ECU SSANGYONG MUSSO 1998 Workshop Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 644 of 1463

1F1-74 M162 ENGINE CONTROLS

KNOCK SENSOR

Functions

Vibration of the engine block is transmitted to the sensor and

transferred to the ECU in the form of an alternating voltage

signal via a shielded cable. The knock sensor is fastened to

the engine block to recognize knocking in all cylinders. The

ECU compares the signal and the retards firing point.

Removal & Installation Procedure

1. Disconnect the knock sensor connector from the intake

manifold bracket.

2. Unscrew the mounting bolt (M8 X 28) from the knock sensor

installed on the cylinder block and remove the knocking

sensor.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 22.5 - 27.5 Nm

Page 646 of 1463

1F1-76 M162 ENGINE CONTROLS

2. Measure the resistance between the coolant temperature

sensor terminal No.1 and No.4 with the coolant temperature

sensor disconnected.

Inspection

1. Measure the coolant sensor input voltage between the ECU

terminal No.79 and No.78 while the ignition switch in "ON"

position.

Notice

Replace wiring and coolant temperature sensor if out of

specified value.

allowable error :±5%

allowable error :±5%

Voltage (V)

3.57

1.22

0.78

Temperature (°C)

20

30

40

Resistance (W)

2,500

322

185

Temperature (°C)

20

30

40

Page 650 of 1463

SECTION 1F2

M161 ENGINE CONTROLS

TABLE OF CONTENTS

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F2-2

Fastener Tightening Specifications . . . . . . . . 1F2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1F2-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1F2-3

Schematic and Routing Diagrams . . . . . . . 1F2-4

E23 ECU (MSE) . . . . . . . . . . . . . . . . . . . . . . 1F2-4

E23 ECU (HFM) . . . . . . . . . . . . . . . . . . . . . . 1F2-5

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-6

Self Diagnosis Socket Pin Numbers and

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 1F2-6

Self Diagnosis Failure Code (for E23 ENG) . 1F2-7

Test Box Connection . . . . . . . . . . . . . . . . . . 1F2-10

Fuel Injection System Test . . . . . . . . . . . . . 1F2-11

Ignition System Test . . . . . . . . . . . . . . . . . . 1F2-20

Idling Control and Electronic Pedal

System Test . . . . . . . . . . . . . . . . . . . . . . . 1F2-25

Air Conditioner Control System Test . . . . . . 1F2-27

Fuel Pressure and Internal Leakage Test . . 1F2-28

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F2-30Injector Test . . . . . . . . . . . . . . . . . . . . . . . . 1F2-32

Maintenance and Repair . . . . . . . . . . . . . 1F2-34

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F2-34

ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-34

Fuel Pressure Regulator . . . . . . . . . . . . . . 1F2-45

Fuel Distributor . . . . . . . . . . . . . . . . . . . . . . 1F2-49

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-54

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-57

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F2-58

Purge Switchover Valve . . . . . . . . . . . . . . . 1F2-62

Vacuum System . . . . . . . . . . . . . . . . . . . . . 1F2-64

Crankshaft Position Sensor . . . . . . . . . . . . 1F2-66

Camshaft Position Sensor . . . . . . . . . . . . . 1F2-68

Hot Film Air Mass (HFM) Sensor . . . . . . . . . 1F2-70

Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . 1F2-73

Knock Sensor . . . . . . . . . . . . . . . . . . . . . . . 1F2-75

Coolant Temperature Sensor . . . . . . . . . . . 1F2-76

Accelerator Pedal Module . . . . . . . . . . . . . . 1F2-79

Page 652 of 1463

M161 ENGINE CONTROLS 1F2-3

SPECIAL TOOLS

SPECIAL TOOLS TABLE

129 589 00 21 00

Test Box

119 589 04 63 00

Pressure Hose

106 589 00 21 00

Pressure Tester

210 589 08 63 00

ECU Test Cable210201

Adaptor Line

Page 653 of 1463

1F2-4 M161 ENGINE CONTROLS

SCHEMATIC AND ROUTING DIAGRAMS

E23 ECU (MSE)

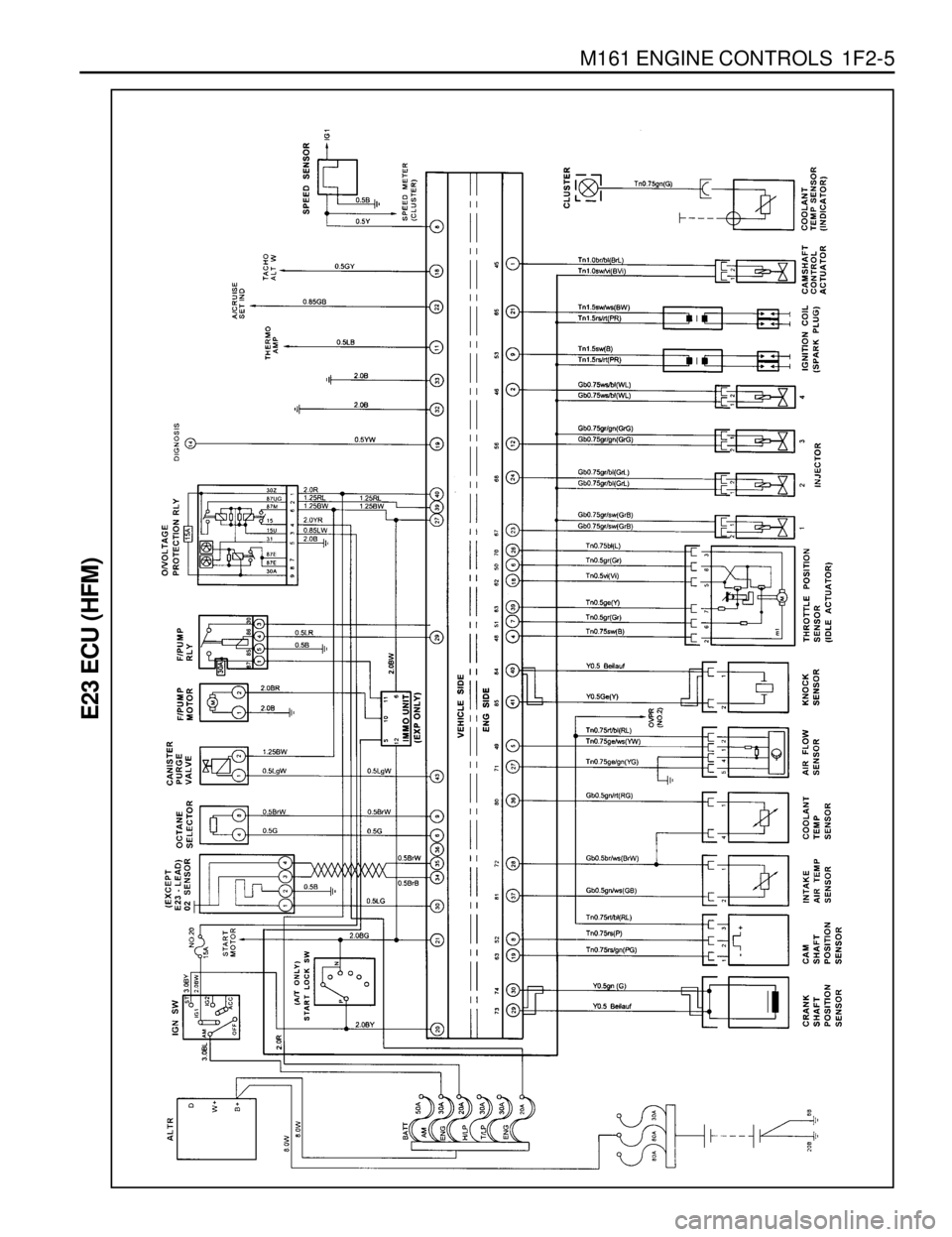

Page 654 of 1463

M161 ENGINE CONTROLS 1F2-5

E23 ECU (HFM)

Page 655 of 1463

1F2-6 M161 ENGINE CONTROLS

DIAGNOSIS

SELF DIAGNOSIS SOCKET PIN NUMBERS AND DESCRIPTIONS

1 Ground

2 Ignition 1

3 Battery Power Supply (Fuse NO.17)

4 REKES :PIN 6

5 Engine Speed Signal :MSE PIN 60

6 TCCU(Part-time)

7 STICS(PIN 26)

8-

9-

10 Air Bag(PIN 20)

11 Remote Engine Start Unit(PIN 10)12 -

13 Brake System

(ABS 5.3:PIN 11, ABS/ABD 5.3:PIN 46)

14 MSE 3.62S/3.53S(ECU Data Output:PIN 58)

15 TOD(PIN 20)

1 6 Immobilizer

17 -

1 8 TCU(PIN 23)

19 -

2 0 K-LINE(ECS:PIN 23)

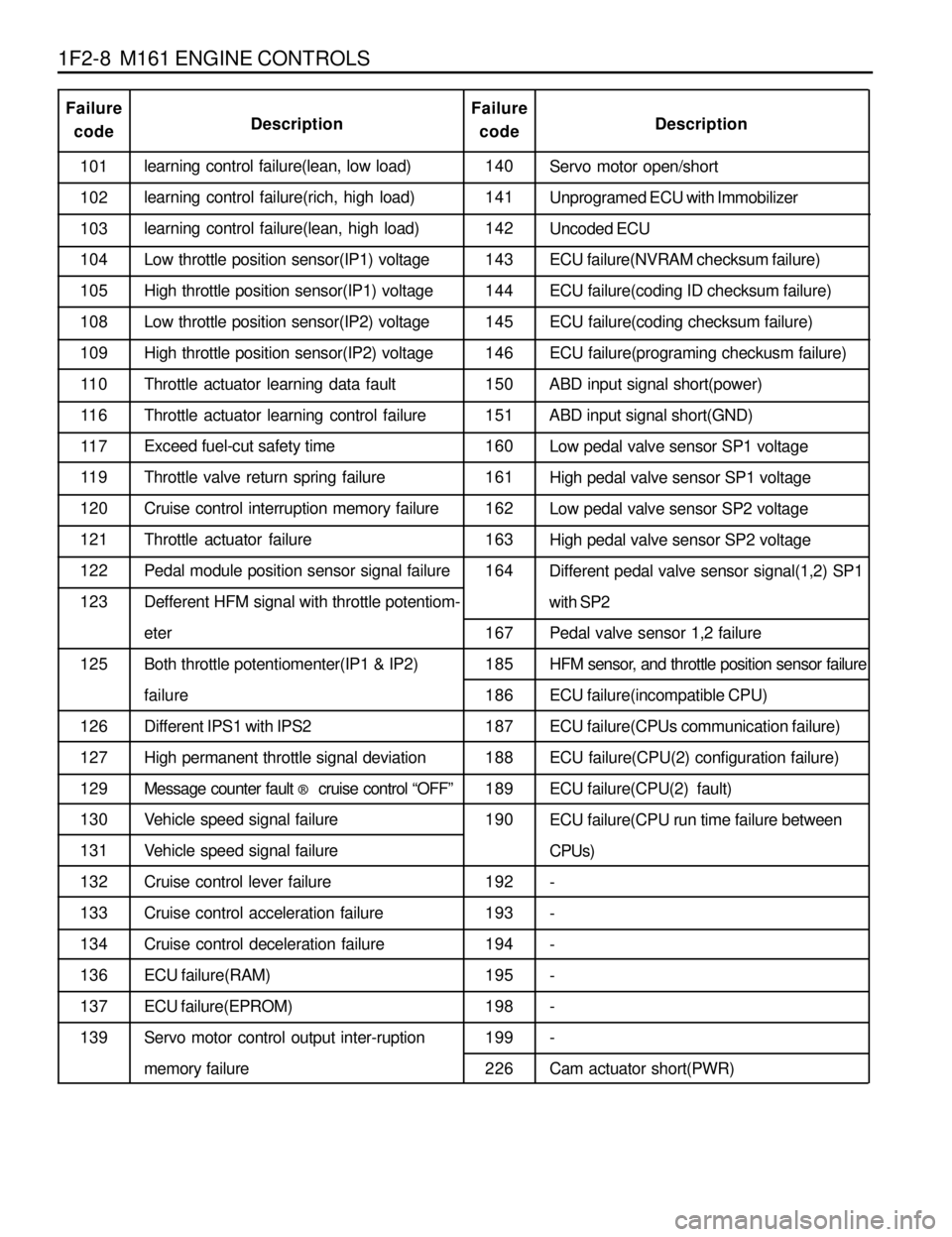

Page 657 of 1463

1F2-8 M161 ENGINE CONTROLS

Servo motor open/short

Unprogramed ECU with Immobilizer

Uncoded ECU

ECU failure(NVRAM checksum failure)

ECU failure(coding ID checksum failure)

ECU failure(coding checksum failure)

ECU failure(programing checkusm failure)

ABD input signal short(power)

ABD input signal short(GND)

Low pedal valve sensor SP1 voltage

High pedal valve sensor SP1 voltage

Low pedal valve sensor SP2 voltage

High pedal valve sensor SP2 voltage

Different pedal valve sensor signal(1,2) SP1

with SP2

Pedal valve sensor 1,2 failure

HFM sensor, and throttle position sensor failure

ECU failure(incompatible CPU)

ECU failure(CPUs communication failure)

ECU failure(CPU(2) configuration failure)

ECU failure(CPU(2) fault)

ECU failure(CPU run time failure between

CPUs)

-

-

-

-

-

-

Cam actuator short(PWR) 101

102

103

104

105

108

109

11 0

11 6

11 7

11 9

120

121

122

123

125

126

127

129

130

131

132

133

134

136

137

139140

141

142

143

144

145

146

150

151

160

161

162

163

164

167

185

186

187

188

189

190

192

193

194

195

198

199

226 learning control failure(lean, low load)

learning control failure(rich, high load)

learning control failure(lean, high load)

Low throttle position sensor(IP1) voltage

High throttle position sensor(IP1) voltage

Low throttle position sensor(IP2) voltage

High throttle position sensor(IP2) voltage

Throttle actuator learning data fault

Throttle actuator learning control failure

Exceed fuel-cut safety time

Throttle valve return spring failure

Cruise control interruption memory failure

Throttle actuator failure

Pedal module position sensor signal failure

Defferent HFM signal with throttle potentiom-

eter

Both throttle potentiomenter(IP1 & IP2)

failure

Different IPS1 with IPS2

High permanent throttle signal deviation

Message counter fault ® cruise control “OFF”

Vehicle speed signal failure

Vehicle speed signal failure

Cruise control lever failure

Cruise control acceleration failure

Cruise control deceleration failure

ECU failure(RAM)

ECU failure(EPROM)

Servo motor control output inter-ruption

memory failure

Failure

codeDescriptionFailure

codeDescription

Page 659 of 1463

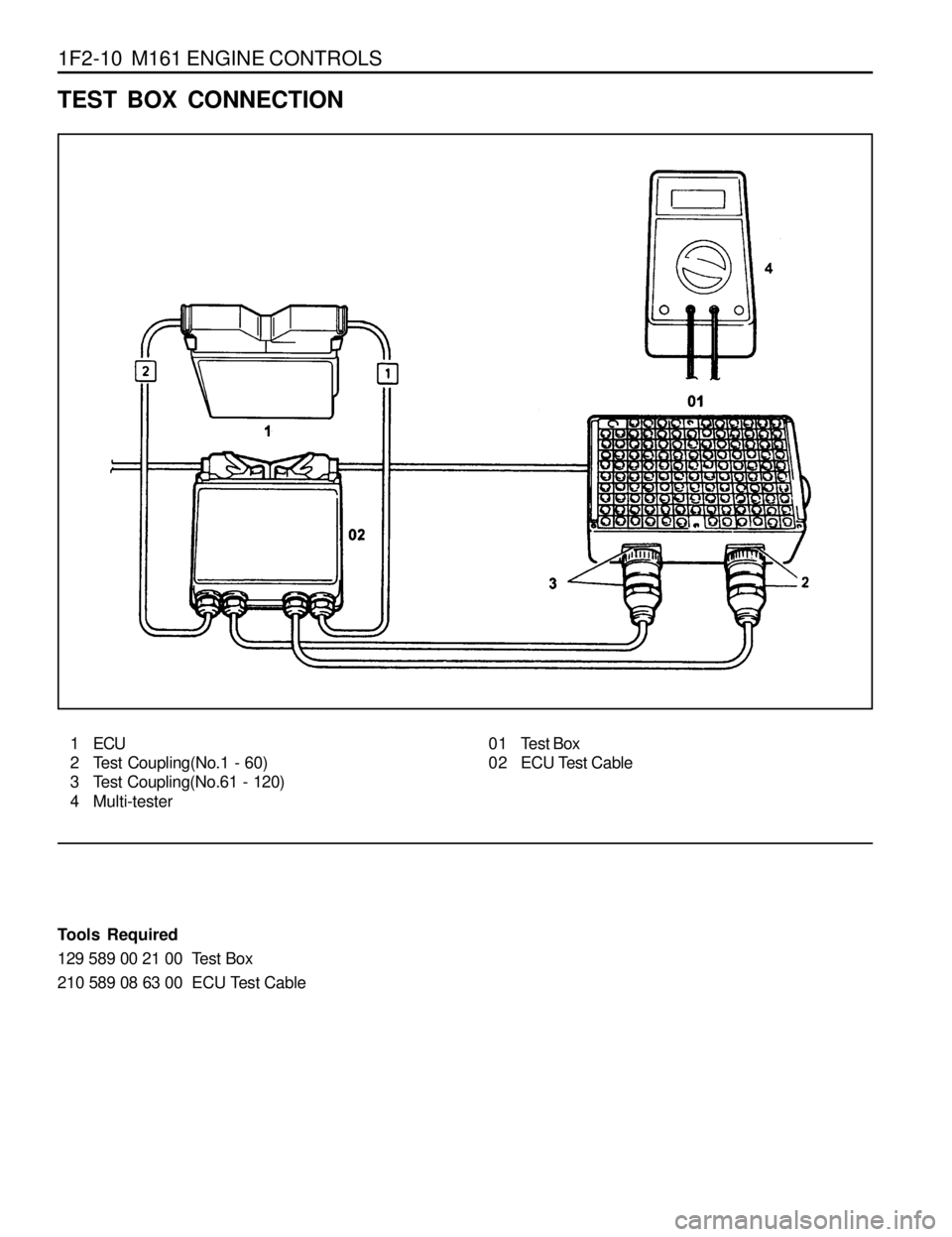

1F2-10 M161 ENGINE CONTROLS

TEST BOX CONNECTION

1 ECU

2 Test Coupling(No.1 - 60)

3 Test Coupling(No.61 - 120)

4 Multi-tester0 1 Test Box

02 ECU Test Cable

Tools Required

129 589 00 21 00 Test Box

210 589 08 63 00 ECU Test Cable

Page 660 of 1463

M161 ENGINE CONTROLS 1F2-11

FUEL INJECTION SYSTEM TEST

Failure

codeItem

Þ 1.0

Checking method

· Ignition:ON

Test

stepRequirementSpecified

valuePossible cause

10 1211 -14V

· ·· ·

· ECU:power

supply

- terminal 30

(TM.30)

Þ 2.2· ·· ·

· Power

supply:

- terminal 87

(TM.87)· Ignition:ON· Power supply cable

· OVPR 08,

·Þ 1.1

·Þ 1.2

Þ 1.1

· Ignition:ON

10 211 -14V· ·· ·

· Ground

cable:

- Battery

ground· Ground cable

· Ground conditionDiagnosis

socket

69 2

Diagnosis

socket

Þ 1.2· Ignition:ON

11211 -14V· ·· ·

· Power

supply:

- terminal 30

(TM.30)· Power supply cable

Diagnosis

socket

Þ 2.0· Ignition:ON

51111 -14V· ·· ·

· ECU:power

supply

- terminal 87

(TM.87)08,·Þ 1.1

·Þ 2.1

Þ 2.1

· Ignition:ON 11 -14V· ·· ·

· Ground

cable

- Electronic

ground· Ground cable

52

Diagnosis

socket

111

Diagnosis

socket· Ignition:OFF

11 -14V

< 1V

Þ 3.0

· Engine:in Cranking

52· Cable

· Ignition Swith 11 -14

(during engine

cranking)

· ·· ·

· Start signal:

- terminal 50

(TM.50)