radiator SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 4 of 1574

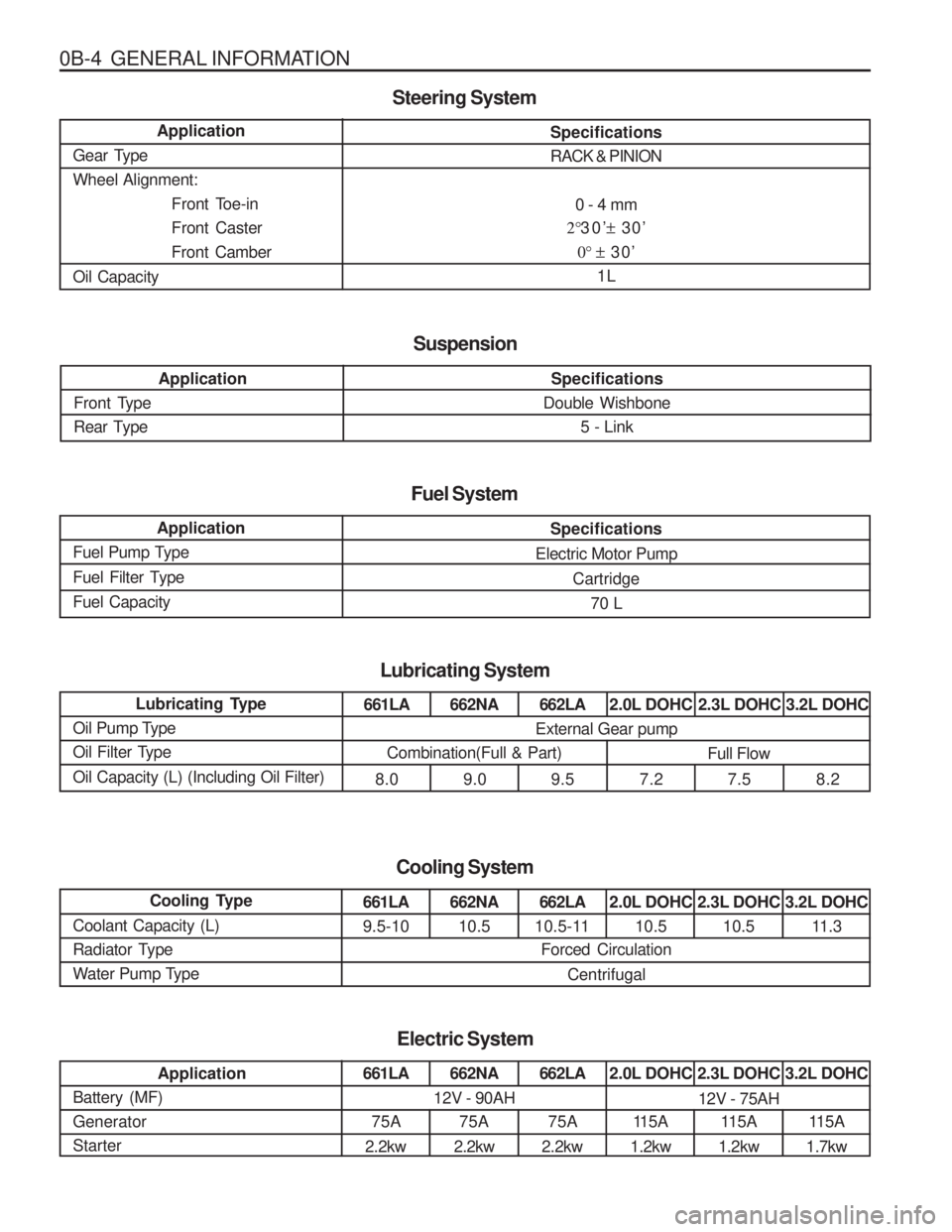

0B-4 GENERAL INFORMATIONSpecifications RACK & PINION0 - 4 mm

2° 30’ ± 30’

0° ± 30’

1L

Application

Gear TypeWheel Alignment: Front Toe-inFront CasterFront Camber

Oil Capacity

Steering System

Application

Front Type

Rear Type

Suspension

Specifications

Double Wishbone

5 - Link

Application

Fuel Pump Type

Fuel Filter TypeFuel Capacity

Specifications

Electric Motor Pump Cartridge70 L

Fuel System

Lubricating Type

Oil Pump Type

Oil Filter Type Oil Capacity (L) (Including Oil Filter)

Lubricating System

661LA

8.0662NA 9.0 662LA

9.5 2.0L DOHC

7.2 2.3L DOHC

7.5 3.2L DOHC

8.2

External Gear pump

Combination(Full & Part) Full Flow

Cooling Type

Coolant Capacity (L)

Radiator Type

Water Pump Type

Cooling System

661LA 9.5-10662NA 10.5 662LA

10.5-11 2.0L DOHC

10.5 2.3L DOHC

10.5 3.2L DOHC

11.3

Forced Circulation

Centrifugal

Application

Battery (MF) GeneratorStarter

Electric System

661LA

75A

2.2kw662NA

75A

2.2kw 662LA

75A

2.2kw 2.0L DOHC

11 5 A

1.2kw 2.3L DOHC

115A

1.2kw 3.2L DOHC

115A

1.7kw

12V - 90AH12V - 75AH

Page 13 of 1574

GENERAL INFORMATION 0B-13

Weather-Strip Lubrication Apply a thin film silicone grease using a clean cloth. EACH TIME THE OIL IS CHANGED Brake System Inspection This inspection should be done when the wheels are removed for rotation. Inspect the lines and the hoses for proper hookup, binding, leaks, cracks, chafing, etc.

Inspect the disc brake pads for wear. Inspect the rotors for surface condition. Inspect other brake parts, theparking brake, etc., at the same time. Inspect the brakes more often if habit or conditions result in frequent braking. Steering, Suspension and Front Drive Axle Boot And Seal Inspection Inspect the front and rear suspension and the steering system for damaged, loose or missing parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for proper hookup, binding, leaks, cracks, chafing, etc. Clean and inspect the drive axle boot and seals for damage, tears or leakage. Replace

the seals if necessary. Exhaust System Inspection Inspect the complete system (including the catalytic converter if equipped). Inspect the body near the exhaustsystem. Look for broken, damaged, missing, or out-of- position parts as well as open seams, holes, loose connections, or other conditions which could cause heat buildup in the floor pan or could let exhaust fumes seep into the trunk or passenger compartment. Throttle Linkage Inspection Inspect the throttle linkage for interference or binding, damaged, or missing parts. Lubricate all linkage joints and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and the accelerator pedal sliding face with suitable grease. Check the throttle cable for free movements. Engine Drive Belts Inspect all belts for cracks, fraying, wear and proper tension. Adjust or replace the belts as needed. Hood Latch Operation When opening the hood, note the operation of the secondary latch. It should keep the hood from opening all the way when the primary latch is released. The hood

must close firmly. AT LEAST ANNUALLY Lap and Shoulder Belts Condition and Operation Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops and the anchors. Movable Head Restraint Operation On vehicles with movable head restraints, the restraints must stay in the desired position. Spare Tire and Jack Storage Be alert to rattles in the rear of the vehicle. The spare tire, all the jacking equipment, and the tools must besecurely stowed at all times. Oil the jack ratchet or the screw mechanism after each use. Key Lock Service

Lubricate the key lock cylinder. Body Lubrication Service Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the latches, the glove box and the console doors, and anyfolding seat hardware. Underbody Flushing Flushing the underbody will remove any corrosive materials used for ice and snow removal and dust control.

At least every spring clean the underbody. First, loosen the sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water. Engine Cooling System Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling system with new coolant. Keep the coolant at the propermixture in order to ensure proper freeze protection, corrosion protection and engine operating temperature. Inspect the hoses. Replace the cracked, swollen, or

deteriorated hoses. Tighten the clamps. Clean the outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure test the cooling system and the cap in order to help ensure proper operation.

Page 38 of 1574

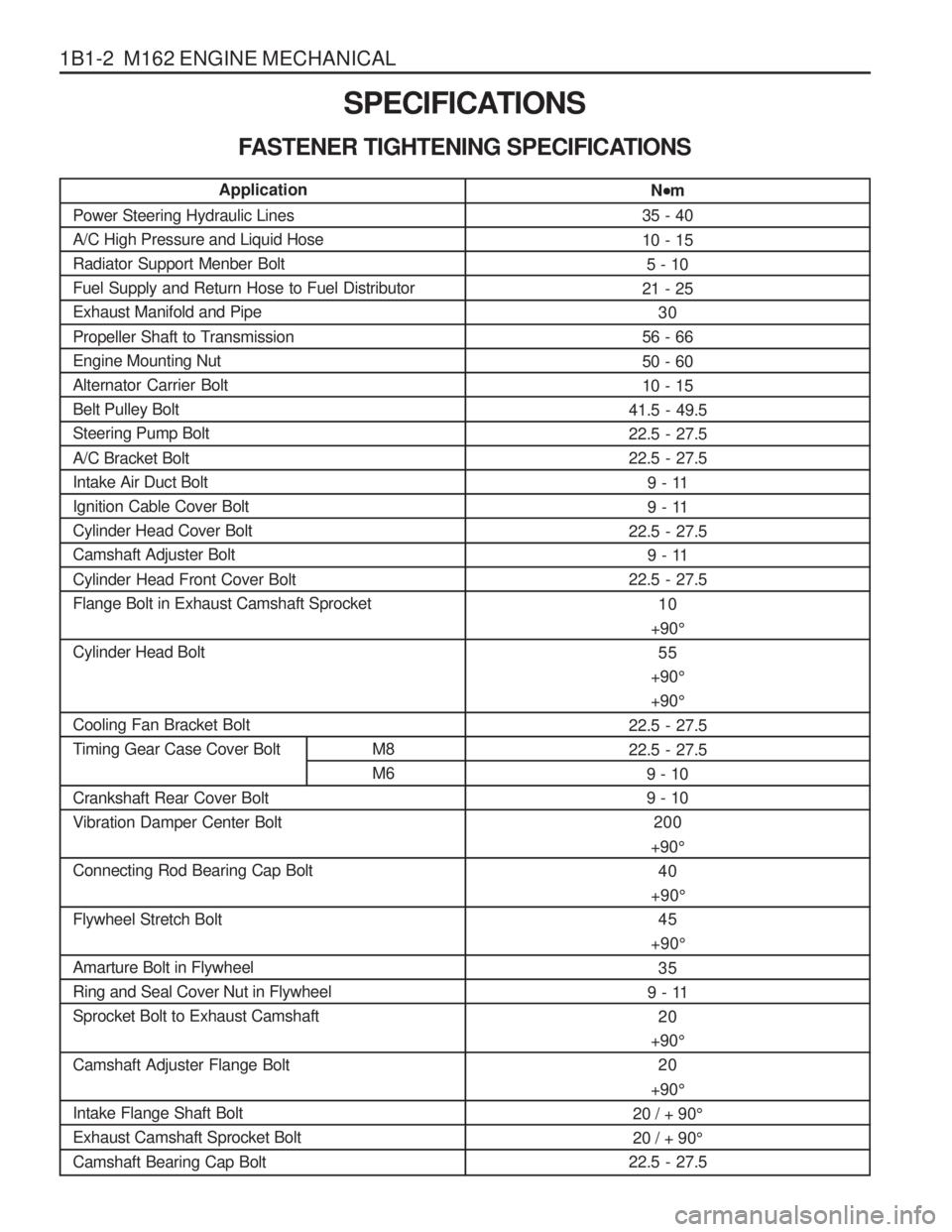

1B1-2 M162 ENGINE MECHANICALSPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS N

m

35 - 40 10 - 15 5 - 10

21 - 25 30

56 - 6650 - 60 10 - 15

41.5 - 49.522.5 - 27.522.5 - 27.5

9 - 11

9 - 11

22.5 - 27.5

9 - 11

22.5 - 27.5

10

+90 °

55

+90 °

+90 °

22.5 - 27.522.5 - 27.5 9 - 109 - 10200

+90 °

40

+90 °

45

+90 °

35

9 - 11 20

+90 °

20

+90 °

20 / + 90 °

20 / + 90 °

22.5 - 27.5

Application

Power Steering Hydraulic Lines A/C High Pressure and Liquid HoseRadiator Support Menber BoltFuel Supply and Return Hose to Fuel DistributorExhaust Manifold and Pipe

Propeller Shaft to Transmission Engine Mounting NutAlternator Carrier BoltBelt Pulley BoltSteering Pump Bolt A/C Bracket Bolt Intake Air Duct BoltIgnition Cable Cover BoltCylinder Head Cover BoltCamshaft Adjuster Bolt Cylinder Head Front Cover Bolt Flange Bolt in Exhaust Camshaft Sprocket Cylinder Head Bolt Cooling Fan Bracket Bolt

Timing Gear Case Cover Bolt M8 M6

Crankshaft Rear Cover BoltVibration Damper Center Bolt Connecting Rod Bearing Cap Bolt Flywheel Stretch Bolt Amarture Bolt in Flywheel Ring and Seal Cover Nut in FlywheelSprocket Bolt to Exhaust Camshaft Camshaft Adjuster Flange Bolt Intake Flange Shaft Bolt Exhaust Camshaft Sprocket Bolt Camshaft Bearing Cap Bolt

Page 40 of 1574

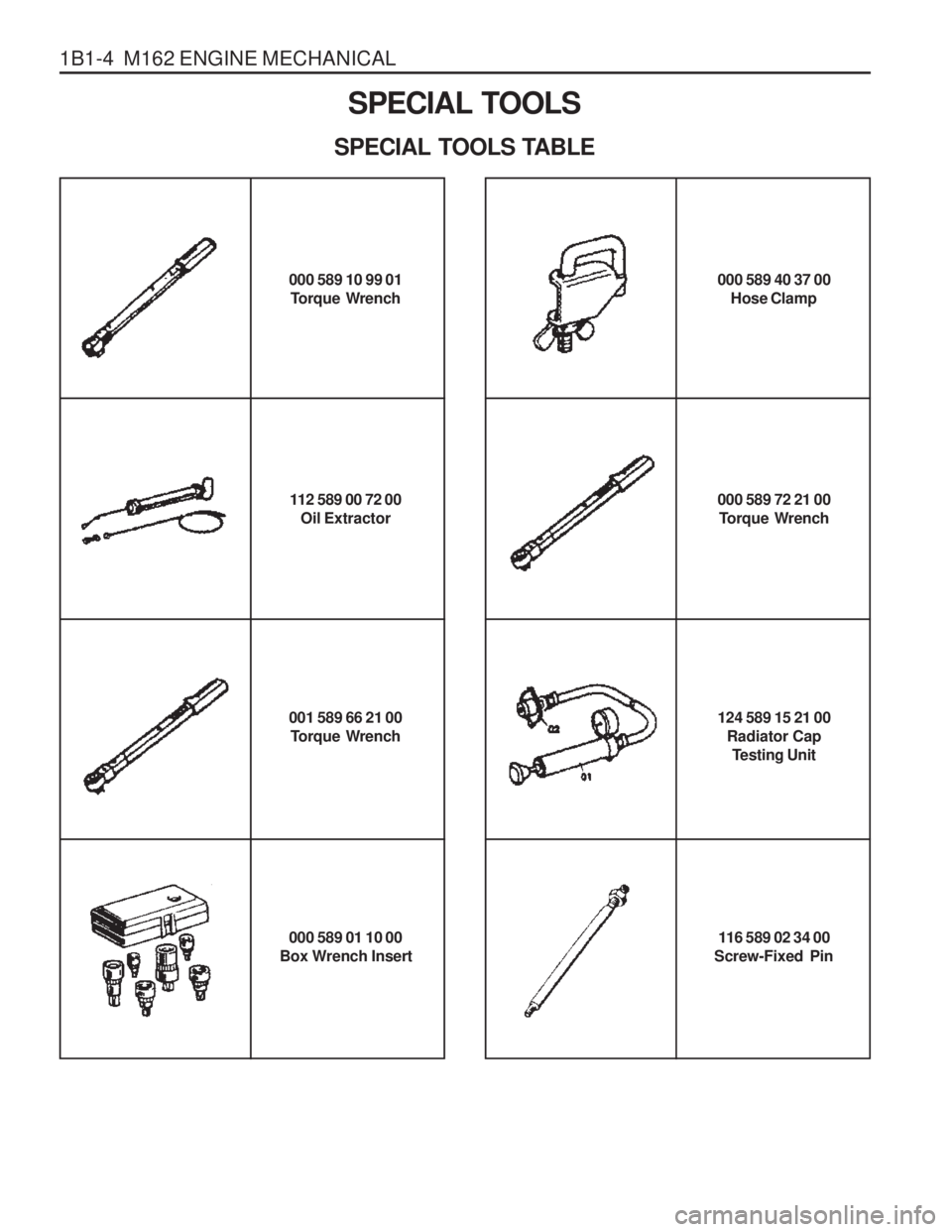

1B1-4 M162 ENGINE MECHANICALSPECIAL TOOLS

SPECIAL TOOLS TABLE

001 589 66 21 00 Torque Wrench

000 589 01 10 00

Box Wrench Insert 124 589 15 21 00

Radiator CapTesting Unit

116 589 02 34 00

Screw-Fixed Pin

000 589 10 99 01 Torque Wrench

112 589 00 72 00 Oil Extractor 000 589 72 21 00

Torque Wrench

000 589 40 37 00

Hose Clamp

Page 45 of 1574

M162 ENGINE MECHANICAL 1B1-9

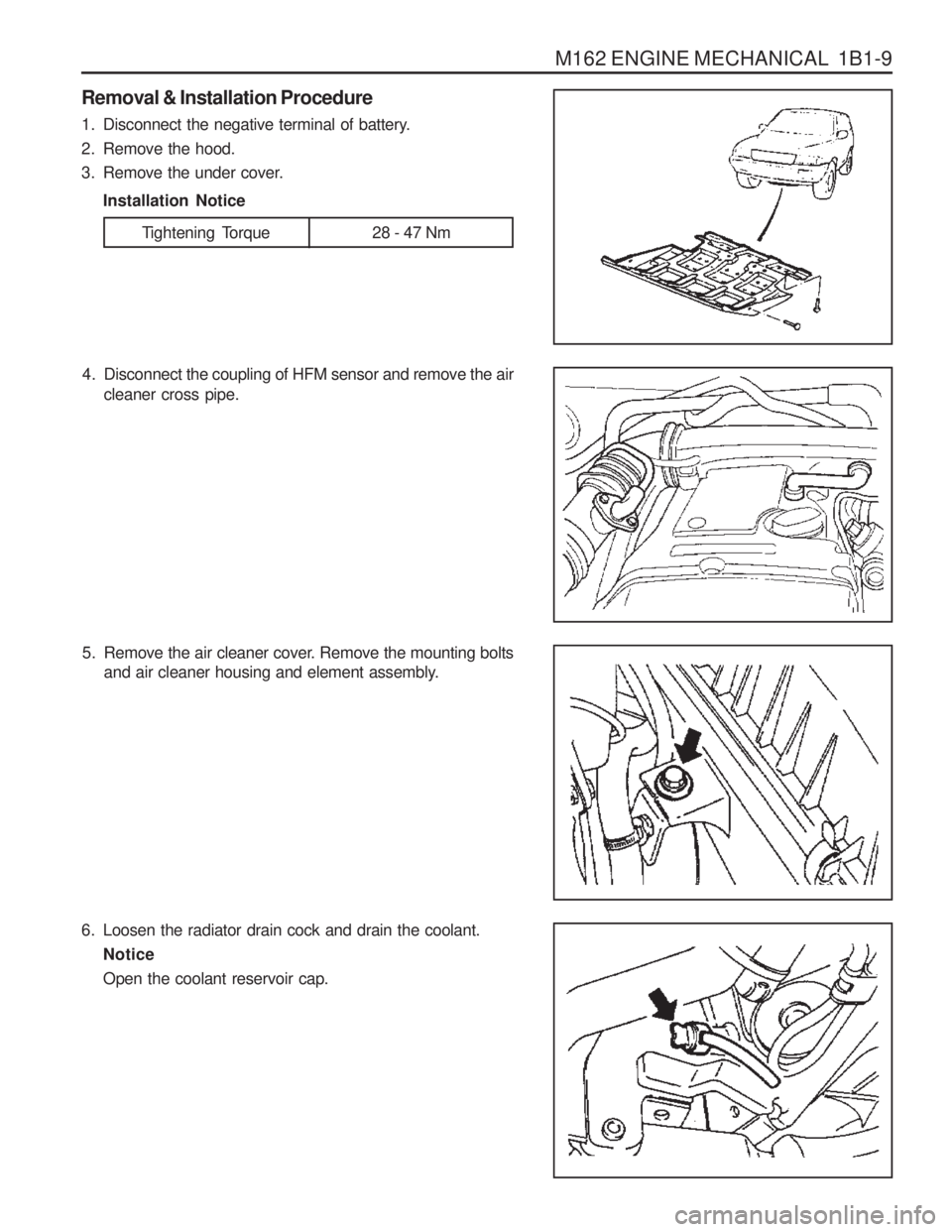

4. Disconnect the coupling of HFM sensor and remove the aircleaner cross pipe.

6. Loosen the radiator drain cock and drain the coolant. Notice Open the coolant reservoir cap.

5. Remove the air cleaner cover. Remove the mounting bolts

and air cleaner housing and element assembly.

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque 28 - 47 Nm

Page 46 of 1574

1B1-10 M162 ENGINE MECHANICAL

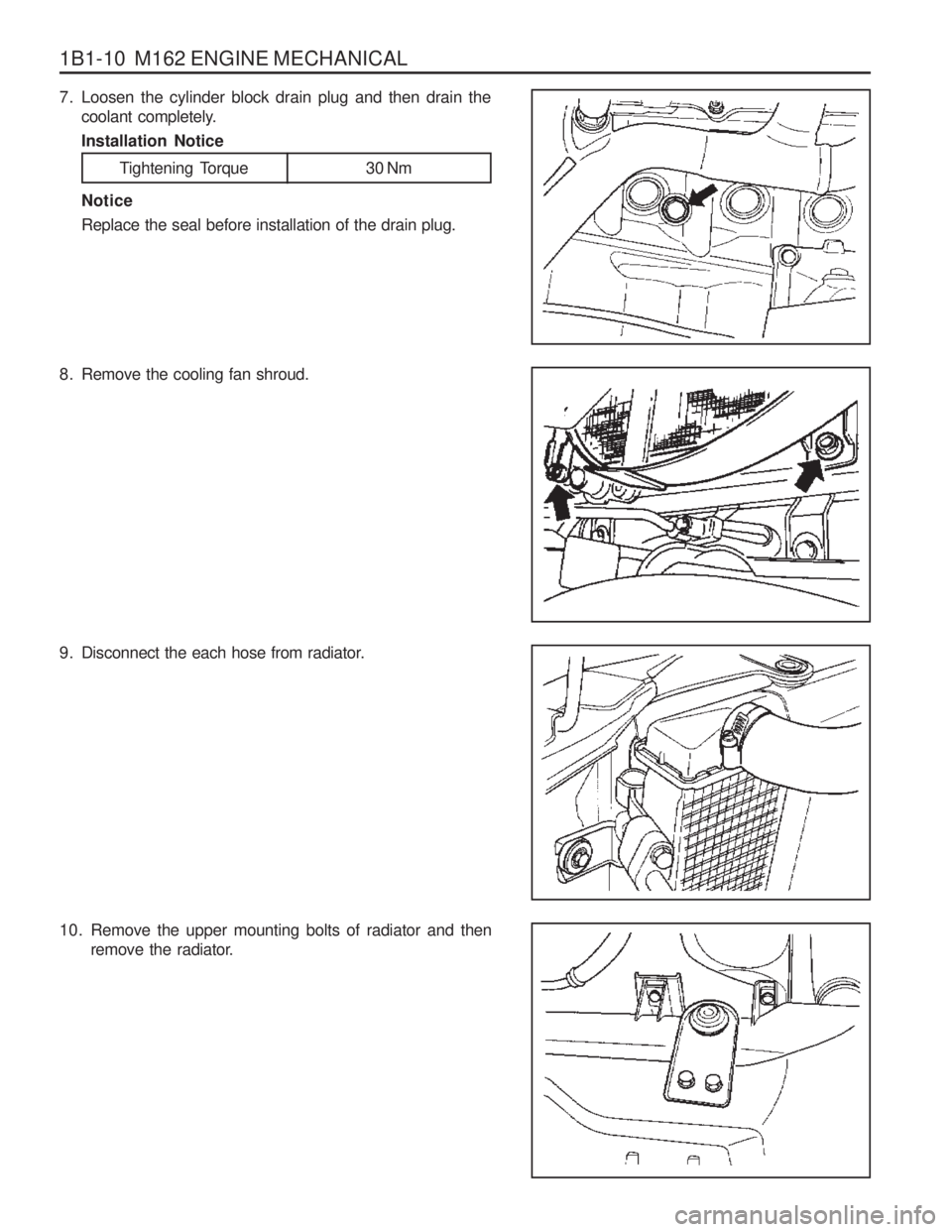

10. Remove the upper mounting bolts of radiator and thenremove the radiator.

7. Loosen the cylinder block drain plug and then drain thecoolant completely. Installation Notice

Tightening Torque 30 Nm

Notice Replace the seal before installation of the drain plug.

8. Remove the cooling fan shroud.

9. Disconnect the each hose from radiator.

Page 154 of 1574

1B2-2 M161 ENGINE MECHANICALSPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS N

m

35 - 40 10 - 15 5 - 10

21 - 25 30

56 - 6650 - 60

22.5 - 27.5 41.5 - 49.522.5 - 27.522.5 - 27.5

9 - 11

9 - 11

9 - 11

9 - 11

22.5 - 27.5

10

+90 °

55

+90 °

+90 °

22.5 - 27.522.5 - 27.5 9 - 109 - 10200

+90 °

40

+90 °

45

+90 °

35

9 - 11 20

+90 °

20

+90 °

20 / + 90 °

20 / + 90 °

22.5 - 27.5

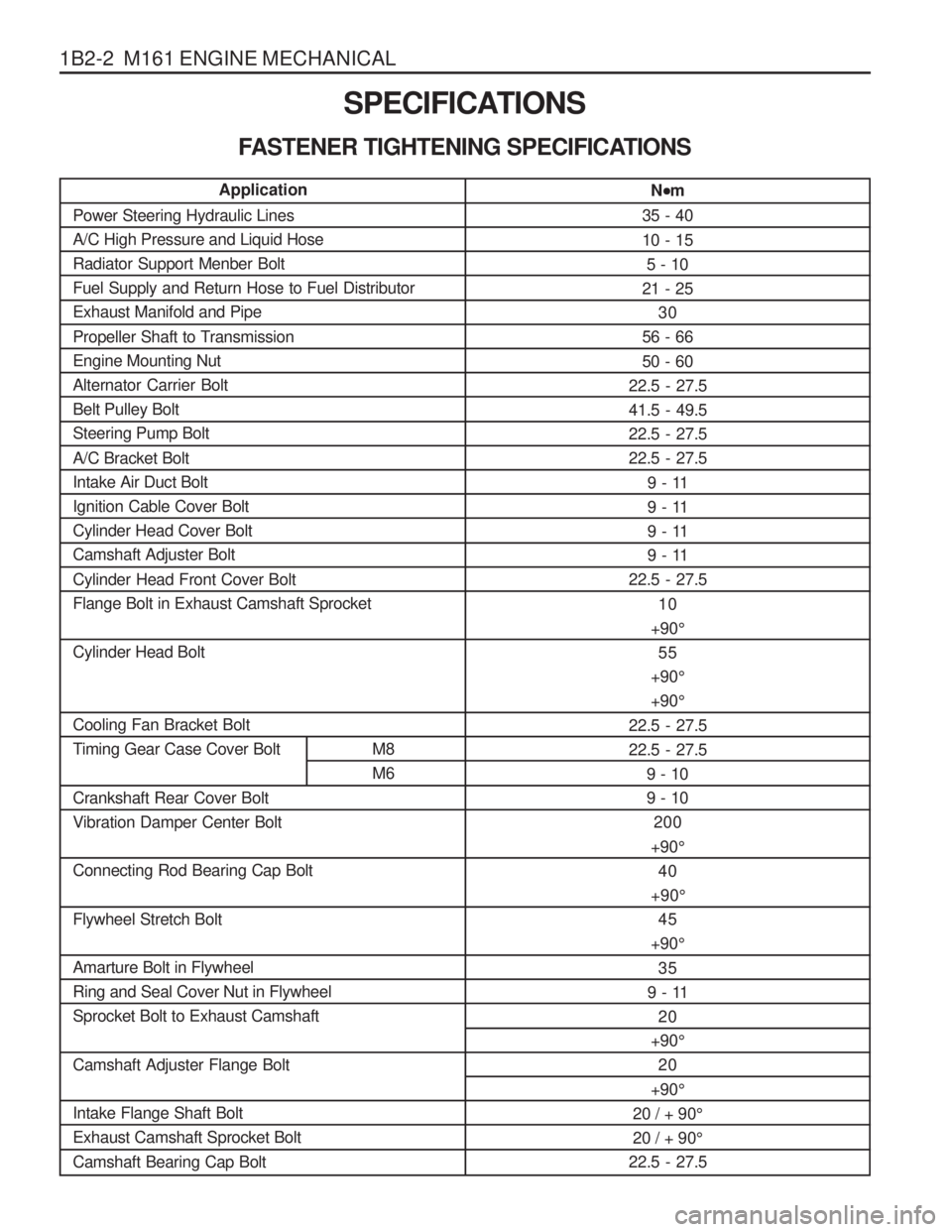

Application

Power Steering Hydraulic Lines A/C High Pressure and Liquid HoseRadiator Support Menber BoltFuel Supply and Return Hose to Fuel DistributorExhaust Manifold and Pipe

Propeller Shaft to Transmission Engine Mounting NutAlternator Carrier BoltBelt Pulley BoltSteering Pump Bolt A/C Bracket Bolt Intake Air Duct BoltIgnition Cable Cover BoltCylinder Head Cover BoltCamshaft Adjuster Bolt Cylinder Head Front Cover Bolt Flange Bolt in Exhaust Camshaft Sprocket Cylinder Head Bolt Cooling Fan Bracket Bolt

Timing Gear Case Cover Bolt M8 M6

Crankshaft Rear Cover BoltVibration Damper Center Bolt Connecting Rod Bearing Cap Bolt Flywheel Stretch Bolt Amarture Bolt in Flywheel Ring and Seal Cover Nut in FlywheelSprocket Bolt to Exhaust Camshaft Camshaft Adjuster Flange Bolt Intake Flange Shaft Bolt Exhaust Camshaft Sprocket Bolt Camshaft Bearing Cap Bolt

Page 156 of 1574

1B2-4 M161 ENGINE MECHANICALSPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01 Torque Wrench

112 589 00 72 00 Oil Extractor 000 589 72 21 00

Torque Wrench

001 589 66 21 00 Torque Wrench

000 589 01 10 00

Box Wrench Insert 124 589 15 21 00

Radiator CapTesting Unit

116 589 02 34 00

Screw-Fixed Pin 000 589 40 37 00

Hose Clamp

Page 162 of 1574

1B2-10 M161 ENGINE MECHANICAL

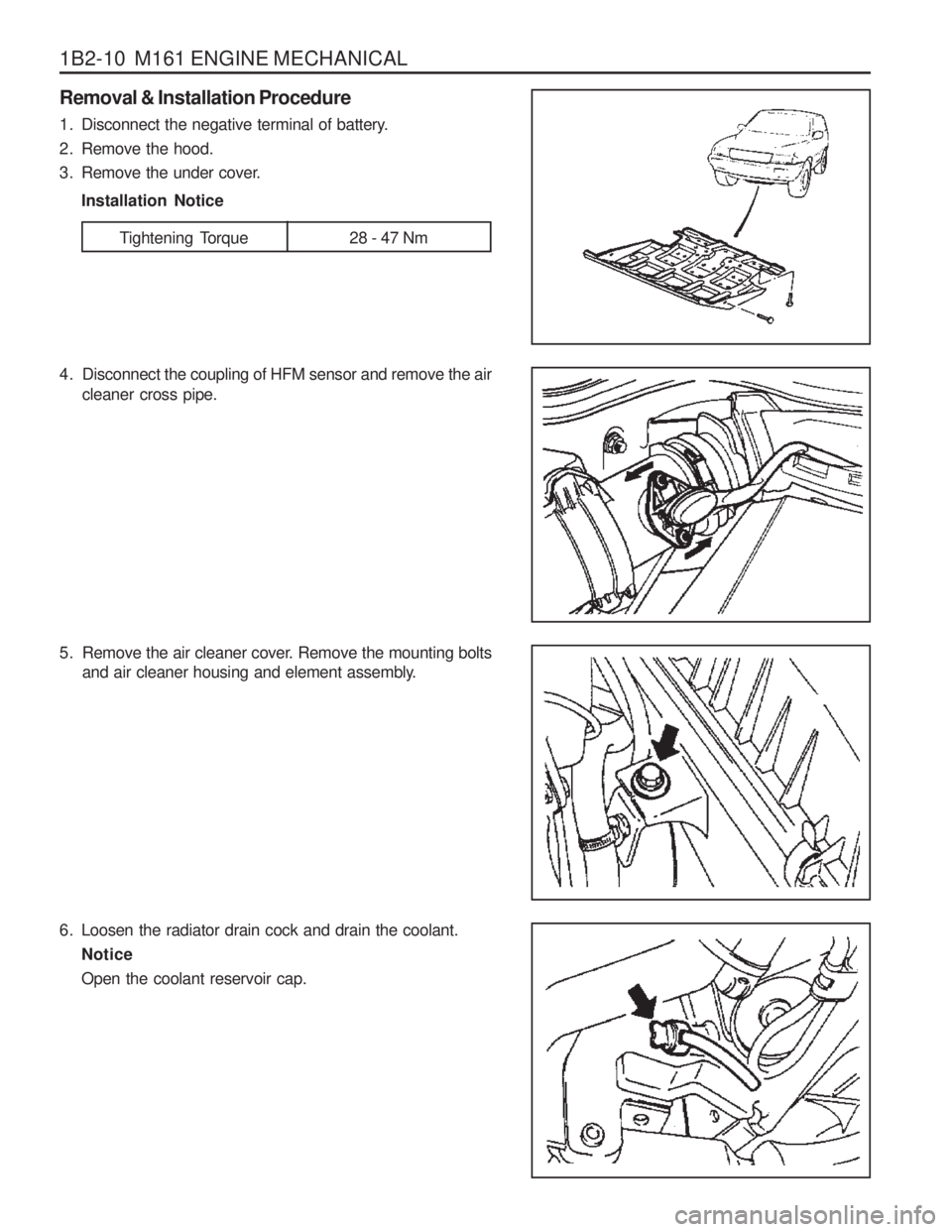

4. Disconnect the coupling of HFM sensor and remove the aircleaner cross pipe.

6. Loosen the radiator drain cock and drain the coolant. Notice Open the coolant reservoir cap.

5. Remove the air cleaner cover. Remove the mounting bolts

and air cleaner housing and element assembly.

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque 28 - 47 Nm

Page 163 of 1574

M161 ENGINE MECHANICAL 1B2-11

10. Remove the upper mounting bolts of radiator and thenremove the radiator.

7. Loosen the cylinder block drain plug and then drain thecoolant completely. Installation Notice

Tightening Torque 30 Nm

Notice Replace the seal before installation of the drain plug.

8. Remove the cooling fan shroud.

9. Disconnect the each hose from radiator.