oil SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 328 of 1574

OM600 ENGINE MECHANICAL 1B3-63

TIMING CASE COVER

Preceding Work : Removal of the cooling fanRmoval of the V-belt tensioning device Removal of the vibration damper and hub Removal of the alternator

1 Bolt............................................................ 10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt ................................................ 25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt ................................................ 10Nm

9 Bolt .................................................... M6 : 10Nm

M8 : 23Nm 10 Power Steering Pump

11 Bolt

12 Belt Pulley 13 Bolt

............................................................ 32Nm

14 Timing Case Cover

15 Bolt ............................................................ 23Nm

16 Alternator Bracket

17 Bolt ............................................................ 45Nm

18 Bolt ............................................................ 25Nm

19 Bolt ............................................................ 10Nm

20 Closing Cover

21 Socket Bolt ................................................ 23Nm

22 Guide Pulley

23 Bolt .............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut ............................................................. 23Nm

Page 329 of 1574

1B3-64 OM600 ENGINE MECHANICAL

8. Remove the guide pulley bracket (24).

Tools Required

116 589 03 07 00 Socket Wrench Removal Procedure

1. Remove the fan clutch and cooling fan belt pulley.

2. Drain the engine oil completely.

3. Remove the oil dipstick tube bracket bolts.

4. Remove the crankshaft pulley.

5. Loosen the bolt (1) and then remove the cylinder head cover(2) and gasket.

6. Remove the vacuum pump.

7. Detach the closing cover (20). Remove the bolts(21) and then remove the guide pulley (22).

Page 331 of 1574

1B3-66 OM600 ENGINE MECHANICAL

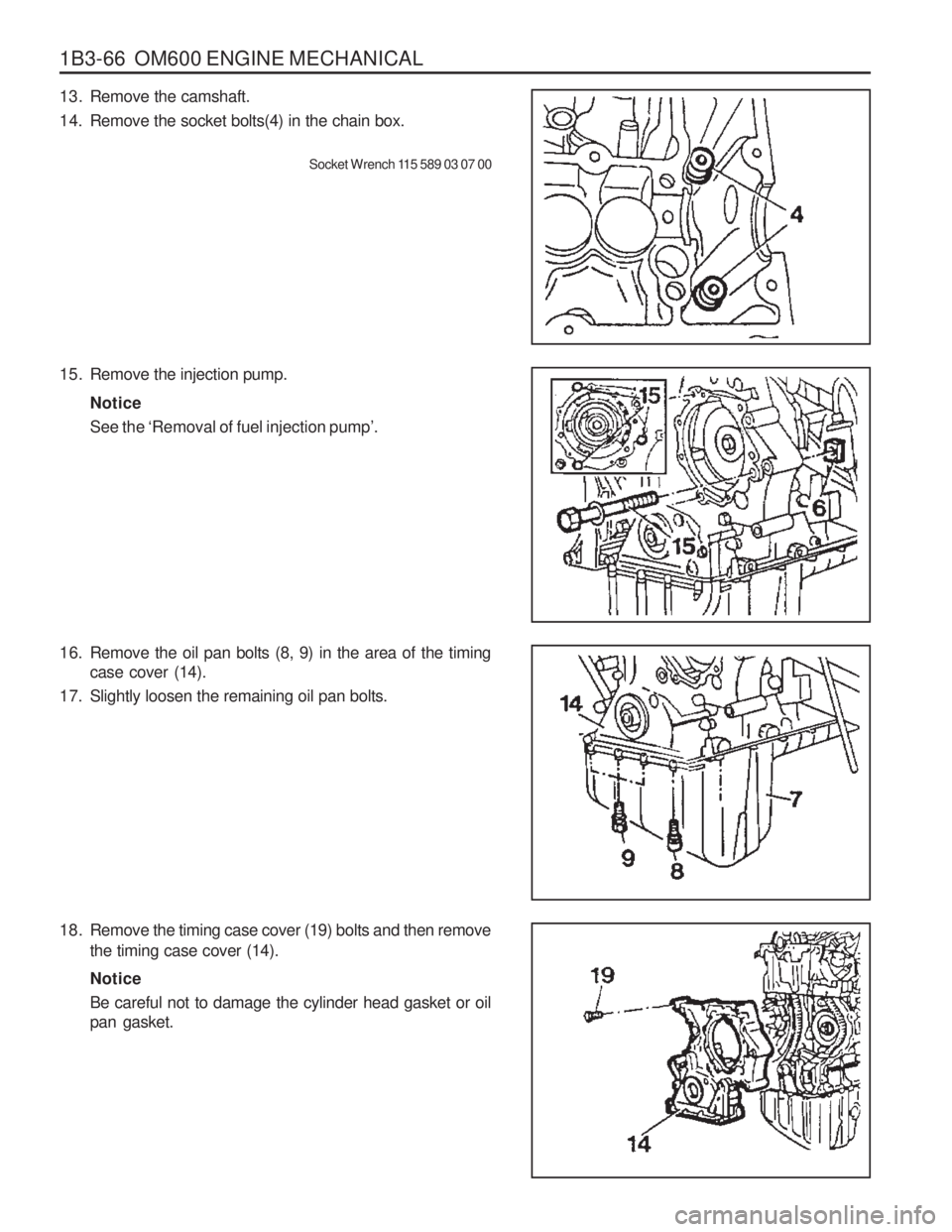

18. Remove the timing case cover (19) bolts and then removethe timing case cover (14). Notice Be careful not to damage the cylinder head gasket or oil pan gasket.

13. Remove the camshaft.

14. Remove the socket bolts(4) in the chain box.

Socket Wrench 115 589 03 07 00

15. Remove the injection pump. NoticeSee the ‘Removal of fuel injection pump ’.

16. Remove the oil pan bolts (8, 9) in the area of the timing case cover (14).

17. Slightly loosen the remaining oil pan bolts.

Page 332 of 1574

OM600 ENGINE MECHANICAL 1B3-67

Installation Procedure

1. Thoroughly clean the sealing surface and apply sealant.

2. Install the timing case cover.Notice Bolts arrangement

1.M6 x 60

2.M6 x 70

3.M6 x 40

3. Tighten the socket bolts in the chain box.

Tightening Torque 10 Nm

Tightening Torque 23 Nm

4. Tighten the oil pan bolts.

Tightening Torque 10 Nm 10 Nm23 Nm

Socket bolt

M6 bolt M8 bolt

Page 335 of 1574

1B3-70 OM600 ENGINE MECHANICAL

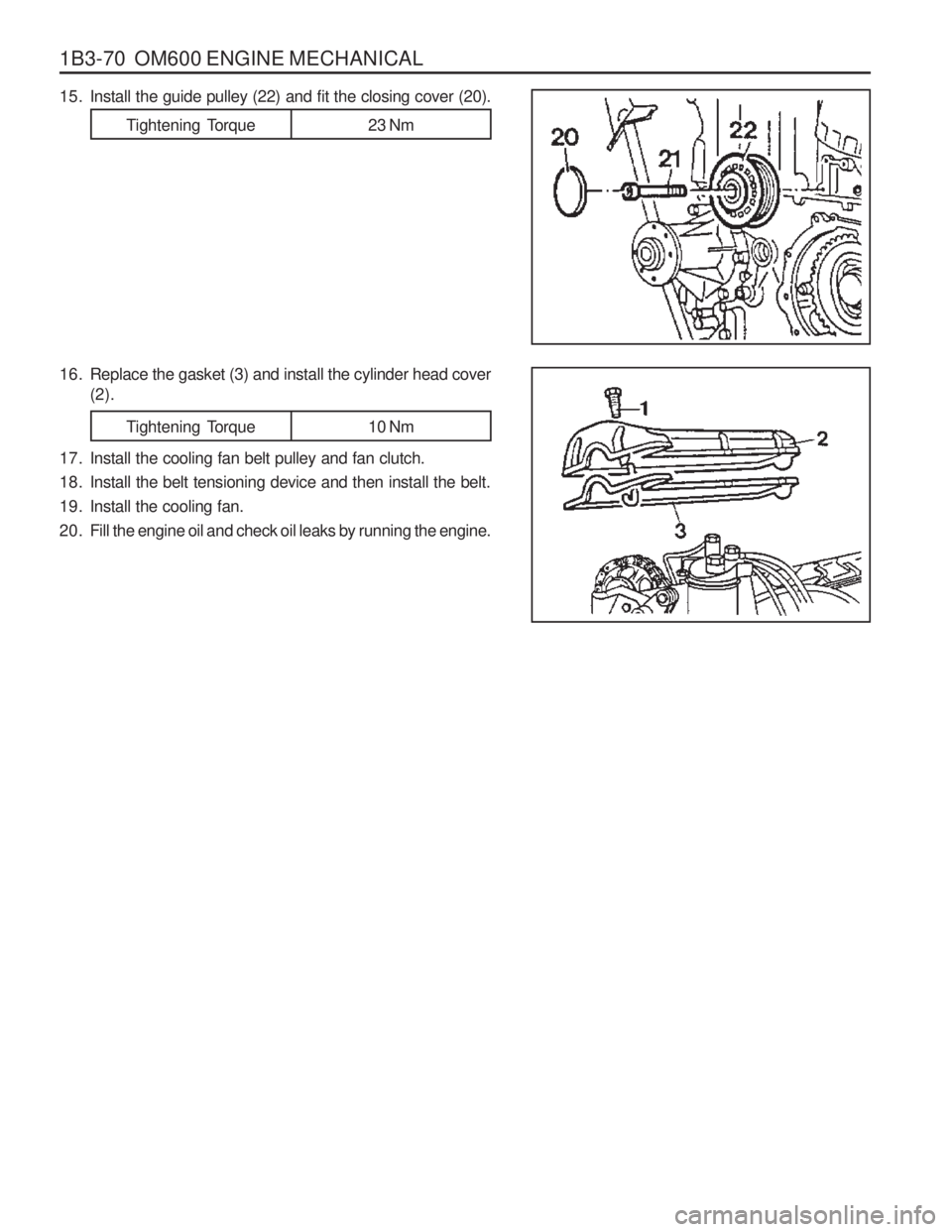

15. Install the guide pulley (22) and fit the closing cover (20).

16. Replace the gasket (3) and install the cylinder head cover(2).

17. Install the cooling fan belt pulley and fan clutch.

18. Install the belt tensioning device and then install the belt.

19. Install the cooling fan.

20. Fill the engine oil and check oil leaks by running the engine.

Tightening Torque 23 Nm

Tightening Torque 10 Nm

Page 337 of 1574

1B3-72 OM600 ENGINE MECHANICAL

Tools Required 601 589 03 43 00 Oil Seal Assmbler Removal Procedure

1. Remove the bolts (3, 6) from end cover, By pulling out thelugs (arrow), remove the cover. Notice Be careful not to damage the oil pan gasket.

2. Remove the radial seal (4) with care not to damage the sealing surface.

Installation Procedure

1. Thoroughly clean the sealing surface of end cover and applyLoctite 573.

2. Clean the groove of radial seal.

3. Apply Loctite 573 on the bolts and install the end cover.

Tightening Torque 10 Nm

Notice Be careful not to damage the oil pan gasket.

4. Install the inner oil seal assembler to the crankshaft flange.

Oil Seal Assembler 601 589 03 43 00

Page 338 of 1574

OM600 ENGINE MECHANICAL 1B3-73

Notice The sealing lip of the repair radial seal is offset to the inside by 3mm to ensure that it does not run in any groove whichthe standard radial seal may have left on the crankshaftflange.

7. Install the outer oil seal assembler on he seal and by tightening the bolts, press the radial seal into the end coveras far as the stop. Notice The seal must be positioned exactly at right angles in the end cover to ensure that it provides a proper seal.

Oil Seal Assembler 601 589 03 43 00 A Standard Radial Seal

B Repair Radial Seal

5. Coat a little oil on the sealing lip of new radial seal and

contacting surface. Notice Don ’t use grease.

6. Insert the new radial seal (4) onto the oil seal assembler (7).

Page 339 of 1574

1B3-74 OM600 ENGINE MECHANICAL

VIBRATION DAMPER AND HUB

Preceding Work : Removal of the cooling fanRemoval of poly V-belt

1 Bolt............................................................ 10Nm

2 Cooling Fan Belt Pulley

3 Socket Bolt ................................................ 23Nm

4 Crankshaft Belt Pulley

5 Vibration Damper 6 Bolt

................................................ 200Nm + 90 °

7 Washer

8 Straight Pin

9 Hub

10 Oil Pan

Page 346 of 1574

OM600 ENGINE MECHANICAL 1B3-81

Notice The sealing lip of the repair radial seal is offset to the inside by 2mm to ensure that is does not run in any groove which the standard radial seal may have left on the crankshaft flange.A Standard Radial SealB Repair Radial Seal

Replacement Procedure

1. Pull out the radial seal (1) and be careful not to damage the sealing surface of timing case cover.

2. Thoroughly clean the mounting bore of the radial seal.

3. Coat a little oil on the sealing lip of new radial (1) and contact surface. Notice Don ’t use grease.

4. Install the radial seal (1) by using a sleeve (4).

NoticeAlign the groove of sleeve and woodruff key(arrow).

Sleeve 601 589 03 14

Page 354 of 1574

OM600 ENGINE MECHANICAL 1B3-89

14. Measure crankshaft bearing journal diameter (F).Notice When measured in A and B, the runout should not exceed 0.010mm.

8. Thoroughly clean the oil gallery.

9. Select a proper new bearing shells with reference to table.

10. Coat the new bearing shells with oil and insert into the crankcase and into the crankshaft bearing caps. Notice Do not mix up upper and lower crankshaft bearing shells.

11. Install the bearing caps according to marking and tighten the 12-sided stretch bolts.

Tightening Torque 35 - 40 Nm

Notice No. 1 is vibration damper side.

12. Measure crankshaft bearing diameters (E).

Extension 366 589 00 21 05

13. Measure at 3 points (A, B and C) and if the average value of B and C is less than A ’s value, the average value of B

and C is the mean value and if more than A ’s value, A ’ s

value is the mean value.