check engine SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 19 of 1463

GENERAL INFORMATION 0B-7

MAINTENANCE AND REPAIR

MAINTENANCE AND LUBRICATION

Fuel Filter Replacement

Replace the engine fuel filter every.

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 45,000km (24,000 miles)

Spark Plug Replacement

Replace spark plugs with same type.

lType : BOSCH : F8DC4

BERU : 14F-8DU4

Champion : C11YCC

lGap : 0.8 ± 0.1 mm

Spark Plug Wire Replacement

Clean wires and inspect them for burns, cracks or other

damage. Check the wire boot fit at the Distributor and at

the spark plugs. Replace the wires as needed.

Brake System Service

Check the disc brake pads or the drum brake linings.

Check the pad and the lining thickness carefully.

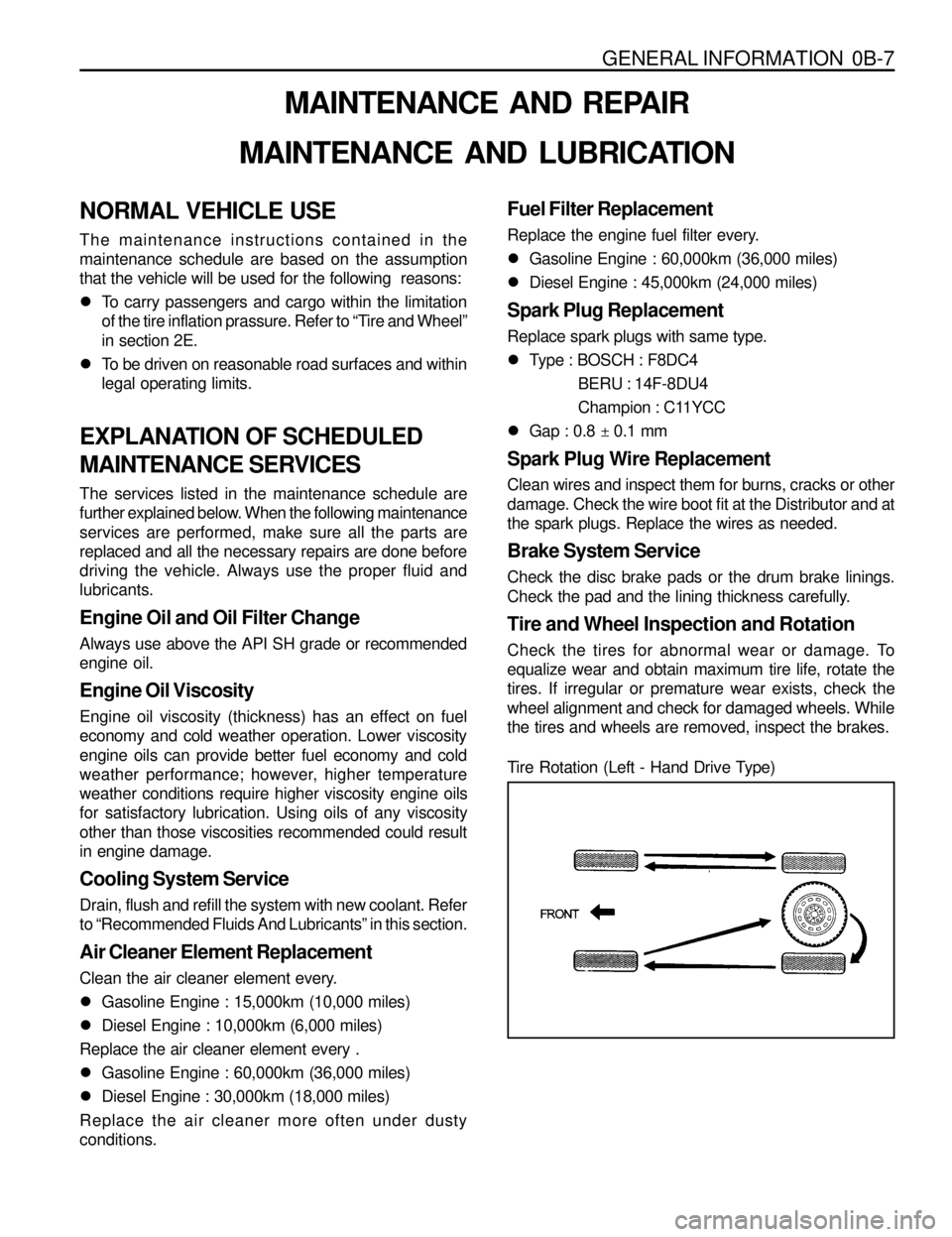

Tire and Wheel Inspection and Rotation

Check the tires for abnormal wear or damage. To

equalize wear and obtain maximum tire life, rotate the

tires. If irregular or premature wear exists, check the

wheel alignment and check for damaged wheels. While

the tires and wheels are removed, inspect the brakes.

NORMAL VEHICLE USE

The maintenance instructions contained in the

maintenance schedule are based on the assumption

that the vehicle will be used for the following reasons:

lTo carry passengers and cargo within the limitation

of the tire inflation prassure. Refer to “Tire and Wheel”

in section 2E.

lTo be driven on reasonable road surfaces and within

legal operating limits.

EXPLANATION OF SCHEDULED

MAINTENANCE SERVICES

The services listed in the maintenance schedule are

further explained below. When the following maintenance

services are performed, make sure all the parts are

replaced and all the necessary repairs are done before

driving the vehicle. Always use the proper fluid and

lubricants.

Engine Oil and Oil Filter Change

Always use above the API SH grade or recommended

engine oil.

Engine Oil Viscosity

Engine oil viscosity (thickness) has an effect on fuel

economy and cold weather operation. Lower viscosity

engine oils can provide better fuel economy and cold

weather performance; however, higher temperature

weather conditions require higher viscosity engine oils

for satisfactory lubrication. Using oils of any viscosity

other than those viscosities recommended could result

in engine damage.

Cooling System Service

Drain, flush and refill the system with new coolant. Refer

to “Recommended Fluids And Lubricants” in this section.

Air Cleaner Element Replacement

Clean the air cleaner element every.

lGasoline Engine : 15,000km (10,000 miles)

lDiesel Engine : 10,000km (6,000 miles)

Replace the air cleaner element every .

lGasoline Engine : 60,000km (36,000 miles)

lDiesel Engine : 30,000km (18,000 miles)

Replace the air cleaner more often under dusty

conditions.

Tire Rotation (Left - Hand Drive Type)

Page 24 of 1463

0B-12 GENERAL INFORMATION

OWNER INSPECTIONS

AND SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal

travel or repeated puling to one side when braking. Also,

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system.

Exhaust System Operation

Be alert to any changes in the sound of the system or

the smell of the fumes. These are signs that the system

may be leaking or overheating. Have the system

inspected and repaired immediately.

Tires, Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the

seats at normal highway speeds. This may mean a wheel

needs to be balanced. Also, a pull right or left on a

straight, level road may show the need for a tire pressure

adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn or

has too much free play, or is unusual sounds are noticed

when turning or parking.

Headlight Aim

Take note of the light pattern occasionally. Adjust the

headlights if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system

may indicate a problem. Have the system inspected and

repaired immediately.

Engine Oil Level

Check the oil level and add oil if necessary. The best

time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level

on it.5. Add oil, if needed, to keep the oil level above the

lower mark. Avoid overfilling the engine, since this

may cause engine damage.

6. Push the indicator all the way back down into the

engine after taking the reading.

If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the

pan fast enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank

and add coolant if necessary. Inspect the coolant.

Replace dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH

Tire And Wheel Inspection and Pressure

Check

Check the tire for abnormal wear or damage. Also check

for damaged wheels. Check the tire pressure when the

tires are cold ( check the spare also, unless it is a

stowaway). Maintain the recommended pressures. Refer

to “Tire and Wheel” is in section 0B.

AT LEAST MONTHLY

Light Operation

Check the operation of the license plate light, the

headlights (including the high beams), the parking lights,

the fog lights, the taillight, the brake lights, the turn

signals, the backup lights and the hazard warning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air

conditioning system after use is normal. If you notice

fuel leaks or fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to

Section 6A,

Power Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low

fluid level can indicate worn disc brake pads which may

need to be serviced. Check the breather hole in the

reservoir cover to be free from dirt and check for an

open passage.

Page 25 of 1463

GENERAL INFORMATION 0B-13

Weather-Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

EACH TIME THE OIL IS CHANGED

Brake System Inspection

This inspection should be done when the wheels are

removed for rotation. Inspect the lines and the hoses

for proper hookup, binding, leaks, cracks, chafing, etc.

Inspect the disc brake pads for wear. Inspect the rotors

for surface condition. Inspect other brake parts, the

parking brake, etc., at the same time. Inspect the brakes

more often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears or leakage. Replace

the seals if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the exhaust

system. Look for broken, damaged, missing, or out-of-

position parts as well as open seams, holes, loose

connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep

into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints

and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and

the accelerator pedal sliding face with suitable grease.

Check the throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper

tension. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the

secondary latch. It should keep the hood from opening

all the way when the primary latch is released. The hood

must close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and

Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops

and the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare

tire, all the jacking equipment, and the tools must be

securely stowed at all times. Oil the jack ratchet or the

screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the

latches, the glove box and the console doors, and any

folding seat hardware.

Underbody Flushing

Flushing the underbody will remove any corrosive

materials used for ice and snow removal and dust control.

At least every spring clean the underbody. First, loosen

the sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture in order to ensure proper freeze protection,

corrosion protection and engine operating temperature.

Inspect the hoses. Replace the cracked, swollen, or

deteriorated hoses. Tighten the clamps. Clean the

outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure

test the cooling system and the cap in order to help

ensure proper operation.

Page 28 of 1463

0B-16 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER SYSTEM

K P T P 0 A 1 9 S W P 122357

12~17.Production Serial Number

: 000001- 999999

11.Plant Code

P : PyongTaek Plant

10.Model Year

M : 1991

N : 1992

P : 1993

R : 1994

S : 1995

T : 1996

V : 1997

W : 1998

X : 1999

Y : 2000

9. Check Digit

Constant “S”

8. Engine Type

3 : 2299cc, In-line 4Cylinder, Diesel (OM601)

4 : 2874cc, In-line 5Cylinder, Diesel (OM602)

8 : 1998cc, In-line 4Cylinder, Gasoline (E20)

6 : 2295cc, In-line 4Cylinder, Gasoline (E23)

9 : 3199cc, In-line 6Cylinder, Gasoline (E32)

A : 2299cc, In-line 4Cylinder, Diesel (OM601)

B : 2874cc, In-line 5Cylinder, Diesel (OM602)

C : 2299cc, In-line 4Cylinder, Diesel (SY662LA)

D : 2874cc, In-line 5Cylinder, Diesel (SY662LA)

7. Restraint System

0 : NO Seat Belt,

1 : 3-Point Seat Belts, 2 : 2-Point Seat Belts

6. Trim Level

A : Standard, B : Deluxe, C : Super Deluxe

5. Body Type

0 : 5-Door

1 : 4-Door

2 : 3-Door

4. Line Models

P : Musso, LHD, R : Musso, RHD

3. Vehicle Type

T (Passengr Cars)

2. Name of Mamufacturer : P

1. Nation : K

Page 38 of 1463

GENERAL ENGINE INFORMATION 1A1-7

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating

conditoins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer's directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the threads

are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal wear.

DIAGNOSIS

Page 43 of 1463

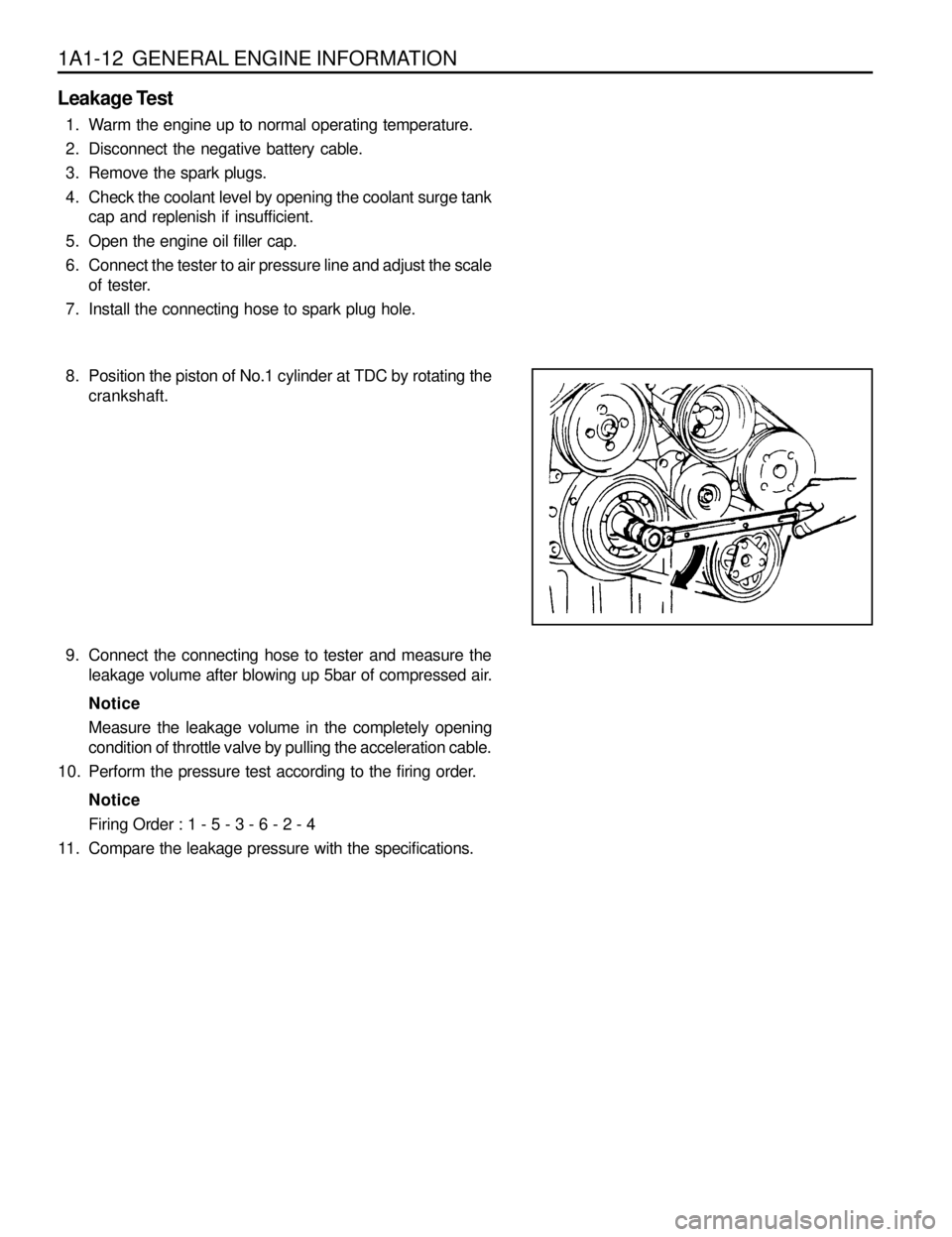

1A1-12 GENERAL ENGINE INFORMATION

Leakage Test

1. Warm the engine up to normal operating temperature.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant surge tank

cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the scale

of tester.

7. Install the connecting hose to spark plug hole.

9. Connect the connecting hose to tester and measure the

leakage volume after blowing up 5bar of compressed air.

Notice

Measure the leakage volume in the completely opening

condition of throttle valve by pulling the acceleration cable.

10. Perform the pressure test according to the firing order.

Notice

Firing Order : 1 - 5 - 3 - 6 - 2 - 4

11. Compare the leakage pressure with the specifications.8. Position the piston of No.1 cylinder at TDC by rotating the

crankshaft.

Page 52 of 1463

1A2-8 GENERAL ENGINE INFORMATION

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following procedures

may help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating

conditoins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer's directions when using the kit.

1. Pour the specified amount of dye into the engine oil

fill tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid will appear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a

gasket is replaced, but the sealing flange is bent, the

new gasket will not repair the leak. The bent flange must

be repaired also. Before attempting to repair a leak,

check for the following conditions and correct them as

they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the threads

are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal wear.

DIAGNOSIS

Page 57 of 1463

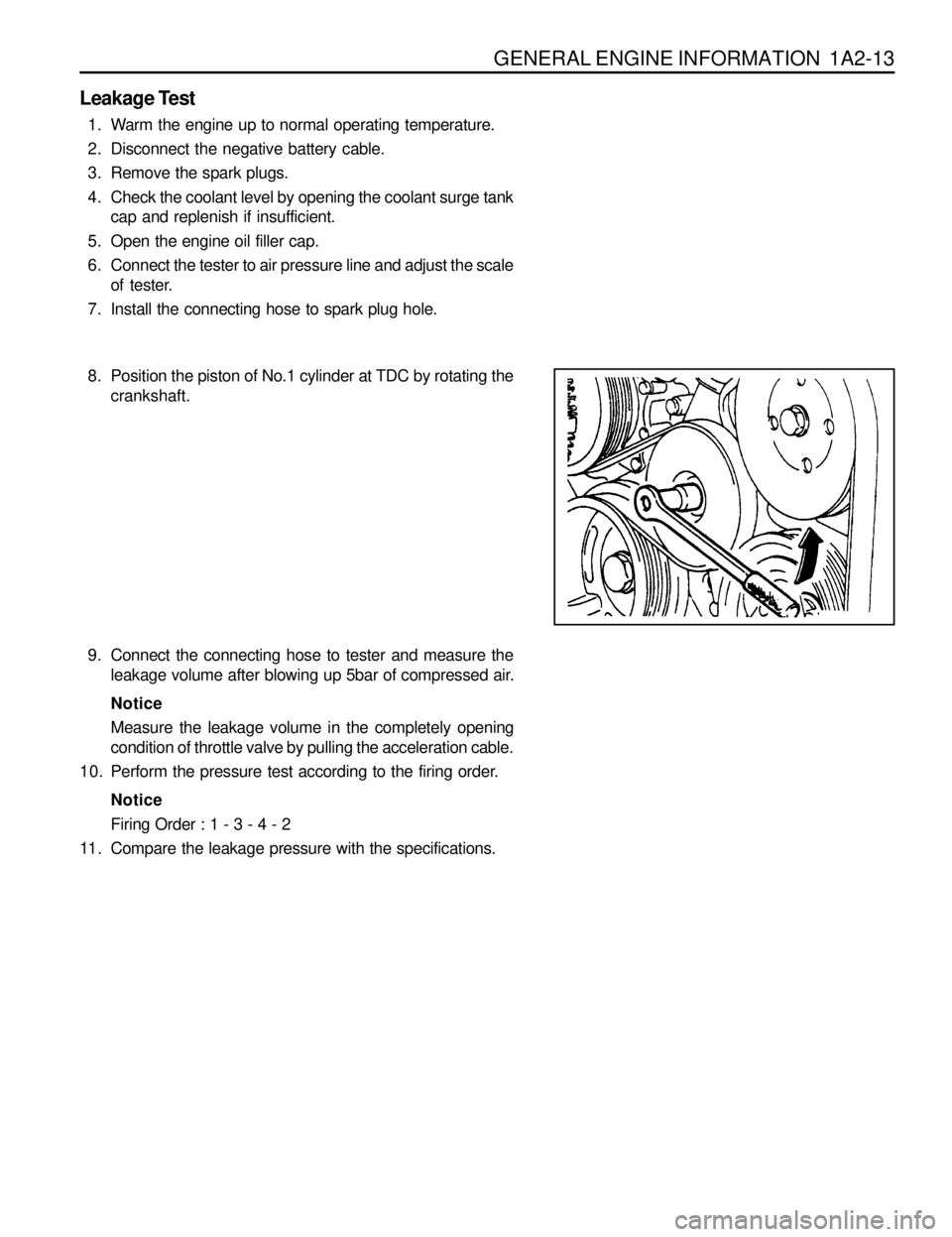

GENERAL ENGINE INFORMATION 1A2-13

Leakage Test

1. Warm the engine up to normal operating temperature.

2. Disconnect the negative battery cable.

3. Remove the spark plugs.

4. Check the coolant level by opening the coolant surge tank

cap and replenish if insufficient.

5. Open the engine oil filler cap.

6. Connect the tester to air pressure line and adjust the scale

of tester.

7. Install the connecting hose to spark plug hole.

9. Connect the connecting hose to tester and measure the

leakage volume after blowing up 5bar of compressed air.

Notice

Measure the leakage volume in the completely opening

condition of throttle valve by pulling the acceleration cable.

10. Perform the pressure test according to the firing order.

Notice

Firing Order : 1 - 3 - 4 - 2

11. Compare the leakage pressure with the specifications.8. Position the piston of No.1 cylinder at TDC by rotating the

crankshaft.

Page 68 of 1463

1A3-10 GENERAL ENGINE INFORMATION

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may

be difficult to locate or repair. The following

procedures may help you in locating and repairing

most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine

oil, automatic transmission fluid, power steering

fluid, etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large

sheet of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate

location of the leak by the drippings on the

paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas

that are hard to reach.

4. If the leak still cannot be found, it may be

necessary to clean the suspected area with a

degreaser, steam or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at

normal operating temperature and varying

speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-type powder (such as foot

powder) to the suspected area.

3. Operate the vehicle under normal operating

conditions.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer

to the manufacturer's directions when using the kit.1. Pour the specified amount of dye into the engine

oil fill tube.

2. Operate the vehicle normal operating conditions

as directed in the kit.

3. Direct the light toward the suspected area. The

dyed fluid will appear as a yellow path leading to

the source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must

be determined n order for it to be repaired properly. If

a gasket is replaced, but the sealing flange is bent,

the new gasket will not repair the leak. The bent flange

must be repaired also. Before attempting to repair a

leak, check for the following conditions and correct

them as they may cause a leak.

Gaskets

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe fasteners are tightened improperly or the

threads are dirty or damaged.

lThe flanges or the sealing surface is warped.

lThere are scratches, burrs or other damage to the

sealing surface.

lThe gasket is damaged or worn.

lThere is cracking or porosity of the component.

lAn improper seal was used (where applicable).

Seals

lThe fluid level/pressure is too high.

lThe crankcase ventilation system is malfunctioning.

lThe seal bore is damaged (scratched, burred or

nicked).

lThe seal is damaged or worn.

lImproper installation is evident.

lThere are cracks in the components.

lThe shaft surface is scratched, nicked or damaged.

lA loose or worn bearing is causing excess seal

wear.

DIAGNOSIS

Page 72 of 1463

1A3-14 GENERAL ENGINE INFORMATION

Leakage Test

1. Run the engine to be the coolant temperature 80°C.

2. Remove the fuel injection nozzle.

3. Open the coolant subtank cap.

4. Check the coolant level and replenish if necessary.

5. Open the oil filler cap.

6. Remove the air cleaner cover and element.

7. Position the piston at TDC.

8. Install the connector (1) and connection piece (2).

9. Calibrate the tester and connect the connection hose

(3)

10. Pressurize with compressed air and compare the

pressure changes with permissible pressure leakage.

11. If permissible pressure leakage is out of standard, check

followings :

- Intake and exhaust lines.

- Sounds in oil filler area.

- Air bubbles in radiator coolant.

12. Do pressure leakage test for the remaining cylinders

according to the firing order.

lOM 662LA Engine : 1-2-4-5-3

lOM 661LA Engine : 1-3-4-2

13. Remove the tester.

14. Close the coolant pressure cap and oil filler cap.

15. Install the air cleaner element and cover.

16. Install the fuel injection nozzle.