ESP SSANGYONG MUSSO 2003 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 889 of 1574

5A-30 AUTOMATIC TRANSMISSION

Solenoid Valve Symbols (On/off Solenoids)

The solenoid symbol shown adjacent to each solenoid on the

hydraulic system schematics indicates the state of the oil flow

through the solenoid valve with the power On or 0ff. Refer to

figure 3.6 for the On/off operational details of NO solenoidvalves. Normally Open (NO) Solenoid POWER ON

Line 500 port is closed. The output port is open to exhaust at the solenoid valve. POWER OFF

The exhaust port is closed. The output port is open to line 500,Figure 3.6- Normally Open (NO) Symbols

Variable Pressure Solenoid Multiplexing System

Friction element shifting pressures are controlled by the variable pressure solenoid (VPS).

Line pressure is completely independent of shift pressure and is a function of throttle position, gear state and enginespeed.

S5 is a proportional or variable pressure solenoid that provides the signal pressure to the clutch and band regulator

valves thereby controlling shift pressures.

VPS pressure is multiplexed to the clutch regulator valve, the band regulator valve and the converter clutch regulator

valve during automatic gearshifts.

A variable pressure solenoid produces a hydraulic pressure inversely proportional to the current applied. During a

gearshift the TCU applies a progressively increasing or decreasing (ramped) current to the solenoid. Current applied will vary between a minimum of 200 mA and a maximum of 1000 mA, Increasing current decreases output (55)

pressure. Decreasing current increases output (55) pressure.

Line 500 pressure, (approximately 440 to 560 kPa), is the reference pressure for the VPS, and the VPS outputpressure is always below line 500 pressure.

When the VPS is at standby, that is no gearshift is taking place, the VPS current is set to 200 mA giving maximum output pressure.

Under steady state conditions the band and clutch regulator valve solenoids are switched off. This applies full Line

500 pressure to the plunger and because Line 500 pressure is always greater than S5 pressure it squeezes the S5

oil out between the regulator valve and the plunger. The friction elements are then fed oil pressure equal to Line 500multiplied by the amplification ratio.

When a shift is initiated the required On/off solenoid is switched on cutting the supply of Line 500 to the plunger.

At the same time the VPS pressure is reduced to the ramp start value and assumes control of the regulator valve by

pushing the plunger away from the valve. The VPS then carries out the required pressure ramp and the timed shift is

completed by switching Off the On/off solenoid and returning the VPS to the standby pressure.

This system enables either the band or clutch or both to be electrically controlled for each gearshift. Mode Indicator Light

Depending on the application, the mode indicator light may be used to indicate the mode that has been selected or

if an overheat condition exists. The mode indicator light is usually located on the instrument cluster. Communication Systems CAN

The controller area network (CAN) connects various control modules by using a twisted pair of wires, to share

common information. This results in a reduction of sensors and wiring. Typical applications include using the engine

controller to obtain the actual engine speed and throttle position, and adding these to the network. The ABS controller

(if fitted) can be used to obtain the road speed signal. This information is then available to the TCU without anyadditional sensors.

Page 923 of 1574

5A-64 AUTOMATIC TRANSMISSION

Default Transmission Operating Modes

The TCU relies on accurate information from its inputs and complete control of its outputs to effectively control the

transmission. To ensure that it has both valid inputs and functioning outputs, the TCU carries out both hardware and

software fault detection routines. The TCU will respond to any faults detected by adopting the operating modes which

are detailed below.

The following symptoms of faults are the most obvious results of each fault under ‘normal ’ conditions.

There is always the possibility that a fault may not be detected. If undetected fault conditions are present, the

operation of the transmission is difficult to predict.

1 Throttle Fault

� All shifts will occur as if a nominal throttle (approx. 44%) were applied for shift scheduling.

� All shifts will be firm as full throttle and hence high engine torque is assumed.

� The torque converter will be unlocked at all times.

� All downshifts initiated by the shift lever will occur as though they were ‘automatic ’ shifts. That is the engine

braking effect will not occur until near the end of the shift.

� Line pressure will always stay high (solenoid 6 OFF) to cope with assumed high throttle/torque.

If a fault is undetected, the percent throttle is most likely to be interpreted as higher than actual, resulting in late

upshifts, early downshifts, firm shifting and a harsh 3-1 shift when stopping.

2 Throttle Not Learnt Fault

The transmission operates from default throttle calibration values which results in the evaluation of the throttle being

higher (more open) than it is. There(ore at zero throttle settings, the transmission may calculate that sufficient throttle

opening is present to justify high line pressure and switch solenoid 6 to OFF. Other symptoms are:

a. late upshifts and

b. lock-up maintained at zero throttle when the vehicle speed is sufficiently high.

3 Engine Speed Fault � All shifts will be firm because an engine speed corresponding to peak engine torques is assumed.

If a fault is undetected, the engine speed is likely to be interpreted as stalled resulting in soft shifting possibly with an end of shift bump.

4 Vehicle Speed Sensor Fault

� All shifts will be controlled by the shift lever with skip downshifts disabled and downshifts only allowed if the

engine speed is low. Fourth gear will be inhibited.

� The torque converter will be unlocked at all times.

If a fault is undetected, the vehicle is likely to be interpreted as being stationary resulting in first gear operation at all

times. Note that speedometer transducer faults are likely to cause the vehicle ’s speedometer to become inoperative.

5 Gear Lever Fault (Inhibitor/PRNDL Switch) � The gear lever is assumed to be in the Drive position.

� The transmission is limited to 2nd,3rd, and R gears only.

� The rear band will apply at all times when the lever is shifted to P, R or N. (B2 inhibition and reverse lockout

protection is disabled.)

� The torque converter will be unlocked at all times.

� Manually (gear lever) initiated downshifts will not be available.

If a fault is undetected, the gear lever position is likely to be interpreted as being higher than actual. Where Park is the

highest position and Manual 1 is the lowest, the result being the availability of higher gears than selected by the gear

lever.

Page 924 of 1574

AUTOMATIC TRANSMISSION 5A-65

If the gear lever is incorrectly adjusted, the transmission may shift gears on bumpy road surfaces.

6 Transmission Oil Temperature Sensing Fault�All shifts will be firm until the transmission has warmed up, because a high transmission oil temperature is

assumed.

If a fault is undetected, the temperature is likely to be evaluated as being lower than actual, resulting in softer shifts with ‘end bump ’ (very firm feel at the end of the shift).

7 Mode Setting Fault �All shifts will occur as if the mode is set to ‘NORMAL ’ .

� The mode indicator will always be off indicating that ‘NORMAL ’ mode is selected.

� The mode indicator will not respond to changes in switch setting.

If a fault is undetected, the mode as indicated by the mode indicator is not likely to respond to the mode switch.

8 Battery Voltage Sensing Fault

If the battery voltage is low then shifts to first gear are inhibited.9 the battery voltage is high (>16.5V) then the transmission goes into limp home (LHM) mode.

If a fault is undetected, the transmission is likely to incorrectly evaluate an ON/OFF solenoid fault resulting in limp home mode (LHM) operation.

9 ON/OFF Solenoid Fault (Solenoids 1,2,3 and 4)

The transmission adopts its limp home mode (LHM) operation, described above. However, if solenoid 1 is faulty then

the fourth gear LHM strategy will be adopted independent of vehicle speed.

If a fault is undetected, the operation of the transmission is dependent on which solenoid is actually faulty. The

characteristics for different solenoid fault conditions are listed in table 6.1.2.

10 ON/OFF Solenoid Fault (Solenoids 6,7)

If solenoid 6 is found faulty it is always disabled resulting in high line pressure being applied continuously.

If solenoid 7 is found faulty it is disabled resulting in the transmission being locked always.The transmission does not go into LHM.

11 Variable Pressure Solenoid Fault The transmission adopts its LHM operation.

If a fault is undetected, the transmission shift feel is likely to be poor for all shifts.

12 Software Fault

The transmission adopts the third gear LHM strategy of operation, independent of vehicle speed. The operation of

the TCU under this condition is difficult to predict. Its operation may be erratic.

If a fault is undetected, the operation of the TCU is likely to be erratic.

13 Power Supply Fault

The transmission adopts the third gear LHM strategy of operation, independent of vehicle speed. If there is an

intermittent power supply connection, the TCU will power-up in fourth gear and then shift to the appropriate gear to

satisfy the conditions present. The power supply is not monitored for fault evaluation.

All faults except for solenoid faults can be recovered without having to turn the TCU off and back on. However, in

general the recovery requires that no faults are present for a period of time (approx. 3 or 30 seconds). Recovery from

a fault will not clear the fault from the keep alive memory

14 Transmission Sump Temperature Exceeding 135°C

�The converter lockup clutch will be applied at lower speeds, causing a shudder through the vehicle.

� The mode indicator will flash in some vehicles.

These faults can be due to the transmission oil overheating or due to an incorrect signal received from the temperature

sensor.

Page 926 of 1574

AUTOMATIC TRANSMISSION 5A-67

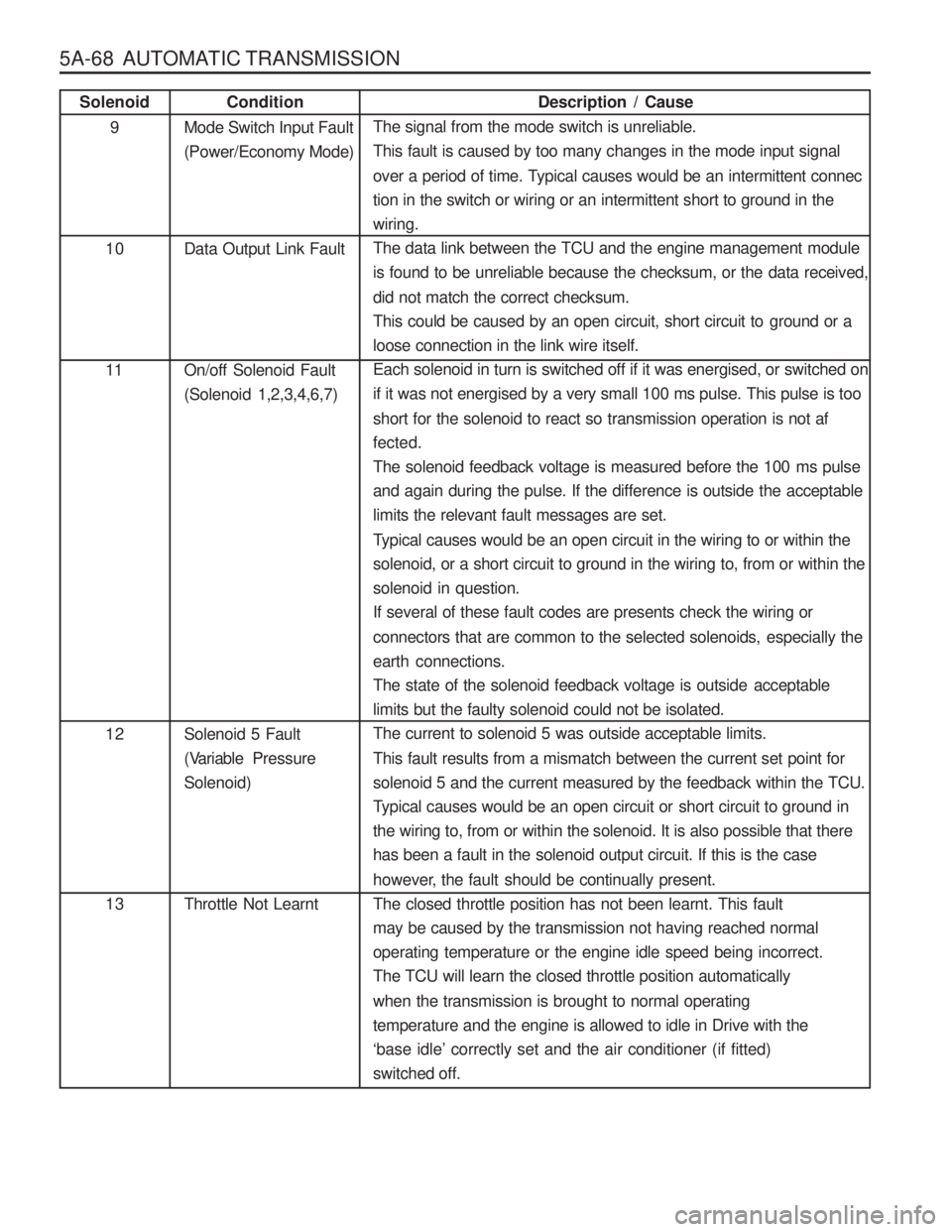

Table 6.1.3 - Diagnostic Trouble Messages

Description / Cause

There have been no faults recorded since the TCU was last cleared. If

the fault history has never been cleared, then there have been no

faults recorded since the TCU was originally powered up.There is an internal fault within the TCU.

The voltage measured by the TCU corresponding to the battery sup-

ply voltage has been outside the range of the maximum operatingvoltage of 16.5 volts.

The minimum operating voltage depends on the transmission tem-

perature but is typically between 8-9 V for a warm transmission.

The voltage measured by the TCU from the throttle potentiometer has been outside acceptable levels.

This would typically indicate a loose connection in the wiring to, or

within, the throttle sensor which has caused the signal at the TCU to

read 0V or 5V.

The voltage measured by the TCU across the temperature Input ter-

minals has been outside acceptable levels.

This would typically be caused by a loose connection or short to ground

in the wiring to, or within, the temperature sensor which has caused

the signal at the TCU to read 0V or 5V. The voltage measured by the TCU across the shift lever input termi- nals has been outside acceptable levels for a significant length of

time. This would typically be caused by a loose connection or short to

ground in the wiring to, or within, the inhibitor switch which has caused

the signal at the TCU to read 0V or 5V.

The signal from the ignition, of ignition pulses, has either been non- existent or has been unreliable.

There are two reasons this fault could occur. The first is due to a lack

of ignition pulses when other TCU inputs would indicate that the en-

gine is running, that is the gear lever is in a driving position, the throttle is applied and vehicle speed increasing. The second cause of this (aunt is the frequency of the pulses of theignition pulse input to the TCU indicate an unachievable engine speed.

The pulses from the shaft speed sensor have either been non-exis-tent or have been unreliable.

There are three reasons this fault could occur. The first is due to a sudden loss of speedometer pulses at a time when they were fre quent,thus indicating an unachievable degree of deceleration of the drive

line. The second cause of this fault is that the frequency of the pulses

on the shaft speed sensor input to the TCU indicate an unachievable

propeller shaft speed. The third is the presence of a high engine speed

in a driving gear with no speedometer pulses.

Condition

Test Pass

Transmission Control Module Fault

Battery Voltage InputFault Throttle Input Fault

Temperature Input FaultShift Lever Position Input Fault(Inhibitor/PRNDL Switch) Engine Speed Sensor Fault Shaft Speed Sensor Fault(Speedo Sensor)Solenoid 1 2 3 4567 8

Page 927 of 1574

5A-68 AUTOMATIC TRANSMISSION

Description / Cause

The signal from the mode switch is unreliable.

This fault is caused by too many changes in the mode input signal

over a period of time. Typical causes would be an intermittent connec

tion in the switch or wiring or an intermittent short to ground in thewiring.

The data link between the TCU and the engine management module

is found to be unreliable because the checksum, or the data received, did not match the correct checksum.

This could be caused by an open circuit, short circuit to ground or aloose connection in the link wire itself.

Each solenoid in turn is switched off if it was energised, or switched on

if it was not energised by a very small 100 ms pulse. This pulse is too

short for the solenoid to react so transmission operation is not af fected.

The solenoid feedback voltage is measured before the 100 ms pulse

and again during the pulse. If the difference is outside the acceptablelimits the relevant fault messages are set.

Typical causes would be an open circuit in the wiring to or within the

solenoid, or a short circuit to ground in the wiring to, from or within thesolenoid in question.If several of these fault codes are presents check the wiring or

connectors that are common to the selected solenoids, especially the earth connections.

The state of the solenoid feedback voltage is outside acceptablelimits but the faulty solenoid could not be isolated.The current to solenoid 5 was outside acceptable limits.

This fault results from a mismatch between the current set point for

solenoid 5 and the current measured by the feedback within the TCU.

Typical causes would be an open circuit or short circuit to ground in

the wiring to, from or within the solenoid. It is also possible that there

has been a fault in the solenoid output circuit. If this is the case

however, the fault should be continually present.

The closed throttle position has not been learnt. This fault may be caused by the transmission not having reached normaloperating temperature or the engine idle speed being incorrect.The TCU will learn the closed throttle position automatically when the transmission is brought to normal operating temperature and the engine is allowed to idle in Drive with the‘ base idle ’ correctly set and the air conditioner (if fitted)

switched off.

Condition

Mode Switch Input Fault(Power/Economy Mode) Data Output Link Fault On/off Solenoid Fault (Solenoid 1,2,3,4,6,7) Solenoid 5 Fault

(Variable Pre ssure

Solenoid) Throttle Not LearntSolenoid

9

10 11 12 13

Page 962 of 1574

AUTOMATIC TRANSMISSION 5A-103

11. Assemble the piston return spring to the piston, and fit thespring retainer over the spring. NoticeThe wire diameter of this spring is 4.3 mm.

12. Using special tool No. 0555-331899, compress the spring sufficiently to enable the installation of the retaining circlip

ensuring that the circlip is firmly seated in its groove, then remove the tool.

13. Check the C1 piston check valves are not damaged and are free to move, and that the cylinder feed orifices areclear of obstructions.

14. Lubricate the ’0’rings with automatic transmission fluid and

fit them to their respective grooves. Notice

‘O’ rings must not be twisted in the grooves.

15. Position the cylinder with the C1 cavity upwards. Install the piston into the cylinder until the outer diameter of the piston

enters the inner diameter of the cylinder.

16. Install the spring and spring retainer onto the piston. Notice The wire diameter of this spring is 5.26 mm.

17. Using special tool No. 0555-331899, compress the spring sufficiently to enable the installation of the retaining circlip

ensuring that the circlip is firmly seated in its groove, then remove the tool.

18. Install the C2 wave washer into the cylinder with the crest of one wave covering one of the bleed orifices in the C2 piston.

19. Measure and record the thickness of the flange of the C2 sleeve. Refer to figure 8.25.

20. Install the C4 clutch plates and wave washer into the C2 actuating sleeve, with the rounded edge of the steel plates

down, in the following sequence:

� Steel plate (selective)

� Friction disc

� Steel plate

� Friction disc

� Steel plate

� Friction disc

� Steel plate

� Wave washer

Page 969 of 1574

5A-110 AUTOMATIC TRANSMISSION C1 Clutch Overdrive Shaft and Input Shaft Assembly Notice

1. Ensure that the snap rings are fitted correctly.

2. Check pistons for cracks, especially the C1 piston.

3. Do not mix clutch piston return springs.

4. If the C1/C2 clutch packs separate from the C3 clutch pack,make sure the No. 6 bearing doesn ’t drop out of the bearing

retainer.

To assemble the C1 clutch overdrive shaft and input shaft

assembly, proceed as follows:

1. Check the overdrive shaft grooves for any defect.

2. Coat the sealing rings, large and small, with petroleum jelly and fit them to the overdrive shaft. The sealing rings may

be held in place with a small amount of petroleum jelly.

3. Assemble the clutch plate and disc into the cylinder in the following sequence:

� steel plate

� friction disc

� steel plate

� friction disc

� steel plate

� steel plate - 0574-GOOGOl, 0574-000003, 0574-000004, 0574-000005, 0574-000020,

0574-000021, or friction disc -0574-000002

� steel plate (selective)

� friction disc

� steel plate (selective)

� friction disc

4. Check the clutch pack clearance using special tool No.0555- 331900. Refer to figure 8.31.Use selective plates to achieve the correct specification.NoticeThe clutch pack supporting a 2 kg weight, the dimension from the input shaft locating stop to the friction disc mustbe 0.70-0.90 mm.

5. If new friction plates are being fitted, remove the clutch pack and soak the friction elements in automatic transmission

fluid for a minimum of five minutes prior to assembly. NoticeThe clutch pack clearance must be taken before elements are soaked in automatic transmission fluid.

6. Check the fit of the C1 clutch hub on the overdrive shaft. If it is loose, the hub and shaft assembly must be replaced. Figure 8.31 - Typical C1 Clutch Assembly

Clearance

Page 1093 of 1574

5D2-4 TRANSFER CASE (TOD)FUNCTION DESCRIPTION

� TOD System Select Mode (4H and 4L) 4H is the mode when drive normally of which gear ratio is 1:1 and 4L mode distributes power to front and rear wheels 50:50 of which gear ratio is 2.48:1.

� TOD System Function (select 4H mode) TOD system controls clutch mechanism to comply with rotation in front and rear propeller shaft and if its difference exceeds the permissible range, corresponding power is distributed into front wheel through EMC (Electro-MagneticClutch). Hall effect sensor signals speed on front and rear propeller shafts going through with TOD control unit.

Transfercase clutch coil is activated by variable current on exceeding difference of speed in front and rear propeller shafts.

� Function of 4L Mode When select 4L mode, EMC is locked to apply maximum torque into front and rear propeller shafts. Shift motor rotates also 4L position by rotation of cam thus propeller shaft torque changes from 1:1 to 2.48:1 by planetarygear set.

� Shift Motor It locates backside transfer case, which drives rotary helical cam. When mode select switch changes to 4L, shift fork is on position for 2.48:1 by rotation of helical cam.

� Transfer Case

TOD transfer case distributes power into front and rear axle by operation of 4H/4L switch and shift motor. Shifting 4H to 4L, is performed towards reducing HI-LO collar by means for connection HI-LO shift fork with

output shaft in order to join with planetary gear. Torque transmits input shaft then sun gear rotating front planetary

gear. Front planetary gear join with output shaft and drives LO position.

Page 1094 of 1574

TRANSFER CASE (TOD) 5D2-5

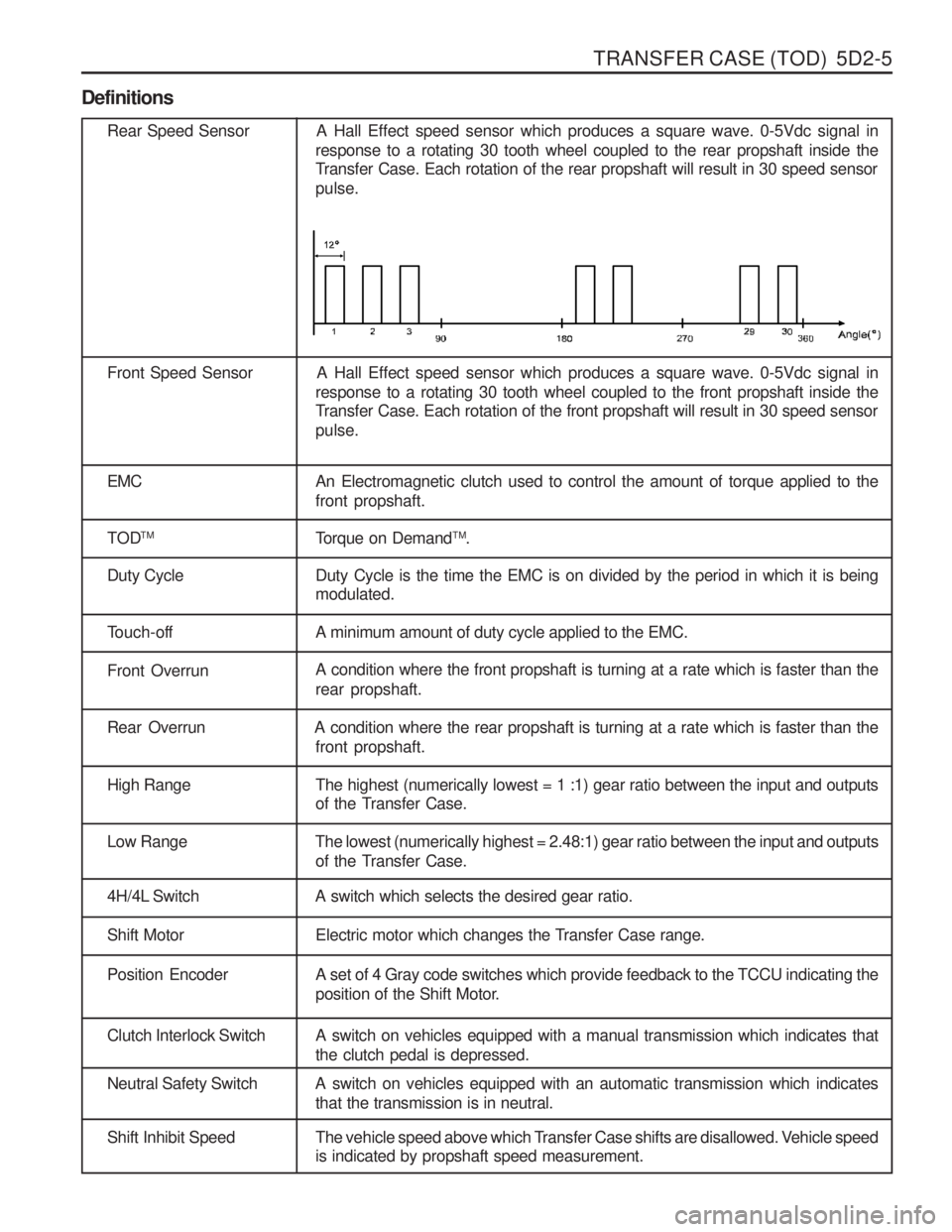

Definitions

Rear Speed Sensor A Hall Effect speed sensor which produces a square wave. 0-5Vdc signal inresponse to a rotating 30 tooth wheel coupled to the rear propshaft inside the

Transfer Case. Each rotation of the rear propshaft will result in 30 speed sensor pulse.

Front Speed Sensor A Hall Effect speed sensor which produces a square wave. 0-5Vdc signal in response to a rotating 30 tooth wheel coupled to the front propshaft inside the

Transfer Case. Each rotation of the front propshaft will result in 30 speed sensor pulse.

EMC An Electromagnetic clutch used to control the amount of torque applied to the front propshaft.

TOD TM

Torque on DemandTM

.

Duty Cycle Duty Cycle is the time the EMC is on divided by the period in which it is being modulated.

Touch-off A minimum amount of duty cycle applied to the EMC.

Front OverrunA condition where the front propshaft is turning at a rate which is faster than the rear propshaft.

Rear Overrun A condition where the rear propshaft is turning at a rate which is faster than the

front propshaft.

High Range The highest (numerically lowest = 1 :1) gear ratio between the input and outputsof the Transfer Case.

Low Range The lowest (numerically highest = 2.48:1) gear ratio between the input and outputs

of the Transfer Case.

4H/4L Switch A switch which selects the desired gear ratio.

Shift Motor Electric motor which changes the Transfer Case range.

Position Encoder A set of 4 Gray code switches which provide feedback to the TCCU indicating theposition of the Shift Motor.

Clutch Interlock Switch A switch on vehicles equipped with a manual transmission which indicates that the clutch pedal is depressed.

Neutral Safety Switch A switch on vehicles equipped with an automatic transmission which indicatesthat the transmission is in neutral.

Shift Inhibit Speed The vehicle speed above which Transfer Case shifts are disallowed. Vehicle speedis indicated by propshaft speed measurement.

Page 1098 of 1574

TRANSFER CASE (TOD) 5D2-9

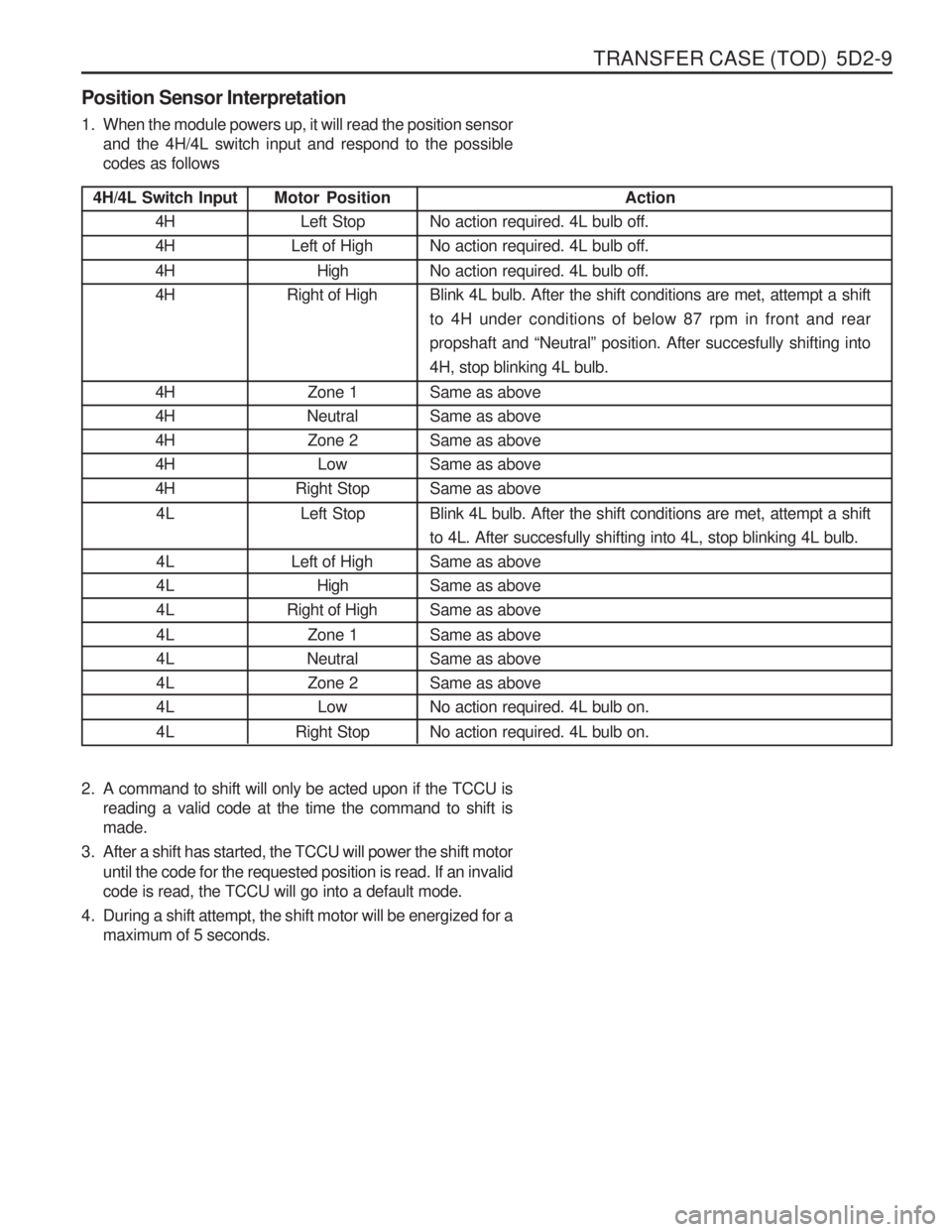

4H/4L Switch Input4H 4H 4H 4H 4H 4H4H4H4H

4L 4L 4L4L 4L 4L4L4L 4L

Position Sensor Interpretation

1. When the module powers up, it will read the position sensor

and the 4H/4L switch input and respond to the possible codes as follows

2. A command to shift will only be acted upon if the TCCU is reading a valid code at the time the command to shift ismade.

3. After a shift has started, the TCCU will power the shift motor until the code for the requested position is read. If an invalidcode is read, the TCCU will go into a default mode.

4. During a shift attempt, the shift motor will be energized for a maximum of 5 seconds. Motor Position

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2 Low

Right Stop

Left Stop

Left of High High

Right of High

Zone 1

Neutral Zone 2 Low

Right Stop Action

No action required. 4L bulb off. No action required. 4L bulb off. No action required. 4L bulb off. Blink 4L bulb. After the shift conditions are met, attempt a shiftto 4H under conditions of below 87 rpm in front and rearpropshaft and “Neutral ” position. After succesfully shifting into

4H, stop blinking 4L bulb. Same as above Same as aboveSame as aboveSame as aboveSame as above Blink 4L bulb. After the shift conditions are met, attempt a shift to 4L. After succesfully shifting into 4L, stop blinking 4L bulb.Same as aboveSame as aboveSame as above Same as above Same as aboveSame as aboveNo action required. 4L bulb on. No action required. 4L bulb on.