SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Trending: wipers, run flat, tailgate, charging, belt, high beam, warning lights

Page 691 of 1574

OM600 ENGINE INTAKE & EXHAUST 1G3-7

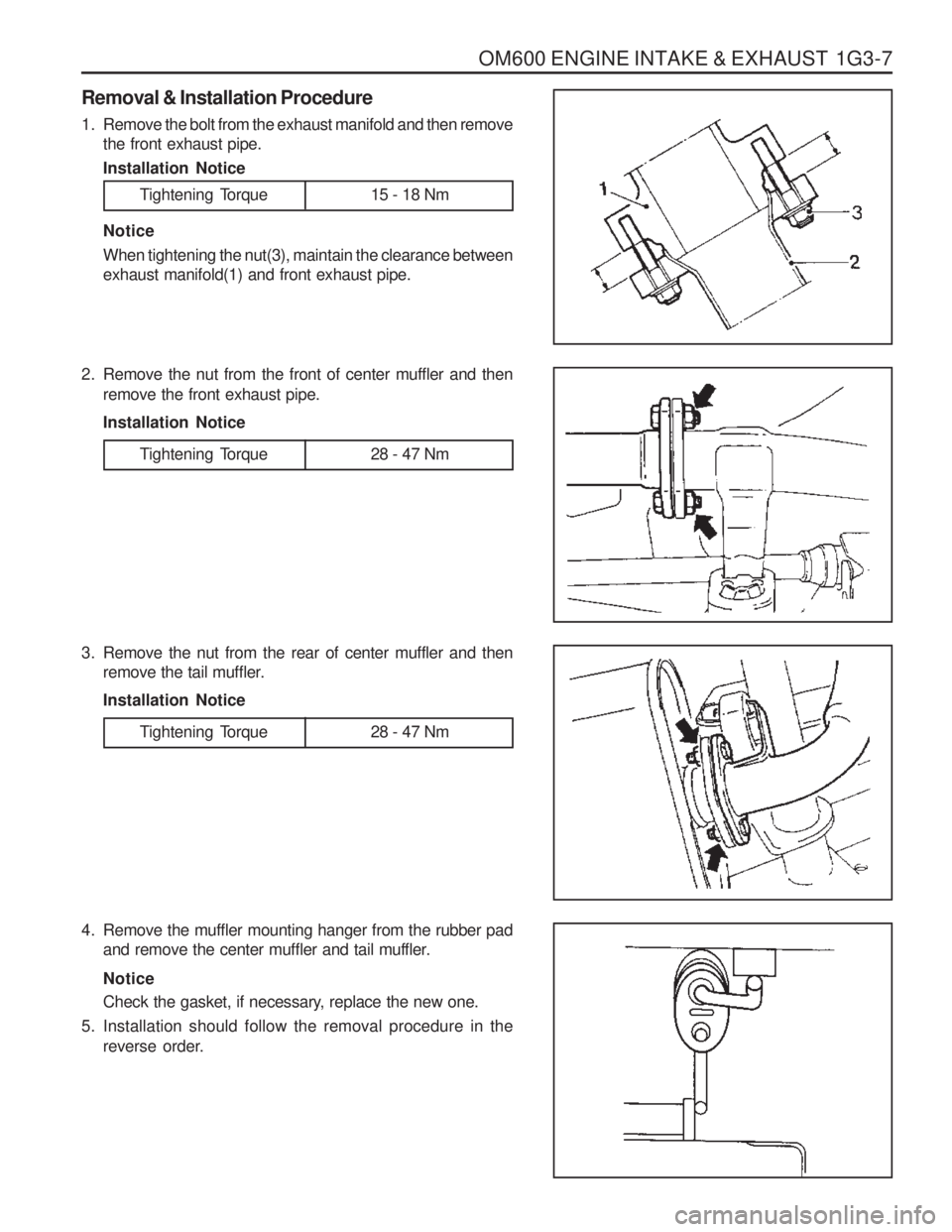

Removal & Installation Procedure

1. Remove the bolt from the exhaust manifold and then removethe front exhaust pipe. Installation Notice

Tightening Torque 15 - 18 Nm

Notice When tightening the nut(3), maintain the clearance between exhaust manifold(1) and front exhaust pipe.

2. Remove the nut from the front of center muffler and then remove the front exhaust pipe. Installation Notice

3. Remove the nut from the rear of center muffler and then remove the tail muffler.Installation Notice

4. Remove the muffler mounting hanger from the rubber pad and remove the center muffler and tail muffler. Notice

Check the gasket, if necessary, replace the new one.

5. Installation should follow the removal procedure in the reverse order.

Tightening Torque 28 - 47 Nm

Tightening Torque 28 - 47 Nm

Page 692 of 1574

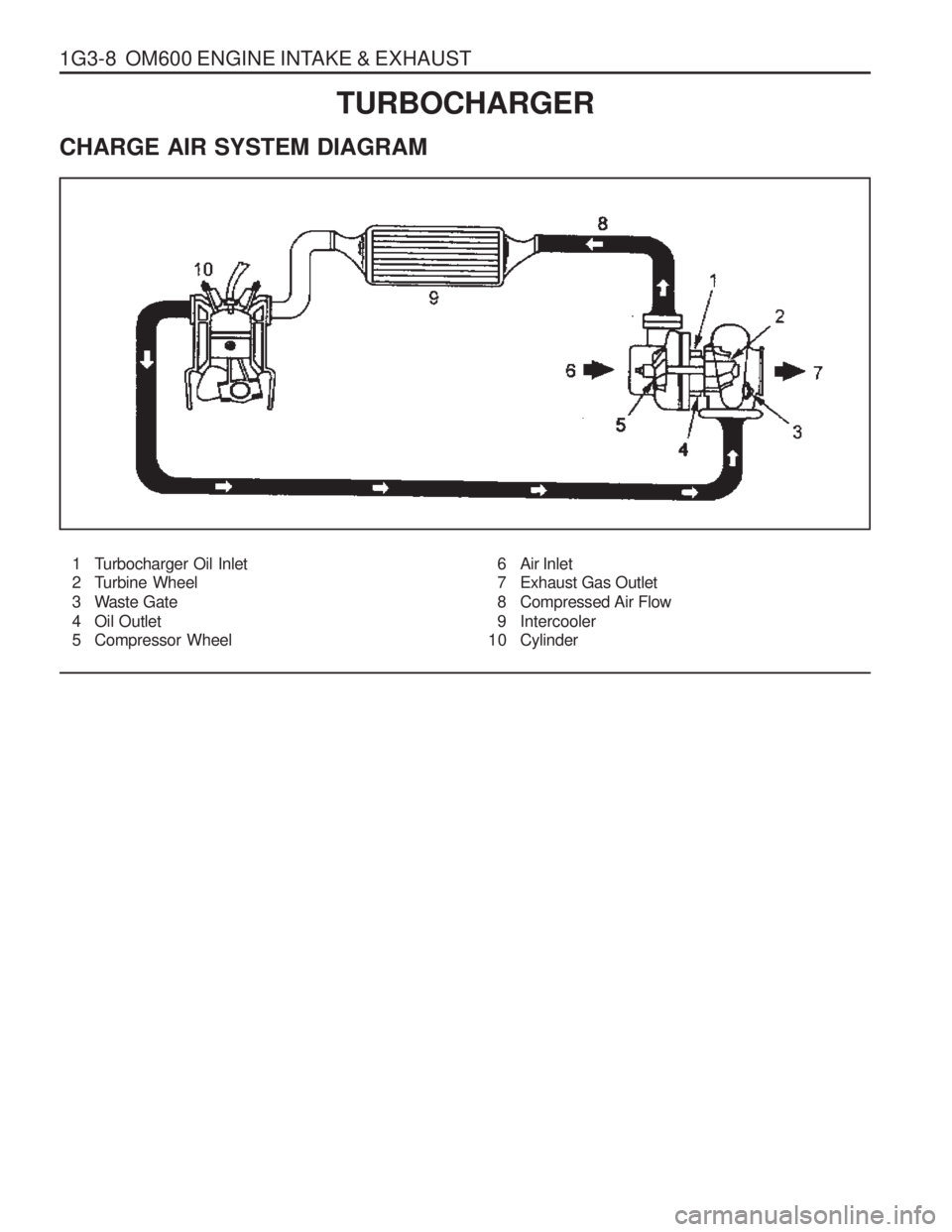

1G3-8 OM600 ENGINE INTAKE & EXHAUST

1 Turbocharger Oil Inlet

2 Turbine Wheel

3 Waste Gate

4 Oil Outlet

5 Compressor Wheel6 Air Inlet

7 Exhaust Gas Outlet

8 Compressed Air Flow

9 Intercooler

10 Cylinder

TURBOCHARGER

CHARGE AIR SYSTEM DIAGRAM

Page 693 of 1574

OM600 ENGINE INTAKE & EXHAUST 1G3-9

INTERCOOLER

1 Hoses

2 Pipes

3 Hoses

4 Intercooler5 Cover

6 Bolts

7 Screws

8 Bolts

Page 694 of 1574

1G3-10 OM600 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

1. Remove the hose connected to turbocharger and intakeduct.

2. Remove the protective cover.

3. Loosen the clamps and remove the pipe and hose connected to intercooler.

4. Unscrew the mounting bolts and remove the intercooler.

5. Installation should follow the removal procedure in the reverse order.

Page 695 of 1574

OM600 ENGINE INTAKE & EXHAUST 1G3-11

TURBOCHARGER ASSEMBLY

1 Oil Supply Line

2 Oil Return Line3 Nuts

4 Turbocharger

Page 696 of 1574

1G3-12 OM600 ENGINE INTAKE & EXHAUST

Removal & Installation Procedure

1. Remove the 2 hoses connected to intercooler.

2. Remove the hose(air cleaner to turbocharger) with blow byhose.

3. Disconnect the oil supply pipe.

4. Remove the oil return pipe.

5. Remove the support assembly.

6. Remove the 3 nuts(arrows).

Page 697 of 1574

OM600 ENGINE INTAKE & EXHAUST 1G3-13

7. Remove the turbocharger disconnecting the exhaust pipefrom the turbocharger.

8. Installation should follow the removal procedure in the reverse order.

Page 698 of 1574

SECTION 2A

SUSPENSION DIAGNOSIS

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2A-1

General Specifications . . . . . . . . . . . . . . . . . . 2A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-3

General Diagnosis . . . . . . . . . . . . . . . . . . . . . 2A-3

Input & Output Devices and Damping Force Control Logic . . . . . . . . . . . . . . . . . 2A-5

Input & Output Devices . . . . . . . . . . . . . . . . . . 2A-5

System Layout . . . . . . . . . . . . . . . . . . . . . . . . 2A-5Damping Force Control Logic . . . . . . . . . . . . . 2A-6

Normal Control . . . . . . . . . . . . . . . . . . . . . . . . 2A-6

Self-Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 2A-7

Actuator Inspection . . . . . . . . . . . . . . . . . . . . . 2A-8

Schematic and Routing Diagrams . . . . . . . . 2A-9

ECS Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-9

Self Diagnosis Test . . . . . . . . . . . . . . . . . . 2A-12

Diagnosis Test . . . . . . . . . . . . . . . . . . . . . . . 2A-12

SPECIFICATIONS

GENERAL SPECIFICATIONS

188

Application

Front

3-stage Variable Damping Force Control Type Rear

ECS Control Type

344 - 350

Shock Absorber517 - 523

Max. Length (mm)

245 ± 3

Compressed Length (mm) 102

Stroke (mm)331 ± 3

Page 699 of 1574

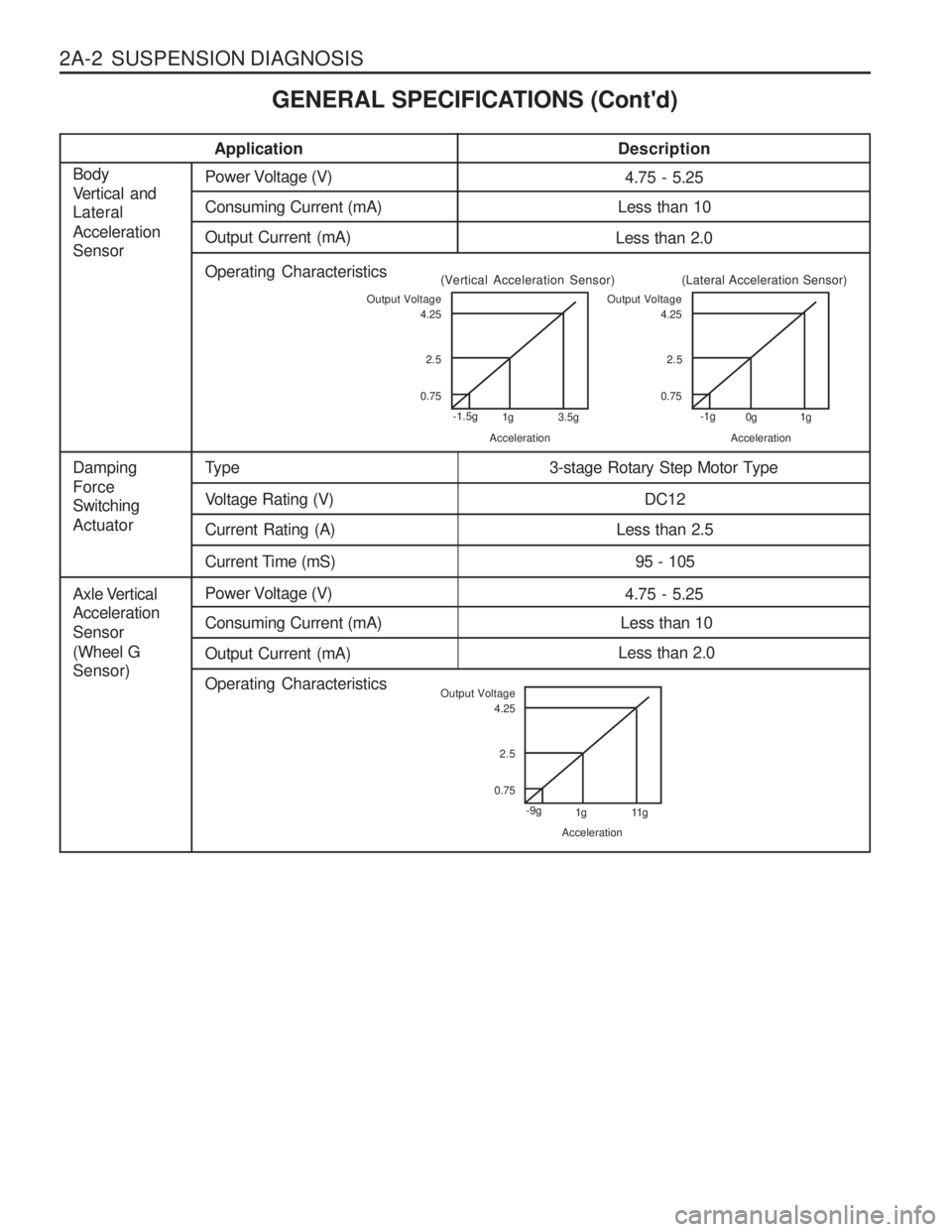

2A-2 SUSPENSION DIAGNOSISApplication

Description

4.75 - 5.25Power Voltage (V)

Axle Vertical Acceleration Sensor(Wheel G Sensor) Less than 10

Consuming Current (mA)

Less than 2.0

Output Current (mA)

Operating Characteristics

Type

Damping Force Switching Actuator3-stage Rotary Step Motor Type

Voltage Rating (V)

DC12

Current Rating (A)

Less than 2.5

Current Time (mS) 95 - 105

4.75 - 5.25Power Voltage (V)

Body

Vertical and Lateral Acceleration Sensor

Less than 10

Consuming Current (mA)

Less than 2.0

Output Current (mA)

Operating Characteristics

Output Voltage

0.752.5

4.25

-1.5g 1g 3.5g

Acceleration

(Vertical Acceleration Sensor)Output Voltage

0.752.5

4.25

-1g 0g 1g

Acceleration

(Lateral Acceleration Sensor)

Output Voltage

0.752.5

4.25

-9g 1g 11g

Acceleration

GENERAL SPECIFICATIONS (Cont'd)

Page 700 of 1574

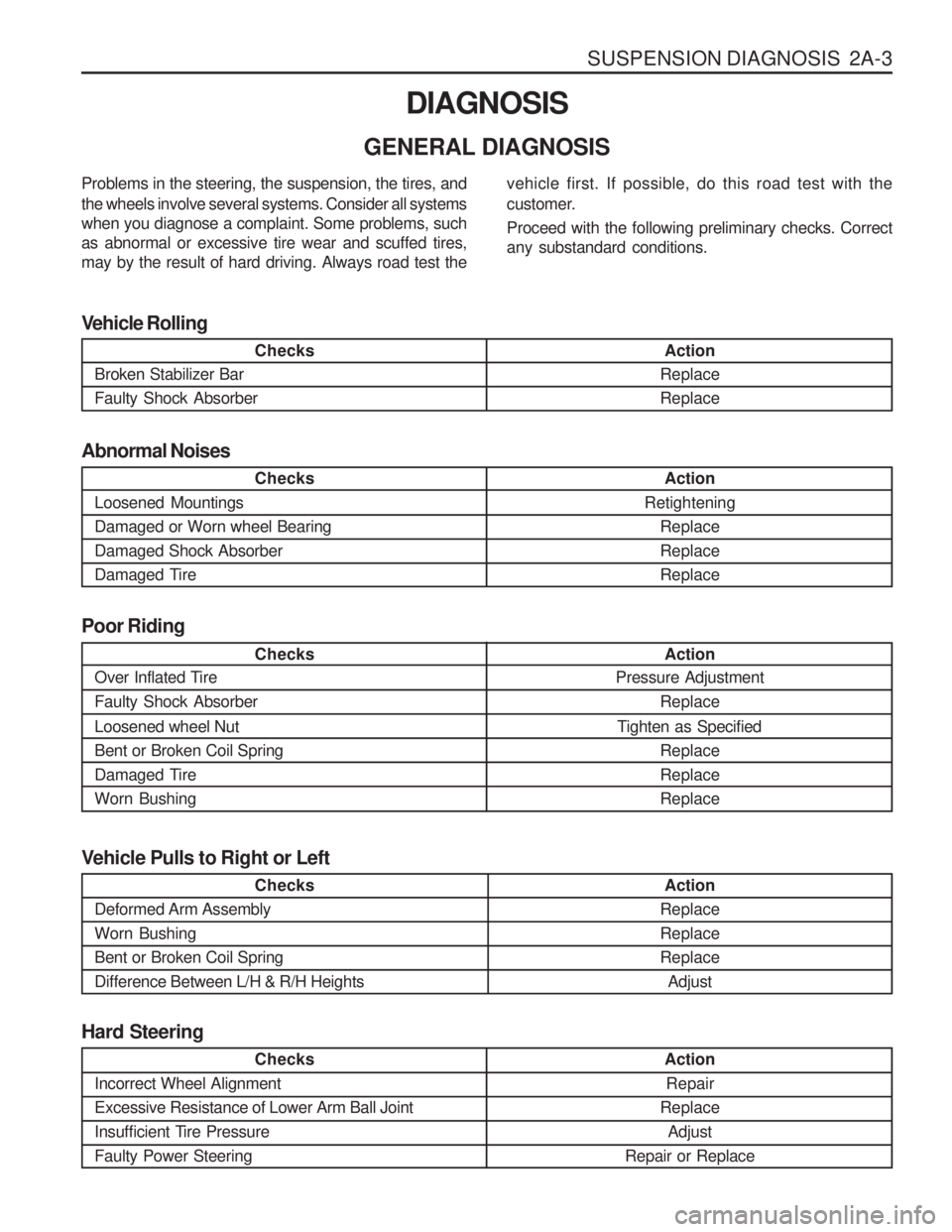

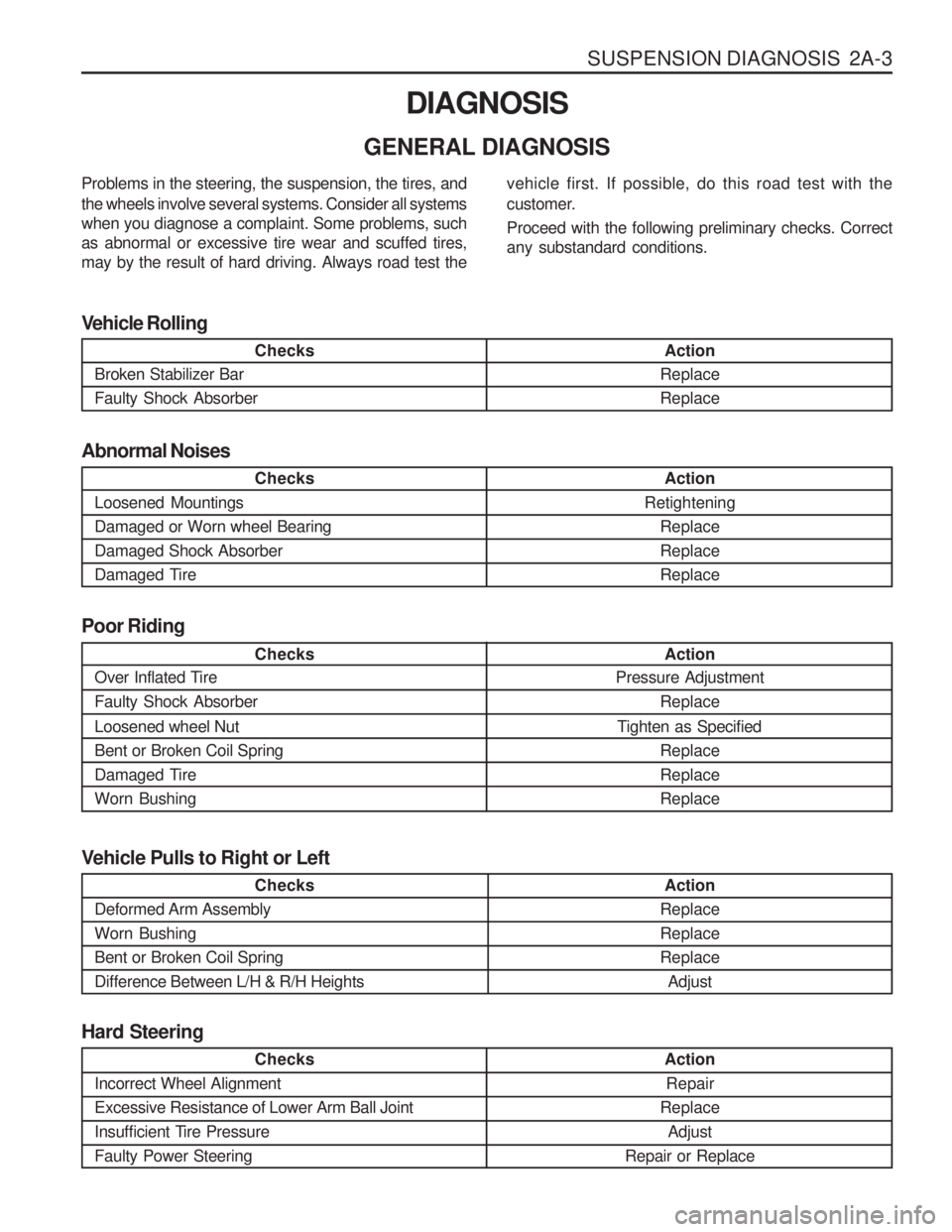

SUSPENSION DIAGNOSIS 2A-3

DIAGNOSIS

GENERAL DIAGNOSIS

Checks

Loosened Mountings Damaged or Worn wheel BearingDamaged Shock Absorber

Damaged Tire Action

Retightening ReplaceReplaceReplace

Abnormal Noises

Checks

Broken Stabilizer Bar Faulty Shock Absorber Action

ReplaceReplace

Vehicle Rolling

Checks

Over Inflated Tire Faulty Shock Absorber Loosened wheel Nut Bent or Broken Coil Spring

Damaged TireWorn Bushing Action

Pressure Adjustment

Replace

Tighten as Specified ReplaceReplaceReplace

Poor Riding

Problems in the steering, the suspension, the tires, and the wheels involve several systems. Consider all systems when you diagnose a complaint. Some problems, suchas abnormal or excessive tire wear and scuffed tires,may by the result of hard driving. Always road test the

vehicle first. If possible, do this road test with the

customer. Proceed with the following preliminary checks. Correct any substandard conditions.

Checks

Incorrect Wheel Alignment Excessive Resistance of Lower Arm Ball Joint

Insufficient Tire PressureFaulty Power Steering

Action Repair

Replace Adjust

Repair or Replace

Hard Steering

Checks

Deformed Arm Assembly Worn BushingBent or Broken Coil SpringDifference Between L/H & R/H Heights Action

ReplaceReplaceReplace Adjust

Vehicle Pulls to Right or Left

Trending: air conditioning, seat memory, wheel bolt torque, battery, ESP inoperative, lights, tailgate