SSANGYONG MUSSO 1998 Workshop Owner's Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Owner's Manual

Page 91 of 1463

1B1-18 M162 ENGINE MECHANICAL

ALTERNATOR

1 Nut (M8).........................................22.5-27.5 Nm

2 Bolt (M8 x 30, 3 pieces).................22.5-27.5 Nm

3 Bolt (M8 x 40, 1 piece)...................22.5-27.5 Nm

Removal & Installation Procedure

1. Remove the drive belt.

2. Remove the alternator.

3. Unscrew the alternator carrier bolts and remove the carrier.

Installation Notice4 Bolt (M8 x 70, 1 piece)...................22.5-27.5 Nm

5 Bolt (M8 x 75, 1 piece)...................22.5-27.5 Nm

Tightening Torque 10 - 15 Nm

4. Installation should follow the removal procedure in the

reverse order.

Page 93 of 1463

1B1-20 M162 ENGINE MECHANICAL

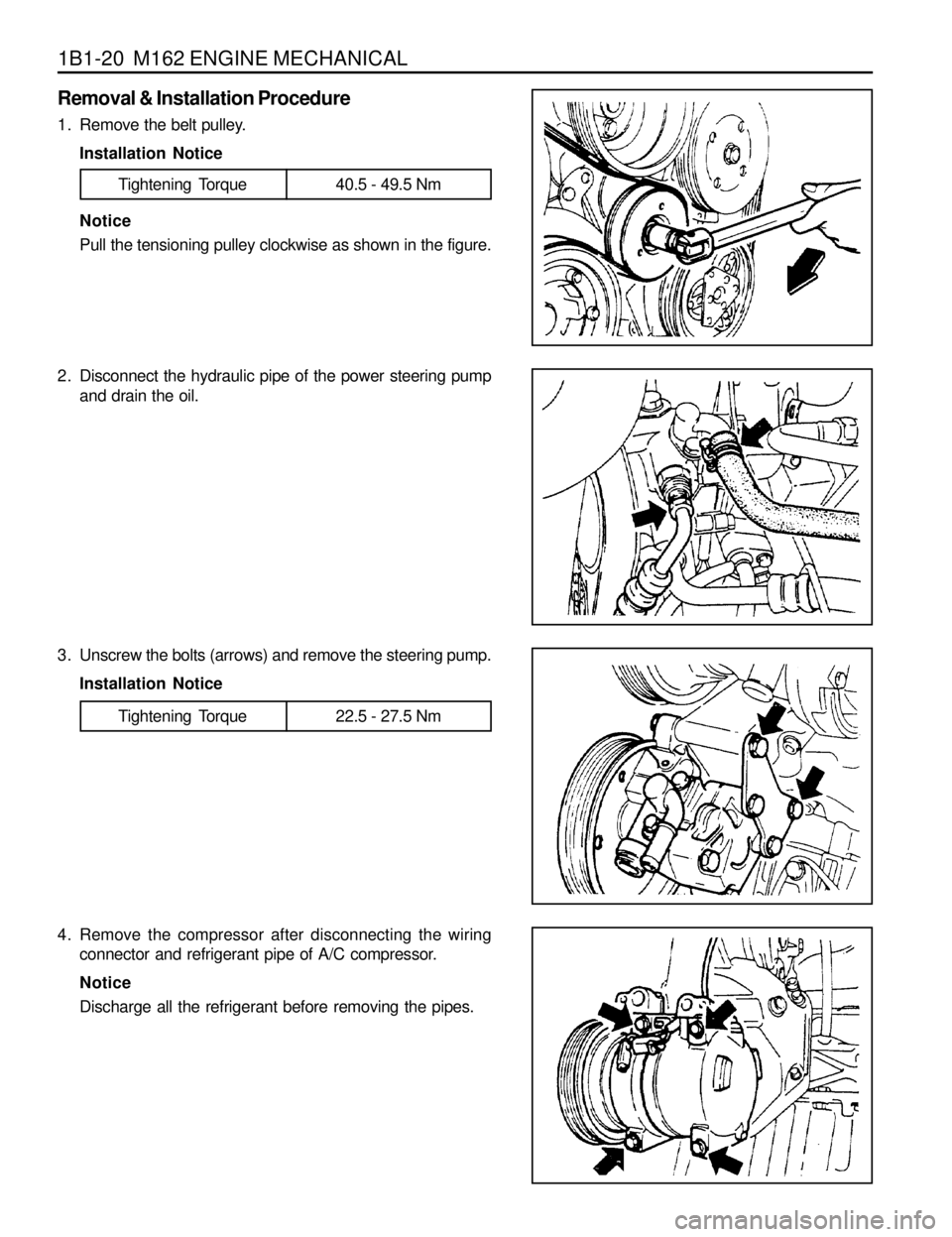

Removal & Installation Procedure

1. Remove the belt pulley.

Installation Notice

2. Disconnect the hydraulic pipe of the power steering pump

and drain the oil.

3. Unscrew the bolts (arrows) and remove the steering pump.

Installation Notice Notice

Pull the tensioning pulley clockwise as shown in the figure.

4. Remove the compressor after disconnecting the wiring

connector and refrigerant pipe of A/C compressor.

Notice

Discharge all the refrigerant before removing the pipes.

Tightening Torque 40.5 - 49.5 Nm

Tightening Torque 22.5 - 27.5 Nm

Page 94 of 1463

M162 ENGINE MECHANICAL 1B1-21

5. Disconnect the vent hose from the A/C bracket.

6. Unscrew all the mounting bolts (arrows) and remove the

A/C bracket and the gasket.

Installation Notice

7. Clean the sealing surface.

8. Replace the gasket with new one.

9. Installation should follow the removal procedure in the

reverse order.

10. Check the oil leakage by operating the engine after

installation.

Tightening Torque 22.5 - 27.5 Nm

Page 97 of 1463

1B1-24 M162 ENGINE MECHANICAL

1 Upper Nut

2 Hydraulic Installor.................62-93 Nm

3 Lower Nut.............................28-47 Nm

Removal and Installation Procedure

1. Unscrew the upper nut(1) on engine mounting and remove

the engine.

Installation Notice

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 62 - 93 Nm

2. Unscrew the lower nut(3) and remove the hydraulic engine

mounting insulator.

Installation Notice

Tightening Torque 28 - 47 Nm

Notice

If the insulator is spotted with oil, replace the hydraulic

insulator assembly.

Page 100 of 1463

M162 ENGINE MECHANICAL 1B1-27

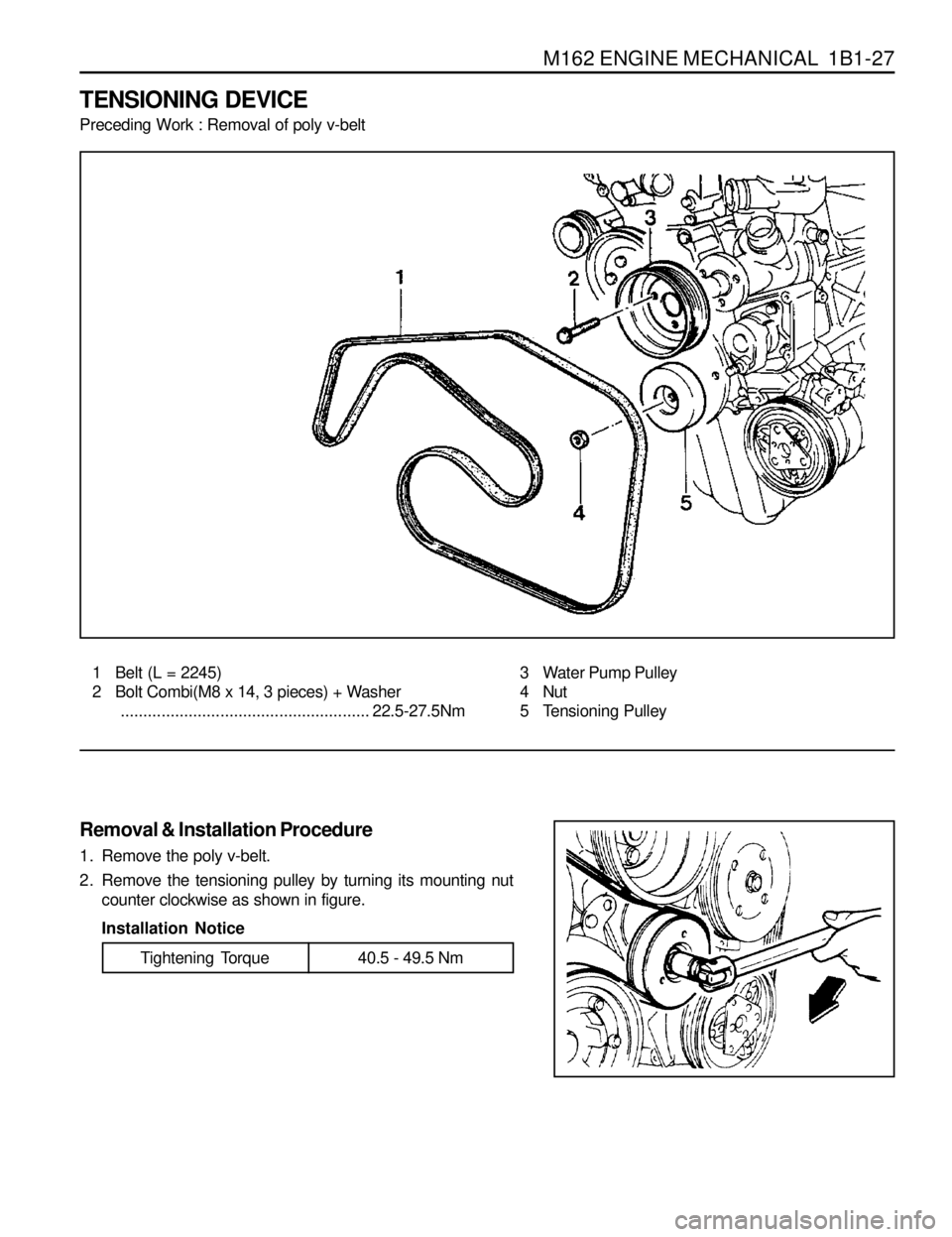

TENSIONING DEVICE

Preceding Work : Removal of poly v-belt

1 Belt (L = 2245)

2 Bolt Combi(M8 x 14, 3 pieces) + Washer

.......................................................22.5-27.5Nm

Removal & Installation Procedure

1. Remove the poly v-belt.

2. Remove the tensioning pulley by turning its mounting nut

counter clockwise as shown in figure.

Installation Notice3 Water Pump Pulley

4 Nut

5 Tensioning Pulley

Tightening Torque 40.5 - 49.5 Nm

Page 101 of 1463

1B1-28 M162 ENGINE MECHANICAL

4. Remove the mounting bolts(M8 x 30, 3 pieces) at the

tensioning device, and remove the tensioning device (arrow).

Installation Notice 3. Remove the 3 bolts (2) and remove the water pump pulley

(arrow).

Installation Notice

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 26 - 32 Nm

Page 105 of 1463

1B1-32 M162 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the intake air duct.

Installation Notice

2. Remove the ignition cable cover.

Installation Notice

3. Remove the spark plug connector and ignition cable.

4. Unscrew all the bolts (2,3) and remove the head cover and

the gasket.

Installation Notice Notice

Unscrew the seven (M6 x 60) bolts and remove the ignition

cable cover.

Notice

Replace the gasket with a new one if necessary.

5. Installation should follow the removal procedure in the

reverse order.

6. Check for oil leaks by operating the engine.

Tightening Torque 8 - 9 Nm

Tightening Torque 9 - 10 Nm

Tightening Torque 9 - 10 Nm

Page 106 of 1463

M162 ENGINE MECHANICAL 1B1-33

CYLINDER HEAD FRONT COVER

Preceding Work : Removal of cylinder head cover

Removal of coolant connection fitting

1 Camshaft Position Sensor

2 Magnet Assembly

3 Upper Guide Rail

4 Bolt (M6 x 60, 3 pieces).................22.5-27.5 Nm5 Bolt (M8 x 80, 3 pieces).................22.5-27.5 Nm

6 Front Cover

7 Rubber Gasket...................................... Replace

8 Bolt (M6 x 16, 3 pieces)......................... 9-11 Nm

Removal & Installation Procedure

1. Remove the magnet assembly.

Installation Notice

Tightening Torque 9 - 11 Nm

Page 107 of 1463

1B1-34 M162 ENGINE MECHANICAL

2. Remove the cylinder head front cover (6).

Installation Notice

4. Remove the gasket (arrow).

Installation Notice

Replace the gasket with new one and apply the sealant.

5. Installation should follow the removal procedure in the

reverse order. Apply the sealant at the mating surface of the cylinder head

and the front cover.

3. Remove the upper guide rail pin and the guide rail (3).

Installation Notice

Install it while the chain tensioner is loose.

Tightening Torque 22.5 - 27.5 Nm

Page 109 of 1463

1B1-36 M162 ENGINE MECHANICAL

4. Remove the three flange bolts in the exhaust camshaft

sprocket.

Installation Notice

5. Separate the chain from the camshaft sprockrt.

Notice

Be careful not to drop the chain into the timing case. Do not reuse the removed bolts. Tools Required

000 589 01 10 00 Box Wrench Insert

116 589 02 34 00 Screw-fixed Pin

116 589 20 33 00 Sliding Hammer

Removal & Installation Procedure

1. Rotate the crankshaft so that the piston of number 1 cylinder

is at TDC.

Notice

Rotate the crankshaft in the normal engine direction.

2. Put the alignment marks (arrows) on the timing chain and

camshaft sprocket.

3. Drain the coolant from the crankcase.

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°