service SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 1122 of 1574

TRANSFER CASE (TOD) 5D2-33

9 - 16 Vdc 6 - 16 Vdc2 mA1 A 7 A

20 A

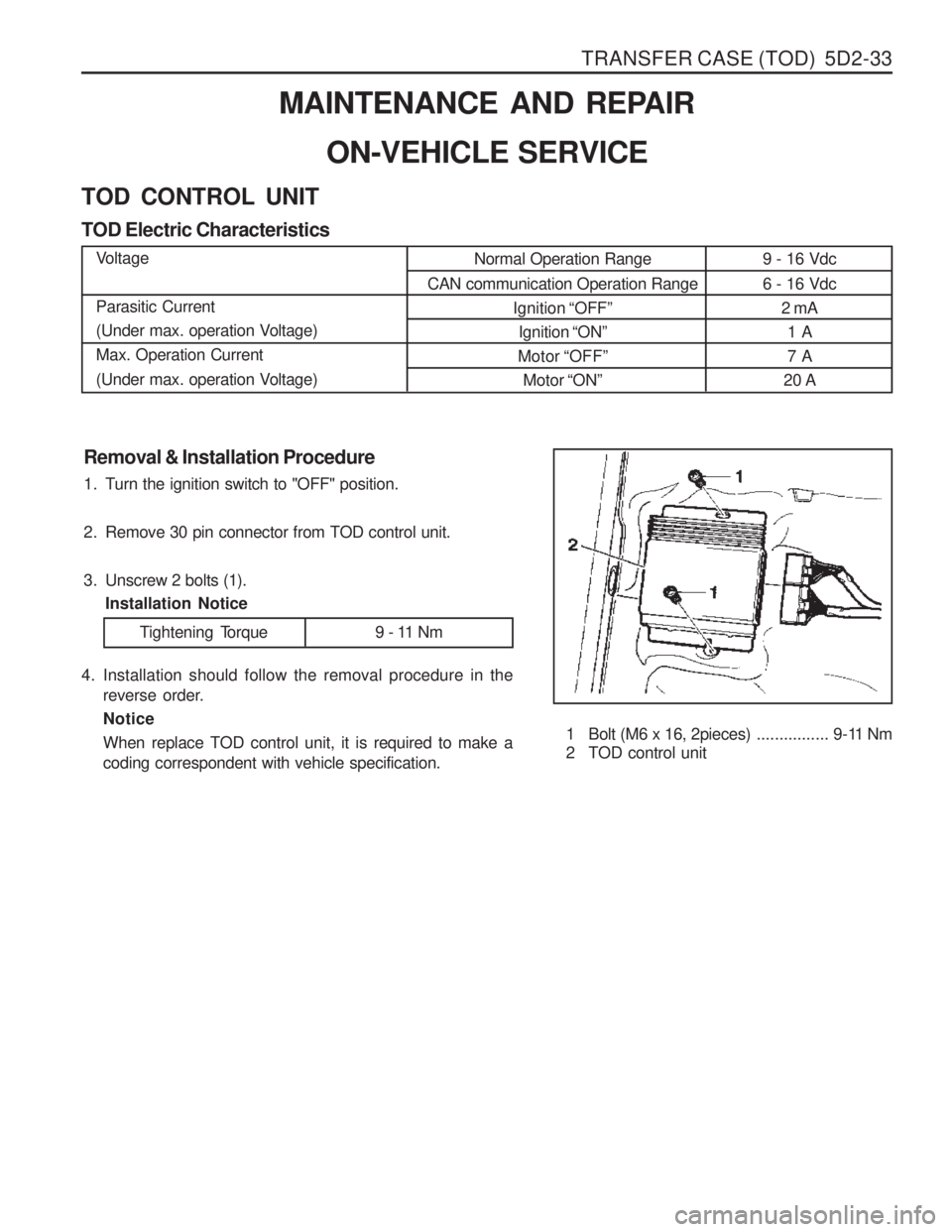

Removal & Installation Procedure

1. Turn the ignition switch to "OFF" position.

2. Remove 30 pin connector from TOD control unit.

3. Unscrew 2 bolts (1). Installation Notice

1 Bolt (M6 x 16, 2pieces)................ 9-11 Nm

2 TOD control unit

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

TOD CONTROL UNIT TOD Electric CharacteristicsVoltage Parasitic Current

(Under max. operation Voltage)Max. Operation Current

(Under max. operation Voltage) Normal Operation Range

CAN communication Operation Range Ignition “OFF ”

Ignition “ON ”

Motor “OFF ”

Motor “ON ”

4. Installation should follow the removal procedure in the

reverse order. Notice When replace TOD control unit, it is required to make a coding correspondent with vehicle specification.

Tightening Torque 9 - 11 Nm

Page 1129 of 1574

5D2-40 TRANSFER CASE (TOD)

REPLACEMENT OF OIL Oil Specification Specified Oil Level

SpecificationStandard

Capacity Service A.T.F S-3, S-4 or Dexron II, III

1.4 Litre

Inspection every 15,000km, Replacement every 50,000km =

Oil Replacement

1. Lift on vehicle then make sure on safety.

2. Prepare a vessel to drain transfer case oil.

3. Release filler plug.

4. Drain oil completely.

5. Wash drain plug and than tighten. Installation Notice

Tightening Torque 19 - 30 Nm

6. Replenish standardized oil by specified level through filler plug hole.

7. Tighten filler plug after washing.

Installation Notice

8. Check oil leakage.

Tightening Torque 19 - 30 Nm

. .

Page 1137 of 1574

5D2-48 TRANSFER CASE (TOD)

6. Install the front planet to the sun gear and input shaft.Install the internal snap ring to the planetary carrier.

7. Place the tanged snap ring in the case. Expand snap ring with snap ring pliers and install planetary carrier assembly. Check installation by holding the case and carefully tappingthe face of the input shaft against a wooden block to makesure the snap ring is installed.

8. Remove all traces of gasket sealant from the front case and mounting adapter mating surfaces. Install a bead ofgasket sealant on the surface of the front case.

9. Install the high-low shift fork and high-low collar as an assembly into the front planet. Notice Make sure that the nylon wear pads are installed on the shift fork and snapped securely into place.

12 Rear Output Shaft

13 Oil Strainer

14 Coupling Hose

15 Hose Clamp

16 Pump Body

10. If new pump is used, align the flat of the output shaft and

the flat of the pump. Slide the pump onto the output shaft.

�Do not disassemble oil pump. It is serviced only as an

assembly. Check the pump to make sure the pump

rotates freely.

� Do not remove the plastic insert from the bore of the

new pump. Discard it after it slides out during pumpinstallation to the rear output shaft.

� While turning the output shaft, prime the pump through

the oil filter pickup tube or housing inlet hole with clean

Automatic Transmission Fluid or equivalent.

11. Inspect the outside surfaces and bore of the oil pump. If there is no discoloration in the pump housing, gear or cover,and the pump bore and the lube holes of the output shaft show evidence of oil, the pump is working.

Page 1143 of 1574

Application

Steering Wheel Steering Gear Box Oil Pump Steering Column

Minmum Turning Radius Oil SECTION 6A

POWER STEERING SYSTEM

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 6A-1

General Specifications . . . . . . . . . . . . . . . . . . 6A-1

Fastener Tightening Specifications . . . . . . . . . 6A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Hard Steering . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Steering Pulls to One Side . . . . . . . . . . . . . . . 6A-2

Excessive Wheel Play . . . . . . . . . . . . . . . . . . . 6A-2

Poor Return of Steering Wheel . . . . . . . . . . . . 6A-2

Steering Wheel Shimmy . . . . . . . . . . . . . . . . . 6A-3

SPECIFICATIONS

GENERAL SPECIFICATIONS Abnormal Noise From Steering System . . . . . 6A-3

Component Locator . . . . . . . . . . . . . . . . . . . 6A-4

Steering System . . . . . . . . . . . . . . . . . . . . . . . 6A-4

Maintenance and Repair . . . . . . . . . . . . . . . 6A-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 6A-5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-5

Oil Pump Pressure Check . . . . . . . . . . . . . . . . 6A-6

Bleeding of Power Steering System . . . . . . . . 6A-6

Steering Gear Box . . . . . . . . . . . . . . . . . . . . . 6A-7

Number of Spoke Outer Diameter

Type Gear Ratio Inner Steering AngleOuter Steering Angle

TypeMaximum Pressure

Upper Tilting Angle

Lower Tilting Angle

Type Capacity Change Interval

Description

4

396 mm

Rack and Pinion

�

33°37'

31°50' Vane

75-82 kg/cm 2

4.646° 6.969°

5.25m

ATF DEXRON II

1 L

Every 24,000 km

FASTENER TIGHTENING SPECIFICATIONS

Application

Steering Shaft Bolt Pressure Hose BoltReturn Pipe Nut Slotted Nut Steering Gearbox Bolt

N �m

30 - 40 12 - 1812 - 1835 - 45 35 - 45

Page 1147 of 1574

POWER STEERING SYSTEM 6A-5

MAINTENANCE AND REPAIR ON-VEHICLE SERVICE INSPECTION Steering Wheel Freeplay Inspection Procedure

1. Start the engine and set the wheels in straight ahead position.

2. Slightly move the steering wheel to the left and right andmeasure steering wheel free play when the front wheel is

start to move. Notice

If exceeds specification, the steering column shaft

connections and steering linkage .clearance. Replace orrepair if necessary.

Steering Angle Inspection Procedure

1. Place the front wheel on a measuring tool.

2. Rotate steering wheel all the way right and left and measure steering angle Notice If out of standard, check or adjust toe-in.

Standard 33°37'

31°50'Inner

Outer

Steering Effort Inspection Procedure

1 Place a vehicle on the paved flat ground with front wheels in a straight ahead position.

2 Start the engine and run it at 1,000rpm.

3 Using a scale, measure the steering effort in both directions.

NoticeThe difference in steering effort of left and right should be within 0.6 kg.

Standard Max. 3.0kg

StandardMax. 30mm

Page 1152 of 1574

SECTION 6E

STEERING WHEEL AND COLUMN

TABLE OF CONTENTS

Specification . . . . . . . . . . . . . . . . . . . . . . . . 6E-1

Fastener Tightening Specifications . . . . . . . . . 6E-1

Maintenance and Repair . . . . . . . . . . . . . . . 6E-2

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Steering Wheel Mounting Nut Steering Lower Shaft BoltSteering Column Shaft Bolt Steering Column Mounting Bolt

N �m

50 - 80 30 - 40

9 - 14

15 - 20

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . 6E-2

Steering Column . . . . . . . . . . . . . . . . . . . . . . . 6E-2

Page 1153 of 1574

6E-2 STEERING WHEEL AND COLUMNMAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

STEERING COLUMN

1 Horn Pad

2 Nut ....................................................... 50-80 Nm

3 Washer

4 Steering Wheel

5 Combination Switch Assembly

6 Combination Switch Lower Cover

7 Combination Switch Upper Cover

8 Bolt

9 Bolt

10 Bolt

11 Crash Pad Panel

12 Bolt ...................................................... 30-40 Nm

13 Spring Washer

14 Steering Column Shaft

15 Bolt ........................................................ 9-14 Nm

16 Bolt ...................................................... 13-40 Nm

17 Column & Shaft Assembly

Page 1157 of 1574

SECTION 7D

FULL AUTOMATIC TEMPERATURECONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 7D-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 7D-1

Service Specifications . . . . . . . . . . . . . . . . . . . 7D-3

Schematic and Routing Diagrams . . . . . . . . 7D-4

Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . 7D-4

FATC Block Diagram . . . . . . . . . . . . . . . . . . . . 7D-5

Component Locator . . . . . . . . . . . . . . . . . . . 7D-6 TABLE OF CONTENTS

Ventilation System . . . . . . . . . . . . . . . . . . . . . . 7D-6

Function Description . . . . . . . . . . . . . . . . . . . . 7D-7

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 7D-8

Diagnosis Test . . . . . . . . . . . . . . . . . . . . . . . . 7D-8

Maintenance and Repair . . . . . . . . . . . . . . 7D-11 FATC Control Panel . . . . . . . . . . . . . . . . . . . 7D-11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 7D-15

FATC (Full Automatic Temperature Control) is full automatic heater and airconditioning system that detects incar temperature, ambient temperature, sun load and coolant temperature and controls airconditioner system

blowing capacity, outlet temperature and intaking/outlet mode to maintain interior comfort.

SPECIFICATIONSSPECIFICATIONS

Application

Core Size (LxWxT)

Core Type

Expansion Valve Type Thermostat

Resister TypeCooling Capacity Description

237.0x232.0x92.0 Aluminum plate

Angle

ON:4.5±0.6 °C, OFF:1.5±0.6 °C

Aluminum plate

4,500 Kcal/h(AT 420 CMH)

Evaporator Unit

Application

Capacity

Type Description

650-750 g R134a

Refrigerant

Page 1159 of 1574

FATC-HAVC 7D-3

SERVICE SPECIFICATIONSResistance (25 °C)

Voltage Rating Current RatingResistance (25 °C)

Voltage Rating Current Rating Resistance (25 °C)

Voltage RatingCurrent Rating

Application

Incar Sensor Ambient Sensor

Coolant Temperature Sensor

Description

Input Section

2.186k

�±0.07k �

5V

3mA

1.0k �±0.03k �

5V

3mA

0.55k �±0.02k �

5V

3mA

Current Rating (at 12V) LOCK CurrentCurrent Rating (at 12V)LOCK CurrentCurrent Rating (at 12V) LOCK Current IcPc

Application

Intake Actuator Mode Actuator Mix Actuator Power TRBlower Motor Power Consumption

Description

Output Section

70±30mA

Less than 500mA 100±40mA

Less than 500mA 100±40mA

Less than 500mA 30A

200W 220W

Page 1171 of 1574

FATC-HAVC 7D-15

TROUBLESHOOTING Check and Service Incar sensor is a sensor that detects interior air temperature and a thermistor that decreases its resistance when temperature up and increases when temperature down.

1. Check that there are incar sensor fault code (11,12) by using self-diagnosis function.

2. Disconnect incar sensor 2-pin connector that installed on

inner lower instrument panel cover of driver ’s side and

remove the sensor.

3. Check that measured resistance value among incar sensor terminals is as shown in the right side graph. Notice Measure resistance value by soaking the sensor in the ice water and check changes in resistance values after soaking

it in the very hot water.

4. If resistance value is out of specification, replace the incar sensor.

5. Install the sensor and turn the ignition switch to ON position and check that voltage between No. 12A terminal of incar

sensor and body (-) is 5V.

6. Check current between the No. 12B and 12A connector terminals of the incar sensor and the No. 1 and 5 connector terminals of the airconditioner control unit and repair the wire if defective.