torque SSANGYONG MUSSO 1998 Workshop Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 130 of 1463

M162 ENGINE MECHANICAL 1B1-57

7. Remove the camshaft sprocket (13) and adjust piston (14),

and remove the flange shaft (16) from the intake camshaft

(22) after removing the bolt (15).

Installation Notice

The sprocket bolt is designed to be used only once, so

always replace with new one.

8. Installation should follow the removal procedure in the

reverse order.

9. Adjust the camshaft timing.

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Page 131 of 1463

1B1-58 M162 ENGINE MECHANICAL

CAMSHAFT SPROCKET BOLT

Intake Flange Shaft Bolt

Notice

The sprocket bolts are designed to be used only once, so

always replace with new one.

Exhaust Camshaft Sprocket Bolt

Notice

The sprocket bolts are designed to be used only once, so

always replace with new one.

C. M7 x 13 Collar Bolt Torx-T30

e. 6.8 mm

16. Flange Shaft

18. Control Piston

22. Intake Camshaft

E. M7 x 13 Collar Bolt Torx-T30

e. 6.8 mm

13a. Camshaft Sprocket

22a. Exhaust Camshaft

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Page 134 of 1463

M162 ENGINE MECHANICAL 1B1-61

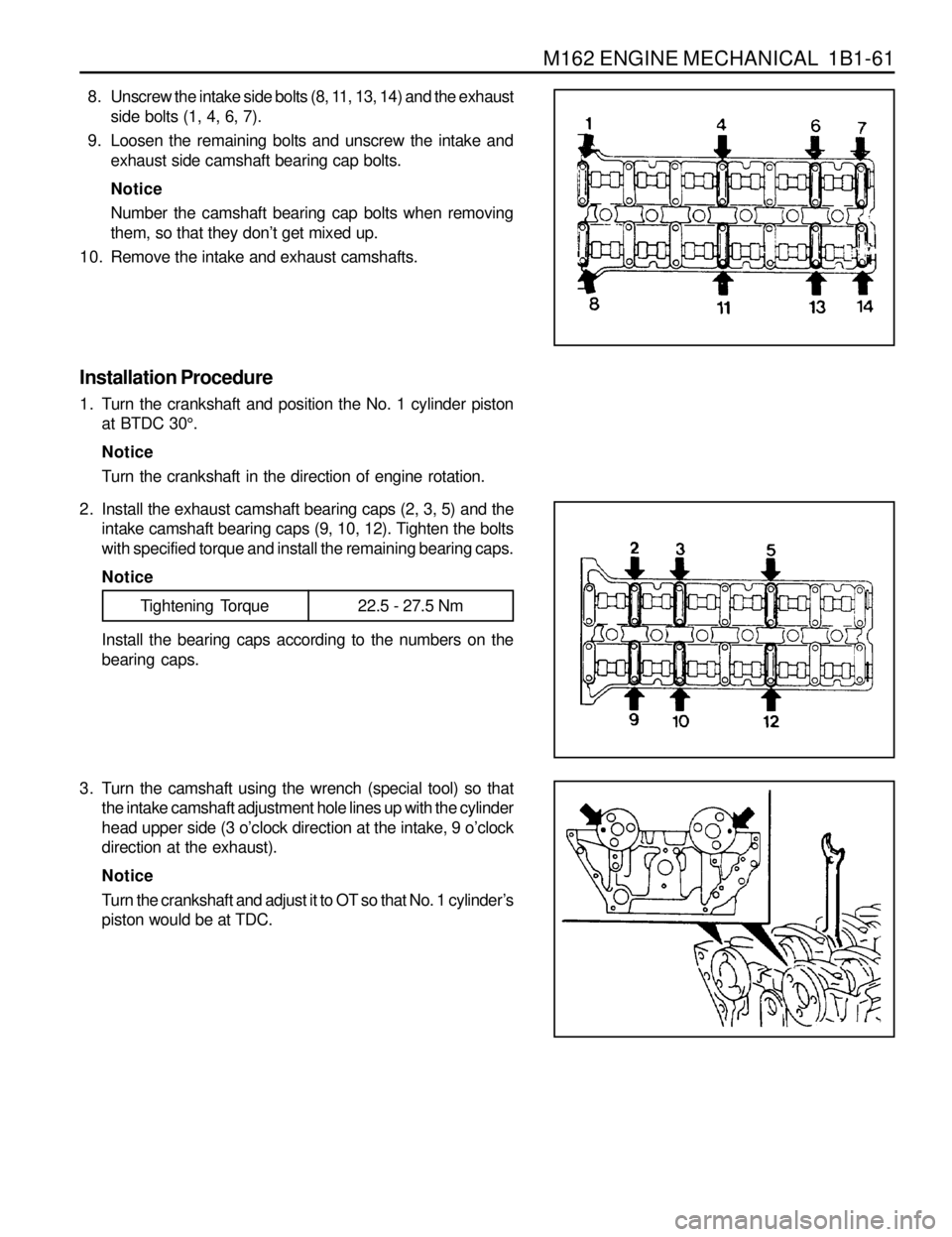

8 . Unscrew the intake side bolts (8, 11, 13, 14) and the exhaust

side bolts (1, 4, 6, 7).

9. Loosen the remaining bolts and unscrew the intake and

exhaust side camshaft bearing cap bolts.

Notice

Number the camshaft bearing cap bolts when removing

them, so that they don’t get mixed up.

10. Remove the intake and exhaust camshafts.

Installation Procedure

1. Turn the crankshaft and position the No. 1 cylinder piston

at BTDC 30°.

Notice

Turn the crankshaft in the direction of engine rotation.

3. Turn the camshaft using the wrench (special tool) so that

the intake camshaft adjustment hole lines up with the cylinder

head upper side (3 o’clock direction at the intake, 9 o’clock

direction at the exhaust).

Notice

Turn the crankshaft and adjust it to OT so that No. 1 cylinder’s

piston would be at TDC. Install the bearing caps according to the numbers on the

bearing caps.

Tightening Torque 22.5 - 27.5 Nm 2. Install the exhaust camshaft bearing caps (2, 3, 5) and the

intake camshaft bearing caps (9, 10, 12). Tighten the bolts

with specified torque and install the remaining bearing caps.

Notice

Page 135 of 1463

1B1-62 M162 ENGINE MECHANICAL

4. Turn the intake camshaft adjuster to the direction of camshaft

rotation by hard until it stops and then install the chain.

Notice

lMake sure that the camshaft sprocket and timing chain

are aligned with marks.

lIntake camshaft adjuster should be in retarded position.

5. Install the chain on the exhaust sprocket and tighten the

sprocket bolts.

Notice

7. Rotate the crankshaft 2 revolutions and check followings:

- TDC of no. 1 cylinder : OT

- Alignment between camshaft adjustment hole and

cylinder head surface.

- Alignments between timing chain and sprocket marks.

Notice

lTurn the crankshaft in the direction of engine rotation.

lRead just if not aligned. 6. Install the chain tensioner and tighten it as specified.

Notice lMake sure that the camshaft sprocket and timing chain

are aligned with marks.

lReplace the sprocket bolt with new one.

Tightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

Tightening Torque( 1 ) 40 Nm

(2) 72 - 88 Nm

Page 139 of 1463

1B1-66 M162 ENGINE MECHANICAL

11. Check the camshaft timing.The sprocket bolt is designed to be used only once, so

replace with new one.

10. Install the chain tensioner.

Installation NoticeTightening Torque1st step 18 - 22 Nm

2nd step 90° ± 5°

9. Install the chain to the exhaust camshaft sprocket and

install it to the camshaft.

Installation Notice (Sprocket Bolt)

Tightening

TorqueScrew Plug

40 Nm

Tensioner Assembly

72 - 88 Nm

Page 141 of 1463

1B1-68 M162 ENGINE MECHANICAL

Tools Required

111 589 01 59 00 Supporting Bar

111 589 18 61 00 Lever Pusher

111 589 25 63 00 Thrust Piece

116 589 06 63 00 Magnetic Finger

Removal & Installation Procedure

1. Place the supporting bar (12) and the slide (9) at the

camshaft bearing cap (Nos 1 & 7/8&14) and tighten them

with the bearing cap bolt.

Installation Notice

2. Turn the crankshaft to position the each cylinder piston at

TDC.

5. Install the engine lock to the ring gear to prevent the

crankshaft from rotating.

6. Blow up with compressed air.Notice

lRemove the valve spring only at TDC.

lAlways rotate the crankshaft by holding the chain to

prevent from timing chain damage and tangling, and for

smooth rotation.

3. Remove the valve tappet (1) using the magnetic finger.

4. Install the leakage tester connecting hose to the spark plug

hole.

Supporting Bar 111 589 01 59 00

Tightening Torque 22.5 - 27.5 Nm

Mark on The Vibration Damper

OT

120°

240°Cylinder

1, 6

2, 5

3, 4

Page 146 of 1463

M162 ENGINE MECHANICAL 1B1-73

Installation Procedure

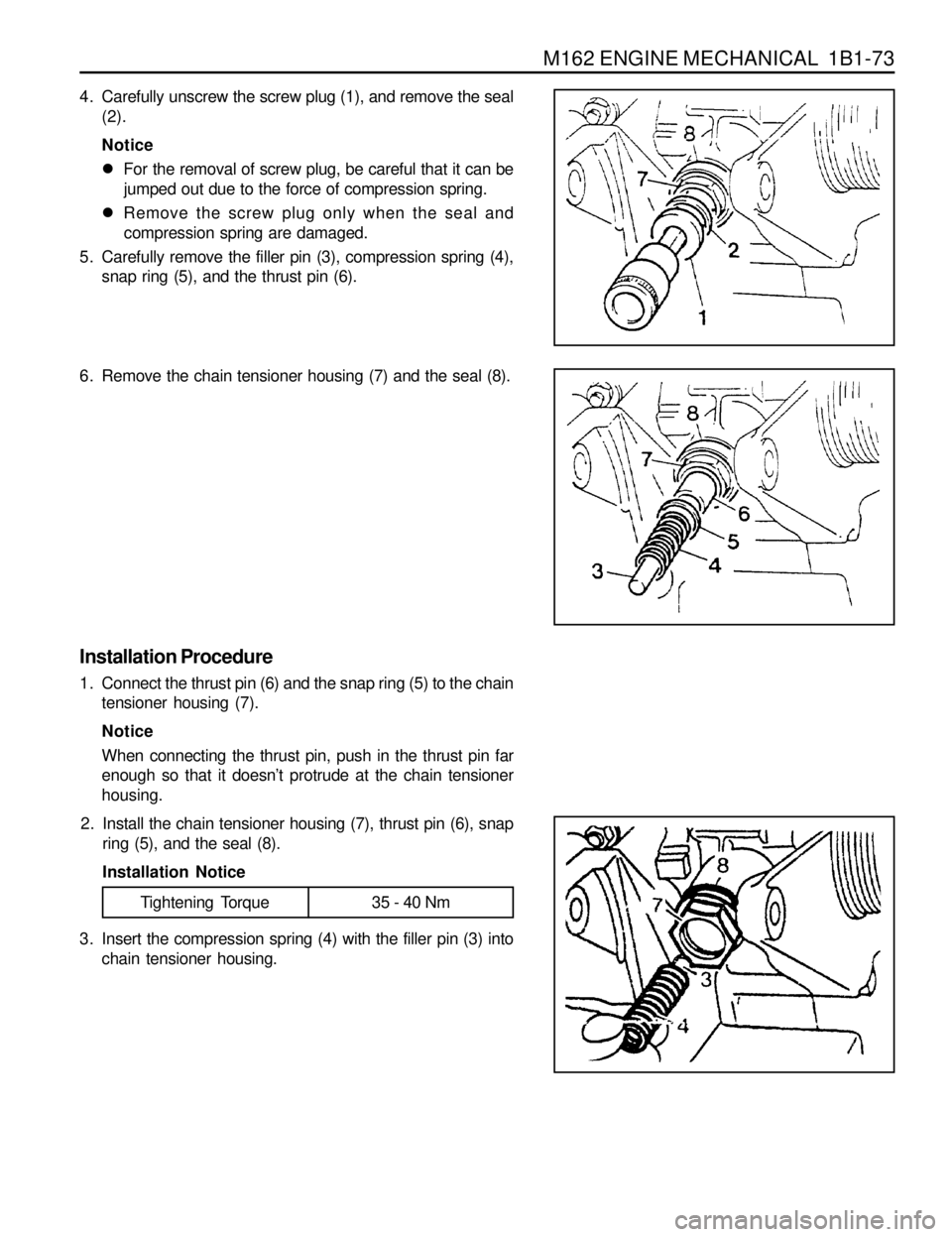

1. Connect the thrust pin (6) and the snap ring (5) to the chain

tensioner housing (7).

Notice

When connecting the thrust pin, push in the thrust pin far

enough so that it doesn’t protrude at the chain tensioner

housing. 4. Carefully unscrew the screw plug (1), and remove the seal

(2).

Notice

lFor the removal of screw plug, be careful that it can be

jumped out due to the force of compression spring.

lRemove the screw plug only when the seal and

compression spring are damaged.

5. Carefully remove the filler pin (3), compression spring (4),

snap ring (5), and the thrust pin (6).

6. Remove the chain tensioner housing (7) and the seal (8).

3. Insert the compression spring (4) with the filler pin (3) into

chain tensioner housing. 2. Install the chain tensioner housing (7), thrust pin (6), snap

ring (5), and the seal (8).

Installation Notice

Tightening Torque 35 - 40 Nm

Page 147 of 1463

1B1-74 M162 ENGINE MECHANICAL

4. Lightly apply the grease to the seal (2) and install the screw

plug (1).

Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece13 Chain Tensioner Housing

1 4 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole 5. Check for leaks by operating the engine.

Tightening Torque 40 Nm

Page 149 of 1463

1B1-76 M162 ENGINE MECHANICAL

Tools Required

000 589 58 43 00 Chain Assembly

103 589 01 63 00 Rivet Set

001 589 72 21 00 Torque Wrench

Replacement Procedure

1. Position the No.1 cylinder to TDC (OT).

4. Mount the wedges to both sides of the camshaft sprocket

as shown in the figure. 2. Insert the

f4mm pin to the intake and exhaust camshaft

flange not to rotate camshaft.

3. Remove the chain tensioner.

5. Cover the chain housing with a clean cloth, and grind off

the timing chain pin from the intake camshaft sprocket with

the grinder.

Page 151 of 1463

1B1-78 M162 ENGINE MECHANICAL

15. Replace the thrust piece (b) as shown in the figure. 13. Install the assembly tool above the link and tighten the

spindle (c) until a block is felt.

14. Place the assembly tool. 12. Place the outer plate (7, thickness 1.2mm) inside the thrust

piece (b).

16. Install the assembly tool to the link pin and tighten the

spindle (c).

Tightening Torque 30 Nm