SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Page 306 of 1574

OM600 ENGINE MECHANICAL 1B3-41

8. Remove the air cleaner cover and element and thenremove the air cleaner housing.

9. Remove the oil return hose and plug.

Notice Cover them to prevent chips from coming into.

10. Unscrew the EGR pipe mounting bolts onto the exhaust manifold.

11. Remove the duct bracket from the cylinder head.

12. Unscrew the intake duct mounting bolts onto the intake manifold.

13. Separate the connecting rod from the control lever.

Page 309 of 1574

1B3-44 OM600 ENGINE MECHANICAL

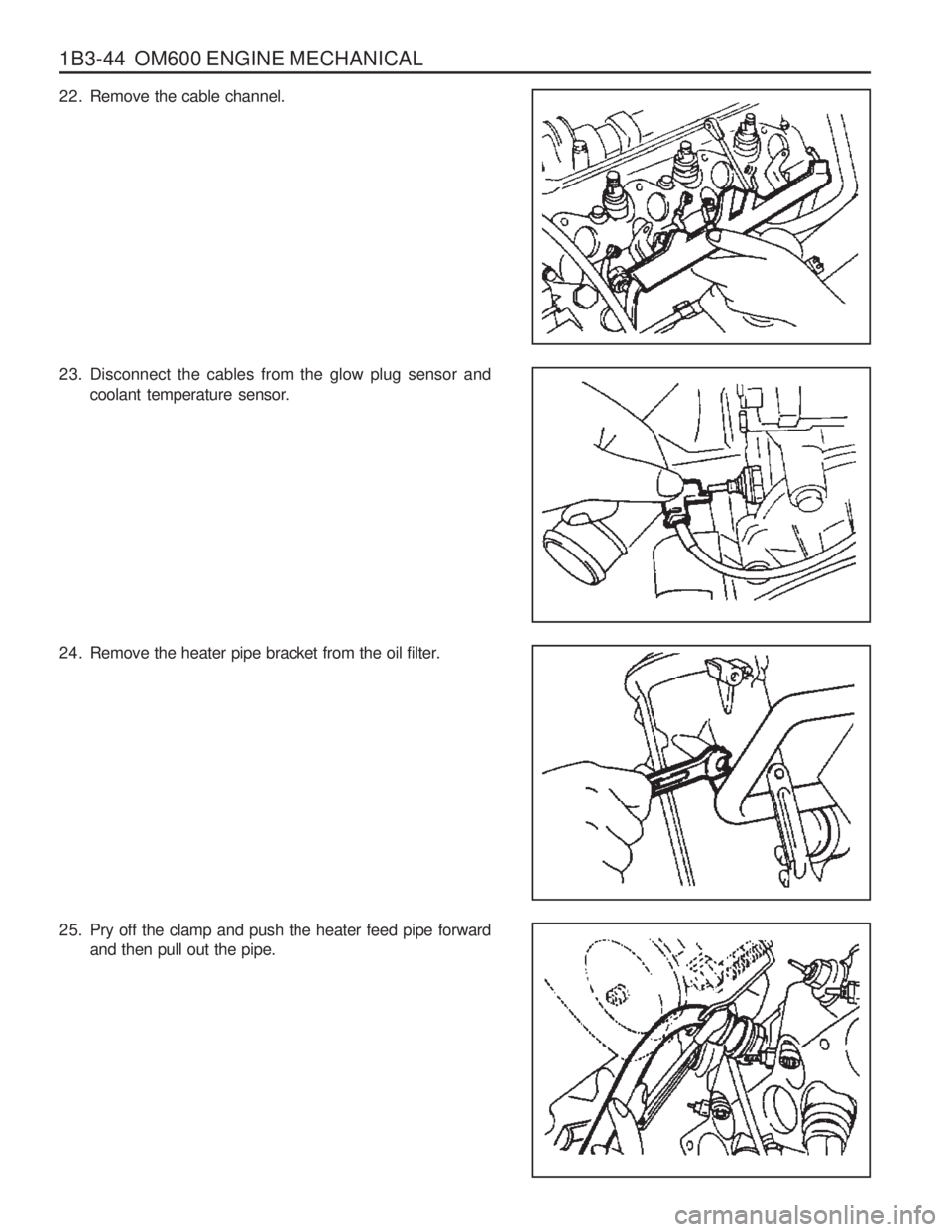

22. Remove the cable channel.

23. Disconnect the cables from the glow plug sensor andcoolant temperature sensor.

24. Remove the heater pipe bracket from the oil filter.

25. Pry off the clamp and push the heater feed pipe forward and then pull out the pipe.

Page 317 of 1574

1B3-52 OM600 ENGINE MECHANICALLength(L)

Assembly Procedure

1. Replace the cylinder head gasket.

2. Install the cylinder head onto the crankcase.

Notice Align the cylinder head holes with the guide pins.

3. Measure the length(L) of cylinder head bolts. Notice If the max. length is exceeded, replace the bolts.

Thread Dia. Max. Limit(L)

M10 M10 M1080mm

102mm 115mm 82mm

104mm 117mm

when new

4. Coat the head contact surface of bolts and thread with oil

and insert them as shown. - Cylinder head bolts arrangement

Bore 1 ........................................... M10 ×

80

2 ........................................... M10 × 102

3 ........................................... M10 × 11 5

4 ........................................... M 8 × 50

5 ........................................... M 8 × 80 OM662LA

Page 321 of 1574

1B3-56 OM600 ENGINE MECHANICAL

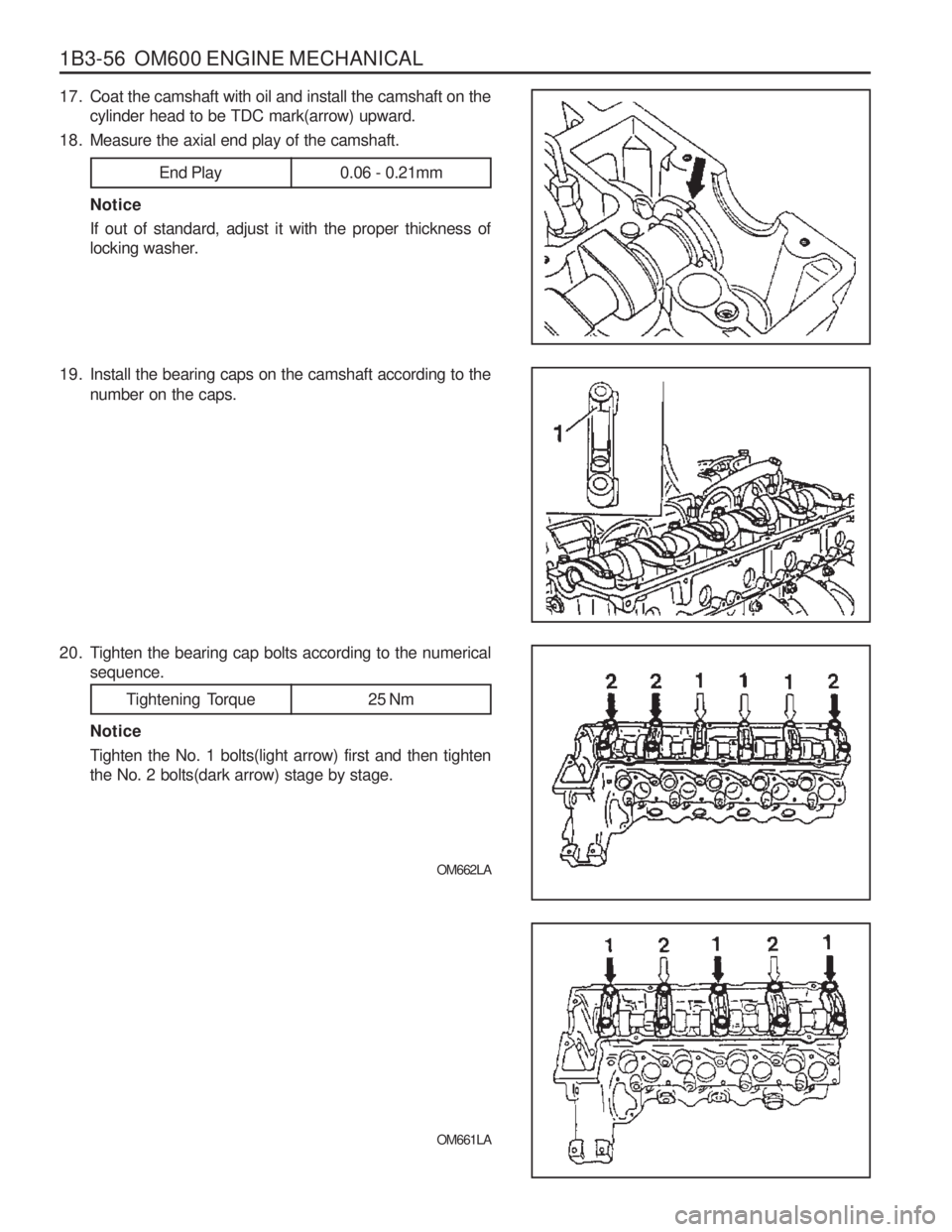

17. Coat the camshaft with oil and install the camshaft on thecylinder head to be TDC mark(arrow) upward.

18. Measure the axial end play of the camshaft.

End Play 0.06 - 0.21mm

Notice If out of standard, adjust it with the proper thickness of

locking washer.

19. Install the bearing caps on the camshaft according to the number on the caps.

20. Tighten the bearing cap bolts according to the numerical sequence.

Tightening Torque 25 Nm

Notice

Tighten the No. 1 bolts(light arrow) first and then tighten the No. 2 bolts(dark arrow) stage by stage.

OM662LA OM661LA

Page 326 of 1574

OM600 ENGINE MECHANICAL 1B3-61

38. Replace the O-ring of heater feed pipe and install it to thecylinder head. NoticeFor installation, clean the hole.

39. Install the bracket of heater feed pipe to the oil filter.

40. Install the fuel pipe and the accelerator control linkage.

41. Connect the fuel lines to the injection nozzles and to the injection pump. Box Wrench Insert 000 589 77 03 00

Tightening Torque 18 Nm

Page 327 of 1574

1B3-62 OM600 ENGINE MECHANICAL

43. By inserting a rod into the tensioning lever upper hole andpulling the rod, install the bolt and then tighten the nut.

44. Install the oil dipstick tube bracket.

Tightening Torque 10 Nm

45. Hold the cooling fan with the counter holder and tighten the bolt.

42. Install the poly V-belt.

Notice Be careful not to contaminate the belt.

Tightening Torque 23 Nm

Page 328 of 1574

OM600 ENGINE MECHANICAL 1B3-63

TIMING CASE COVER

Preceding Work : Removal of the cooling fanRmoval of the V-belt tensioning device Removal of the vibration damper and hub Removal of the alternator

1 Bolt............................................................ 10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt ................................................ 25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt ................................................ 10Nm

9 Bolt .................................................... M6 : 10Nm

M8 : 23Nm 10 Power Steering Pump

11 Bolt

12 Belt Pulley 13 Bolt

............................................................ 32Nm

14 Timing Case Cover

15 Bolt ............................................................ 23Nm

16 Alternator Bracket

17 Bolt ............................................................ 45Nm

18 Bolt ............................................................ 25Nm

19 Bolt ............................................................ 10Nm

20 Closing Cover

21 Socket Bolt ................................................ 23Nm

22 Guide Pulley

23 Bolt .............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut ............................................................. 23Nm

Page 329 of 1574

1B3-64 OM600 ENGINE MECHANICAL

8. Remove the guide pulley bracket (24).

Tools Required

116 589 03 07 00 Socket Wrench Removal Procedure

1. Remove the fan clutch and cooling fan belt pulley.

2. Drain the engine oil completely.

3. Remove the oil dipstick tube bracket bolts.

4. Remove the crankshaft pulley.

5. Loosen the bolt (1) and then remove the cylinder head cover(2) and gasket.

6. Remove the vacuum pump.

7. Detach the closing cover (20). Remove the bolts(21) and then remove the guide pulley (22).

Page 331 of 1574

1B3-66 OM600 ENGINE MECHANICAL

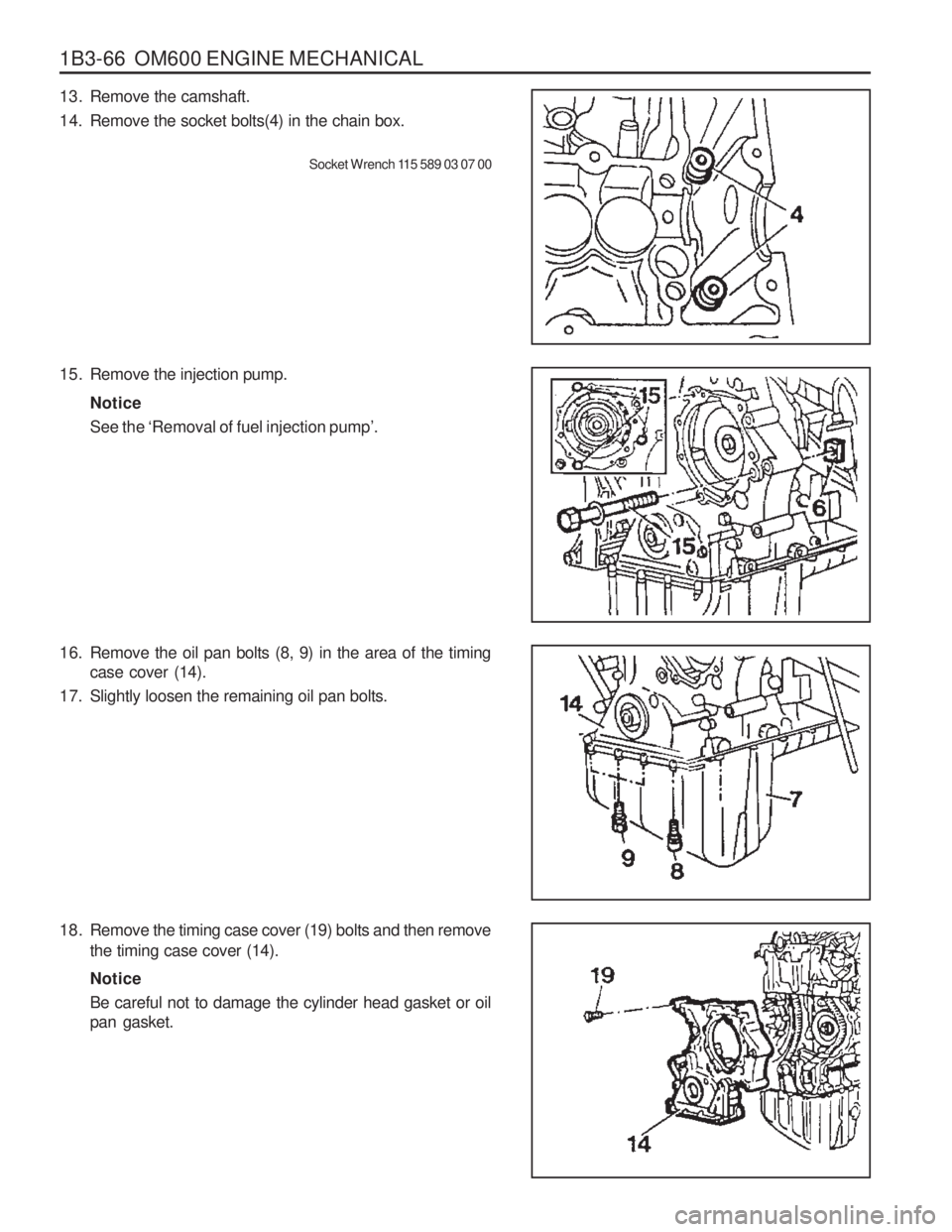

18. Remove the timing case cover (19) bolts and then removethe timing case cover (14). Notice Be careful not to damage the cylinder head gasket or oil pan gasket.

13. Remove the camshaft.

14. Remove the socket bolts(4) in the chain box.

Socket Wrench 115 589 03 07 00

15. Remove the injection pump. NoticeSee the ‘Removal of fuel injection pump ’.

16. Remove the oil pan bolts (8, 9) in the area of the timing case cover (14).

17. Slightly loosen the remaining oil pan bolts.

Page 332 of 1574

OM600 ENGINE MECHANICAL 1B3-67

Installation Procedure

1. Thoroughly clean the sealing surface and apply sealant.

2. Install the timing case cover.Notice Bolts arrangement

1.M6 x 60

2.M6 x 70

3.M6 x 40

3. Tighten the socket bolts in the chain box.

Tightening Torque 10 Nm

Tightening Torque 23 Nm

4. Tighten the oil pan bolts.

Tightening Torque 10 Nm 10 Nm23 Nm

Socket bolt

M6 bolt M8 bolt