SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Page 658 of 1574

1F3-48 OM600 ENGINE CONTROLS

10. Install the assembly cage (29) and remove the bolt (20)and pull off the washer (21). Notice Be careful that the bolt (20) is left hand thread.

Assembly Cage 601 589 05 14 00

11. Remove the chain tensioner (18) and seal (19).

12. Remove the bolt (12) and pull off the washer (11).

13. Remove the bolt (22) and pull off the square nut (28).

14. Pull out the fuel injection pump (25) and seal (23).

Page 659 of 1574

OM600 ENGINE CONTROLS 1F3-49

Installation Procedure

1. Remove the screw plug (27) and seal (26) and collect oil ina vessel.

2. Insert flange (31) onto the injection pump camshaft and turn until the cam of the governor is visible in the hole.

Flange 601 589 00 08 00

3. Tighten the locking screw. Locking Screw 601 589 05 21 00

4. Ensure that the No.1 cylinder is positioned at A TDC 15°.

Page 660 of 1574

1F3-50 OM600 ENGINE CONTROLS

10. Connect the fuel pipesNotice Replace the seal. Box Wrench Insert 000 589 77 03 00

Return Line Fuel Injection LineFuel feed LineSuction and Pressure Line 46 Nm18 Nm13 Nm13 Nm

5. Coat the new seal (23) with engine oil and install it.

6. Insert the fuel injection pump (25) and tighten the bolts

(22).

7. Remove the locking screw (32).

Tightening Torque 23 Nm

8. Tighten the bolt(12).

9. Insert the washer (21) and tighten the bolts (20) and then remove the assembly cage (29).

Tightening Torque 23 Nm

Tightening Torque 46 Nm

Page 661 of 1574

OM600 ENGINE CONTROLS 1F3-51

12. Connect the vacuum line (13, 14).

13. Connect the connecting rod (9).

14. Connect the accelerator control damper (10).(Manual transmission vehicle)

15. Install the chain tensioner.

16. Install the vacuum pump.

17. Check the start of delivery.

18. Adjust the idle speed.

11. Assemble the plastic clip (8).

Page 662 of 1574

SECTION 1G1

M162 ENGINE INTAKE & EXHAUST

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1G1-1Fastener Tightening Specifications . . . . . . . . 1G1-1

Maintenance and Repair . . . . . . . . . . . . . . 1G1-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 1G1-2

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . 1G1-2

TABLE OF CONTENTS

Intake Air Duct . . . . . . . . . . . . . . . . . . . . . . . 1G1-4

Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . 1G1-5

Resonance Flap . . . . . . . . . . . . . . . . . . . . . . 1G1-7

Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . 1G1-9

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N �m

9 - 11

22.5 - 27.5 22.5 - 27.5 9.5 - 12.5 15 - 28 28 - 47

Application

Air Cleaner Housing Cover NutIntake Manifold Bolt (M8 x 20) Intake Manifold Bolt (M8)Exhaust Mainfold Stud BoltExhaust Pipe Nut (Engine) Exhaust Pipe Bolt

Page 663 of 1574

1G1-2 M162 ENGINE INTAKE & EXHAUSTMAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

AIR CLEANER

1 Air - Cleaner Assembly

2 Air - Cleaner Shield Upper Cover

3 Blot4 Blot

5 Air Intake Shield

Page 664 of 1574

M162 ENGINE INTAKE & EXHAUST 1G1-3

Removal & Installation Procedure1. Release the clamp securing HFM sensor and air cleaner.

2. Disengage the air cleaner assembly and HFM sensor assembly.

3. Unserew the mounting bolt(6) from the bracket.

Installation Notice

Tightening Torque 22.5 - 27.5 Nm

4. Release the clamp from air cleaner assembly housing and remove the cover.

5. Remove the air cleaner assembly.

6. Remove the air cleaner housing from insulator.

Notice

Make sure the air cleaner to be seated in insulator.

7. Disengage the air duct hose and air cleaner housing and remove the housing.

8. Remove the air duct hose.

9. Unscrew the two bolts(7) from air inlet duct. Installation Notice

10. Remove the air inlet duct.

11. Installation should follow the removal procedure in the reverse order.

Tightening Torque 8 - 9 Nm

Page 665 of 1574

1G1-4 M162 ENGINE INTAKE & EXHAUST

INTAKE AIR DUCT

1 Clamp

2 Sleeve

3 Nut

4 Clamp

5 Intake Air Duct

3. Remove the clamp (4).

4. Remove the intake air duct (5) carefully. Installation NoticeExactly seat the pin of intake air duct onto the crankcase ventilation rubber mount.

5. Installation should follow the removal procedure in the reverse order.

Removal & Installation Procedure

1. Remove the clamp (1) and disconnect the HFM sensor.

2. Remove the nut (3) (arrow).

Page 666 of 1574

M162 ENGINE INTAKE & EXHAUST 1G1-5

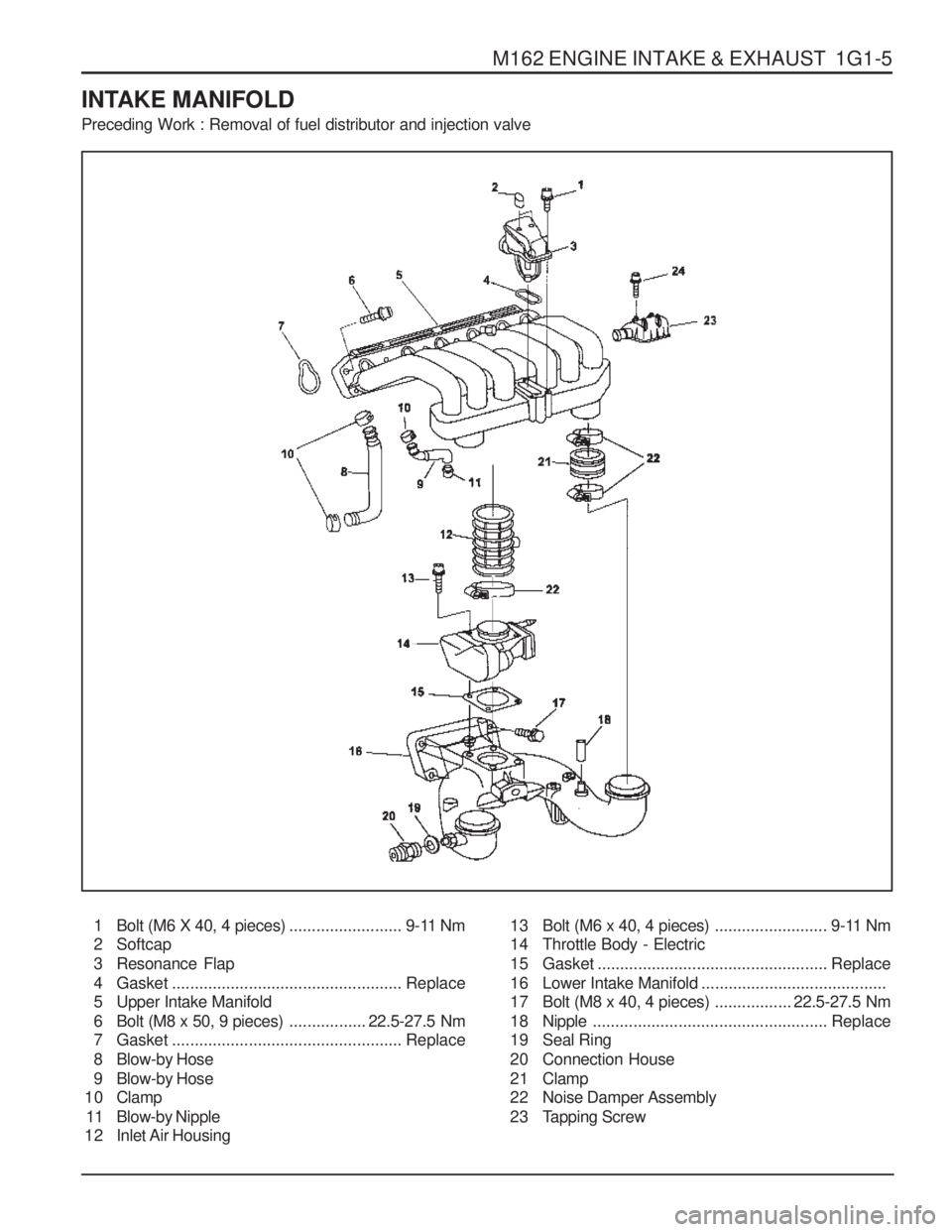

INTAKE MANIFOLD Preceding Work : Removal of fuel distributor and injection valve

1 Bolt (M6 X 40, 4 pieces)......................... 9-11 Nm

2 Softcap

3 Resonance Flap

4 Gasket ................................................... Replace

5 Upper Intake Manifold

6 Bolt (M8 x 50, 9 pieces) .................22.5-27.5 Nm

7 Gasket ................................................... Replace

8 Blow-by Hose

9 Blow-by Hose

1 0 Clamp

11 Blow-by Nipple

12 Inlet Air Housing 13 Bolt (M6 x 40, 4 pieces)

......................... 9-11 Nm

14 Throttle Body - Electric

15 Gasket ................................................... Replace

16 Lower Intake Manifold .........................................

17 Bolt (M8 x 40, 4 pieces) .................22.5-27.5 Nm

1 8 Nipple .................................................... Replace

19 Seal Ring

20 Connection House

2 1 Clamp

22 Noise Damper Assembly

23 Tapping Screw

Page 667 of 1574

1G1-6 M162 ENGINE INTAKE & EXHAUST Removal & Installation Procedure

�Upper Intake Manifold

1. Disconnect the vacuum hose (8,9).

2. Loosen the clip (22).

3. Remove the upper intake manifold (5) after unscrewing the bolt (6). Installation Notice Notice

Check the gasket and replace it if necessary.

4. Installation should follow the removal procedure in the reverse order.

� Lower Intake ManifoldPreceding work : removal of upper intake manifold

1. Remove the hose of brake booster vacuum line and idle speed connector.

2. Disconnect the hot water inlet pipe from the bottom of lower intake manifold.

3. Unscrew the bolt (17) and remove the lower intake manifold (16). Installation Notice

4. Start the engine and check for leaks at each connection part.

Tightening Torque 22.5 - 27.5 Nm

Tightening Torque 22.5 - 27.5 Nm