hub SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 303 of 1463

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B3-2

Fastener Tightening Specifications . . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device . . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection . . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

TABLE OF CONTENTS

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of

Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface . . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Page 337 of 1463

OM600 ENGINE MECHANICAL 1B3-35

TDC (TDC SENSOR BRACKET) SETTING

Preceding Work : Removal of No.1 cylinder prechamber

1 Measuring Device

2 Dial Gauge

3 Cylinder Head

4 Piston................................................Set at TDC

Tools Service

001 589 32 21 00 Dial Gauge

601 589 07 21 00 Deqth Gauge

667 589 01 21 00 Fixing Device

Notice

lThe TDC sensor bracket must be adjusted in case of

followings.

lWhen replacing the TDC sensor bracket.

lWhen replacing the crankshaft, the hub or the vibration

damper.

lWhen replacing or installing the timing case cover.

lAfter engine overhauling.

*If the cylinder head is removed, the measuring pin of the

dial gauge can be positioned on the piston crown.

This is done by placing the magnetic dial holder on the

mating surface of the crankcase.

Page 365 of 1463

OM600 ENGINE MECHANICAL 1B3-63

TIMING CASE COVER

Preceding Work : Removal of the cooling fan

Rmoval of the V-belt tensioning device

Removal of the vibration damper and hub

Removal of the alternator

1 Bolt............................................................10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt................................................25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt................................................10Nm

9 Bolt.................................................... M6 : 10Nm

M8 : 23Nm

10 Power Steering Pump

11 Bolt

12 Belt Pulley1 3 Bolt............................................................32Nm

14 Timing Case Cover

1 5 Bolt............................................................23Nm

16 Alternator Bracket

1 7 Bolt............................................................45Nm

1 8 Bolt............................................................25Nm

1 9 Bolt............................................................10Nm

20 Closing Cover

21 Socket Bolt................................................23Nm

22 Guide Pulley

2 3 Bolt.............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut .............................................................23Nm

Page 376 of 1463

1B3-74 OM600 ENGINE MECHANICAL

VIBRATION DAMPER AND HUB

Preceding Work : Removal of the cooling fan

Removal of poly V-belt

1 Bolt............................................................10Nm

2 Cooling Fan Belt Pulley

3 Socket Bolt................................................23Nm

4 Crankshaft Belt Pulley

5 Vibration Damper6 Bolt................................................200Nm + 90°

7 Washer

8 Straight Pin

9 Hub

10 Oil Pan

Page 377 of 1463

OM600 ENGINE MECHANICAL 1B3-75

Sectional View

3 Socket Bolt

4 Crankshaft Belt Pulley

5 Vibration Damper

6 Bolt

7 Washer

8 Straight Pin

Notice

The mounting position of vibration damper is fixed by straight

pin (8).

Tools Required

602 589 00 40 00 Engine Lock

103 589 00 30 00 Puller9 Hub

11 Radial Seal

12 Timing Gear Case Cover

13 Key

14 Crankshaft Sprocket

16 Crankshaft

Page 379 of 1463

OM600 ENGINE MECHANICAL 1B3-77

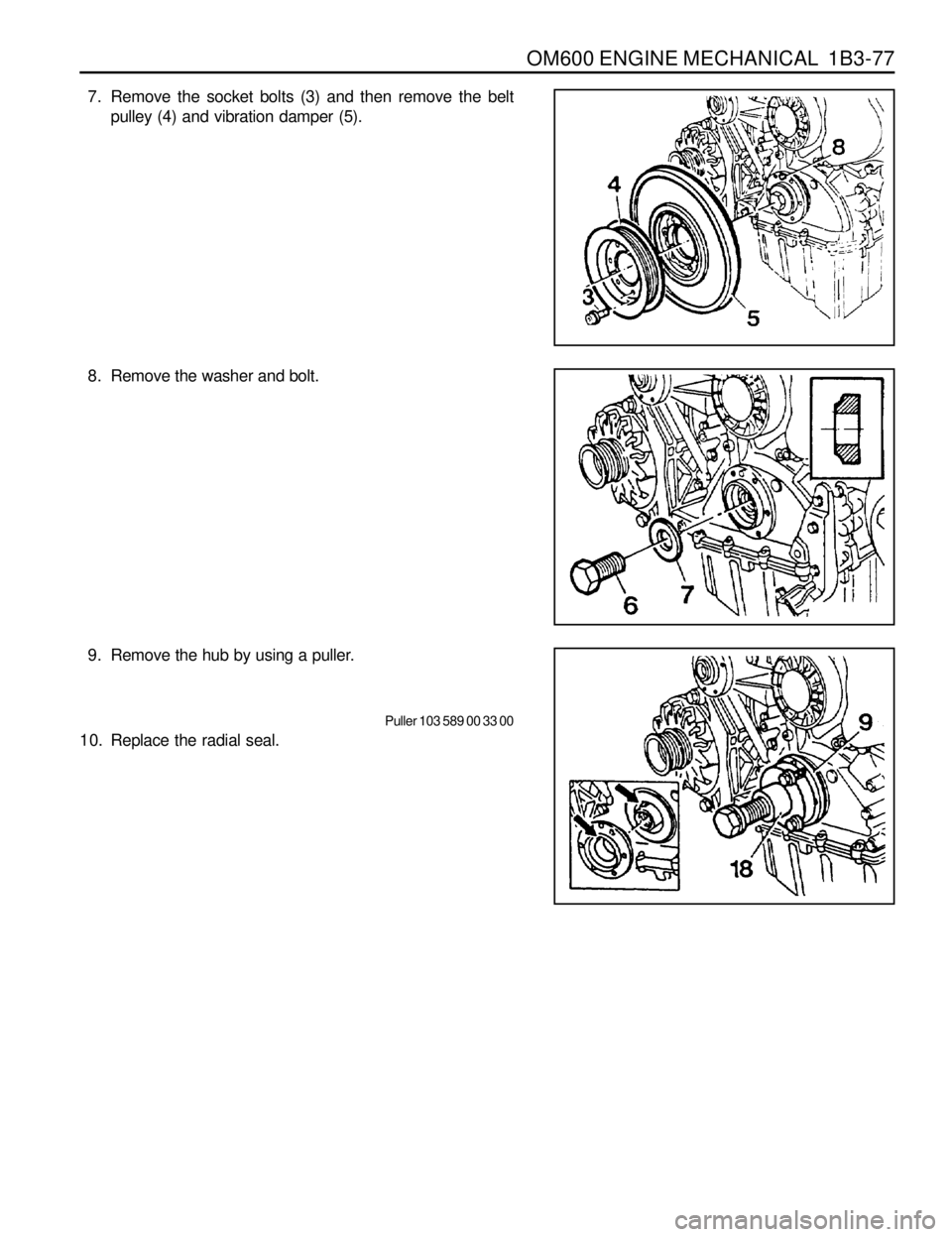

7. Remove the socket bolts (3) and then remove the belt

pulley (4) and vibration damper (5).

8. Remove the washer and bolt.

9. Remove the hub by using a puller.

Puller 103 589 00 33 00

10. Replace the radial seal.

Page 380 of 1463

1B3-78 OM600 ENGINE MECHANICAL

Installation Procedure

1. Install the hub.

Notice

Exactly align the woodruff key and the groove of hub (arrow).

2. Install the washer (7) and tighten the bolt (6).

Washer (new) : 1 EA 200 Nm + 90°

3. Install the vibration damper.

Notice

Exactly align and insert onto the straight pin.

4. Install the belt pulley.

Tightening Torque 25 Nm

Notice

Align the alignment marks.

Page 714 of 1463

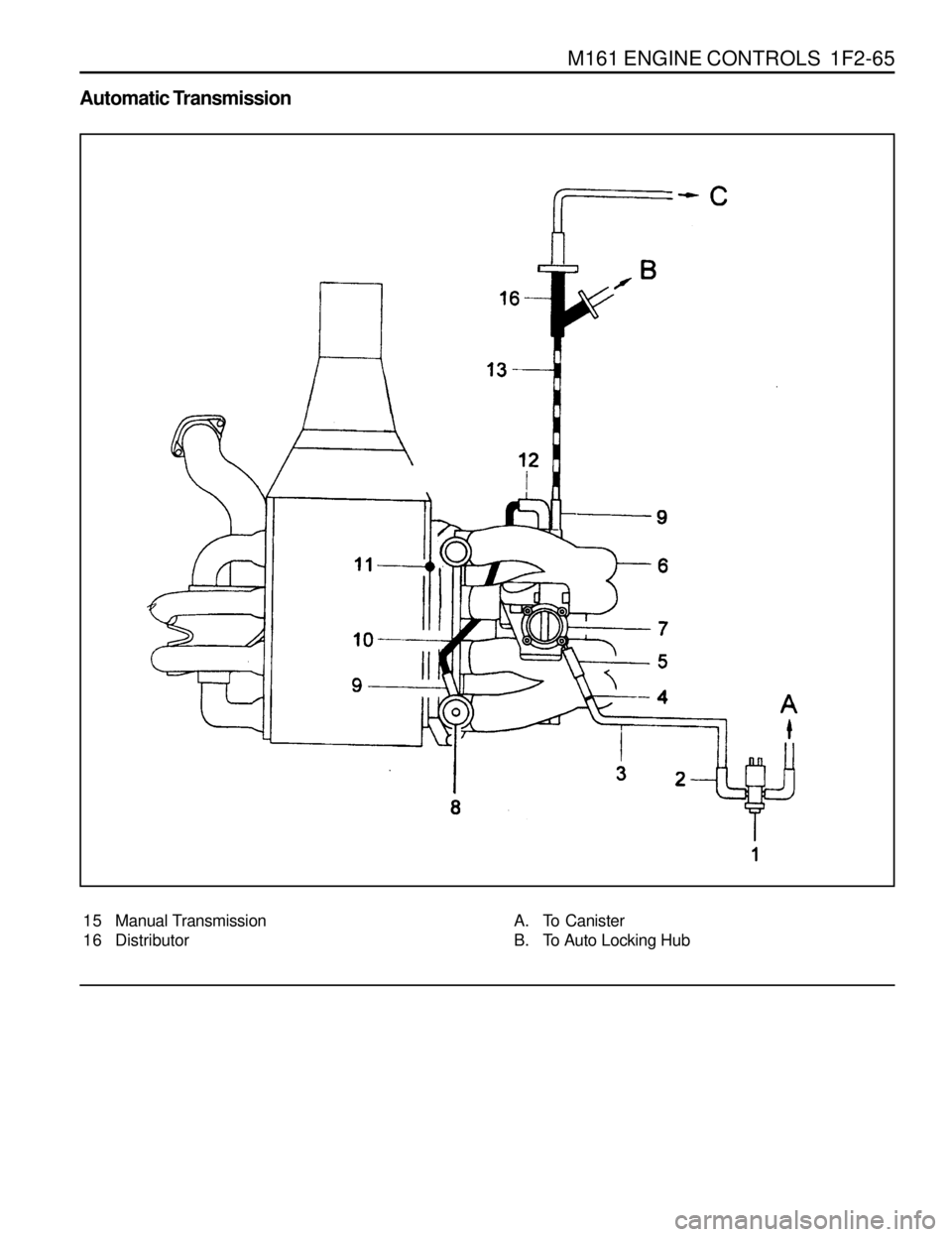

M161 ENGINE CONTROLS 1F2-65

15 Manual Transmission

16 Distributor

Automatic Transmission

A. To Canister

B. To Auto Locking Hub

Page 734 of 1463

OM600 ENGINE CONTROLS 1F3-5

VACUUM CONTROL SYSTEM TEST

2 Engine Cut-Off Valve (Ignition Key Switch)

3 Auto-locking Hub Solenoid Valve

4 Engine Stop Valve Unit

5 PLA Vacuum Unit (Idle Speed Adjustment)

6 Engine

7 Vacuum Pump8 30° Thermovalve

9 Fuel Injection Pump

10 Filter with Restriction

11 Check Valve

12 Modulating Pressure Line (Automatic T/M)

Test Data

Idle Speed Increase

Permissible Pressure Drop of SystemAt least 100 rpm at approx. 500mbr

400 - 500mbar approx. 1 min.

Page 764 of 1463

OM600 ENGINE CONTROLS 1F3-35

INJECTION TIMING DEVICE

Preceding Work : Removal of injection timing device

1 Cam Sprocket........................................... Check

2 Bushing .................................................... Check

3 Governor Weights4 Segment Flange and Drive Hub

5 Compression Springs