sensor SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 848 of 1574

ANTILOCK BRAKE SYSTEM 4F-19

MAINTENANCE AND REPAIRON-VEHICLE SERVICE

WHEEL SPEED SENSOR

1 Bolt

2 Front Wheel Speed Sensor

3 Knuckle 4 Bolt

5 Rear Wheel Speed Sensor

6 Rear Axle

Page 881 of 1574

5A-22 AUTOMATIC TRANSMISSIONCONTROL SYSTEMS

GENERAL

There are two control systems associated with the transmission. The electronic control system monitors vehicle

parameters and adjusts the transmission performance. The hydraulic control system implements the electronic controlsystem commands. ELECTRONIC CONTROL SYSTEM

The electronic control system is comprised of sensors, a TCU and seven solenoids. The TCU reads the inputs, and

under software control activates the outputs according to values stored in read only memory (ROM).

The TCU controls the hydraulic control system. This control is via the hydraulic valve body, which contains seven

electro-magnetic solenoids. Six of the seven solenoids are used to control the line pressure, operate the shift valves

and the torque converter lock-up clutch, and to turn on and off the two regulator valves (The two regulator valvescontrol the shift feel.).

The seventh solenoid is the proportional or variable pressure solenoid (VPS) which works with the two regulator

valves to control shift feel.

Figure 3.1 details a typical TCU control system schematic.

The individual component locations, operation and specifications which make up the electronic control subsystem are covered in this section.

Figure 3.1 - Typical TCU Control System Schematic

Page 883 of 1574

5A-24 AUTOMATIC TRANSMISSION

Transmission Control Unit(TCU)

The TCU is an in-vehicle micro-processor based transmission management system. It is usually mounted in the

vehicle cabin, under the instrument panel, under the seat, behind the side kick panels or under the floor in the

footwell on the passenger side. Different control units are supplied for different vehicle applications.The TCU contains:

� Processing logic circuits which include a central microcontroller and a back-up memory system.

� Input circuits.

� Output circuits which control external devices such as the variable pressure solenoid (VPS), on/off solenoid

drivers, a diagnostics output and the driving mode indicator light.

The various items which make up the TCU are discussed below.

Processing Logic

Shift schedule and calibration information is stored in an erasable programmable read only memory (EEPROM).

Throttle input calibration constants and the diagnostics information are stored in electrically erasable programmable

read only memory (EEPROM) that retains the memory even when power to the TCU is disconnected. In operation the software continuously monitors the input values and uses these, via the shift schedule, to determine the required gear state, At the same time it monitors, via the solenoid outputs, the current gear state. Whenever the

input conditions change such that the required gear state is different to the current gear state, the TCU initiates a

gear shift to bring the two states back into line.

Once the TCU has determined the type of gear shift required the software accesses the shift logic, estimates the

engine torque output, adjusts the variable pressure solenoid ramp pressure then executes the shift.

The TCU continuously monitors every input and output circuit for short or open circuits and operating range. When

a failure or abnormal operation is detected the TCU records the condition code in the diagnostics memory and

implements a limp mode, The actual limp mode used depends upon the failure detected with the object to maintain

maximum driveability without damaging the transmission. In general input failures are handled by providing a default

value. Output failures, which are capable of damaging the transmission, result in full limp mode giving only third or

fourth gear and reverse. For further details of limp modes and memory retention refer to the Diagnostic Section.

The TCU is designed to operate at ambient temperatures between -40 and 85°C . It is also protected against

electrical noise and voltage spikes, however all the usual precautions should be observed, for example when arc welding or jump starting. TCU Inputs

To function correctly, the TCU requires engine speed, road speed, transmission sump temperature, throttle position

and gear position inputs to determine the variable pressure solenoid current ramp and on/off solenoid states. This

ensures the correct gear selection and shift feel for all driving conditions. The inputs required by the TCU are as follows: � Engine Speed

The engine speed signal is derived from the tachometer signal line, a dedicated sensor or a Controlled Area Network (CAN).

� Road Speed

4WD (Diesel) - The shaft speed signal is derived from the speedo sensor located on the transfer case. This signal is transmitted directly to the TCU.

4WD (Gasoline) - The speedo sensor sends the shaft speed signal to the engine control module (ECM). The

information is then transferred to the TCU via the CAN.

� Transmission Sump Temperature

The transmission sump temperature sensor is a thermistor located in the solenoid wiring loom within the transmission.

This sensor is a typical NTC resistor with low temperatures producing a high resistance and high temperatures

Page 884 of 1574

AUTOMATIC TRANSMISSION 5A-25

producing a low resistance.

Temperature/Resistance characteristics and location within the solenoid wiring loom are given in tables 3-1 and 3- 2, and figures 3.2 and 3.3.

If the transmission sump temperature exceeds 135°C, the TCU will impose converter lock-up at lower vehicle

speeds and in some vehicles flashes the mode indicator lamp. This results in maximum oil flow through the

external oil cooler and eliminates slippage in the torque converter. Both these actions combine to reduce the oil

temperature in the transmission.

Connects To

Solenoid 1 Solenoid 2Solenoid 3Solenoid 4Solenoid 5 Solenoid 6 Solenoid 7Solenoid 5

Temp Sensor

Temp SensorWire Color Red

Blue

Yellow

Orange GreenViolet

Brown

Green White WhitePin No.

1 2345 6 789

10

Table 3.2 - Pin No. Codes for Temperature Sensor Location In Solenoid Loom

Figure 3.3 - Temperature Sensor Location in Solenoid Loom

Page 885 of 1574

5A-26 AUTOMATIC TRANSMISSIONInhibitor Switch

Throttle Position SensorThe throttle position sensor(TPS) is a resistance potentiometer mounted on the throttle body of the engine.

It transmits a signal to the TCU proportional to the throttle plate opening. The potentiometer is connected to the TCU by three wires:

5 volts positive supply, earth and variable wiper voltage.Throttle voltage adjustments are as follows:

� Closed throttle voltage is 0.2V to 1.0V.

� Wide open throttle voltage is 3V -4.7V.

These measurements are taken between pins 29 and 27 of the TCU.

Maintaining good shift feel through the transmission life span is dependant on having an accurate measure of

the engine throttle position. To achieve this the TCU

continuously monitors the maximum and minimum throttle

potentiometer voltages and, if a change occurs, stores the new voltage values.

However these limits will be lost and will require relearning

should a new TCU be installed, or the throttle calibration data

is cleared by the execution of a particular sequence, This last

instance depends on the installation, and reference should be

made to the Diagnostics Section of this manual. The relearningwill happen automatically Notice

Above figure of T.P.S. is for the diesel enginewhich is installed on the injection pump.

Gear Position Sensor

The gear position sensor is incorporated in the inhibitor switch mounted on the side of the transmission case.

(Refer to figure 3.5.) The gear position sensor is a multi-function switch providing three functions: � Inhibit starting of the vehicle when the shift lever is in aposition other than Park or Neutral

� Illuminate the reversing lamps when Reverse is

selected indicate to the TCU which lever position has been selected by way of a varying resistance (Refer to

table 3.3.)

Figure 3.5 - Inhibitor Switch

Page 889 of 1574

5A-30 AUTOMATIC TRANSMISSION

Solenoid Valve Symbols (On/off Solenoids)

The solenoid symbol shown adjacent to each solenoid on the

hydraulic system schematics indicates the state of the oil flow

through the solenoid valve with the power On or 0ff. Refer to

figure 3.6 for the On/off operational details of NO solenoidvalves. Normally Open (NO) Solenoid POWER ON

Line 500 port is closed. The output port is open to exhaust at the solenoid valve. POWER OFF

The exhaust port is closed. The output port is open to line 500,Figure 3.6- Normally Open (NO) Symbols

Variable Pressure Solenoid Multiplexing System

Friction element shifting pressures are controlled by the variable pressure solenoid (VPS).

Line pressure is completely independent of shift pressure and is a function of throttle position, gear state and enginespeed.

S5 is a proportional or variable pressure solenoid that provides the signal pressure to the clutch and band regulator

valves thereby controlling shift pressures.

VPS pressure is multiplexed to the clutch regulator valve, the band regulator valve and the converter clutch regulator

valve during automatic gearshifts.

A variable pressure solenoid produces a hydraulic pressure inversely proportional to the current applied. During a

gearshift the TCU applies a progressively increasing or decreasing (ramped) current to the solenoid. Current applied will vary between a minimum of 200 mA and a maximum of 1000 mA, Increasing current decreases output (55)

pressure. Decreasing current increases output (55) pressure.

Line 500 pressure, (approximately 440 to 560 kPa), is the reference pressure for the VPS, and the VPS outputpressure is always below line 500 pressure.

When the VPS is at standby, that is no gearshift is taking place, the VPS current is set to 200 mA giving maximum output pressure.

Under steady state conditions the band and clutch regulator valve solenoids are switched off. This applies full Line

500 pressure to the plunger and because Line 500 pressure is always greater than S5 pressure it squeezes the S5

oil out between the regulator valve and the plunger. The friction elements are then fed oil pressure equal to Line 500multiplied by the amplification ratio.

When a shift is initiated the required On/off solenoid is switched on cutting the supply of Line 500 to the plunger.

At the same time the VPS pressure is reduced to the ramp start value and assumes control of the regulator valve by

pushing the plunger away from the valve. The VPS then carries out the required pressure ramp and the timed shift is

completed by switching Off the On/off solenoid and returning the VPS to the standby pressure.

This system enables either the band or clutch or both to be electrically controlled for each gearshift. Mode Indicator Light

Depending on the application, the mode indicator light may be used to indicate the mode that has been selected or

if an overheat condition exists. The mode indicator light is usually located on the instrument cluster. Communication Systems CAN

The controller area network (CAN) connects various control modules by using a twisted pair of wires, to share

common information. This results in a reduction of sensors and wiring. Typical applications include using the engine

controller to obtain the actual engine speed and throttle position, and adding these to the network. The ABS controller

(if fitted) can be used to obtain the road speed signal. This information is then available to the TCU without anyadditional sensors.

Page 919 of 1574

5A-60 AUTOMATIC TRANSMISSIONDIAGNOSIS

DIAGNOSTIC SYSTEM Recommended T est Equipment and Procedure

The test equipment is designed to be used with the control modules in all vehicles. The components used in the transmission application are: � Multi Function Tester, and

� Appropriate vehicle for testing.

Multi Function Tester (MFT)

The MFT is programmed with the special vehicle diagnostic software that allows selection of the unit under test.

The program allows the proper communication to the Transmission Control Unit (TCU).

It then requests information from the user via a menu system to select the required set up.

Examples are viewing codes, clearing error codes, and real-time operation. Set up and operation instructions are detailed in the user manual.

This equipment can be used by trained personnel such as technicians and mechanics to diagnose electronic and

wiring problems relating to the vehicle transmission. Information that is available includes engine and road (shaft)

speed, transmission oil temperature, throttle position, solenoid/gear status and gear lever position. Current andstored faults detected by the electronics are also available.

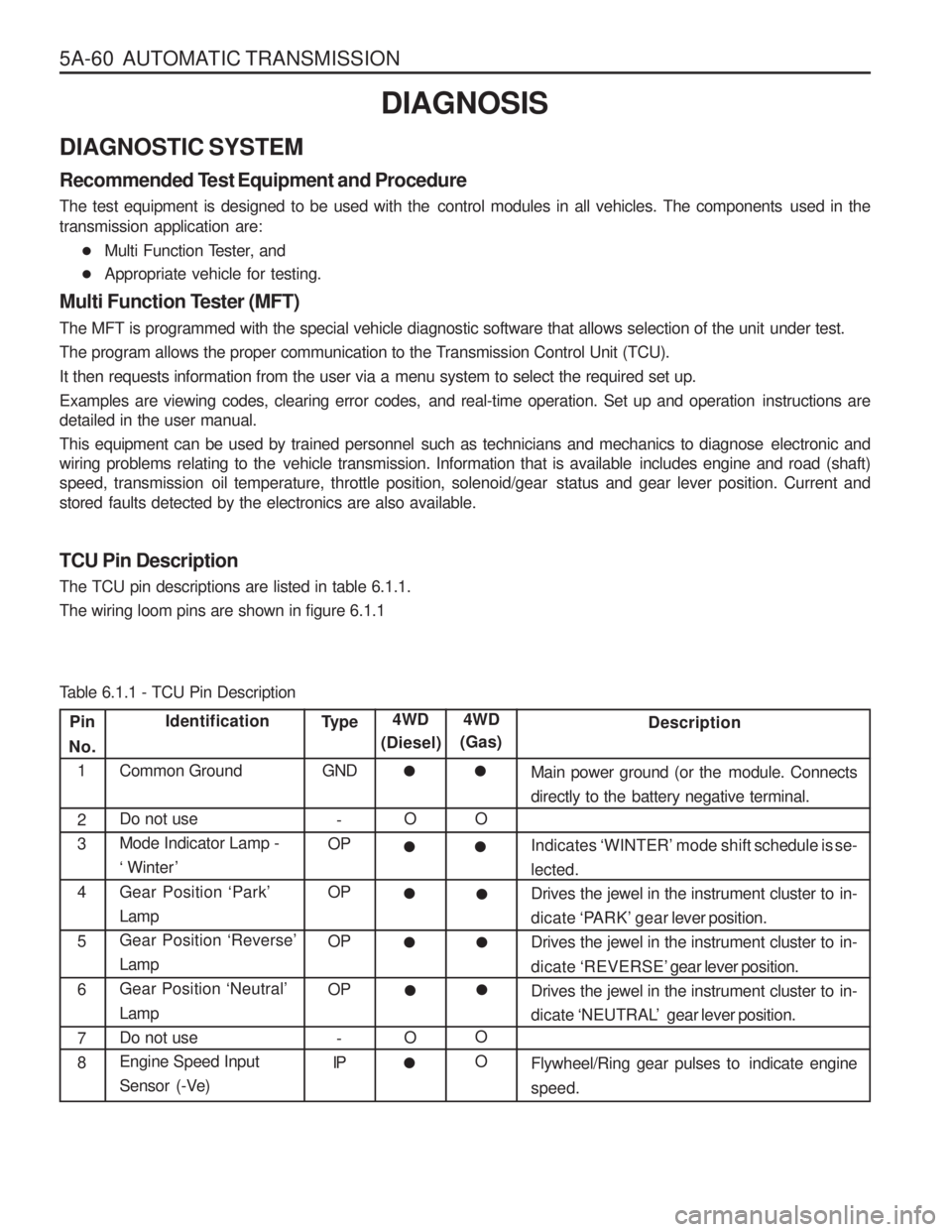

TCU Pin Description The TCU pin descriptions are listed in table 6.1.1. The wiring loom pins are shown in figure 6.1.1

Pin

No. 1 2 3 4 5 6 7 8Identification

Common Ground Do not use Mode Indicator Lamp -‘ Winter ’

Gear Position ‘Park ’

LampGear Position ‘Reverse ’

LampGear Position ‘Neutral ’

LampDo not useEngine Speed Input

Sensor (-Ve) Type

GND -

OP OP OP OP

-

IP Description

Main power ground (or the module. Connects

directly to the battery negative terminal. Indicates ‘WINTER ’ mode shift schedule is se-

lected.

Drives the jewel in the instrument cluster to in-dicate ‘PARK ’ gear lever position.

Drives the jewel in the instrument cluster to in- dicate ‘REVERSE ’ gear lever position.

Drives the jewel in the instrument cluster to in- dicate ‘NEUTRAL ’ gear lever position.

Flywheel/Ring gear pulses to indicate engine speed.

4WD

(Diesel)

O O

�

�

�

�

� 4WD

(Gas)

O O O

�

�

�

�

�

�

Table 6.1.1 - TCU Pin Description

Page 920 of 1574

AUTOMATIC TRANSMISSION 5A-61

Pin

No. 9 10

11

12 13 14 1516 17 1819 20 21 22 2324 25 26 27 28 29 30Identification

Mode Indicator Lamp - ‘ Power ’

Throttle Position Sensor Output as Pulse Width Modulation for TODAir Conditioner Input SignalKickdown Switch Mode Switch

Transfer Case Input (High) -4WD Lamp High Ignition Switch Do not use Gear Position ‘1’ Lamp/

Gear Position Code 1

*Gear Position ‘2’ Lamp/

Gear Position Code 2* Gear Position ‘3’ Lamp/

Gear Position Code 3* Gear Position ‘Drive ’

Lamp/ Gear Position Code 4*CAN (-ve)CAN (+ve) K-line Communication Link Engine Speed InputSensor (+ve)Road Speed Pulses Shaft Speed Sensor SignalThrottle Position Sensor -GroundThrottle Position Sensor - Reference Throttle Position Sensor -Input Signal

Transfer(or Case Input

(Low) - 4WD Lamp Low Type

OP OP

-

IP IP IP IP

-

OPOPOP OP

I/O

I/O

I/O IP

OP

IP

GND

REF IP IP Description

Indicates ‘POWER ’ mode shift schedule is se-

lected.

Provides an analogue signal of the throttle po- sition for the T orque on Demand (T OD) Con-

trol Module. Input

Switch to indicate when a kickdown is required

at high throttle position. Switch to select ‘NORMAL ’, ‘POWER ’ or ‘WIN-

TER ’ shift schedule.

Voltage varies from OV to 12V. Switch to indicate 4WD ’HIGH RANGE ’ is se-

lected.

Ignition power is used as the main power source

to drive the unit and the solenoids.

Drives jewel in the instrument cluster to indi- cate gear leverposition ’1'. Drives jewel in the instru-

ment cluster to indicate gear lever position ’2'. Drives jewel in the instru-

ment cluster to indicate gear lever position’3'.

Drives jewel in the instrument cluster to indi- cate ‘ DRIVE ’. gear lever position.

CAN low side bus communication (CANL).

CAN high side bus communication (CANH).

Diagnostic information and vehicle coding.

Flywheel/Ring gear pulses to indicate engine speed.

Road speed signals derived from shaft speedsensors.

This sensor transmit shaft speed signal to the TCU. Throttle position sensor ground. This is the 5V reference voltage supply gener-

ated by the unit for the throttle position sensor.

This sensor is a resistance potentiometer indi-

cating throttle position.

Voltage varies 0V to 5V.Switch to indicate 4WD ’LOW RANGE ’ is se-

lected.

4WD

(Diesel)

O O O O

�

�

�

4WD

(Gas)

O O O O O O OO

�

�

�

��

��

��

��

��

��

��

��

�

��

�

�

�

�

��

�

Page 921 of 1574

5A-62 AUTOMATIC TRANSMISSION

Identification

Gear Lever Position

Transmission Oil

Temperature Solenoid 4 Solenoid 1 Do not use Solenoid 5Return (-ve) Gear Lever Position - Ground

Transmission Oil

Temperature - Ground Solenoid 6 Solenoid 2 Solenoid 3 Solenoid 7 Do not use Solenoid 5 (+ve) Type

IP IP

OPOP -

IP

GND GND OPOP OP OP -

OP Description

This switch has discreet values indicating the

positions selected by the gear shift lever

(PRNDL). Voltage varies 0V to 5V.

Resistive sensor indicates transmission tem-perature .High R = low temp Low R = high temp

Voltage varies 0V to 5V.

On/Off solenoid normally open, combines with

other On/off solenoid 3 for shift quality and se-quencing.

On/off solenoid normally open, combines with

other On/off solenoid to set the selected gear.

This ensures the earth path for the VPS and

the current in this line is monitored to give feed-

back control of the VPS. PRNDL switch ground. Ground reference for temperature sensor in-

put.

On/Off solenoid normally open, sets low/high line pressure.

On/off solenoid normally open, combines with

other On/off solenoid to set the selected gear.

On/off solenoid normally open, combines with

On/off solenoid 4 for shift quality and sequenc- ing.

On/off solenoid normally open, locks up the

torque converter to Increase cruising efficiency. This is the variable force solenoid which ramps the pressure during gear changes and solenoid

switching, to enhance transmission shift quality.

4WD

(Diesel)

O O

�

� 4WD

(Gas)

O O

�

�

��

��

��

��

Pin

No. 31 32 33 34 35 36 37 38 39 40 41 42 43 44

��

��

��

��

��

��

� = circuit connected

O = circuit not connected

* = unique

OP = Output

IP = Input

I/O = Input/output

GND = Ground

REF = Reference

Notice :

Page 923 of 1574

5A-64 AUTOMATIC TRANSMISSION

Default Transmission Operating Modes

The TCU relies on accurate information from its inputs and complete control of its outputs to effectively control the

transmission. To ensure that it has both valid inputs and functioning outputs, the TCU carries out both hardware and

software fault detection routines. The TCU will respond to any faults detected by adopting the operating modes which

are detailed below.

The following symptoms of faults are the most obvious results of each fault under ‘normal ’ conditions.

There is always the possibility that a fault may not be detected. If undetected fault conditions are present, the

operation of the transmission is difficult to predict.

1 Throttle Fault

� All shifts will occur as if a nominal throttle (approx. 44%) were applied for shift scheduling.

� All shifts will be firm as full throttle and hence high engine torque is assumed.

� The torque converter will be unlocked at all times.

� All downshifts initiated by the shift lever will occur as though they were ‘automatic ’ shifts. That is the engine

braking effect will not occur until near the end of the shift.

� Line pressure will always stay high (solenoid 6 OFF) to cope with assumed high throttle/torque.

If a fault is undetected, the percent throttle is most likely to be interpreted as higher than actual, resulting in late

upshifts, early downshifts, firm shifting and a harsh 3-1 shift when stopping.

2 Throttle Not Learnt Fault

The transmission operates from default throttle calibration values which results in the evaluation of the throttle being

higher (more open) than it is. There(ore at zero throttle settings, the transmission may calculate that sufficient throttle

opening is present to justify high line pressure and switch solenoid 6 to OFF. Other symptoms are:

a. late upshifts and

b. lock-up maintained at zero throttle when the vehicle speed is sufficiently high.

3 Engine Speed Fault � All shifts will be firm because an engine speed corresponding to peak engine torques is assumed.

If a fault is undetected, the engine speed is likely to be interpreted as stalled resulting in soft shifting possibly with an end of shift bump.

4 Vehicle Speed Sensor Fault

� All shifts will be controlled by the shift lever with skip downshifts disabled and downshifts only allowed if the

engine speed is low. Fourth gear will be inhibited.

� The torque converter will be unlocked at all times.

If a fault is undetected, the vehicle is likely to be interpreted as being stationary resulting in first gear operation at all

times. Note that speedometer transducer faults are likely to cause the vehicle ’s speedometer to become inoperative.

5 Gear Lever Fault (Inhibitor/PRNDL Switch) � The gear lever is assumed to be in the Drive position.

� The transmission is limited to 2nd,3rd, and R gears only.

� The rear band will apply at all times when the lever is shifted to P, R or N. (B2 inhibition and reverse lockout

protection is disabled.)

� The torque converter will be unlocked at all times.

� Manually (gear lever) initiated downshifts will not be available.

If a fault is undetected, the gear lever position is likely to be interpreted as being higher than actual. Where Park is the

highest position and Manual 1 is the lowest, the result being the availability of higher gears than selected by the gear

lever.