suspension SSANGYONG MUSSO 2003 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 705 of 1574

2A-8 SUSPENSION DIAGNOSIS-

ACTUATOR INSPECTION Output position of the actuator should be changed as below when battery voltage is applied between actuator connector terminals.

Connector

terminal Battery Voltage

Position of The Actuator Output Remark

1 (White)

-

2 (Black)

OPEN

3 (Red) +

1 (White) +

2 (Black) -

3 (Red)

OPEN

1 (White) OPEN

2 (Black) +

3 (Red) SOFT Mode

MEDIUM Mode

HARD Mode

Page 706 of 1574

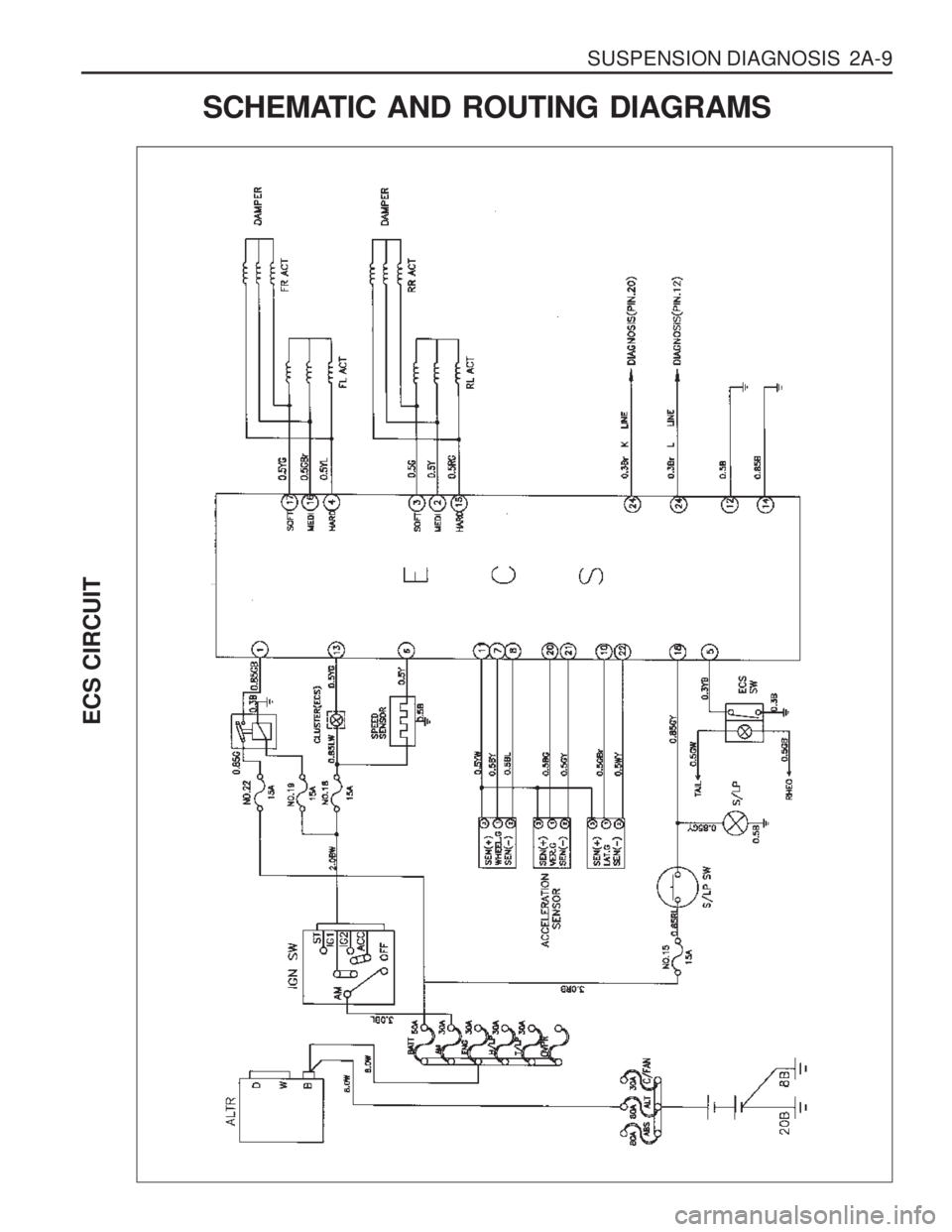

SUSPENSION DIAGNOSIS 2A-9

ECS CIRCUIT

SCHEMATIC AND ROUTING DIAGRAMS

Page 707 of 1574

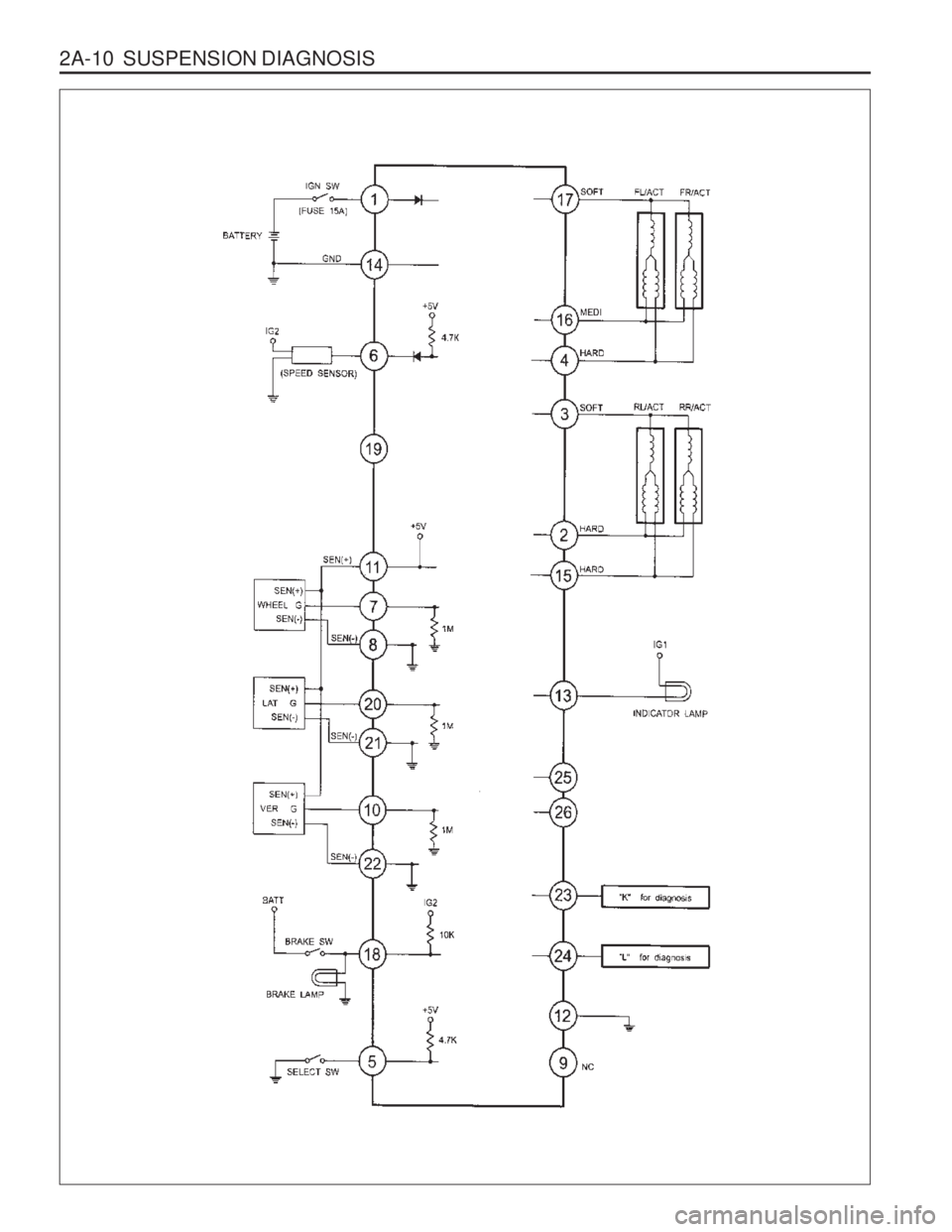

2A-10 SUSPENSION DIAGNOSIS

Page 708 of 1574

SUSPENSION DIAGNOSIS 2A-11

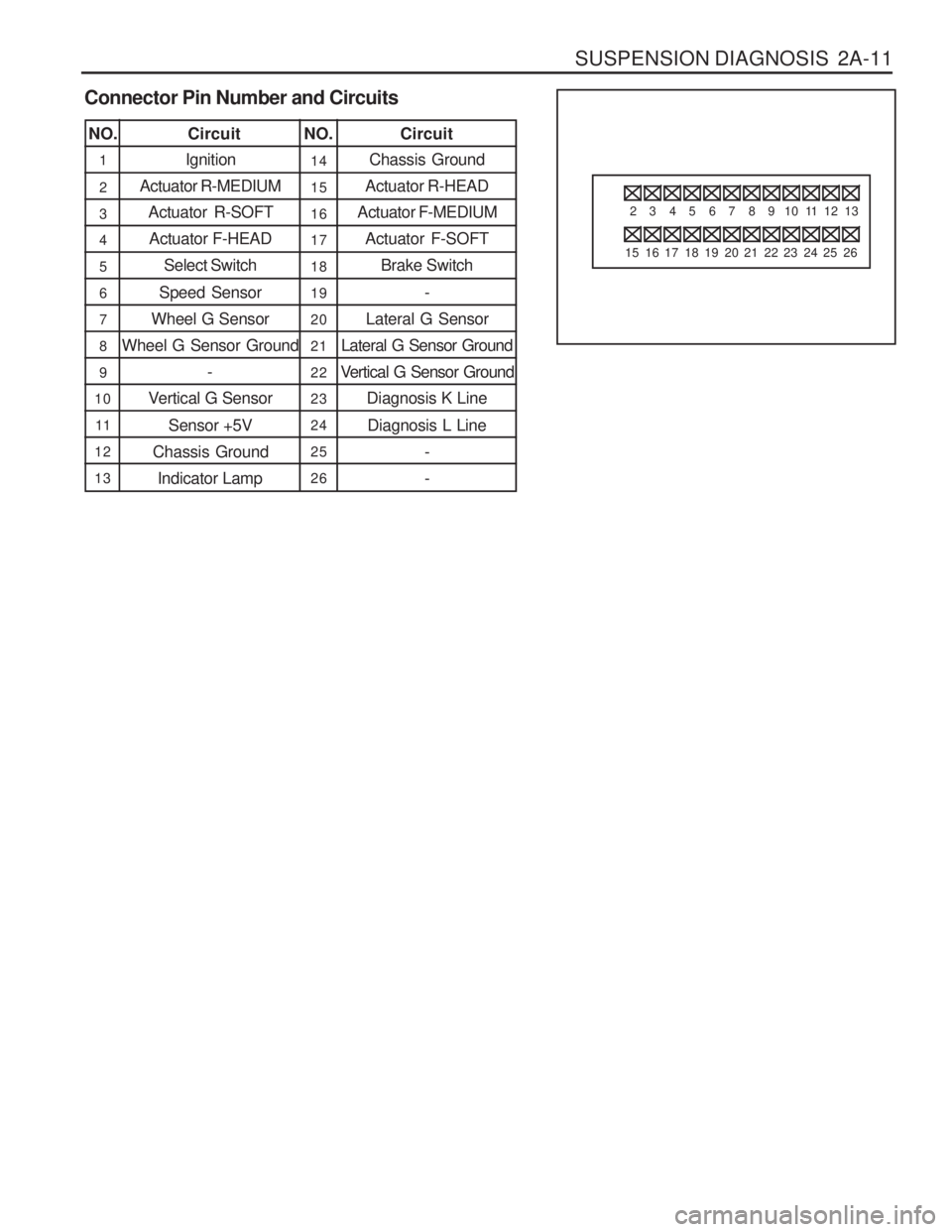

Connector Pin Number and Circuits

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

26

Ignition

Actuator R-MEDIUM Actuator R-SOFT

Actuator F-HEAD Select Switch

Speed Sensor

Wheel G Sensor

Wheel G Sensor Ground

-

Vertical G Sensor

Sensor +5V

Chassis Ground Indicator Lamp

NO. CircuitNO. Circuit

1 14

21 5

316

417

518

619

720

821

922

10 23

11 2 4

12 25

13 26 Chassis Ground

Actuator R-HEAD

Actuator F-MEDIUM

Actuator F-SOFT Brake Switch

-

Lateral G Sensor

Lateral G Sensor Ground

Vertical G Sensor Ground Diagnosis K Line

Diagnosis L Line - -

Page 709 of 1574

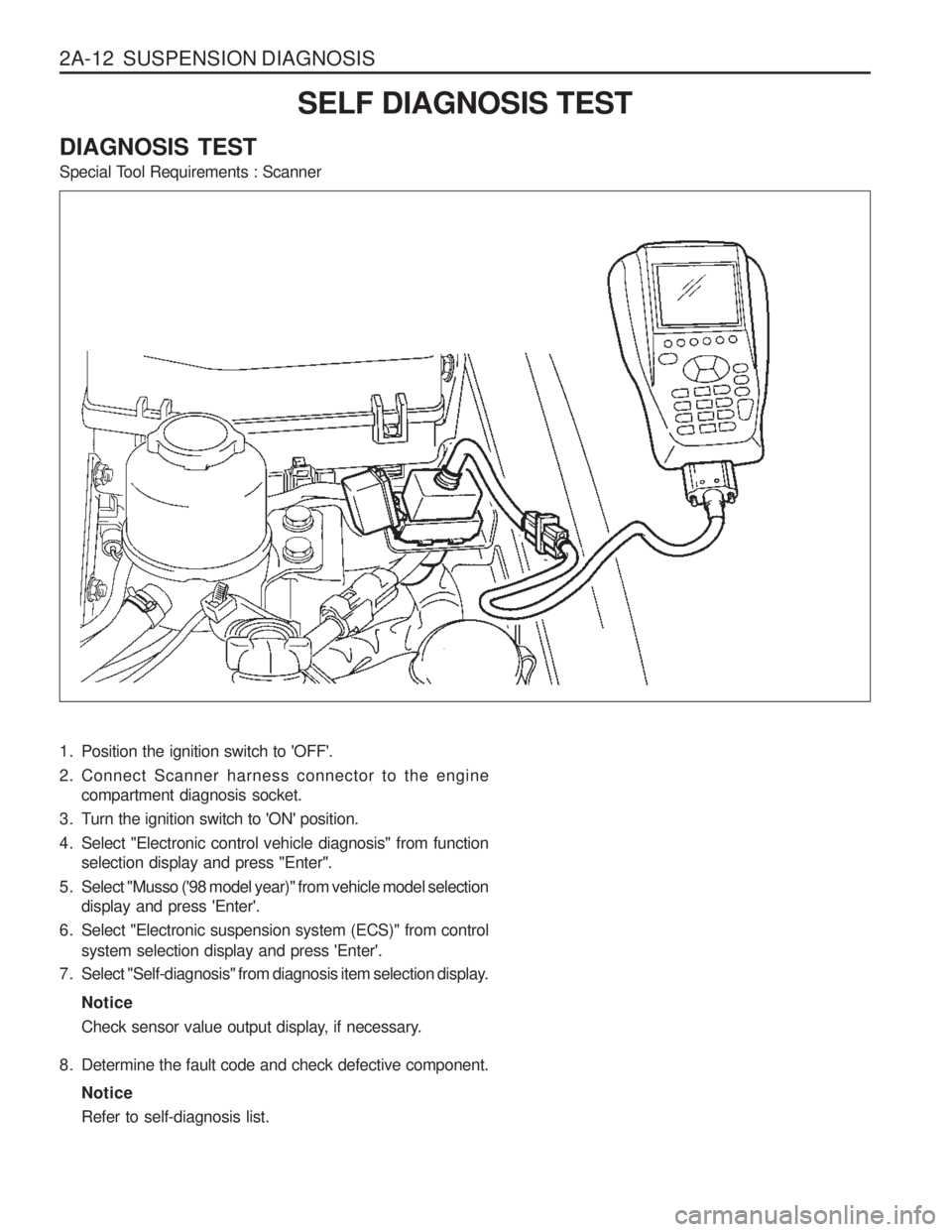

2A-12 SUSPENSION DIAGNOSISSELF DIAGNOSIS TEST

DIAGNOSIS TEST

Special Tool Requirements : Scanner

1. Position the ignition switch to 'OFF'.

2. Connect Scanner harness connector to the engine compartment diagnosis socket.

3. Turn the ignition switch to 'ON' position.

4. Select "Electronic control vehicle diagnosis" from function selection display and press "Enter".

5. Select "Musso ('98 model year)" from vehicle model selection display and press 'Enter'.

6. Select "Electronic suspension system (ECS)" from control system selection display and press 'Enter'.

7. Select "Self-diagnosis" from diagnosis item selection display.

Notice

Check sensor value output display, if necessary.

8. Determine the fault code and check defective component. NoticeRefer to self-diagnosis list.

Page 710 of 1574

SUSPENSION DIAGNOSIS 2A-13

Self - Diagnosis List

Fault

CodeDefects Service Hint

01 Vertical Acceleration Sensor

02 Lateral Acceleration Sensor

03 Wheel Acceleration Sensor

04

05 Rear Step Motor

0 6 ECU Front Step Motor 1. Check sensor supply voltage

�Condition - IGN ON

� Standard value - voltage between pin 11 and 8 of ECU : 4.5 - 5.0V

2. Check sensor output voltage �Condition - IGN ON

� Standard value - voltage between pin 20 and 11 of ECU: 0.5 - 4.5V

3. Check the sensor.

4. Check circuit for open.

5. Check connection of other connectors.

1. Check sensor supply voltage �Condition - IGN ON

� Standard value - voltage between pin 11 and 8 of ECU : 4.5 - 5.0V

2. Check sensor output voltage �Condition - IGN ON

� Standard value - voltage between pin 10 and 11 of ECU : 0.5 - 4.5V

3. Check the sensor.

4. Check circuit for open.

5. Check connection of other connectors.

1. Check step motor supply voltage.

2. Check circuit for open.

3. Check connection of other connectors.

1. Check step motor supply voltage.

2. Check circuit for open.

3. Check connection of other connectors.

1. Check connectors of ECU.

2. Replace the ECU.

1. Check sensor supply voltage

�Condition - IGN ON

� Standard value - voltage between pin 11, 8 and pin

7,11 of ECU : 4.5 - 5.0V

2. Check sensor output voltage

3. Check the sensor.

4. Check circuit for open.

5. Check connection of other connectors.

Page 719 of 1574

WHEEL ALIGNMENT 2B-9

GENERAL DESCRIPTION AND SYSTEM OPERATION

FOUR WHEEL ALIGNMENT CASTER Caster is the tilting 91 the uppermost point of the steering axis either forward or backward from the vertical when viewed from the side of the vehicle. A backward tilt is positive, and a forward tilt is negative. Caster influencesdirectional control of the steering but does not affect

tire wear. Weak springs or overloading a vehicle will affect

caster. One wheel with more positive caster will pull

toward the center of the car. This condition will cause the car to move or lean toward the side with the least

amount of positive caster. Caster is measured in degrees. CAMBER Camber is the tilting of the top of the tire from the vertical when viewed from the front of the vehicle. When thetires tilt outward, the camber is positive. When the tires tilt inward, the camber is negative. The camber angle is measured in degrees from the vertical. Camber

influences both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too much

negative camber, the inside shoulder of the tire will wear.

The first responsibility of engineering is to design safesteering and suspension systems. Each componentmust be strong enough to withstand and absorb extremepunishment. Both the steering system and the front and the rear suspension must function geometrically with thebody mass. The steering and the suspension systems require that the front wheels self-return and that the tire rolling effortand the road friction be held to a negligible force in orderto allow the customer to direct the vehicle with the least effort and the most comfort. A complete wheel alignment check should include

measurements of the rear toe and camber. Four-wheel alignment assures that all four wheels will be running in precisely the same direction. When the vehicle is geometrically aligned, fuel economy and tire life are at their peak, and steering andperformance are maximized. TOE

Toe-in is the turning in of the tires, while toe-out is the turning out of the tires from the geometric centerline or thrust line. The toe ensures parallel rolling of the wheels. The toe serves to offset the small deflections of the wheel support system which occur when the vehicle is rollingforward. The specified toe angle is the setting whichachieves 0 degrees of toe when the vehicle is moving. Incorrect toe-in or toe-out will cause tire wear and

reduced fuel economy. As the individual steering andsuspension components wear from vehicle mileage,

additional toe will be needed to compensate for the wear. Always correct the toe dimension last.

Page 720 of 1574

SECTION 2C

FRONT SUSPENSION

TABLE OF CONTENTSSPECIFICATIONS

GENERAL SPECIFICATIONS

Type

Spring Type

Torsion Bar Shock Absorber

Stabilizer Type

Double Wishbone

Torsion Bar Spring 1,040 mm

24.5 mm

Cylindrical Reciprocation Type

Torsion Bar Spring

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2C-1General Specifications . . . . . . . . . . . . . . . . . . 2C-1

Fastener Tightening Specifications . . . . . . . . . 2C-2

Component Locator . . . . . . . . . . . . . . . . . . . 2C-3

Front Suspension . . . . . . . . . . . . . . . . . . . . . . 2C-3

Maintenance and Repair . . . . . . . . . . . . . . . 2C-4

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 2C-4

Front Stabilizer Bar . . . . . . . . . . . . . . . . . . . . . 2C-4

Application Description

Torsion Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-6

Front Lower and Upper Arm . . . . . . . . . . . . . . 2C-8

Front Shock Absorber . . . . . . . . . . . . . . . . .

2C-10

Axle Vertical Acceleration Sensor (Wheel G Sensor) . . . . . . . . . . . . . . . . . . . 2C-12

Vertical and Lateral Sensor . . . . . . . . . . . . . . 2C-13

ECS (ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-14

Length Outer Diameter(

�)

Page 721 of 1574

2C-2 FRONT SUSPENSIONApplication

Torque Arm Bolt N

�m

40 - 60 60 - 80

FASTENER TIGHTENING SPECIFICATIONS

Stabilizer Bar

Application

Stabilizer Bar Retaining Nut Stabilizer Bar Link NutLower Arm Nut N

�m

30 - 45 60 - 80 16 - 22

Torsion Bar

Lower and Upper Arm

Application

Upper Arm Nut Upper Arm End Castle NutLower Arm Nut Lower Arm End Castle Nut N

�m

120 - 140 80 - 150

150 - 180 120 - 180

Steering Knuckle and Drive Shaft

Application

Brake Caliper Hose Bolt Brake Caliper Mounting Bolt

Tie Rod Retaining Nut Upper Arm Retaining NutLower Arm Retaining Nut N

�m

25 - 35

85 - 105 35 - 45

80 - 150

120 - 180

M10 M12

Page 722 of 1574

FRONT SUSPENSION 2C-3

COMPONENT LOCATOR

FRONT SUSPENSION

1 Shock Absorber

2 Upper Arm

3 Steering Knuckle

4 Lower Arm

5 Stabilizer Bar Link

6 Stabilizer Bar

7 Suspension Bumper