engine oil SSANGYONG MUSSO 2003 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 143 of 1574

M162 ENGINE MECHANICAL 1B1-107

Sealing Procedure

1. Remove the screw plug (1) and the seal.Installation Notice

2. Remove the steel ball from the oil gallery (4), (5), (6) and (7) using the round bar (12,

�6 x 700 mm).

4. Enlarge the oil gallery at the rear of the cylinder head to be diameter 9mm, depth 8mm.

5. Tap in the steel ball (3) from the side to the oil gallery using the punch (13).

6. Pull out the steel ball (3) using the round bar (12).

7. Enlarge the oil gallery to be diameter 9mm, depth 8mm.

Tightening Torque 15 Nm

3. Remove the plug (8) using the screw driver.

Page 144 of 1574

1B1-108 M162 ENGINE MECHANICAL

11. Tighten the screw plug with the seal (arrow).Screw Plug (Part No. 000 908 01 00 02)Seal (Part No. 007 603 01 01 03)

8. Make a screw hole at the oil gallery using M10 x 1 thread.

9. All the oil gallery should be cleaned with the compressed

air.

10. Apply the Loctite 270 to new plug and press in using a suitable drift (arrow).

Page 148 of 1574

1B1-112 M162 ENGINE MECHANICAL Service Data Standard Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore size inaxial and transverse direction at three points (1,2,3).

1,2,3. Measuring PointsA . Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c . Location of the Oil Ring at BDC

Chamfer Angle

Wear Limit in Longitudinal and Transverse Direction Permissible Deviation of Cylinder Out-of-round Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area) Basic Peak-to-valley Height After Final Honing and Brushing Chamfer AngleHoning Angle When new

Wear limit 0.1 mm

0.007 mm 0.05 mm0.05 mm

0.003 - 0.006 mm 60°

50 ° ± 10 °

Page 153 of 1574

SECTION 1B2

M161 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B2-2Fastener Tightening Specifications . . . . . . . . 1B2-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B2-4 Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B2-4

Maintenance and Repair . . . . . . . . . . . . . . 1B2-9

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1B2-9

Engine Assembly . . . . . . . . . . . . . . . . . . . . . 1B2-9

Crankcase Ventilation System . . . . . . . . . . 1B2-17

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-21

Power Steering Pump and A/C Bracket . . . 1B2-22

Hydraulic Engine Mounting Insulator . . . . . . 1B2-25

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-28

Tensioning Deivce . . . . . . . . . . . . . . . . . . . . 1B2-30

Tensioning Device Shock Absorber . . . . . . 1B2-31

Poly V-Belt Inspection . . . . . . . . . . . . . . . . . 1B2-32

Cylinder Head Cover . . . . . . . . . . . . . . . . . 1B2-35

Cylinder Head Front Cover . . . . . . . . . . . . . 1B2-37

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B2-39

Timing Gear Case Cover . . . . . . . . . . . . . . 1B2-44

Crankshaft Sealing Rear Cover . . . . . . . . . 1B2-47

Belt Pulley and Vibration Damper . . . . . . . . 1B2-49

Crankshaft Front Radial Seal . . . . . . . . . . . 1B2-52

Crankshaft Rear Radial Seal . . . . . . . . . . . 1B2-53

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-54

Flywheel/Driven Plate . . . . . . . . . . . . . . . . . 1B2-60

Camshaft Adjuster . . . . . . . . . . . . . . . . . . . 1B2-62

TABLE OF CONTENTS

Camshaft Sprocket Bolt . . . . . . . . . . . . . . . 1B2-65

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-66

Camshaft Timing Position . . . . . . . . . . . . . . 1B2-69

Valve Spring . . . . . . . . . . . . . . . . . . . . . . . . 1B2-72

Valve Stem Seal . . . . . . . . . . . . . . . . . . . . . 1B2-76

Chain Tensioner . . . . . . . . . . . . . . . . . . . . . 1B2-77

Timing Chain . . . . . . . . . . . . . . . . . . . . . . . . 1B2-80

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . . 1B2-85

Cylinder Head Guide Rail . . . . . . . . . . . . . . 1B2-86

Crankcase Guide Rail . . . . . . . . . . . . . . . . . 1B2-87

Crankshaft Sprocket . . . . . . . . . . . . . . . . . . 1B2-88

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-90

Connecting Rod . . . . . . . . . . . . . . . . . . . . . 1B2-93

Piston Ring . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-95

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-97

Engine Oil and Oil Filter Element . . . . . . . . 1B2-99

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1B2-101

Oil Pressure Relief Valve . . . . . . . . . . . . . 1B2-103

Oil Non-Return Valve . . . . . . . . . . . . . . . . 1B2-104

Oil Dipstick Guide Tube . . . . . . . . . . . . . . 1B2-105

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B2-106 Core Plugs in Crankcase . . . . . . . . . . . . . 1B2-106

Cylinder Bore . . . . . . . . . . . . . . . . . . . . . . 1B2-108

Crankcase Mating Surface . . . . . . . . . . . . 1B2-110

Cylinder Head Mating Surface . . . . . . . . . 1B2-112

Page 155 of 1574

M161 ENGINE MECHANICAL 1B2-3

N

m

20 / + 90 °

40

72 - 88

20 / + 90 °

25 - 35

22.5 - 27.5 22.5 - 27.5 22.5 - 27.5 22.5 - 27.5 30

26 - 34

30

8 - 10 2525

22.5 - 27.5 29 - 35

22.5 - 27.5 9 - 11

50

9 - 11

15Application

Exhaust Camshaft Sproket Bolt

Chain Tensioner Screw Plug

Chain Tensioner AssemblyExhaust Camshaft Sprocket to CamshaftOil Pump Sprocket Bolt

Tensioning Device Bolt

Water Pump PulleyUpper Intake Manifold BoltLower Intake Mainfold BoltFlange Bolt to Exhaust Mainfold Exhaust Mainfold Nut to Stud Bolt Rivet Nut in Exhuast Mainfold HolePre-Silencer BoltOil Drain PlugOil Filter Cover Oil Filter Bolt Oil Pump Drive Sprocket BoltOil Pump Mounting BoltOil Strainer Bracket Bolt

Oil Pressure Relief Valve Screw Plug Oil Dipstick Guide tube Bolt Oil Gallery Screw Plug

FASTENER TIGHTENING SPECIFICATIONS (Co n t ’d)

Page 156 of 1574

1B2-4 M161 ENGINE MECHANICALSPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01 Torque Wrench

112 589 00 72 00 Oil Extractor 000 589 72 21 00

Torque Wrench

001 589 66 21 00 Torque Wrench

000 589 01 10 00

Box Wrench Insert 124 589 15 21 00

Radiator CapTesting Unit

116 589 02 34 00

Screw-Fixed Pin 000 589 40 37 00

Hose Clamp

Page 159 of 1574

M161 ENGINE MECHANICAL 1B2-7

SPECIAL TOOLS TABLE (Co n t’d)

103 589 01 63 00 Rivet Set

103 589 02 09 00 Oil Filter

Socket Wrench 102 589 12 15 00

Drift

615 589 01 33 00Caulking Bolt

102 589 00 15 00 Drift

000 589 51 37 00 Clamping Strap 001 589 72 21 00

Torque Wrench

601 589 03 14 00

Sleeve

Page 161 of 1574

M161 ENGINE MECHANICAL 1B2-9

MAINTENANCE AND REPAIRON-VEHICLE SERVICE

ENGINE ASSEMBLY

Tools Required

000 589 10 99 01 Torque Wrench

000 589 40 37 00 Hose Clamp

112 589 00 72 00 Oil Extractor

Page 164 of 1574

1B2-12 M161 ENGINE MECHANICAL

12. Discharge the refrigerant from A/C system, and disconnectthe discharge pipe and suction pipe from the compressor.

14. Remove the fuel feed and return line. Notice Before removing the fuel lines, release the pressure in the fuel system. Installation Notice

13. Remove the acceleration control cable and automatic

transmission pressure cable.

11. Remove the hydraulic pipe of power steering.

NoticeCompletely drain the oil.

Tightening Torque 21 - 25 Nm

Page 166 of 1574

1B2-14 M161 ENGINE MECHANICAL

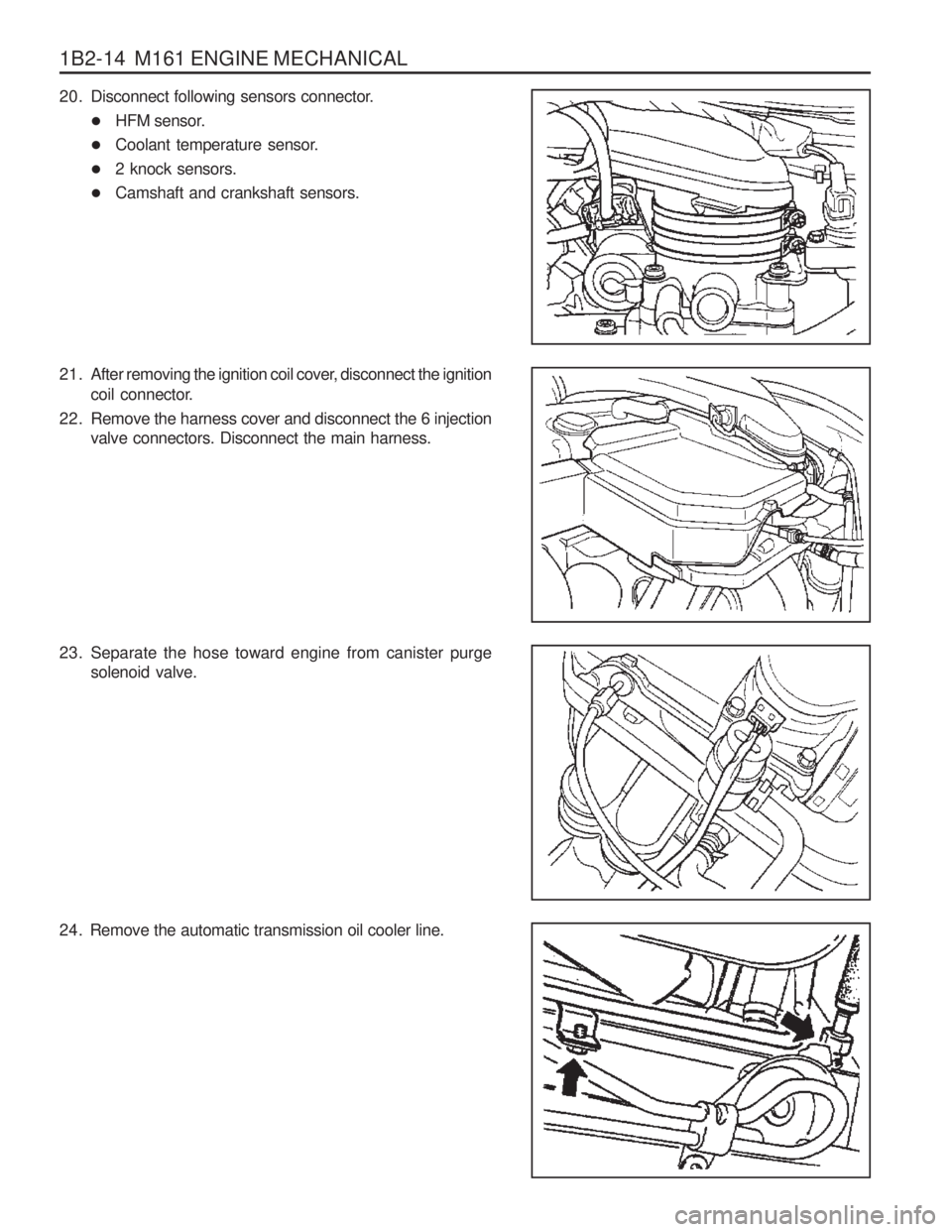

20. Disconnect following sensors connector.�HFM sensor.

� Coolant temperature sensor.

� 2 knock sensors.

� Camshaft and crankshaft sensors.

21. After removing the ignition coil cover, disconnect the ignition coil connector.

22. Remove the harness cover and disconnect the 6 injection valve connectors. Disconnect the main harness.

23. Separate the hose toward engine from canister purge solenoid valve.

24. Remove the automatic transmission oil cooler line.