fuel Pump Pressure Line

Fuel Injection Nozzle

Fuel Injection Pipe

Nozzle Tensioning Nut

Screw Plug

Left-Hand Thread BoltN·m

28 - 47

13

35 - 40

18

80

30

46

Page 732 of 1463

OM600 ENGINE CONTROLS 1F3-3

FUEL INJECTION PUMP CODING

Model Code

PES 4M 55C 320 RS 167

PES 5M 55C 320 RS 168

Fuel Injection Pump Code

Example)PES 5M 55C 320 RS 168

P Pump

E Self-Driven

S End Flange Mounting

5 Number of Cylinders (5EA)

M Pump Size

55 Element Diameter

C Modification Letter

320 Assembly Number

R Direction of Rotation (clockwise)

S188 Special Version

RSF Governor

R Governor

S Coil Spring

F Drive Governor

Component Location

1. Fuel Injection Pump

2. Vacuum Unit (Stop Unit)

3. Control Lever

4. PLA Vacuum Unit (Idle Speed Adjustment)

5. Governor

6. Fuel Pump

OM661 LA Engine

OM662 LA Engine

Page 734 of 1463

OM600 ENGINE CONTROLS 1F3-5

VACUUM CONTROL SYSTEM TEST

2 Engine Cut-Off Valve (Ignition Key Switch)

3 Auto-locking Hub Solenoid Valve

4 Engine Stop Valve Unit

5 PLA Vacuum Unit (Idle Speed Adjustment)

6 Engine

7 Vacuum Pump8 30° Thermovalve

9 Fuel Injection Pump

10 Filter with Restriction

11 Check Valve

12 Modulating Pressure Line (Automatic T/M)

Test Data

Idle Speed Increase

Permissible Pressure Drop of SystemAt least 100 rpm at approx. 500mbr

400 - 500mbar approx. 1 min.

Page 745 of 1463

1F3-16 OM600 ENGINE CONTROLS

Idle Speed

750 - 850 rpm

720 - 820 rpm Engine

OM661LA Engine

OM662LA Engine

Tools Required

667 589 00 21 00 TDC Pulse Generato

Commercial Tool

IDLE SPEED ADJUSTMENT

Service Data

e.g. Bosch, MOT 001.03

Sun, DIT 9000 Digital Tester

Adjustment Procedure

1. Connect the digital tester (1) and TDC pulse sender unit

(11).

2. Run the engine and warm up the coolant to 60~80°C.

TDC pulse generator 667 589 02 21 00

3. Disconnect the vacuum hose (4) from the PLA unit to check

idle speed with tester.

4. Check idle speed with tester.

Notice

To adjust idle speed, loosen the locking nut (6) of PLA unit.

OM 661LA Engine750 - 850rpm

OM 662LA Engine

720 - 820rpm

Page 746 of 1463

OM600 ENGINE CONTROLS 1F3-17

6. After adjustment, tighten the locking nut and place the

position marking with different color of paint.

Notice

If there are no changes in idle speed with PLA unit

adjustment, perform the service at a BOSCH Service Center.

7. Connect the vacuum pump to the PLA vacuum unit and

build up vacuum approx. 500mbar. If engine rpm increases

by approx. 100rpm, It is normal.

Vacuum Pump 001 589 73 21 00

8. Connect the vacuum line (4).

9. Switch on all ancillaries and check the idle speed.

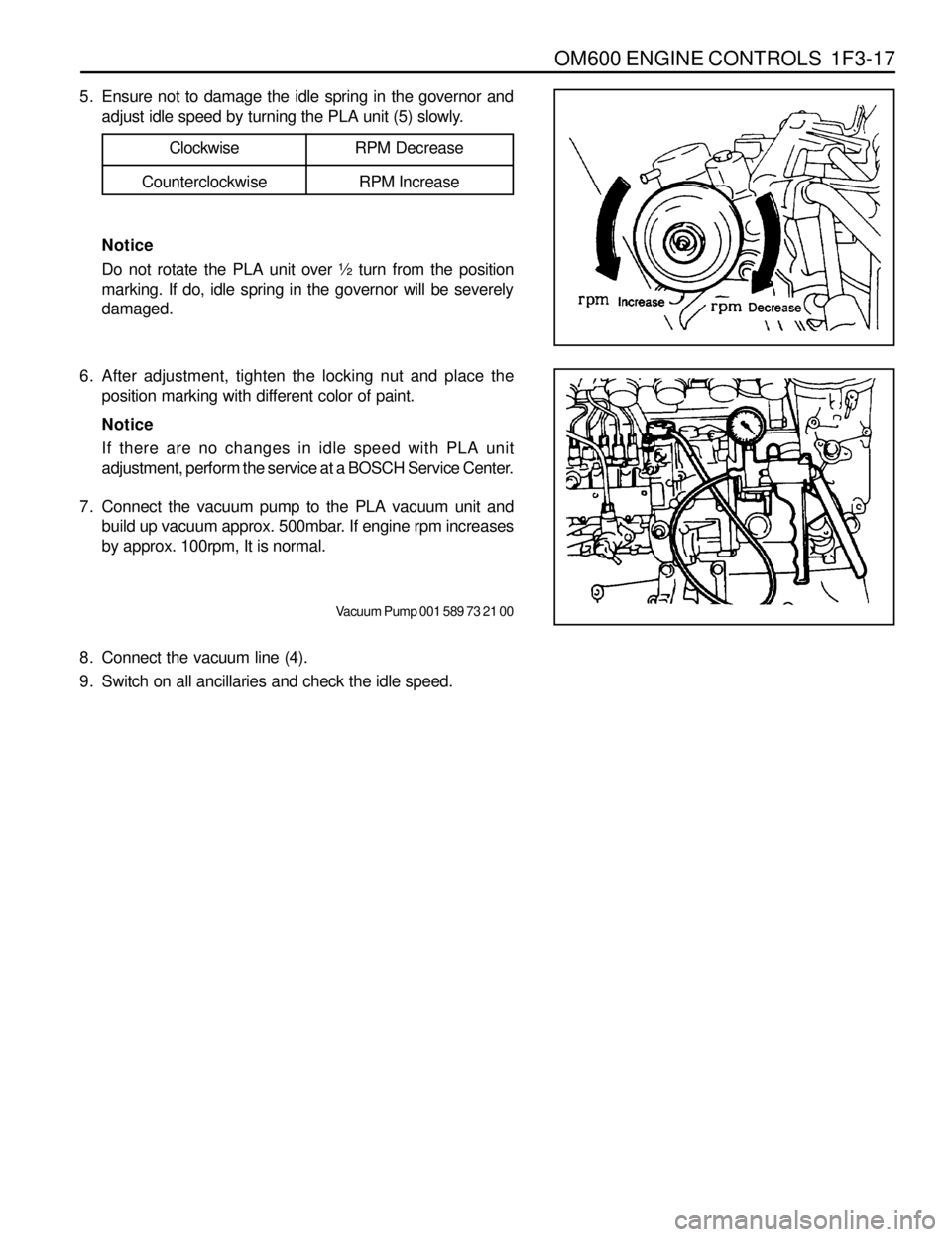

5. Ensure not to damage the idle spring in the governor and

adjust idle speed by turning the PLA unit (5) slowly.

Notice

Do not rotate the PLA unit over ½ turn from the position

marking. If do, idle spring in the governor will be severely

damaged.Clockwise

Counterclockwise

RPM Decrease

RPM Increase

Page 750 of 1463

OM600 ENGINE CONTROLS 1F3-21

FUEL PUMP

1 Fuel Injection Pump

2 Pressure Line............................................13Nm

3 Suction Line

4 Hose Clip............................................... Replace5 Gasket ................................................... Replace

6 Spring Lock Washer

7 Hexagon Nuts

8 Fuel Pump

Page 759 of 1463

1F3-30 OM600 ENGINE CONTROLS

REMOVAL AND INSTALLATION OF INJECTION TIMING DEVICE

Preceding Work : Removal of vacuum pump

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace

4 Fuel Injection Pump

5 Seal....................................................... Replace

6 Screw Plug.................................................30Nm

7 Oil Pan

8 Locking Pin

9 Injection Timing Device10 Washer

11 Bolt (Left-Hand Thread).............................46Nm

12 Camshaft Sprocket

13 Washer

14 12-Sided Stretch Bolt............Check, 25Nm + 90°

15 Timing Chain

1 6 Seal

17 Chain Tensioner.........................................80Nm

Page 760 of 1463

OM600 ENGINE CONTROLS 1F3-31

Tools Required

601 589 00 08 00Flange

601 589 05 21 00 Locking Screw

116 589 20 33 00 Sliding Hammer

116 589 02 34 00 Threaded Bolt

667 589 04 63 00 Retaining Plate

Removal & Installation Procedure

1. Remove the bolts (2) and then remove the cylinder head

cover (1) and gasket (3).

Installation Notice

Tightening Torque 10 Nm

Notice

Replace the gasket.

Rotate the engine 1 revolution by hand and check TDC

marking of the crankshaft and camshaft.

2. Loosen the camshaft sprocket bolt (14).

Notice

Do not remove the bolt.

Installation Notice

Notice

If max. length of bolt exceeds 53.6mm, replace it.

Tightening Torque 25Nm + 90°

3. Loosen the bolt (11) (left-hand thread).

Notice

Do not remove the bolt.

Page 761 of 1463

1F3-32 OM600 ENGINE CONTROLS

5. Remove the plug (6) and seal (5) from the fuel injection

pump and collect oil in a suitable vessel.

Installation Notice

Notice

Replace the seal.

Tightening Torque 30 Nm

6. Install the locking screw (18) into the injection pump.

Notice

Before tightening the bolts for the injection timing device

and the camshaft sprocket, always remove the locking screw

from the injection pump and reinstall the plug.

Locking Screw 601 589 05 21 00

7. Place alignment marks (arrow) on the timing chain (12) and

camshaft sprocket (15). 4. Position the no.1 cylinder at ATDC 15°.

Notice

Do not rotate the engine with camshaft sprocket bolt or

opposite direction of the engine rotation.

Page 762 of 1463

OM600 ENGINE CONTROLS 1F3-33

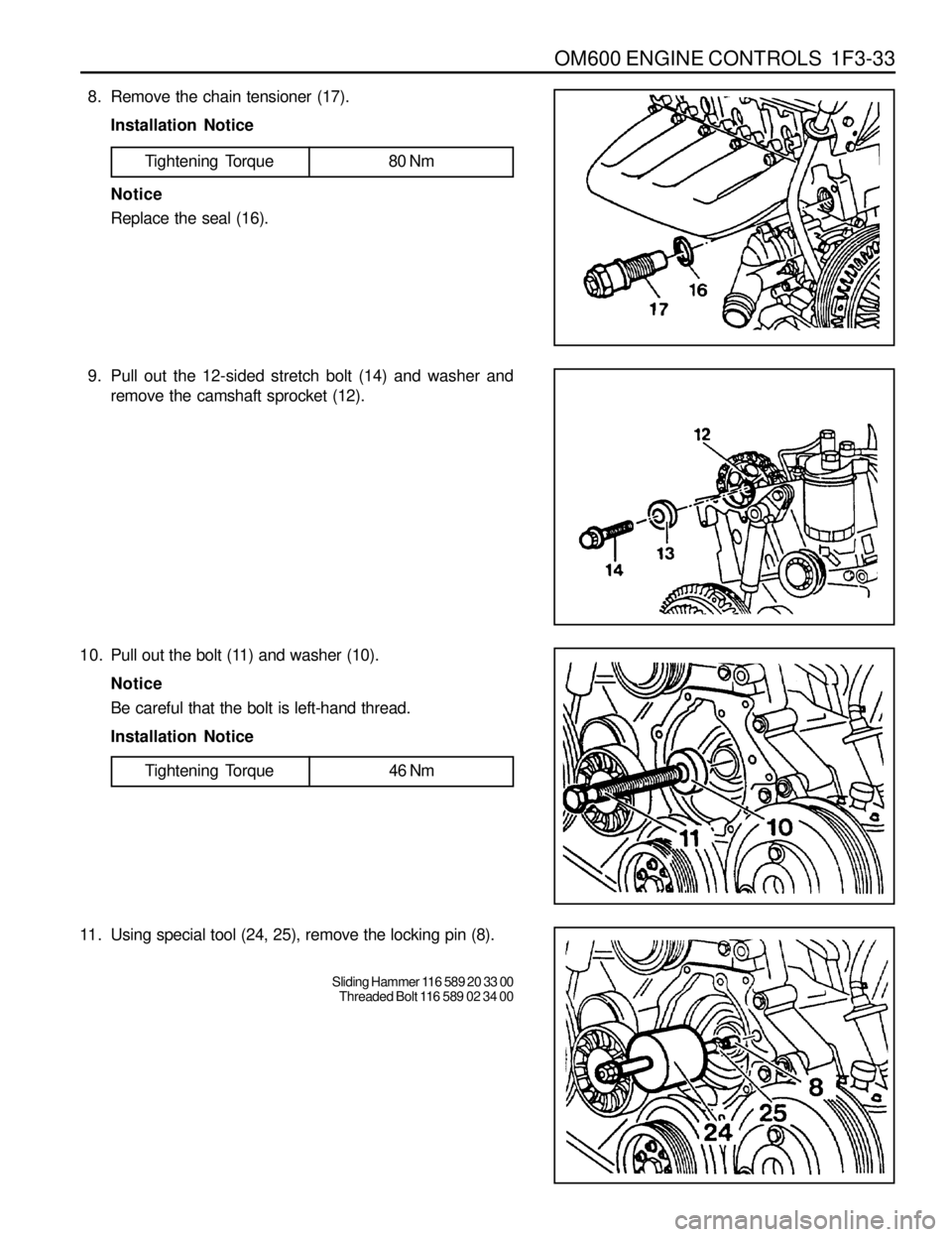

9. Pull out the 12-sided stretch bolt (14) and washer and

remove the camshaft sprocket (12).

Tightening Torque 46 Nm

11. Using special tool (24, 25), remove the locking pin (8).

Sliding Hammer 116 589 20 33 00

Threaded Bolt 116 589 02 34 00

8. Remove the chain tensioner (17).

Installation Notice

Tightening Torque 80 Nm

Notice

Replace the seal (16).

10. Pull out the bolt (11) and washer (10).

Notice

Be careful that the bolt is left-hand thread.

Installation Notice