SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Page 628 of 1574

1F3-18 OM600 ENGINE CONTROLS

Min. volume 150cm for 30 seconds

FUEL PUMP TEST Notice

Before test, replace the fuel filter cartridge and fuel prefilter.

Fuel Feed Test

1. Disconnect the fuel return line (1) and seal up it with plug.

2. Insert the plastic hose (5) and put the end into the measuring

beaker (6).

3. Disconnect the vacuum line (4) from vacuum unit (engine stop) (5) and connect the vacuum pump (7) to the vacuum unit.

4. To avoid the engine starting, build up vacuum (approx. 500 mbar).

5. Operate the starter motor for exactly 30 seconds and measure fuel volume in the beaker.

3

Page 629 of 1574

OM600 ENGINE CONTROLS 1F3-19

Fuel Pressure Test

Page 630 of 1574

1F3-20 OM600 ENGINE CONTROLS

Tools Required

617 589 04 21 00 Tester

1. Disconnect the fuel line (2) from the fuel filter.

2. Remove the banjo bolt (4) from the fuel injection pump andremove the seals (3) and fuel line (2).

3. Connect the tester (5).

4. Start the engine and read off the fuel pressure on tester (5). Notice If out of standard, replace the fuel feed pump.

Tester 617 589 04 21 00

5. Stop the engine. At Idle Speed

At Full load

> 0.3bar > 0.5bar

6. Remove the tester.

7. Replace the seal and connect the fuel line (2).

Page 631 of 1574

OM600 ENGINE CONTROLS 1F3-21

FUEL PUMP

1 Fuel Injection Pump

2 Pressure Line............................................ 13Nm

3 Suction Line

4 Hose Clip ............................................... Replace 5 Gasket ................................................... Replace

6 Spring Lock Washer

7 Hexagon Nuts

8 Fuel Pump

Page 632 of 1574

1F3-22 OM600 ENGINE CONTROLS

INJECTION NOZZLE TEST Preceding Work : Removal of fuel injection nozzle

1. Fuel Injection Nozzle .............New : 115 - 125bar Used : min. 100bar

A Closed Spray = good

B Stringy Spray = poor 2 Tester

3 Valve

Page 633 of 1574

OM600 ENGINE CONTROLS 1F3-23

Tools Required

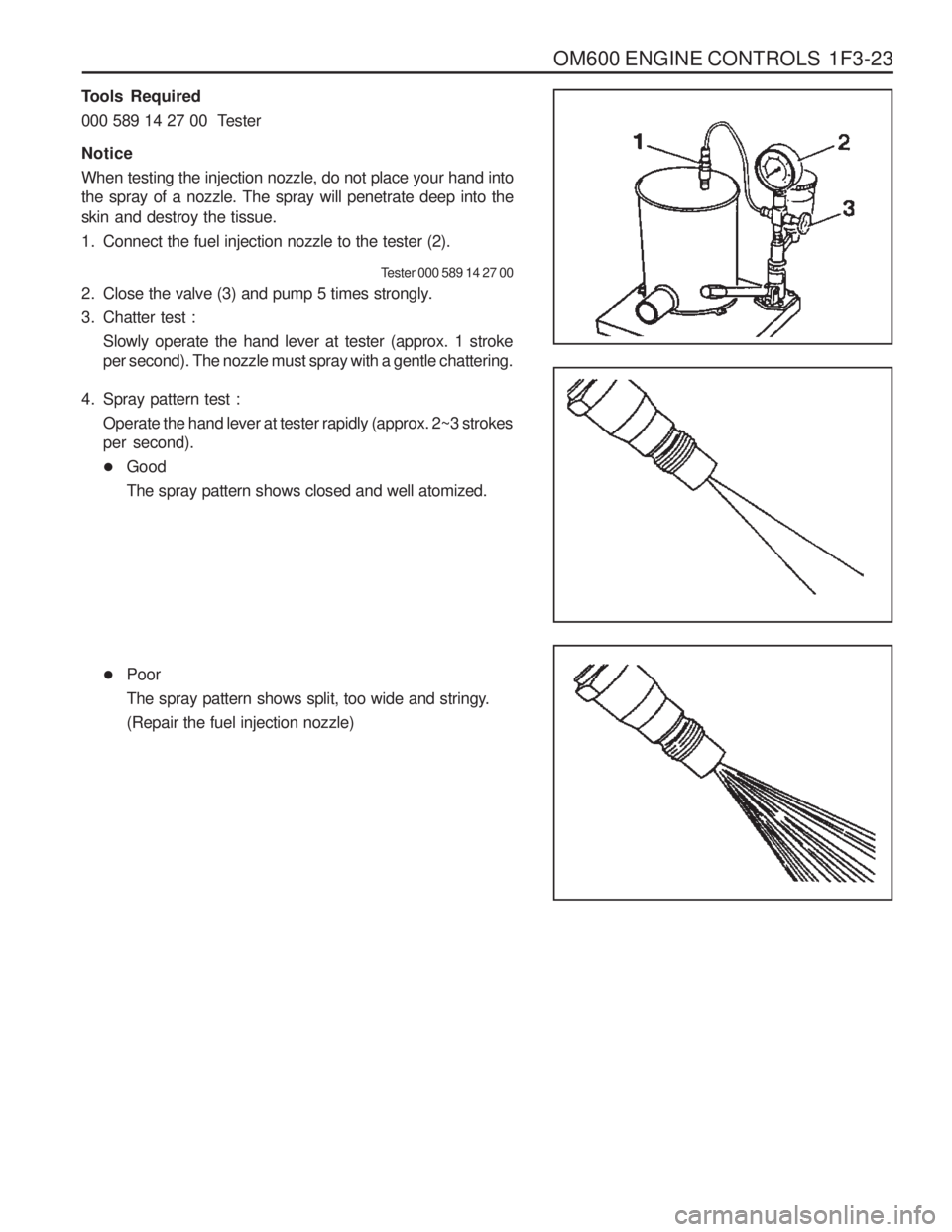

000 589 14 27 00 Tester Notice When testing the injection nozzle, do not place your hand into the spray of a nozzle. The spray will penetrate deep into the skin and destroy the tissue.

1. Connect the fuel injection nozzle to the tester (2).

Tester 000 589 14 27 00

2. Close the valve (3) and pump 5 times strongly.

3. Chatter test :

Slowly operate the hand lever at tester (approx. 1 stroke per second). The nozzle must spray with a gentle chattering.

4. Spray pattern test : Operate the hand lever at tester rapidly (approx. 2~3 strokesper second).

� GoodThe spray pattern shows closed and well atomized.

�Poor

The spray pattern shows split, too wide and stringy.(Repair the fuel injection nozzle)

Page 634 of 1574

1F3-24 OM600 ENGINE CONTROLS

5. Opening pressure test :Open the valve (3) and slowly operate the hand lever at tester (approx. 1 stroke / second) and measure opening pressure. Notice If out of standard, repair the injection nozzle.

New Nozzle Used NozzleDifference Between Nozzles 115 - 125bar

Min. 100bar Max. 5bar

6. Leak test Slowly operate the hand lever at the tester until get a

pressure of approx. 90bar. Maintain this pressure for morethan 20 seconds and within this period no drop of fuel should build up at the nozzle tip.

Page 635 of 1574

OM600 ENGINE CONTROLS 1F3-25

INJECTION NOZZLES

1 Fuel Injection Nozzle.............................35-40Nm

2 Fuel Return Hose

3 Plug

4 Nozzle Washer ....................................... Replace

5 Fuel Injection Pipe ..................................... 18Nm

Page 636 of 1574

1F3-26 OM600 ENGINE CONTROLS

Tools Required 001 589 65 09 00 Serration Wrench Removal & Installation Procedure

1. Remove the plastic clip from the injection pipe

2. Remove the fuel return hose.

3. Disconnect the injection pipes from the injection nozzles andpush them to the side.

4. Remove the fuel injection nozzle. Serration Wrench 001 589 65 09 00

Notice Replace the washers.

5. Installation should follow the removal procedure in the reverse order. Notice Pay attention to the installation position of new nozzle washer and tightening torque

Page 637 of 1574

OM600 ENGINE CONTROLS 1F3-27

INJECTION NOZZLE REPAIR Preceding Work : Removal of fuel injection nozzle

1 Nozzle Holder

2 Steel Washer

3 Compression Spring

4 Thrust Pin5 Intermediate Disc

6 Nozzle Needle

7 Nozzle Body

8 Nozzle Tensioning Nut

................................80Nm