service interval SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 9 of 1574

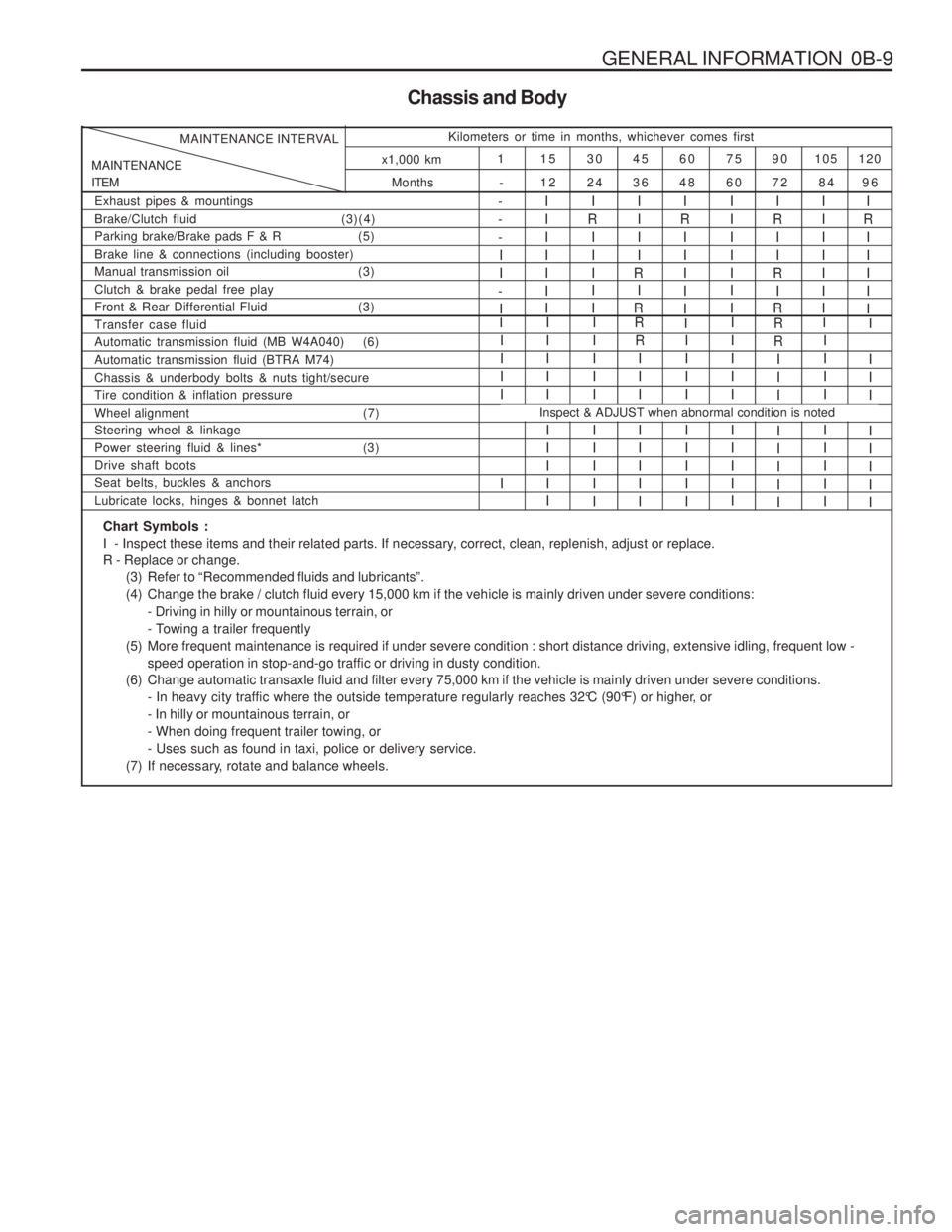

GENERAL INFORMATION 0B-9

Chassis and Body

Months

MAINTENANCE ITEM MAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

120

105

90

75

60

45

30

15

1

96

84

72

60

48

36

24

12

-

x1,000 km

Exhaust pipes & mountings Brake/Clutch fluid

(3)(4)

Parking brake/Brake pads F & R (5)Brake line & connections (including booster)

Manual transmission oil (3) Clutch & brake pedal free play

Front & Rear Differential Fluid (3)I

R

IIIII- --II

-

I IIIIII I

I

R I II I I IIII

R I

R IIIII I II

R

II

R I

R IIIIII II

R I IIII

Automatic transmission fluid (MB W4A040) (6) Automatic transmission fluid (BTRA M74)Chassis & underbody bolts & nuts tight/secure Tire condition & inflation pressure

Wheel alignment (7) Steering wheel & linkage

Power steering fluid & lines* (3)Drive shaft boots Seat belts, buckles & anchors Lubricate locks, hinges & bonnet latchIIII I I IIII I III I I IIII I IIII

R

III I IIII IIII I IIIIIIIII I III I

R R

III I IIII IIII I IIII

Transfer case fluidRII

I

Inspect & ADJUST when abnormal condition is noted

I

I II I IIII

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid every 15,000 km if the vehicle is mainly driven under severe conditions:- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low - speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transaxle fluid and filter every 75,000 km if the vehicle is mainly driven under severe conditions. - In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or- In hilly or mountainous terrain, or- When doing frequent trailer towing, or- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 11 of 1574

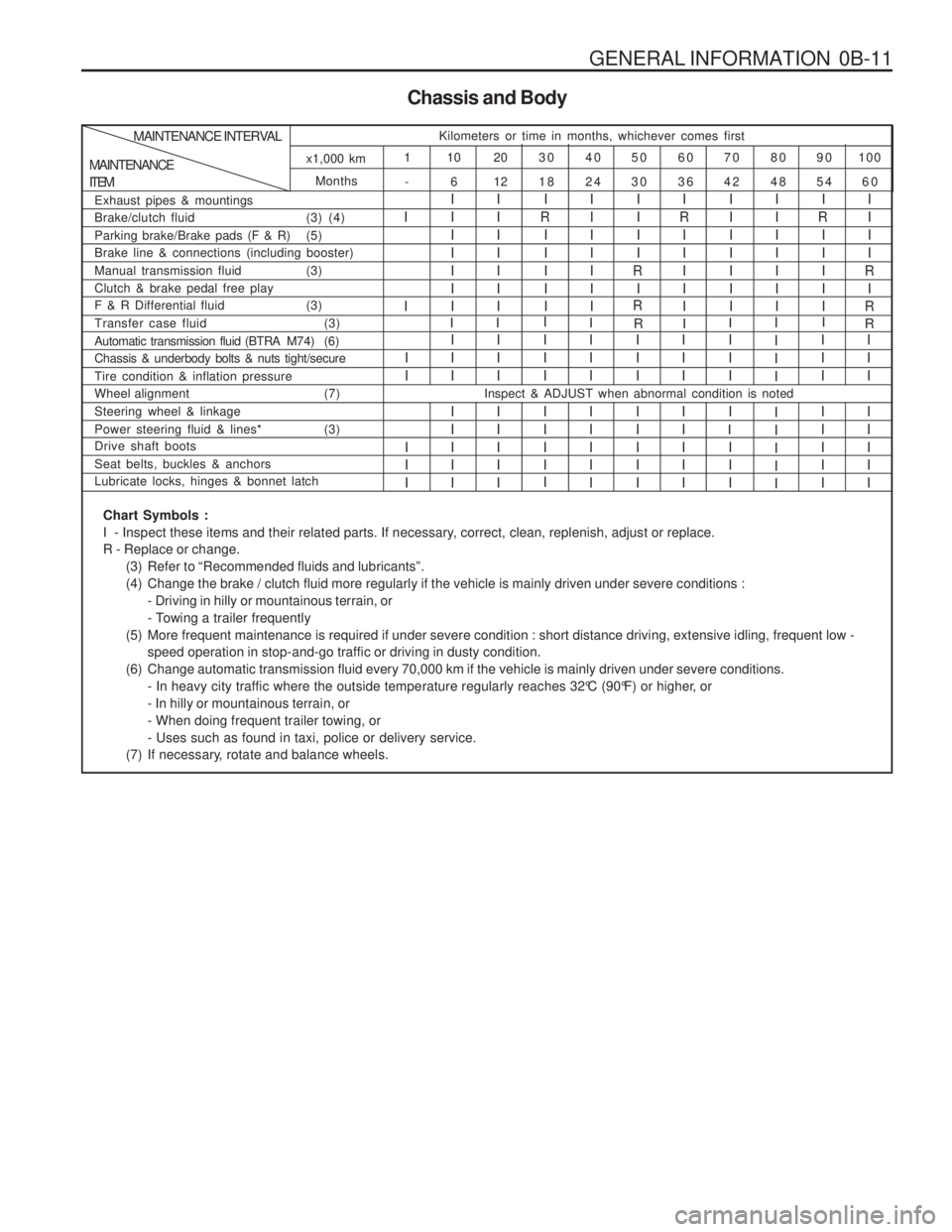

GENERAL INFORMATION 0B-11

Chassis and Body

Months -

MAINTENANCE ITEMMAINTENANCE INTERVAL

Kilometers or time in months, whichever comes first

100

90

80

70

60

50

40

30

20

10

1

60

54

48

42

36

30

24

18

12

6

x1,000 km

Exhaust pipes & mountings

Brake/clutch fluid (3) (4)

Parking brake/Brake pads (F & R) (5) Brake line & connections (including booster)

Manual transmission fluid (3)Clutch & brake pedal free play

F & R Differential fluid (3)

I I I IIIIIIIIIIIII I

R

IIIII IIIIIII IIII

R I

R I

R

IIIII IIIIIIIIIIIIII I

R

IIIII IIII

R I

R

Automatic transmission fluid (BTRA M74) (6) Chassis & underbody bolts & nuts tight/secure Tire condition & inflation pressure

Wheel alignment (7) Steering wheel & linkage

Power steering fluid & lines* (3) Drive shaft boots Seat belts, buckles & anchors Lubricate locks, hinges & bonnet latchI II I IIII III I IIII IIII I III I

I II I IIII III I IIIIIII I IIII III II II III I IIIIIII I IIII

Transfer case fluid (3)

RI R

I

I

I

I I I II IIII I IIII

Inspect & ADJUST when abnormal condition is noted

II I

Chart Symbols :

I - Inspect these items and their related parts. If necessary, correct, clean, replenish, adjust or replace.R - Replace or change.

(3) Refer to “Recommended fluids and lubricants”.

(4) Change the brake / clutch fluid more regularly if the vehicle is mainly driven under severe conditions :- Driving in hilly or mountainous terrain, or

- Towing a trailer frequently

(5) More frequent maintenance is required if under severe condition : short distance driving, extensive idling, frequent low - speed operation in stop-and-go traffic or driving in dusty condition.

(6) Change automatic transmission fluid every 70,000 km if the vehicle is mainly driven under severe conditions. - In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or- In hilly or mountainous terrain, or- When doing frequent trailer towing, or- Uses such as found in taxi, police or delivery service.

(7) If necessary, rotate and balance wheels.

Page 838 of 1574

ANTILOCK BRAKE SYSTEM 4F-9

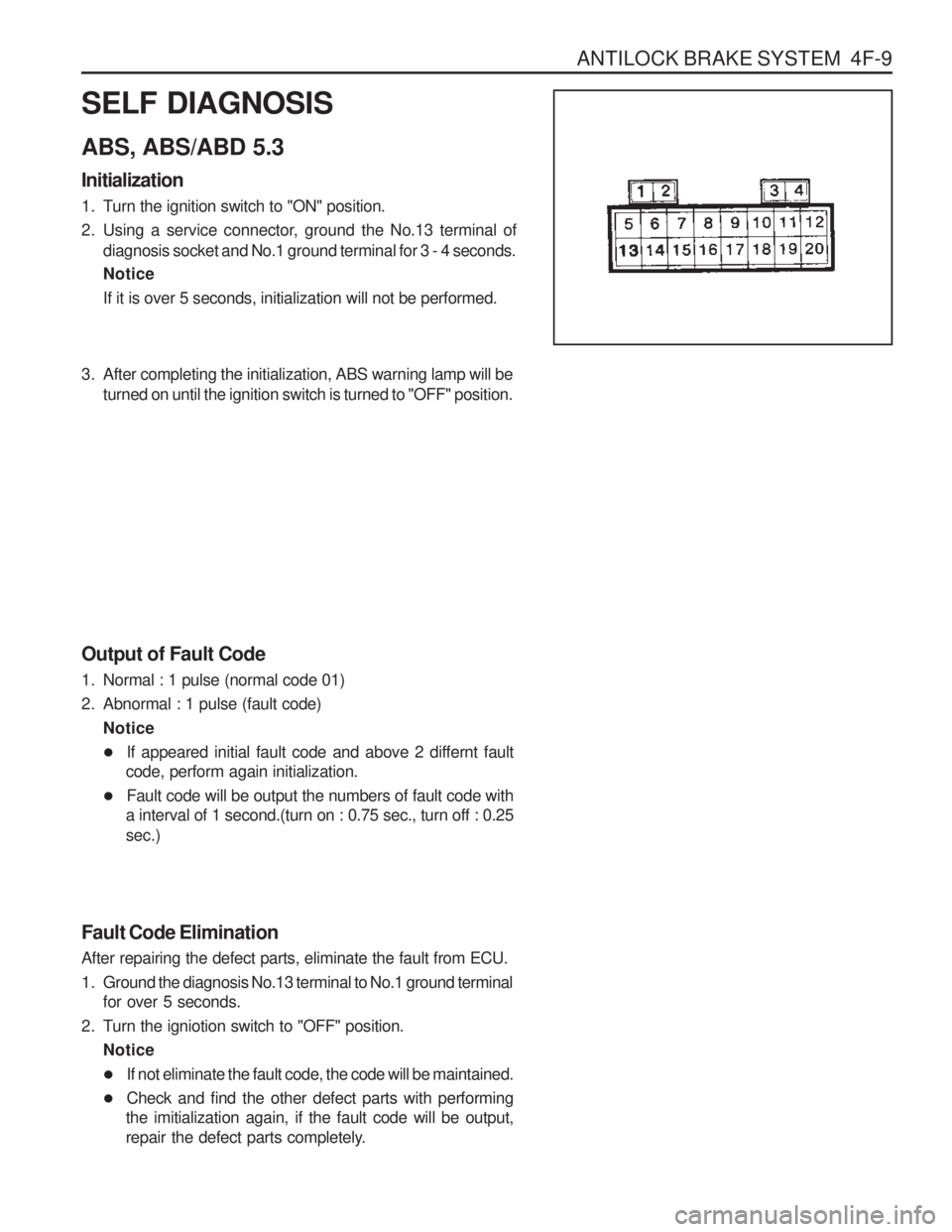

SELF DIAGNOSIS ABS, ABS/ABD 5.3 Initialization

1. Turn the ignition switch to "ON" position.

2. Using a service connector, ground the No.13 terminal ofdiagnosis socket and No.1 ground terminal for 3 - 4 seconds. Notice If it is over 5 seconds, initialization will not be performed.

3. After completing the initialization, ABS warning lamp will beturned on until the ignition switch is turned to "OFF" position.

Output of Fault Code

1. Normal : 1 pulse (normal code 01)

2. Abnormal : 1 pulse (fault code) Notice

� If appeared initial fault code and above 2 differnt fault

code, perform again initialization.

� Fault code will be output the numbers of fault code with

a interval of 1 second.(turn on : 0.75 sec., turn off : 0.25 sec.)

Fault Code Elimination After repairing the defect parts, eliminate the fault from ECU.

1. Ground the diagnosis No.13 terminal to No.1 ground terminal for over 5 seconds.

2. Turn the igniotion switch to "OFF" position. Notice

� If not eliminate the fault code, the code will be maintained.

� Check and find the other defect parts with performing

the imitialization again, if the fault code will be output,

repair the defect parts completely.

Page 990 of 1574

Model

Type Gear Ratio Oil Weight (Dry)SECTION 5B

MANUAL TRANSMISSION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5B-1 General Specifications . . . . . . . . . . . . . . . . . . 5B-1

Fastener Tightening Specifications . . . . . . . . . 5B-2

External View . . . . . . . . . . . . . . . . . . . . . . . . 5B-3 Gear T rain . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-3

Power Flow . . . . . . . . . . . . . . . . . . . . . . . . . 5B-4

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5 Will not Shift (Control Lever Moves) . . . . . . . . 5B-5 Hard Shift or Control Lever Will not Move Into

Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5

Gears Crash When Shifting . . . . . . . . . . . . . . 5B-5

Transmission Jumps Out . . . . . . . . . . . . . . . . . 5B-6

Transmission Locked in One Gear . . . . . . . . . 5B-6

Transmission Noise . . . . . . . . . . . . . . . . . . . . . 5B-6

Transmission Leakage . . . . . . . . . . . . . . . . . . 5B-7Diagnosis Table . . . . . . . . . . . . . . . . . . . . . . .

5B-8

Component Locator . . . . . . . . . . . . . . . . . . . 5B-9

Maintenance and Repair . . . . . . . . . . . . . . 5B-11

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 5B-11 Shift Control Cable . . . . . . . . . . . . . . . . . . . . 5B-11

Transmission . . . . . . . . . . . . . . . . . . . . . . . . 5B-14

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17 Major Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17

Main Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-27

Input Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-32

Counter Shaft . . . . . . . . . . . . . . . . . . . . . . . . 5B-34

Extension Housing . . . . . . . . . . . . . . . . . . . . 5B-35

Shift Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-36

Inspection of Components . . . . . . . . . . . . . . 5B-40

Pre-Installation Checks . . . . . . . . . . . . . . . . . 5B-45

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application Description

T5WC

Floor Change

3.97 : 1 2.34 : 11.46 : 11.00 : 10.85 :1

3.71 : 1

ATF DEXRON II / III 3.4 L

Check : Every 15,000km, Replace : Every 50,000km

33kg

1st

2nd 3rd

4th 5th

Reverse

Specification

Capacity(litre)

Change Interval

Notice Add LUBRIZOL (280cc) in oil after overhauling.

Page 1090 of 1574

SECTION 5D2

TRANSFER CASE (TOD)

Specifications . . . . . . . . . . . . . . . . . . . . . . . 5D2-1General Specifications . . . . . . . . . . . . . . . . . 5D2-1

Schematic and Routing Diagrams . . . . . . . 5D2-2 TOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5D2-2

T.C.C.U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5D2-3

Function Description . . . . . . . . . . . . . . . . . 5D2-4

TOD Control Unit . . . . . . . . . . . . . . . . . . . 5D2-12

Control Unit Diagram . . . . . . . . . . . . . . . . 5D2-14

TOD Control Unit . . . . . . . . . . . . . . . . . . . . 5D2-14

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 5D2-15 Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . 5D2-15

Diagnostic Trouble Codes (DTC's) . . . . . . . 5D2-17

TABLE OF CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS

ModelLength (mm)Weight (kg)Shift ModeGear Ratio Oil

Max. Torque

High Low SpecificationCapacityInterval TOD(Torque On Demand) Transfer Case (4423E)

343.036.6

4H and 4L

1 : 1

2.48 : 1

ATF S-3, S-4 or Dexron II, III 1.4 L

Inspect Every 15,000km, Replace Every 50,000km 550 lbft ( 76kg m)

.

= .

.

= .

Application Description

Coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5D2-18

Eliminate the Memorized Fault Code . . . . .

5D2-20

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 5D2-21

Maintenance and Repair . . . . . . . . . . . . . 5D2-33

On-Vehicle Service . . . . . . . . . . . . . . . . . . . 5D2-33

TOD Control Unit . . . . . . . . . . . . . . . . . . . . 5D2-33

Transfer Case (TOD) . . . . . . . . . . . . . . . . . 5D2-34

Speed Sensor in Front and Rear Propeller Shaft . . . . . . . . . . . . . . . . . . . . . 5D2-38

Replacement of Oil . . . . . . . . . . . . . . . . . . . 5D2-40

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . 5D2-41 Transfer Case . . . . . . . . . . . . . . . . . . . . . . . 5D2-41

Page 1143 of 1574

Application

Steering Wheel Steering Gear Box Oil Pump Steering Column

Minmum Turning Radius Oil SECTION 6A

POWER STEERING SYSTEM

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 6A-1

General Specifications . . . . . . . . . . . . . . . . . . 6A-1

Fastener Tightening Specifications . . . . . . . . . 6A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Hard Steering . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Steering Pulls to One Side . . . . . . . . . . . . . . . 6A-2

Excessive Wheel Play . . . . . . . . . . . . . . . . . . . 6A-2

Poor Return of Steering Wheel . . . . . . . . . . . . 6A-2

Steering Wheel Shimmy . . . . . . . . . . . . . . . . . 6A-3

SPECIFICATIONS

GENERAL SPECIFICATIONS Abnormal Noise From Steering System . . . . . 6A-3

Component Locator . . . . . . . . . . . . . . . . . . . 6A-4

Steering System . . . . . . . . . . . . . . . . . . . . . . . 6A-4

Maintenance and Repair . . . . . . . . . . . . . . . 6A-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 6A-5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-5

Oil Pump Pressure Check . . . . . . . . . . . . . . . . 6A-6

Bleeding of Power Steering System . . . . . . . . 6A-6

Steering Gear Box . . . . . . . . . . . . . . . . . . . . . 6A-7

Number of Spoke Outer Diameter

Type Gear Ratio Inner Steering AngleOuter Steering Angle

TypeMaximum Pressure

Upper Tilting Angle

Lower Tilting Angle

Type Capacity Change Interval

Description

4

396 mm

Rack and Pinion

�

33°37'

31°50' Vane

75-82 kg/cm 2

4.646° 6.969°

5.25m

ATF DEXRON II

1 L

Every 24,000 km

FASTENER TIGHTENING SPECIFICATIONS

Application

Steering Shaft Bolt Pressure Hose BoltReturn Pipe Nut Slotted Nut Steering Gearbox Bolt

N �m

30 - 40 12 - 1812 - 1835 - 45 35 - 45

Page 1181 of 1574

SECTION 8B

SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 8B-1General Specifications . . . . . . . . . . . . . . . . . . 8B-1

Schematic and Routing Diagrams . . . . . . . . 8B-2 Air Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-2

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-3

Function Description . . . . . . . . . . . . . . . . . . 8B-4 Air Bag Module . . . . . . . . . . . . . . . . . . . . . . . . 8B-6

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-7 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-7

Self Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 8B-10

Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . 8B-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwisenoted.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Air bag System Deployment Time

Detection Time

Operating Temperature

Storage TemperatureAir Bag Replacement Interval

Voltage Range Current Consumption Acceleration Range Max. Acceleration

Voltage Ramp Energy Reservation Inflator Ignition EnergySquib Resistance

Air Bag Warning Lamp ON Time (When Ignition ON) Description

< 20ms< 5ms

-40°C ~ +85°C

-40°C ~ +90°C

Every 10-year after installation 9-16V

5ms after ignition switch ON < 1A,

5ms ~ 5sec. <300mA, after 5sec. < 100mA

+/-50g

+/-600g pulse 0.5 ~ 2.0 V/s

150ms after battery disconnection

4.3mJ

2.15 ± 0.35 �

6 sec.Air Bag Diagram . . . . . . . . . . . . . . . . . . . . . . 8B-17

Maintenance and Repair . . . . . . . . . . . . . . 8B-18

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 8B-18

Air Bag Module . . . . . . . . . . . . . . . . . . . . . . . 8B-18

Clock Spring . . . . . . . . . . . . . . . . . . . . . . . . . 8B-19

Air Bag Control Unit (AC4) . . . . . . . . . . . . . . 8B-21

General Description and System Operation . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8B-22

Page 1183 of 1574

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-3

CAUTIONS

Failure to follow the correct service procedure can cause air bag damage or personal injury due to unexpected air

bag deployment. Before service (removal and installation of part, check for replacement), please be weal noticed offollowing items for your correct service.

1. For service, turn the ignition switch to ‘LOCK’ position and wait for 30 seconds after disconnecting the negative battery cable.

2. If the vehicle collapsed, remove the air bag ECU first to reserve the crash records.

3, Never use other vehicles’ air bag components and replace with specified new part.

4. Never disassemble or repair the air bag module, air bag unit and wiring harness to re-use.

5. Replace the air bag module and air bag unit with new if it dropped, cracked or damaged.

6. Only qualified technicians in service shop should check or repair the air bag,

7. Before service, should be well noticed of warning labels on the vehicle.

A. Sun Visor Side

[Warning] Pull down the sun visor and see SRS air bag warning lamp on the head lining. B. Head Lining

[Warning]

1 . This vehicle is equipped with air bag. Air bag is supplemental device for the seatbelt. Fasten your seatbelt.

2. This air bag should be replaced by authorized supplier within replacement intervals.

3. When the ignition key is turned to ON position, SRS warning lamp will turn on for 6 sec. and go off. In this case, the system is normal. For the following cases, see service manual. - SRS warning lamp does not turn on. - SRS warning lamp does not go off.- SRS warning lamp continues to blink.

C. Steering Wheel Body Inner

[Warning] Before removing the steering wheel, read service manual first. Set the front wheels straight forward

and align the center position marks of SRS clock spring. Improper removal or installation of the steering wheel can damage the SRS components. D. Engine Compartment

[Warning] This vehicle is equipped with air bag. Before checking the engine compartment, read servicemanual first. Faultuy check and service can cause SRS air bag deployment and system defects that can be led to severe damage. E. Battery Cable

[Warning]

Before disconnecting the battery power, read service manual first.