check engine SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 1190 of 1574

8B-10 SUPPLEMENTAL RESTRAINT SYSTEM(SRS)

1. Position the ignition switch to ‘OFF’.

2. Connect the harness connector of scanner to the diagnosissocket in engine compartment.

3. Turn the ignition switch to ‘ON’ position.

4. Select “Electronic control vehicle diagnosis” from function selection display and press ‘Enter’ .

5. Select “Musso (’98 model year)” from vehicle model selection display and press ‘Enter’ .

6. Select “Electronic air bag” from control system selection display and press ‘Enter’ .

7. Select “Self-diagnosis” from diagnosis item selection display.

Notice

Check sensor value of output display, if necessary.

8. Determine the fault code and trace defective component.

NoticeRefer to self-diagnosis list.

SELF DIAGNOSIS

Page 1238 of 1574

9B-10 LIGHTING SYSTEM Head Lamp Focusing When using the beam setting device

1. The head lamp focus should be adjusted by using a properbeam setting device.

2. Adjust the head lamp focus by using Up/Down, Left/Right adjusting screws.

When using the screen

1. Put the vehicle on the leveling surface.

2. One person is needed to seat on the driver's seat without other loads(CVW) and check the tire pressure if it is in the specification.

3. The distance between the headlamp and the screen is 25m.

4. Draw the vertical line (crossing the center of each headlamp) on the screen.

5. Start the engine.

6. Check if the cut-off line of the headlamp on the screen is in the specification.

1 ) Left/right direction

- The degree of the cross point at the cut-off line of theheadlamp and the vertical line should be 15.

2 ) Up/down direction - The distance between the cut-off line of the headlampand the horizontal line should be 25cm.

7. Adjust the focus if the cut-off line of the headlamp is out of

the specification by using up/down, left/right adjusting screws. A : Up/down direction adjusting screwB : Left/right direction adjusting secrw

Page 1318 of 1574

1A-6 MUSSO-SPORTS

SUPPLEMENT

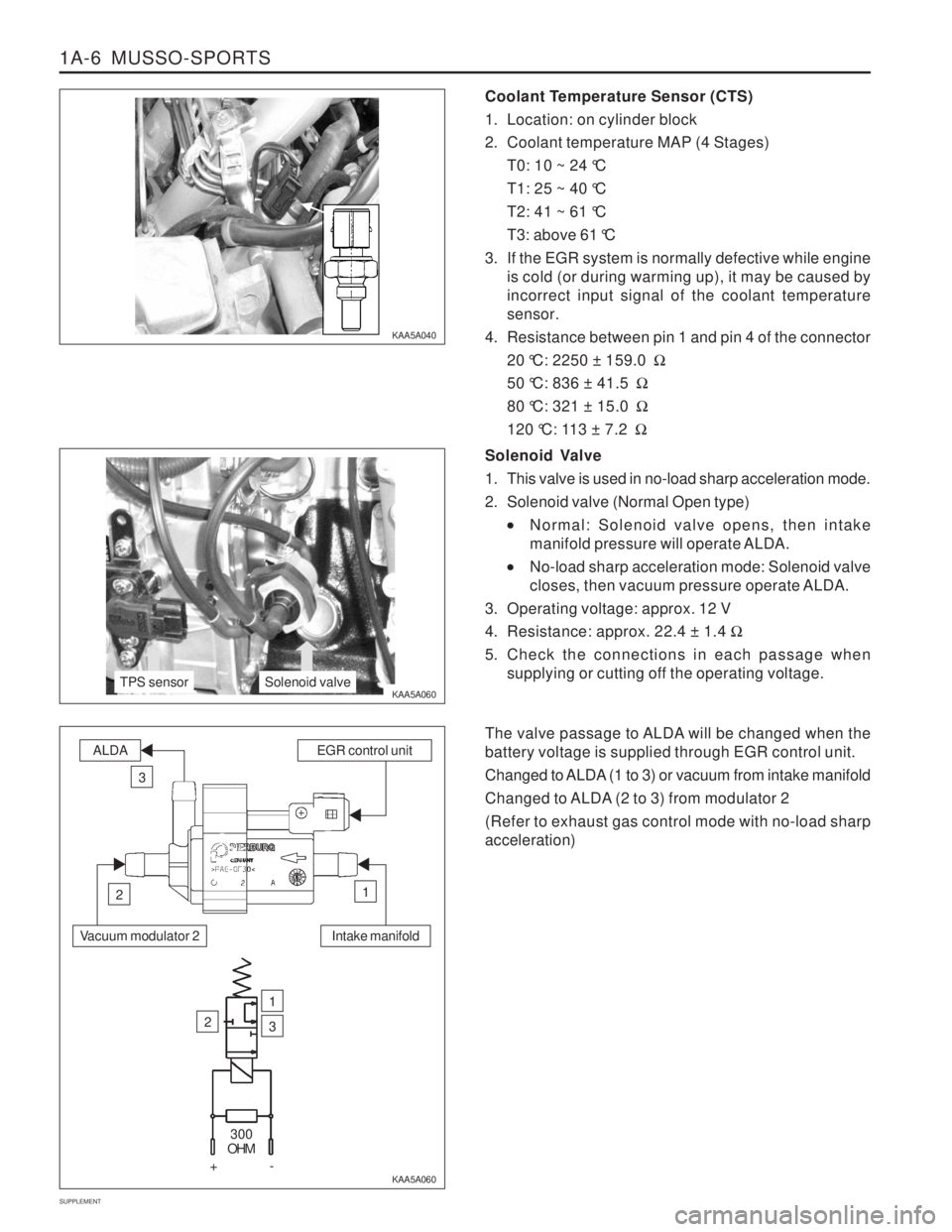

Coolant Temperature Sensor (CTS)

1. Location: on cylinder block

2. Coolant temperature MAP (4 Stages) T0: 10 ~ 24 °C

T1: 25 ~ 40 °C

T2: 41 ~ 61 °C

T3: above 61 °C

3. If the EGR system is normally defective while engine is cold (or during warming up), it may be caused by incorrect input signal of the coolant temperaturesensor.

4. Resistance between pin 1 and pin 4 of the connector 20 °C: 2250 ± 159.0 �

50 °C: 836 ± 41.5 �

80 °C: 321 ± 15.0 �

120 °C: 113 ± 7.2 �

KAA5A040 KAA5A060

KAA5A060Solenoid Valve

1. This valve is used in no-load sharp acceleration mode.

2. Solenoid valve (Normal Open type)

Normal: Solenoid valve opens, then intake

manifold pressure will operate ALDA.

No-load sharp acceleration mode: Solenoid valve

closes, then vacuum pressure operate ALDA.

3. Operating voltage: approx. 12 V

4. Resistance: approx. 22.4 ± 1.4 �

5. Check the connections in each passage when supplying or cutting off the operating voltage.

The valve passage to ALDA will be changed when the battery voltage is supplied through EGR control unit.

Changed to ALDA (1 to 3) or vacuum from intake manifold

Changed to ALDA (2 to 3) from modulator 2 (Refer to exhaust gas control mode with no-load sharp acceleration)

TPS sensorSolenoid valve

Intake manifold

ALDAEGR control unit

3

12

Vacuum modulator 2

2

1

3

300

OHM

+-

Page 1319 of 1574

MUSSO-SPORTS 1A-7

SUPPLEMENT

Throttle Position Sensor (TPS)

1. EGR unit receives TPS signal from TCU (A/T) or input

signal from pin 61 of EGR unit (M/T). The load value of engine is important signal because Huber EGRsystem make EGR valve operate in extended rangeexcept no-load sharp acceleration mode.

2. Resistance check

Disconnect the TPS sensor connector from fuelinjection pump and measure the entire resistancebetween pin 1 and pin 4. Specified value: 5 k � ± 20 %

Measure the resistance between pin 1 and pin 2 at no-load and full-load. Approx. 10 ~ 20 % of full resistance at no-load Approx. 70 ~ 85 % of full resistance at full-load

3. Voltage check

The supplied voltage to TPS from EGR unit (for

M/T) or TCU (for A/T) is approx. 5 V. 0.60 ± 0.2 V at no-load 3.85 ± 0.3 V at full-load

VACUUM LINE Installation of modulator and vacuum line (on-vehicle)

E GR n

Page 1320 of 1574

1A-8 MUSSO-SPORTS

SUPPLEMENT MAINTENANCE AND REPAIR

VACUUM PUMP AND VACUUM LINE This diagnosis procedure checks for vacuum leaks and actuator's operation while performing the actual control of EGR unit through vacuum lines in vacuum pump. The following special service tools should be used for this procedure.

001 589 73 21 00

Manual Vacuum Pump

Multi-Tester 201 589 13 21 00

Vacuum Tester

KAA5A2P0

KAA5A2R0 KAA5A2Q0

VACUUM LINE TEST Check the EGR system when the vehicle produces excessive exhaust gas. Check the vacuum lines for leaks and blocks. If there are not any faults, check the actuators controlled by EGR control unit. Install the tester in position according to the vacuum circuit diagram.

To prevent personal injury, beware of moving parts of engine.

Page 1321 of 1574

MUSSO-SPORTS 1A-9

SUPPLEMENT

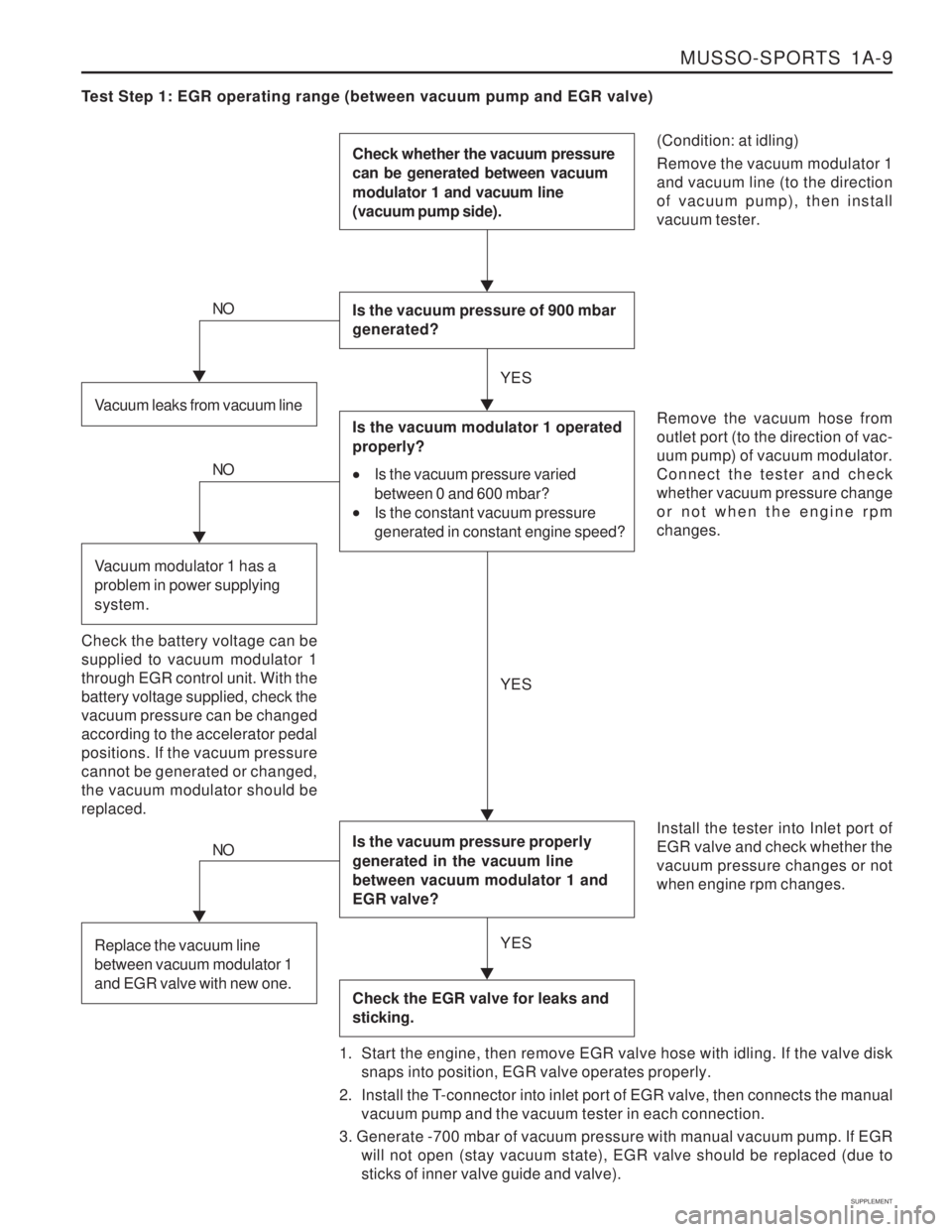

Test Step 1: EGR operating range (between vacuum pump and EGR valve)

(Condition: at idling) Remove the vacuum modulator 1 and vacuum line (to the directionof vacuum pump), then installvacuum tester.

Check whether the vacuum pressure can be generated between vacuum modulator 1 and vacuum line (vacuum pump side).

Is the vacuum pressure of 900 mbar generated?

Is the vacuum pressure properly generated in the vacuum line between vacuum modulator 1 and EGR valve?

Check the EGR valve for leaks and sticking.

Remove the vacuum hose from outlet port (to the direction of vac-uum pump) of vacuum modulator.Connect the tester and checkwhether vacuum pressure changeor not when the engine rpmchanges. Install the tester into Inlet port of EGR valve and check whether thevacuum pressure changes or notwhen engine rpm changes.

1. Start the engine, then remove EGR valve hose with idling. If the valve disk snaps into position, EGR valve operates properly.

2. Install the T-connector into inlet port of EGR valve, then connects the manual vacuum pump and the vacuum tester in each connection.

3. Generate -700 mbar of vacuum pressure with manual vacuum pump. If EGR will not open (stay vacuum state), EGR valve should be replaced (due tosticks of inner valve guide and valve).Vacuum leaks from vacuum line

NO

Is the vacuum modulator 1 operated properly?

Is the vacuum pressure varied

between 0 and 600 mbar?

Is the constant vacuum pressure

generated in constant engine speed?

Check the battery voltage can be supplied to vacuum modulator 1through EGR control unit. With thebattery voltage supplied, check thevacuum pressure can be changedaccording to the accelerator pedalpositions. If the vacuum pressurecannot be generated or changed,the vacuum modulator should bereplaced.

NO

Vacuum modulator 1 has a problem in power supplying system.

NO

Replace the vacuum line between vacuum modulator 1 and EGR valve with new one.

YES YES

YES

Page 1350 of 1574

HOW TO USE ELECTRICAL WIRING DIAGRAM 1-3

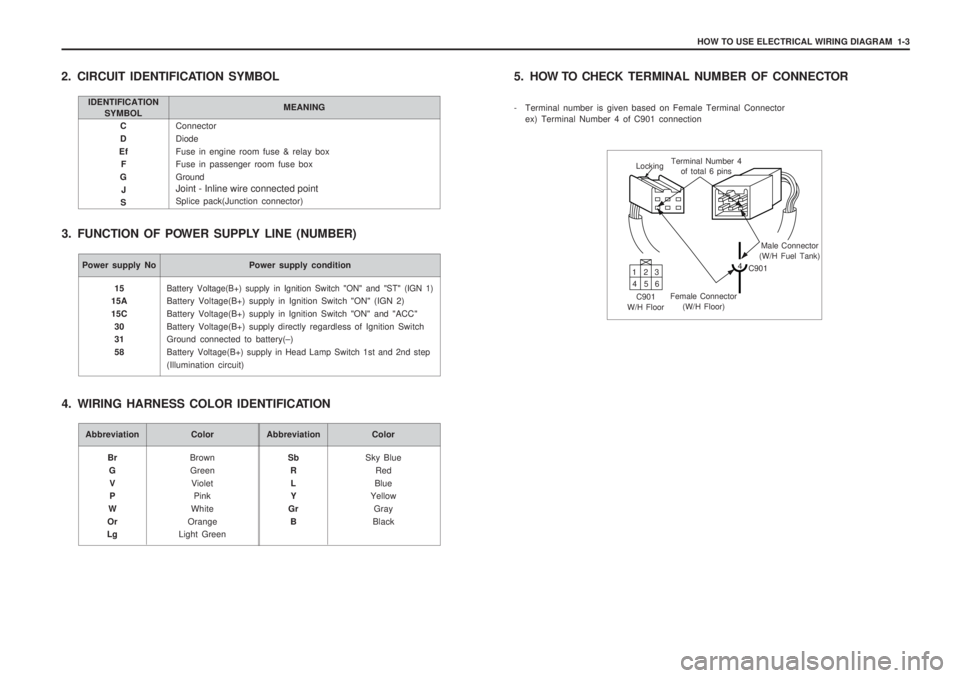

Connector DiodeFuse in engine room fuse & relay box Fuse in passenger room fuse box Ground Joint - Inline wire connected point Splice pack(Junction connector)

C D

Ef F

G J

S

2. CIRCUIT IDENTIFICATION SYMBOL

3. FUNCTION OF POWER SUPPLY LINE (NUMBER)

IDENTIFICATION SYMBOL MEANING

Power supply No Power supply condition

Battery Voltage(B+) supply in Ignition Switch "ON" and "ST" (IGN 1)

Battery Voltage(B+) supply in Ignition Switch "ON" (IGN 2) Battery Voltage(B+) supply in Ignition Switch "ON" and "ACC"Battery Voltage(B+) supply directly regardless of Ignition Switch Ground connected to battery(

–)

Battery Voltage(B+) supply in Head Lamp Switch 1st and 2nd step

(Illumination circuit)

15

15A 15C

30 31 58

Abbreviation Color

BrownGreen Violet Pink

White

Orange

Light Green

Br

GV P

W

Or

LgAbbreviation Color

Sky BlueRed

Blue

Yellow

Gray

Black

Sb

RL Y

Gr B

4. WIRING HARNESS COLOR IDENTIFICATION 5. HOW TO CHECK

TERMINAL NUMBER OF CONNECTOR

- Terminal number is given based on Female Terminal Connector ex) Terminal Number 4 of C901 connection

Locking Terminal Number 4

of total 6 pins

Male Connector

(W/H Fuel Tank)

4 C901

Female Connector (W/H Floor)

C901

W/H Floor 13

2

46 5

Page 1456 of 1574

5-90 ELECTRICAL WIRING DIAGRAMS

14. TCCU-FULL TIME

1) POWER SUPPLY, GROUND, INDICATION LAMP, PNP RELAY, CLUTCH SWITCH CIRCUIT Main - Engine Main - Engine Main - Engine DLC Connector - Main MainMain

C101 (21Pin, Colorless)C102 (2Pin, Colorless)C103 (2Pin, White) C211 (14Pin, Black) G201 G207

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Inside The Engine Room Fuse Block Inside The Engine Room Fuse Block Beside The Steering ColumnRight The I/P Fuse Block Beside THe ECM

12

11 2

29 38

28

13 2021

39 434842

CLUSTER

C101

W/H MAIN

12345 678910

11 12 13 14 15 16 17 18 19 20 21

C103

W/H MAIN

141516 13 12 11 10 9

87654321

DLC

CLUTCH SWITCH

C102

W/H MAIN

C211

W/H DLC

87654321

23222120191817161514131211109

TCCU

5

C208B

"40"

Cluster (N) TCM

"A9" (E23

MB

A/T) "N"

Start Lock Switch (E32

MB

A/T) "N"

LL L L

LL

9C208B

30 15

BAT+IGN 1

31 GND

E

f2

C103 RB

LB

Cluster

YW

Full Time TCCU

YW

G201 G201

B

2

1

G207

18

4WD

Low 4WD

Check

35

80A

F22

10A

LW

B

BB

F20

10A

F10 10 15

9

20A

B+ SIG

5V

B+

IGN 1

GND

2

C211

3

GrR

LgW 31

L

W

"12" DLC

Clutch switch(M/T) 87 86

30 85

B

Y Y

PNP

Relay (A/T) (A/T)

(M/T) 22 19

11

4

C211

4

L

BrW

"13" DLC 8

14 GND

3

: M/T

910 1213

12

11

34

56

71 4

81

2

Page 1460 of 1574

5-94 ELECTRICAL WIRING DIAGRAMS

15. TOD (TORQUE ON DEMAND) - E32, MSE

1) POWER SUPPLY, GROUND, WARNING LAMP, 4WD SWITCH, T/C MOTOR CIRCUIT Main - Engine Main - Engine Main Main Main

C101 (21Pin, Colorless)C103 (2Pin, White)S203 (Gray) G203 G205

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

TOD

CONNECTOR(NUMBER) CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Inside The Engine Room Fuse Block Under Right The Audio Upper The ECMBeside The TCCU

A1 A9 A8

A18

B1

B6 B5

B12

11 2

29 38

28

13 2021

39 434842

CLUSTER

C101

W/H MAIN

12345 678910

11 12 13 14 15 16 17 18 19 20 21

C103

W/H MAIN

45

12

67

3

T/C MOTOR

1

5678910 23

4

4WD SWITCH

1

7 7 S203

GND

BAT+

30

IGN1

ILL

15 58

31

Ef9 60A

F20 10A

F10 20A

B4 B5

G205 G203

TOD

YW LW

LgW LgW

B11 YW

2

C103

WYW

IGN1

F22

10AEf1010A

A9 LB 18

35 31

4L

4WD

CHECK

B+

B+

GND

SIG

A16 B9

BB

GNDB10

B

A1

5V

5V

5V

5V

5V SIG

A4

B7B2

6

B 7

G 4

A 2

E 1

D 3

C 5

F

RW RWB6

R

B1

R

LgWSIG

A5RW SIG

A15Br

T/C MOTOR SIG

A18

Ef2 80A

"A15"

TCMGrR BW BW GW GW

GW

B

59 1

0

A24L 4H

4

C101

4WD Switch

Cluster

M

1

2

Page 1509 of 1574

5-144 ELECTRICAL WIRING DIAGRAMS

2) WARNING LAMP(BATTERY CHARGE, BRAKE, OIL PRESSURE, SEAT BELT,ENGINE CHECK, AIR BAG) CIRCUIT

Main - Engine Engine - MainGenerator - EngineGenerator - Engine Generator - Engine Engine - MainEngine Main - ECM MainMain Air BagMain - T/M Main - T/M (GSL) Main - T/M (DSL)Main - T/MMain - T/MMain - ECM Main Engine

C101 (21Pin, Colorless) C104 (15Pin, Black)C106 (4Pin, Black)C107 (3Pin, Black) C108 (2Pin, Black) C109 (16Pin, Black)C111 (40Pin, Black)C203 (4Pin, Colorless)C207 (16Pin, Black) C208 (16Pin, Black) C208 (12Pin, Black)C209 (8Pin, Black)C210 (4Pin, Black) C213 (6Pin, Colorless) G101

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Under The Engine Room Fuse Block Under The Air Cleaner Housing (DSL, Turbo)Under The Air Cleaner Housing (DSL, N/Turbo)Under The Air Cleaner Housing (GSL)Under The Coolant Reservoir Tank Center The Engine Room Dash Panel Left The AudioUpper The T/CUpper The T/CUpper The T/C Upper The T/C (DSL) Upper The T/C (GSL)Beside Yhe ECM (MSE)Behind The Left Lamp

C101

W/H MAINC104

W/H ENGINE C106

W/H GENERATOR C107

W/H GENERATOR

C108

W/H GENERATOR C109

W/H ENGINE

C111

W/H ECM MAIN

C203

W/H MAIN

C207

W/H T/M C208

W/H MAIN (DSL) C209

W/H MAIN

C210

W/H MAIN C213

W/H ECM MAIN CLUSTER

BRAKE FLUID

LEVEL SWITCH

10 1

20 11

30 21

40 31

1234 5678

9 101112

13 14 15 16

321

654

11 2

29 38

28

13 2021

39 434842

C208

W/H T/M (GSL)

1234 5678

9 101112

13 14 15 16

1212

34

1234 5678

9 1011121234

5678

12 3412