ECU SSANGYONG MUSSO 1998 Workshop Manual Online

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 705 of 1463

1F2-56 M161 ENGINE CONTROLS

The Injector Spray Pattern Check

1. Connect the test box (129 589 00 21 00) to the ECU.

2. Disconnect the connector from connector.

3. Disconnect the fuel distributor and injector with a unit from

engine without removing the fuel supply and return line.

Notice

Prepare the beaker for taking the poping fuel.

4. Connect either end of shop made cable to the injector.

5. Connect the other end of shop made cable to the (+:63)

and (-:69) terminal of the test box.

6. Turn the ignition switch to "ON" position.

7. Check the injector for normal spray pattern as shown in the

figure. Check injector for leaks or later drops.

Notice

Refer to fuel injector test of engine diagnosis in this section

for detailed information.

Page 710 of 1463

M161 ENGINE CONTROLS 1F2-61

Notice

Replace the fuel pump relay if the measured value is over

9A. Notice

Check the fuel filter and fuel line when the fuel delivery is

not within specified value.

Measure the Current Consumption of Fuel Pump

1. Remove the fuel pump relay from fuse and relay box in

trunk, and turn the ignition switch to "ON" position.

2. Using a multi-tester, measure the current consumption by

connecting the terminal No.1 and No.3 of pump.

Measure the Fuel Delivery From the Fuel Pump

1. Disconnect the return pipe from fuel distributor and insert

the appropriate hose into it.

2 . Place the hose end into the beaker with the minimum capacity

of 1Liter.

3. Turn the ignition switch to "ON" position.

4. Connect the terminal No.33 and No.5 of ECU with a service

wire.

5. Measure the fuel delivery from the fuel pump.

1Liter/max.35sec. Specifed Value

5 - 9A Specifed Value

Page 711 of 1463

1F2-62 M161 ENGINE CONTROLS

PURGE SWITCHOVER VALVE

1 Purge Control valve

2 Line to engine

3 Line to canister

4 Canister

Functions

The fuel vaporization control system is installed to inhibit the

fuel vaporized gas from discharging into the atmosphere. The

fuel vaporized gas that is accumulated in the canister abstracts

through the purge switchover valve purification during the

engine combustion (except the decreasing mode) and coolant

temperature of over 80°C. For this reason, the ECU transacts

the engine speed, air inflow quantity, coolant temperature, and

intake temperature.

The purge switchover valve is activated by the ECU frequency

according with the engine rotating speed to adjust the

purification rate. The purification rate is determined by the

continuous valve opening interval.

The purge switchover valve is activated by the ECU for the

following conditions :

lCoolant temperature of over 80°C

lEngine speed of over 1000rpm

l2 Minutes after starting

lWhen the fuel cut-off mode is not activated

Page 712 of 1463

M161 ENGINE CONTROLS 1F2-63

4. Remove the line to canister and measure the pressure with

the vacuum pressure gauge.

Test

1. Maintain the normal temperature and idling state by

operating the engine.

2. Connect the ECU terminal No.11 and No.34 and check for

normal operation through the output waves using the

scanner.

Notice

Test during purge control switchover valve operation after

the minimum of 1 minute after the engine turned on.

3. Connect the ECU terminal No.34 and No.10 and check for

current consumption during the ignition switch ON.

Purge switchover valve output wave Specified Value

0.3 - 0.5

Specified Value

> 50mbar

(after approx. 1min.)

purge switchover valve

operates at this time

Notice

Test while at normal temperature and at idling state by

operating the engine.

Page 716 of 1463

M161 ENGINE CONTROLS 1F2-67

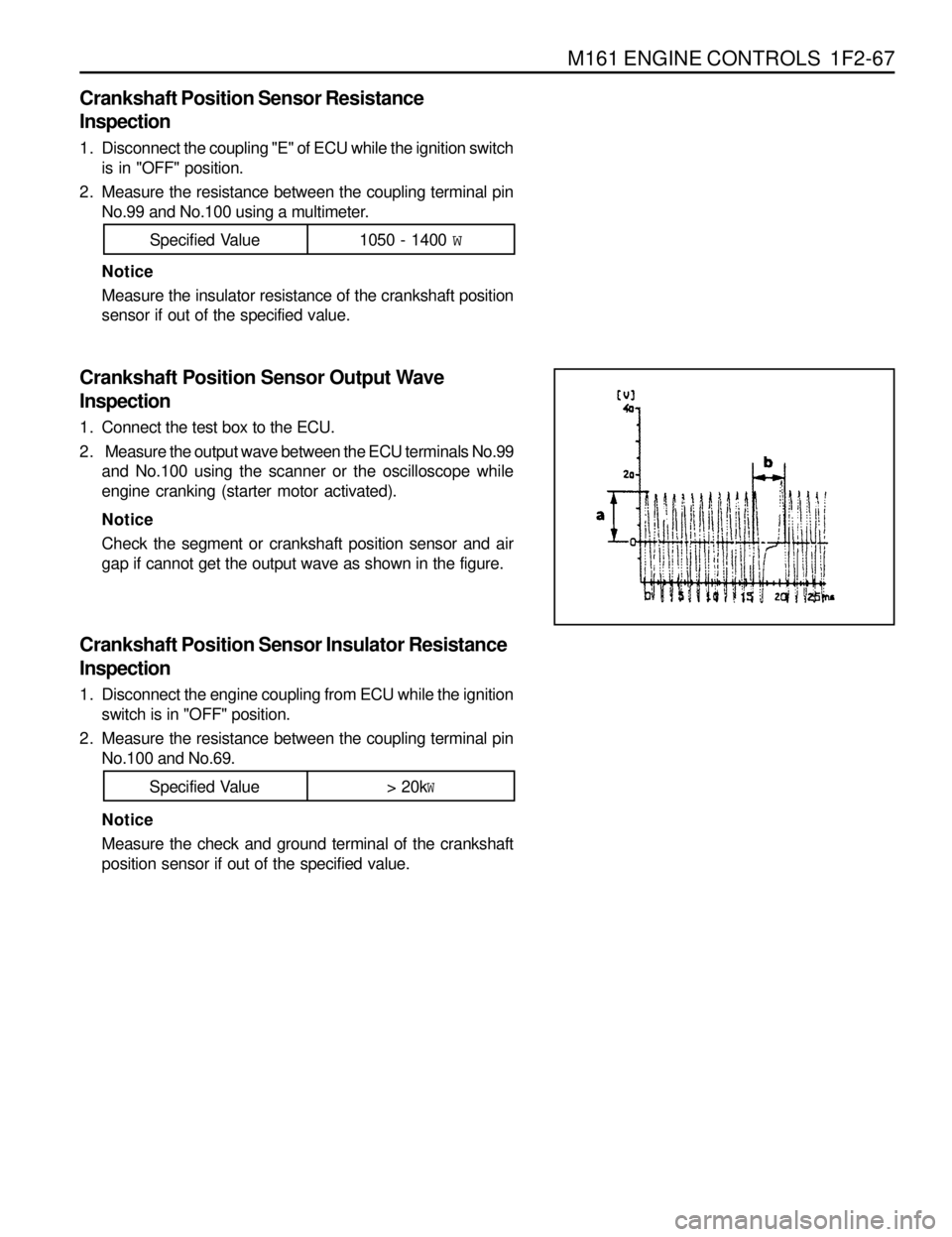

Crankshaft Position Sensor Resistance

Inspection

1. Disconnect the coupling "E" of ECU while the ignition switch

is in "OFF" position.

2. Measure the resistance between the coupling terminal pin

No.99 and No.100 using a multimeter.

Notice

Measure the insulator resistance of the crankshaft position

sensor if out of the specified value.

Crankshaft Position Sensor Output Wave

Inspection

1. Connect the test box to the ECU.

2. Measure the output wave between the ECU terminals No.99

and No.100 using the scanner or the oscilloscope while

engine cranking (starter motor activated).

Notice

Check the segment or crankshaft position sensor and air

gap if cannot get the output wave as shown in the figure.

Specified Value 1050 - 1400 W

Specified Value > 20kW

Crankshaft Position Sensor Insulator Resistance

Inspection

1. Disconnect the engine coupling from ECU while the ignition

switch is in "OFF" position.

2. Measure the resistance between the coupling terminal pin

No.100 and No.69.

Notice

Measure the check and ground terminal of the crankshaft

position sensor if out of the specified value.

Page 718 of 1463

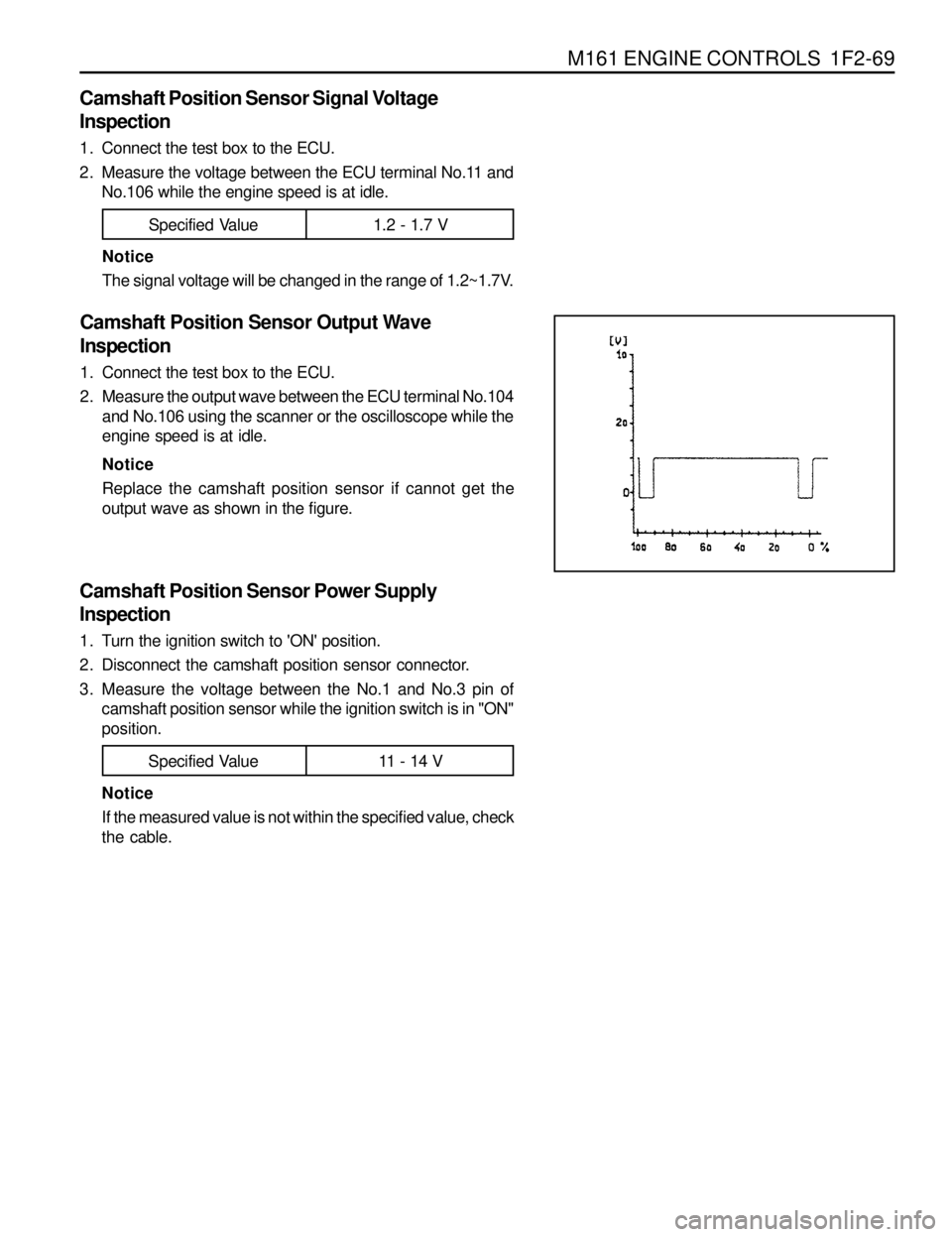

M161 ENGINE CONTROLS 1F2-69

Camshaft Position Sensor Power Supply

Inspection

1. Turn the ignition switch to 'ON' position.

2. Disconnect the camshaft position sensor connector.

3. Measure the voltage between the No.1 and No.3 pin of

camshaft position sensor while the ignition switch is in "ON"

position.

Notice

If the measured value is not within the specified value, check

the cable.Notice

The signal voltage will be changed in the range of 1.2~1.7V.

Camshaft Position Sensor Output Wave

Inspection

1. Connect the test box to the ECU.

2. Measure the output wave between the ECU terminal No.104

and No.106 using the scanner or the oscilloscope while the

engine speed is at idle.

Notice

Replace the camshaft position sensor if cannot get the

output wave as shown in the figure.

Specified Value 11 - 14 V

Specified Value 1.2 - 1.7 V

Camshaft Position Sensor Signal Voltage

Inspection

1. Connect the test box to the ECU.

2. Measure the voltage between the ECU terminal No.11 and

No.106 while the engine speed is at idle.

Page 721 of 1463

1F2-72 M161 ENGINE CONTROLS

If the measured value is not within the specified value, the

possible cause may be in cable or HFM sensor in itself.

Perform the 5V power supply inspection procedures.

HFM Sensor 5V Power Supply Inspection

1. Measure the voltage between the HFM sensor No.108(+) and

No.105(-) after removing the HFM sensor connector.

HFM Sensor Input Voltage Inspection

1. Measure the HFM sensor signal voltage between the ECU

terminal No.81 and No.105.

Specified Value (coolant temperature is over 70°C)

If the measured value is not within the specified value, the

possible cause may be in cable or ECU coupling.

Iginition"ON” 0.9 - 1.1 V

Engine at idle 1.3 - 1.7 V

Specified Value 4.7 - 5.2 V

2. Measure the voltage between the HFM sensor wining

connector terminal No.3 pin and No.102(+) after removing

the HFM sensor connector.

Specified Value

If the measured value is not within the specified value, the

possible cause may be in cable or over voltage protection

relay.

Perfrom the 12V power supple inspection procedures.

Specified Value 4.7 - 5.2 V

HFM Sensor 12V Power Supply Inspection

1. Measure the voltage between the HFM sensor wining

connector 1G No.2 pin(+) and No.3 after removing the HFM

sensor connector.

If the measured value is not within the specified value, the

possible cause may be in cable or over voltage protection

relay.

Specified Value 11 - 14 V

Page 722 of 1463

M161 ENGINE CONTROLS 1F2-73

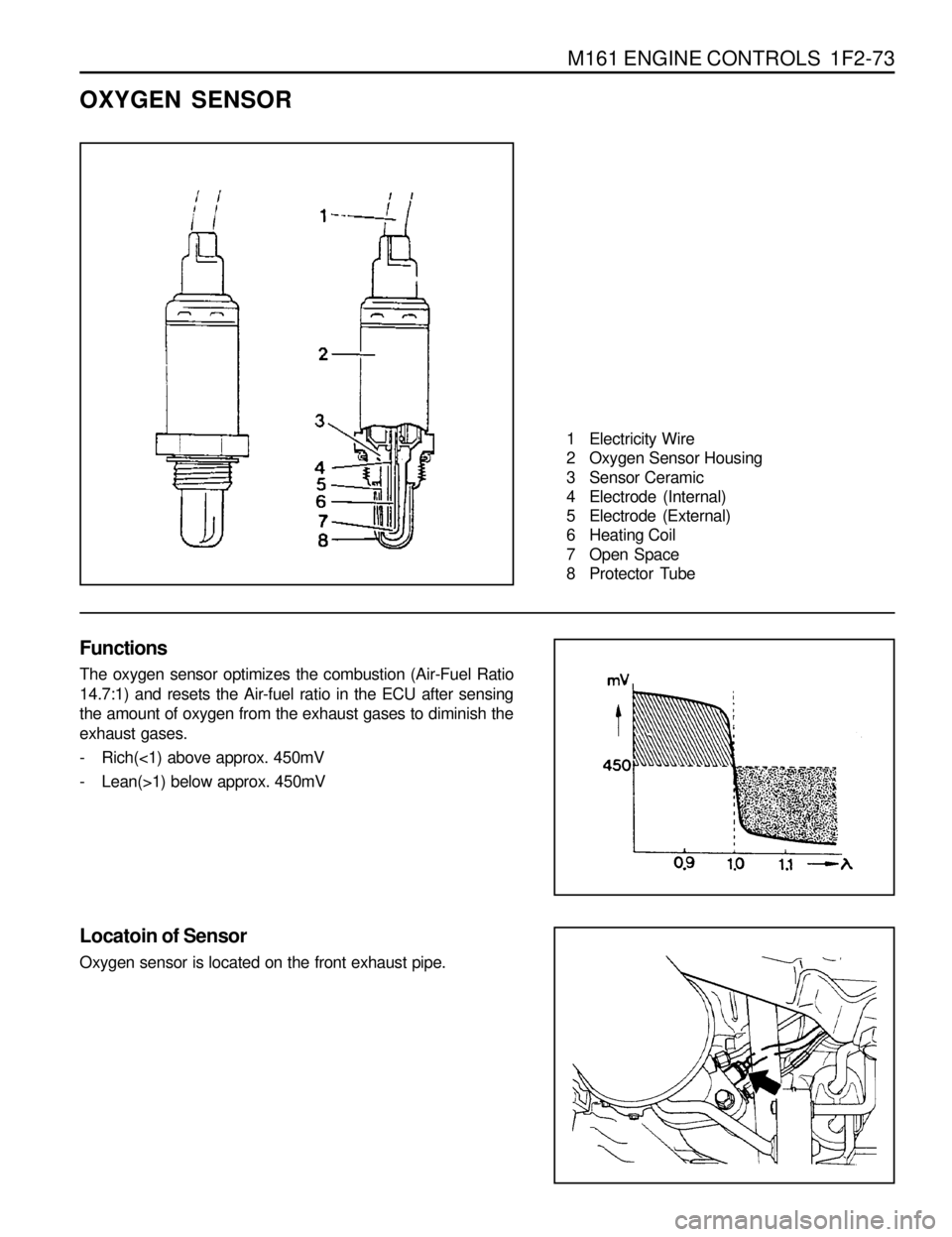

OXYGEN SENSOR

1 Electricity Wire

2 Oxygen Sensor Housing

3 Sensor Ceramic

4 Electrode (Internal)

5 Electrode (External)

6 Heating Coil

7 Open Space

8 Protector Tube

Functions

The oxygen sensor optimizes the combustion (Air-Fuel Ratio

14.7:1) and resets the Air-fuel ratio in the ECU after sensing

the amount of oxygen from the exhaust gases to diminish the

exhaust gases.

- Rich(<1) above approx. 450mV

- Lean(>1) below approx. 450mV

Locatoin of Sensor

Oxygen sensor is located on the front exhaust pipe.

Page 723 of 1463

1F2-74 M161 ENGINE CONTROLS

Oxygen Sensor Signal Voltage Inspection

1. Measure the oxygen sensor signal voltage between the ECU

terminal No.11 and No.9. Maintain the engine speed ia at

idle while the coolant temperature is over 80°C.

If the measured value is not within the specified value, the

possible cause may be in cable, oxygen sensor or ECU.

Oxygen Sensor Heating Voltage Inspection

1. Measure the oxygen sensor heating voltage between the

ECU terminal No.11 and No.9. Maintain the engine speed ia

at idle while the coolant temperature is over 80°C.

If the measured value is not within the specified value, the

possible cause may be in cable, oxygen sensor or ECU.

Oxygen Sensor Heating Current Consumption

Inspection

1. Measure the oxygen sensor heating current consumption

between the ECU terminal No.9 and sensor heating(+) line

while the ignition switch is in "ON" position.

If the measured value is not within the specified value, the

possible cause may be in cable, oxygen sensor or ECU.

Specified Value 0.2 - 2.0 A

Specified Value -0.2 - 1.0 V

Specified Value 11 - 14

Page 724 of 1463

M161 ENGINE CONTROLS 1F2-75

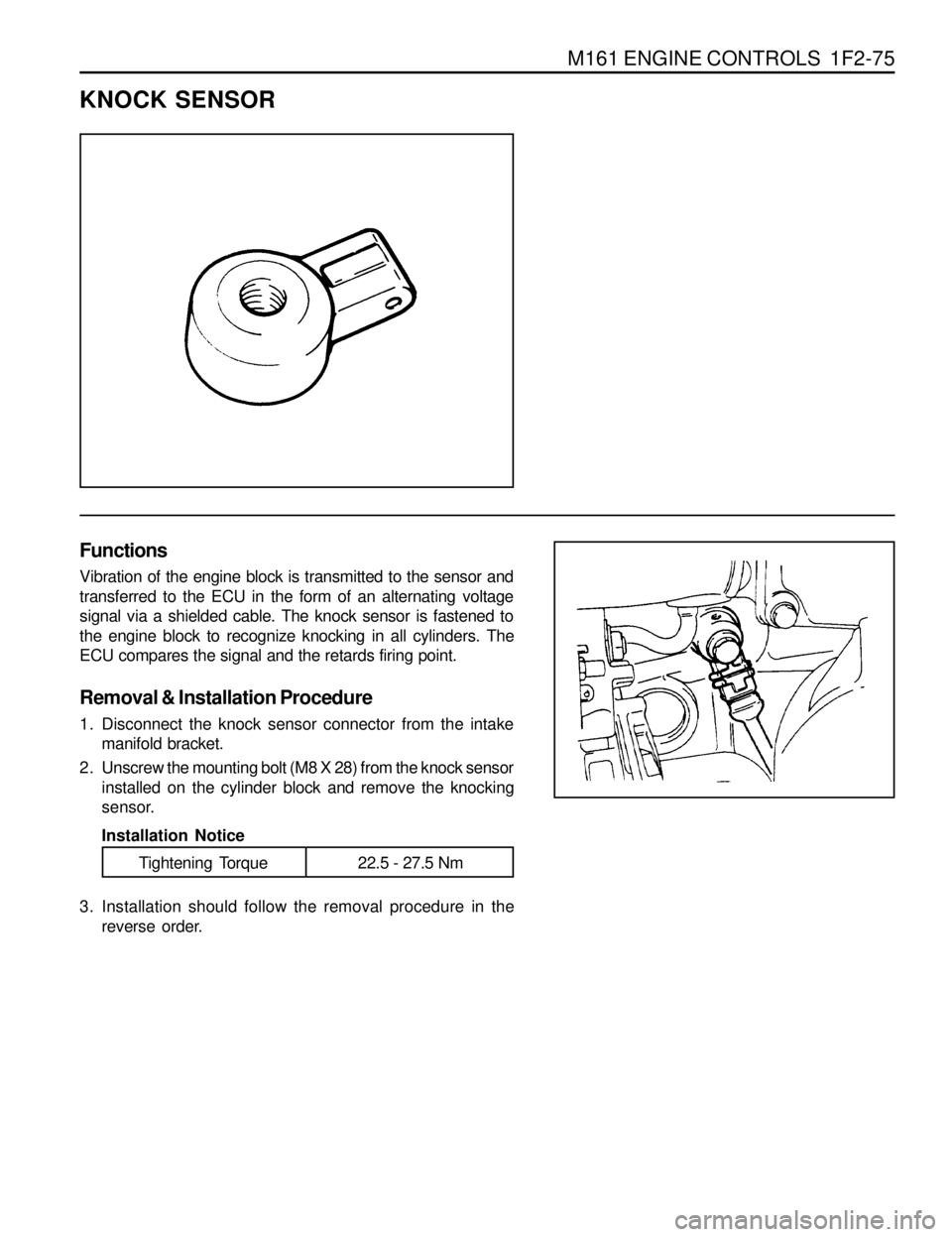

KNOCK SENSOR

Functions

Vibration of the engine block is transmitted to the sensor and

transferred to the ECU in the form of an alternating voltage

signal via a shielded cable. The knock sensor is fastened to

the engine block to recognize knocking in all cylinders. The

ECU compares the signal and the retards firing point.

Removal & Installation Procedure

1. Disconnect the knock sensor connector from the intake

manifold bracket.

2. Unscrew the mounting bolt (M8 X 28) from the knock sensor

installed on the cylinder block and remove the knocking

sensor.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 22.5 - 27.5 Nm