engine oil SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 213 of 1574

M161 ENGINE MECHANICAL 1B2-61

Removal & Installation Procedure

1. Unscrew the stretch bolt.Installation Notice

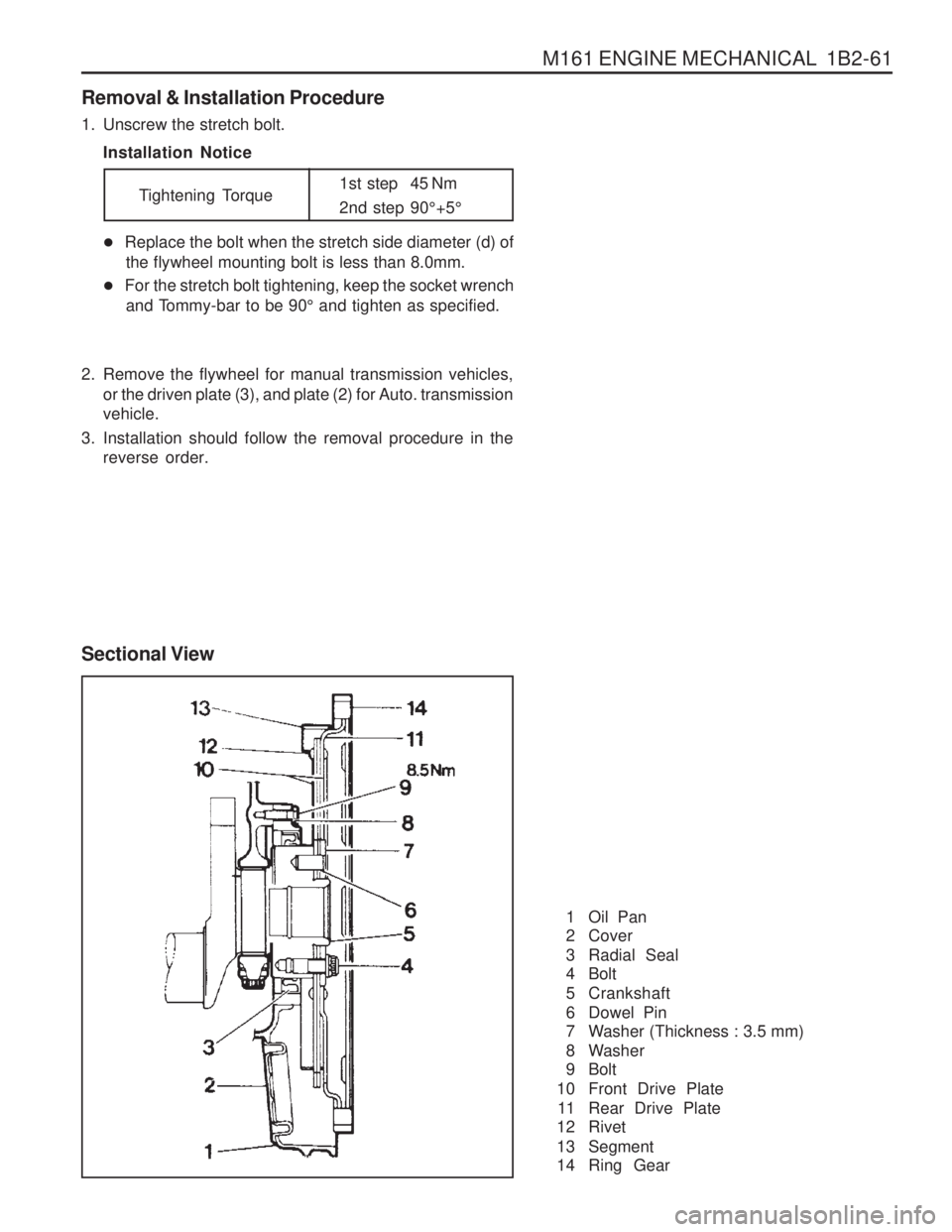

Sectional View

1 Oil Pan

2 Cover

3 Radial Seal

4 Bolt

5 Crankshaft

6 Dowel Pin

7 Washer (Thickness : 3.5 mm)

8 Washer

9 Bolt

10 Front Drive Plate 11 Rear Drive Plate

12 Rivet

13 Segment

14 Ring Gear

�

Replace the bolt when the stretch side diameter (d) of

the flywheel mounting bolt is less than 8.0mm.

� For the stretch bolt tightening, keep the socket wrench

and Tommy-bar to be 90 ° and tighten as specified.

2. Remove the flywheel for manual transmission vehicles, or the driven plate (3), and plate (2) for Auto. transmission vehicle.

3. Installation should follow the removal procedure in the reverse order. Tightening Torque

1st step 45 Nm

2nd step 90

°+5 °

Page 214 of 1574

1B2-62 M161 ENGINE MECHANICAL CAMSHAFT ADJUSTER

1 Bolt (M6 X 16, 3 pieces)......................... 9-11 Nm

2 Cylinder Head Front Cover

3 Bolt ........................................................... 35 Nm

4 Armature

5 Roll Pin

6 Nut (M20 X 1.5) .................................... 60-70 Nm

7 Seal Cover

8 Camshaft Sprocket

9 Adjust Piston

10 Conical Spring 11 Flange Bolt

(M7 X 13, 3 pieces) .................1st Step 20±2 Nm

2nd Step 90 ° ± 5 ° Rotation Added

12 Flange Shaft

13 Compression Spring

14 Control Piston

15 Circlip

16 Oil Gallery

17 Straight Pin

18 Intake Camshaft

Y49 Magnetic Actuator (2-pin connector)

Page 220 of 1574

1B2-68 M161 ENGINE MECHANICAL

7. Remove the bearing cap, and remove the intake and theexhaust camshaft. Installation Notice

Tightening Torque 22.5 - 27.5 Nm

Notice Check the numbers on the bearing cap not to be miked up.

8. Apply the engine oil on the valve tappet and camshaft bearing.

9. Installation should follow the removal procedure in the reverse order. Notice

� Base circle of cam should cantact with the valve tappet.

� Install the camshaft bearing caps according to the

numbers on the cylinder head cast and bearing cap.

10. Check the camshaft timing position.

Page 228 of 1574

1B2-76 M161 ENGINE MECHANICAL

VALVE STEM SEAL Preceding Work : Removal of valve spring

1 Drift (Special Tool)

2 Valve Stem Seal

3 Protective Sleeve

Drift 119 589 00 43 00

Pliers 104 589 00 37 00

Tools Required

104 589 00 37 00 Pliers

119 589 00 43 00

Drift

Replacement Procedure

1. Remove the valve stem seal (2) using the pliers. Notice Check the valve stem seal for damage and replace if

necessary.

2. Coat the valve stem seal with oil and assemble it with the protective sleeve.

3. Insert the valve stem seal by pressing it with the drift.

Page 229 of 1574

M161 ENGINE MECHANICAL 1B2-77

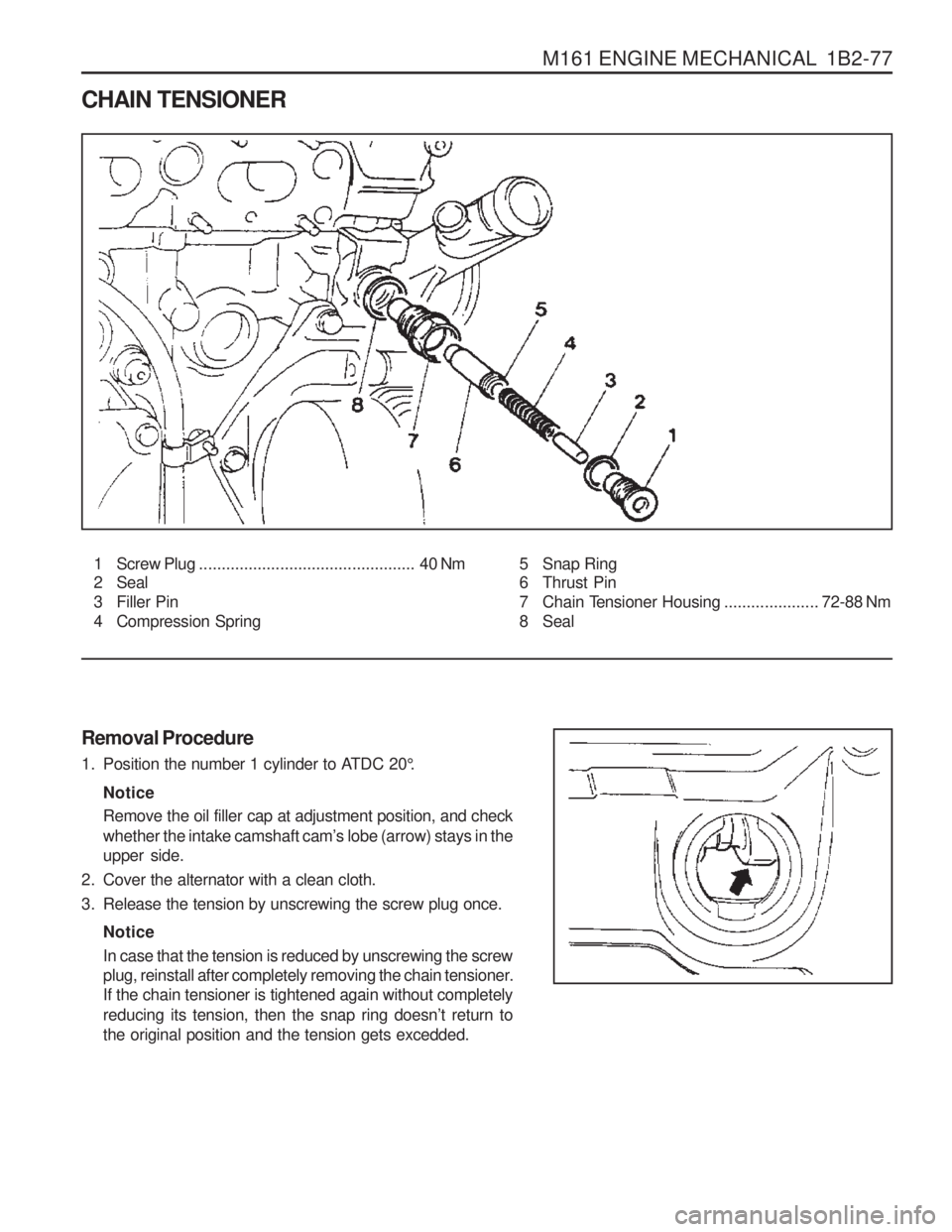

CHAIN TENSIONER1 Screw Plug ................................................ 40 Nm

2 Seal

3 Filler Pin

4 Compression Spring 5 Snap Ring

6 Thrust Pin

7 Chain Tensioner Housing

.....................72-88 Nm

8 Seal

Removal Procedure

1. Position the number 1 cylinder to A TDC 20°.

Notice Remove the oil filler cap at adjustment position, and check whether the intake camshaft cam ’s lobe (arrow) stays in the

upper side.

2. Cover the alternator with a clean cloth.

3. Release the tension by unscrewing the screw plug once.

NoticeIn case that the tension is reduced by unscrewing the screw

plug, reinstall after completely removing the chain tensioner.If the chain tensioner is tightened again without completely reducing its tension, then the snap ring doesn ’t return to

the original position and the tension gets excedded.

Page 231 of 1574

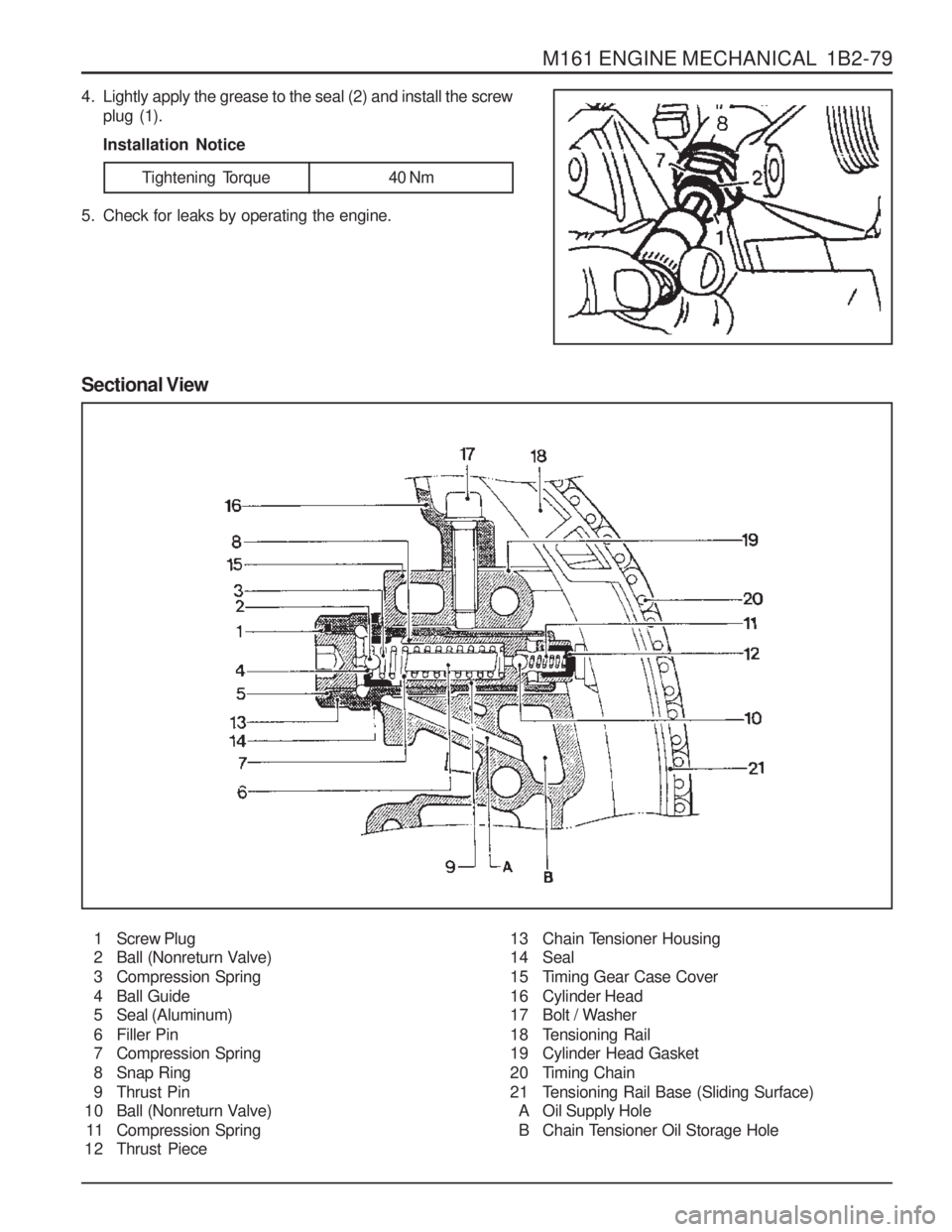

M161 ENGINE MECHANICAL 1B2-79

4. Lightly apply the grease to the seal (2) and install the screwplug (1). Installation Notice

Sectional View

1 Screw Plug

2 Ball (Nonreturn Valve)

3 Compression Spring

4 Ball Guide

5 Seal (Aluminum)

6 Filler Pin

7 Compression Spring

8 Snap Ring

9 Thrust Pin

10 Ball (Nonreturn Valve)

11 Compression Spring

12 Thrust Piece 13 Chain Tensioner Housing

14 Seal

15 Timing Gear Case Cover

16 Cylinder Head

17 Bolt / Washer

18 Tensioning Rail

19 Cylinder Head Gasket

20 Timing Chain

21 Tensioning Rail Base (Sliding Surface)

A Oil Supply Hole

B Chain Tensioner Oil Storage Hole

5. Check for leaks by operating the engine.

Tightening Torque 40 Nm

Page 240 of 1574

1B2-88 M161 ENGINE MECHANICAL

CRANKSHAFT SPROCKET Preceding Work : Removal of oil panRemoval of tensioning rail Removal of crank case guide rail Removal of cylinder head

6 Bolt (M8 x 20, 1 piece) / Washer ..........29-35 Nm

7 Oil Pump Sprocket

8 Oil Pump

9 Oil Pump Roller Chain

10 Timing Chain

1 Oil Pump Chain Tensioner

2 Oil Pump Chain Spring

3 Oil Pump Chain Bushing (Pin)

4 Crankshaft Sprocket

5 Key

Page 241 of 1574

M161 ENGINE MECHANICAL 1B2-89

Tools Required

615 589 01 33 00 Caulking Bolt Removal & Installation Procedure

1. Put the assembly mark at the crankshaft sprocket (4) andthe timing chain (10) with the paint (arrow). Installation Notice Align the assembly marks on cranshaft sprocket and timing chain. Also, align the assembly marks on camshaft sprocketand timing chain when installing.

2. Unscrew the bolt (6) and remove the oil pump sprocket (7) from the oil pump. Installation Notice

Caulking (04) 615 589 01 33 00

3. Remove the oil pump roller chain (9).

4. Remove the oil pump chain tensioner (1), oil pump chain

bushing (3), and the oil pump chain spring (2).

5. Remove the crankshaft sprocket (4) using the puller (04, special tool). Notice

�Make sure not to lose the crankshaft pulley key (5) when

removing.

� Install the crankshaft sprocket (4) after warming it up.

6. Installation should follow the removal procedure in the reverse order.

Tightening Torque 29 - 35 Nm

Page 242 of 1574

1B2-90 M161 ENGINE MECHANICAL PISTON Preceding Work : Removal of engineRemoval of cylinder head Removal of oil pan Removal of oil pumpRemoval of baffle plate

1 Connecting Rod Bearing Cap

2 Connecting Rod

3 Connecting Rod Bolt(M9 x 52, 8 pieces) ......................1st step 40 Nm

2nd step 90 ° +5 ° 4 Piston

5 Snap Ring

6 Piston Pin

Page 244 of 1574

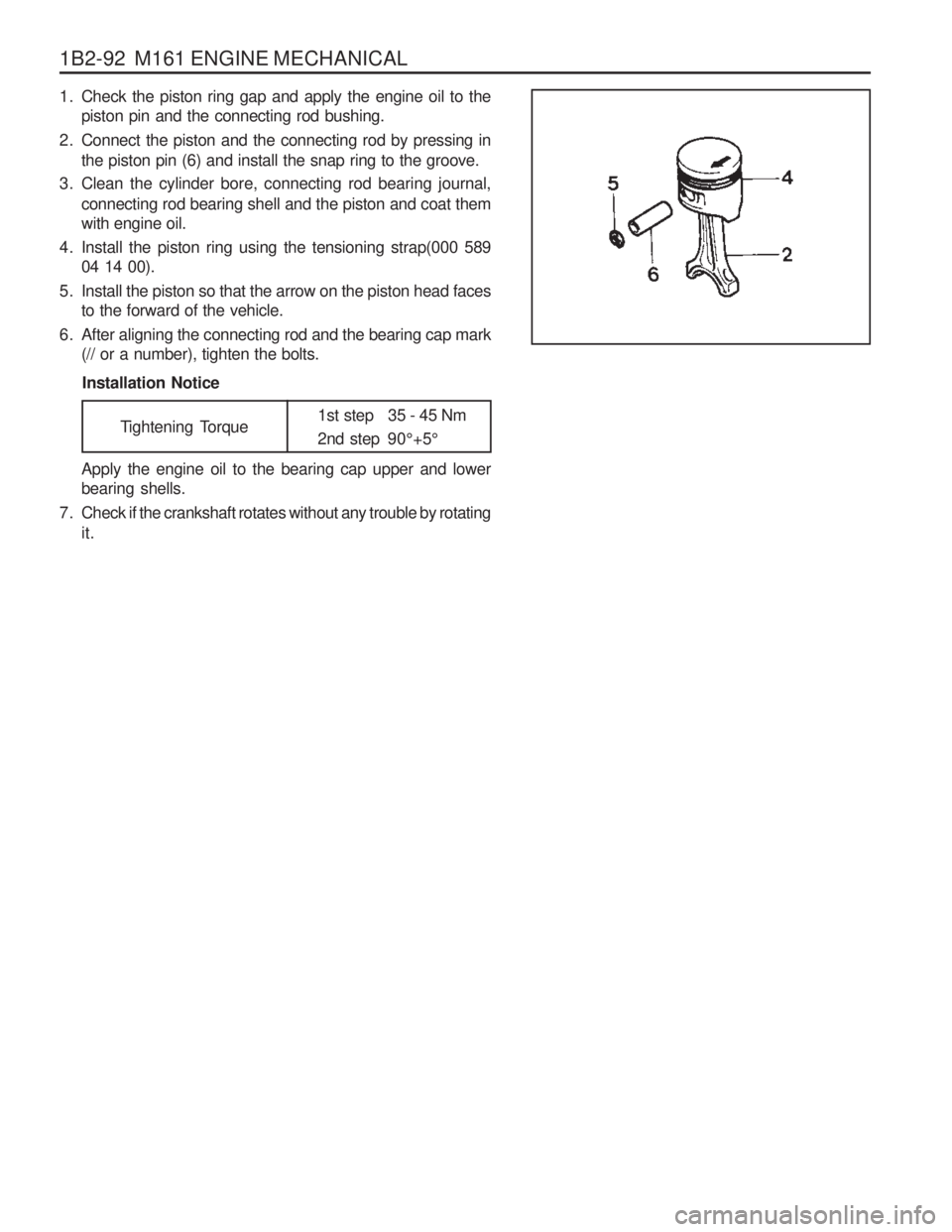

1B2-92 M161 ENGINE MECHANICAL

1. Check the piston ring gap and apply the engine oil to thepiston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by pressing in the piston pin (6) and install the snap ring to the groove.

3. Clean the cylinder bore, connecting rod bearing journal, connecting rod bearing shell and the piston and coat them with engine oil.

4. Install the piston ring using the tensioning strap(000 589 04 14 00).

5. Install the piston so that the arrow on the piston head faces to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap mark (// or a number), tighten the bolts.

Installation Notice

Tightening Torque 1st step 35 - 45 Nm

2nd step 90

°+5 °

Apply the engine oil to the bearing cap upper and lower bearing shells.

7. Check if the crankshaft rotates without any trouble by rotating it.