engine SSANGYONG MUSSO 2003 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 1318 of 1574

1A-6 MUSSO-SPORTS

SUPPLEMENT

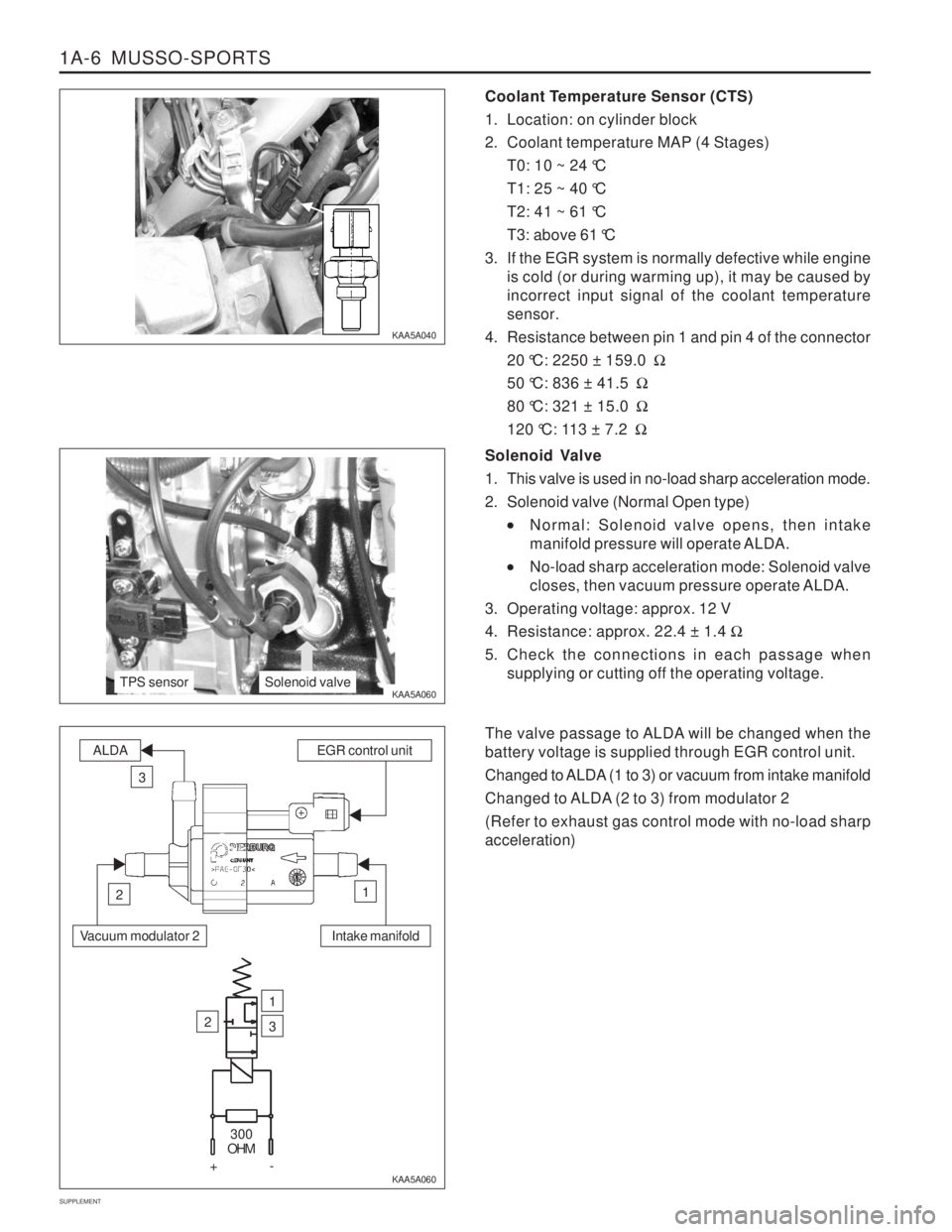

Coolant Temperature Sensor (CTS)

1. Location: on cylinder block

2. Coolant temperature MAP (4 Stages) T0: 10 ~ 24 °C

T1: 25 ~ 40 °C

T2: 41 ~ 61 °C

T3: above 61 °C

3. If the EGR system is normally defective while engine is cold (or during warming up), it may be caused by incorrect input signal of the coolant temperaturesensor.

4. Resistance between pin 1 and pin 4 of the connector 20 °C: 2250 ± 159.0 �

50 °C: 836 ± 41.5 �

80 °C: 321 ± 15.0 �

120 °C: 113 ± 7.2 �

KAA5A040 KAA5A060

KAA5A060Solenoid Valve

1. This valve is used in no-load sharp acceleration mode.

2. Solenoid valve (Normal Open type)

Normal: Solenoid valve opens, then intake

manifold pressure will operate ALDA.

No-load sharp acceleration mode: Solenoid valve

closes, then vacuum pressure operate ALDA.

3. Operating voltage: approx. 12 V

4. Resistance: approx. 22.4 ± 1.4 �

5. Check the connections in each passage when supplying or cutting off the operating voltage.

The valve passage to ALDA will be changed when the battery voltage is supplied through EGR control unit.

Changed to ALDA (1 to 3) or vacuum from intake manifold

Changed to ALDA (2 to 3) from modulator 2 (Refer to exhaust gas control mode with no-load sharp acceleration)

TPS sensorSolenoid valve

Intake manifold

ALDAEGR control unit

3

12

Vacuum modulator 2

2

1

3

300

OHM

+-

Page 1319 of 1574

MUSSO-SPORTS 1A-7

SUPPLEMENT

Throttle Position Sensor (TPS)

1. EGR unit receives TPS signal from TCU (A/T) or input

signal from pin 61 of EGR unit (M/T). The load value of engine is important signal because Huber EGRsystem make EGR valve operate in extended rangeexcept no-load sharp acceleration mode.

2. Resistance check

Disconnect the TPS sensor connector from fuelinjection pump and measure the entire resistancebetween pin 1 and pin 4. Specified value: 5 k � ± 20 %

Measure the resistance between pin 1 and pin 2 at no-load and full-load. Approx. 10 ~ 20 % of full resistance at no-load Approx. 70 ~ 85 % of full resistance at full-load

3. Voltage check

The supplied voltage to TPS from EGR unit (for

M/T) or TCU (for A/T) is approx. 5 V. 0.60 ± 0.2 V at no-load 3.85 ± 0.3 V at full-load

VACUUM LINE Installation of modulator and vacuum line (on-vehicle)

E GR n

Page 1320 of 1574

1A-8 MUSSO-SPORTS

SUPPLEMENT MAINTENANCE AND REPAIR

VACUUM PUMP AND VACUUM LINE This diagnosis procedure checks for vacuum leaks and actuator's operation while performing the actual control of EGR unit through vacuum lines in vacuum pump. The following special service tools should be used for this procedure.

001 589 73 21 00

Manual Vacuum Pump

Multi-Tester 201 589 13 21 00

Vacuum Tester

KAA5A2P0

KAA5A2R0 KAA5A2Q0

VACUUM LINE TEST Check the EGR system when the vehicle produces excessive exhaust gas. Check the vacuum lines for leaks and blocks. If there are not any faults, check the actuators controlled by EGR control unit. Install the tester in position according to the vacuum circuit diagram.

To prevent personal injury, beware of moving parts of engine.

Page 1321 of 1574

MUSSO-SPORTS 1A-9

SUPPLEMENT

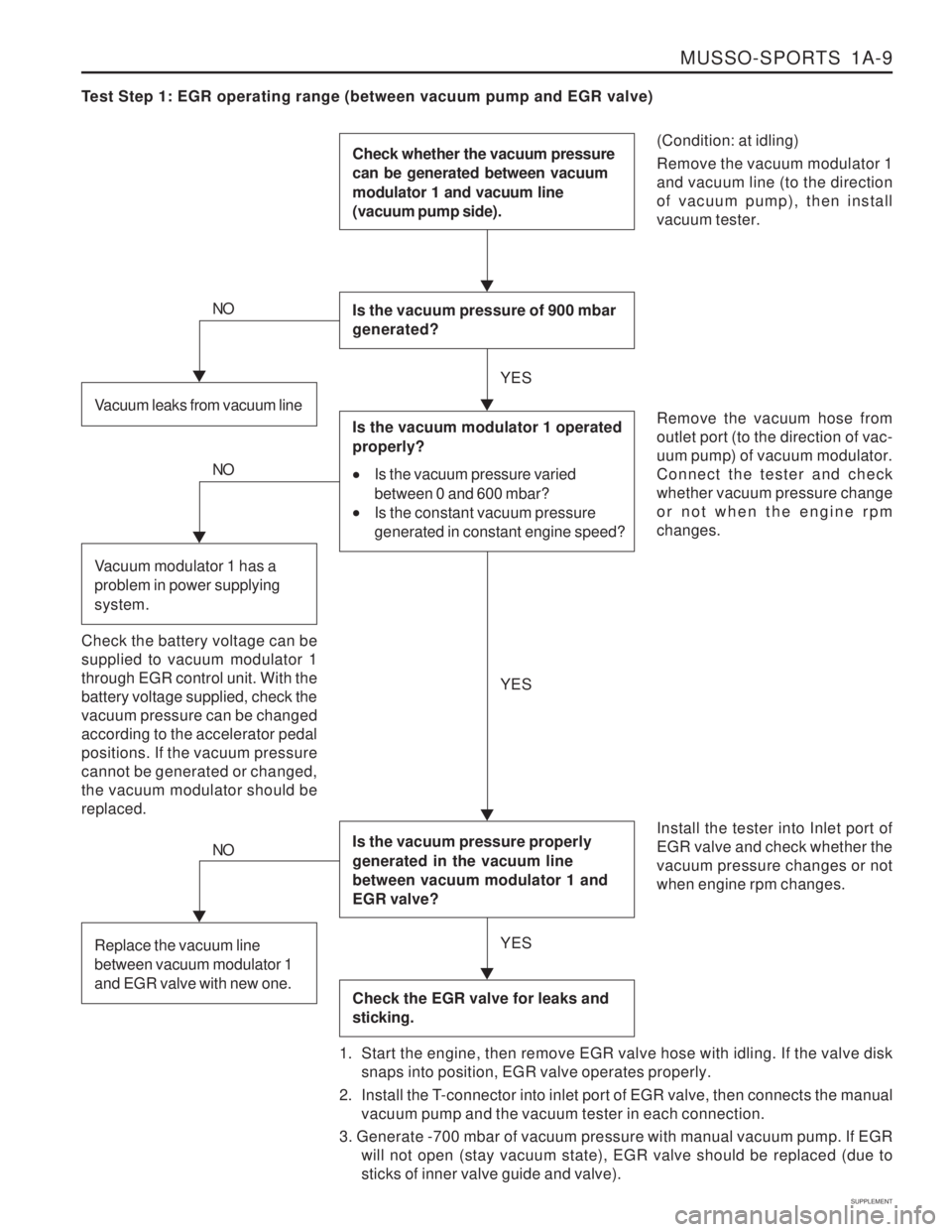

Test Step 1: EGR operating range (between vacuum pump and EGR valve)

(Condition: at idling) Remove the vacuum modulator 1 and vacuum line (to the directionof vacuum pump), then installvacuum tester.

Check whether the vacuum pressure can be generated between vacuum modulator 1 and vacuum line (vacuum pump side).

Is the vacuum pressure of 900 mbar generated?

Is the vacuum pressure properly generated in the vacuum line between vacuum modulator 1 and EGR valve?

Check the EGR valve for leaks and sticking.

Remove the vacuum hose from outlet port (to the direction of vac-uum pump) of vacuum modulator.Connect the tester and checkwhether vacuum pressure changeor not when the engine rpmchanges. Install the tester into Inlet port of EGR valve and check whether thevacuum pressure changes or notwhen engine rpm changes.

1. Start the engine, then remove EGR valve hose with idling. If the valve disk snaps into position, EGR valve operates properly.

2. Install the T-connector into inlet port of EGR valve, then connects the manual vacuum pump and the vacuum tester in each connection.

3. Generate -700 mbar of vacuum pressure with manual vacuum pump. If EGR will not open (stay vacuum state), EGR valve should be replaced (due tosticks of inner valve guide and valve).Vacuum leaks from vacuum line

NO

Is the vacuum modulator 1 operated properly?

Is the vacuum pressure varied

between 0 and 600 mbar?

Is the constant vacuum pressure

generated in constant engine speed?

Check the battery voltage can be supplied to vacuum modulator 1through EGR control unit. With thebattery voltage supplied, check thevacuum pressure can be changedaccording to the accelerator pedalpositions. If the vacuum pressurecannot be generated or changed,the vacuum modulator should bereplaced.

NO

Vacuum modulator 1 has a problem in power supplying system.

NO

Replace the vacuum line between vacuum modulator 1 and EGR valve with new one.

YES YES

YES

Page 1341 of 1574

MUSSO-SPORTS 1A-29

SUPPLEMENT

C101

W/H MAIN

12345 678910

11 12 13 14 15 16 17 18 19 20 21

Main - Engine Main - Engine Engine - MainMain - Floor Floor - FRAME FRAME - DECKMain Engine EngineMain Main Floor

C101 (21Pin, Colorless) C103 (2Pin, White) C108 (16Pin, Black)C206 (Colorless) C904 (10Pin, Black) C905 (12Pin, Black)S101 (Black) G101 G102G201 G204 G301

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Inside The Engine Room Fuse Block Under The Coolant Reservoir Tank Inside Co-Driver Side Cowl PanelBehind The Left FRAME Behind The Left FRAME Inside The Engine Room Fuse BlockBehind The Left Lamp Behind The Right Head Lamp Right The I/P Fuse BlockUpper The ECM Center The Left 'B' Pillar

123 456

HEAD LAMP

MULTI-FUNCTION SWITCH

C1C2

C3 C4

B1 B2 B3 B4

B5 B6 B7 B8 B9

B10

A1 A2 A3 A4 A5 A6

A7 A8 A9

A10 A11 A12 A13 A14

123456789101112

29 30 31 32 33 34 35 36 37 38

28 13 2714261525162417231822

19 2021

39 43 40

44 45 46 4147

48

42

CLUSTER C108

W/H ENGINE

1234 5678

9 101112

13 14 15 16

C103

W/H MAIN

12

5678910 34

HAZARD

SWITCH

2

1

TAIL

LAMP

123 456

1234 5678

9 101112

C905

W/H DECK

5432

109871 6

C904

W/H FLOOR

Page 1343 of 1574

MUSSO-SPORTS 1A-31

SUPPLEMENT

C101

W/H MAIN

12345 678910

11 12 13 14 15 16 17 18 19 20 21

Main - Engine Main - Floor Floor - FRAMMEFRAME - DECK DECK - DECK LID MainEngine Engine MainFloor

C101 (21Pin, Colorless) C206 (Colorless) C904 (10Pin, Black)C905 (12Pin, Black) C906 (2Pin, Black) S101 (Black)G101 G102 G201G301

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block Inside Co-Driver Side Cowl Panel Behind The Left FRAME Behind The Left FRAMEBehind The Left DECK LID Inside The Engine Room Fuse Block Behind The Left The LampBehind The Right Head Lamp Right The I/P Fuse Block Center The Left 'B' Pillar

12

TAIL LAMP

LICENCE

LAMP

123 456

HEAD LAMP

MULTI-FUNCTION SWITCH

C1C2

C3 C4

B1 B2 B3 B4

B5 B6 B7 B8 B9

B10

A1 A2 A3 A4 A5 A6

A7 A8 A9

A10 A11 A12 A13 A14

123456789101112

29 30 31 32 33 34 35 36 37 38

28 13 2714261525162417231822

19 2021

39 43 40

44 45 46 4147

48

42

CLUSTER

123 456

C206

W/H MAIN

12 45

78 3

9 10111213 6

14

1234 5678

9 101112

C905

W/H DECK

5432

109871 6

C904

W/H FLOOR

2

1

C906

W/H DECK

Page 1345 of 1574

MUSSO-SPORTS 1A-33

SUPPLEMENT

a. CONNECTOR INFORMATION

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

C351

W/H DRIVER

DOOR

C103

W/H MAIN

C101

W/H MAIN

C361

W/H CO-DRIVER

DOOR TWEETER

12345 678910

11 12 13 14 15 16 17 18 19 20 21

68 9

34

5 2

1

11 7

12 13 14

10

16 1720 21 22 18 19

15

68 9

34

5 2

1

11 7

12 13 14

10

16 1720 21 22 18 19

15

Main - Engine Main - Engine Main - Driver DoorMain - Co-Driver Door Main MainMain

C101 (21Pin, Colorless) C103 (2Pin, White) C351 (22Pin, Blue)C361 (22Pin, White) S201 (Black) S202 (Black)G203 Inside The Engine Room Fuse BlockInside The Engine Room Fuse BlockUpper The I/P Fuse Block Inside Co-Driver Side Cowl Panel Behind The ClusterUnder Right The Audio Right The I/P Fuse Block

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESSCONNECTOR POSITION

12

1234 5678

9 101112

13 14 15 16

Page 1347 of 1574

MUSSO-SPORTS 1A-35

SUPPLEMENT

Main - Engine Engine - Engine Genertor - EngineMain - T/M Main - T/M MainMain

C103 (2Pin, White) C105 (8Pin, Black) C108 (16Pin, Black)C901 (16Pin, Black) C902 (12Pin, Black) S201 (Black)G204

b. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

a. CONNECTOR INFORMATION

C902

W/H T/M

C101

W/H MAIN C102

W/H MAIN C108

W/H ENGINE

CONNECTOR(NUMBER) CONNECTING. WIRING HARNESSCONNECTOR POSITION

Inside The Engine Room Fuse Block

Beside Pre-Heating Unit (DSL):MUSSO SPORT

Under The Air Cleaner Housing (DSL, N/Turbo) Upper The T/C(M/T)Upper The T/C(A/T) Behind The Cluster Upper The Huber EGR

1

2

1234

5678

1234 5678

9 101112

13 14 15 16

1234 5678

9 101112

13 14 15 16

C901

W/H T/M

1234

5678

9101112

HUBER EGR

CONTROL UNIT

24

43

23

42

22

41

21

40

20

39

19

38

18

37

17

36

16

35

15

34

14

33

13

32

12

31

11

30

10

29

9

28

8

27

7

26

6

25

62

81

61

80

60

79

59

78

58

77

57

76

56

75

55

74

54

73

53

72

52

71

51

70

50

69

49

68

48

67

47

66

46

65

45

64

12 45 3

44

63

Page 1349 of 1574

1-2 HOW TO USE ELECTRICAL WIRING DIAGRAM

1. HOW TO READ ELECTRICAL WIRING DIAGRAM1) CONTENTS OF ELECTRICAL WIRING DIAGRAM (CIRCUIT)

POSITION EXPLANATION

- Upper horizontal lines : Power supply lines

- Power supply lines : 30, 15, 15A, 15C, 58

- Ef20 or F2 : Fuse Number

• Ef20 : Fuse No #20 in engine room compartment

F2 : Fuse No #2 in passenger room compartment

- Connector (C101~C901) Connector No C203 terminal No1

* Refer to Major Connector Position (Section 2)

- S201 : Splice pack (S101~S306) * Refer to Major Splice Pack Position (Section2)

- Wiring Harness Color * Refer to Wiring Harness Color Abbreviation

- Internal circuit of component (Relay) (Component Name and Terminal Number)

- Internal circuit of component (Switch) (Component Name, Terminal Number and Connecting Wiring Circuit)

- J201 : Joint(J101~J401) * Refer to Major Joint Position(Section2)

- Lower horizontal line : Ground line Ground position(G101~G402)

B : Body Ground

* Refer to Major Ground Position (Section2)

A

B C D E

F

G

H

I

A

B

C

D F

G

E I

H

Page 1350 of 1574

HOW TO USE ELECTRICAL WIRING DIAGRAM 1-3

Connector DiodeFuse in engine room fuse & relay box Fuse in passenger room fuse box Ground Joint - Inline wire connected point Splice pack(Junction connector)

C D

Ef F

G J

S

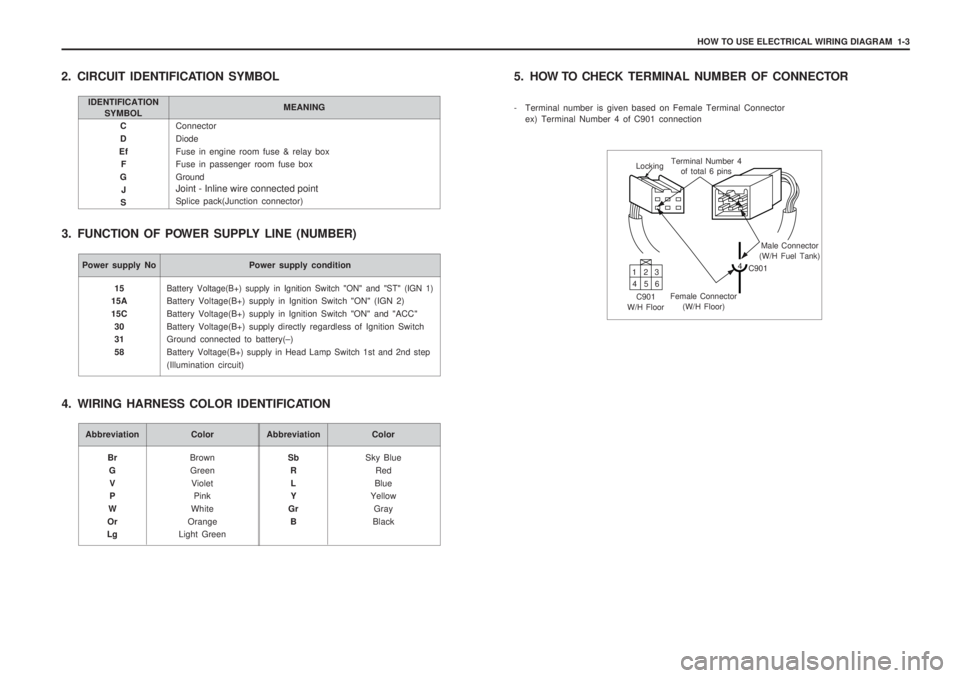

2. CIRCUIT IDENTIFICATION SYMBOL

3. FUNCTION OF POWER SUPPLY LINE (NUMBER)

IDENTIFICATION SYMBOL MEANING

Power supply No Power supply condition

Battery Voltage(B+) supply in Ignition Switch "ON" and "ST" (IGN 1)

Battery Voltage(B+) supply in Ignition Switch "ON" (IGN 2) Battery Voltage(B+) supply in Ignition Switch "ON" and "ACC"Battery Voltage(B+) supply directly regardless of Ignition Switch Ground connected to battery(

–)

Battery Voltage(B+) supply in Head Lamp Switch 1st and 2nd step

(Illumination circuit)

15

15A 15C

30 31 58

Abbreviation Color

BrownGreen Violet Pink

White

Orange

Light Green

Br

GV P

W

Or

LgAbbreviation Color

Sky BlueRed

Blue

Yellow

Gray

Black

Sb

RL Y

Gr B

4. WIRING HARNESS COLOR IDENTIFICATION 5. HOW TO CHECK

TERMINAL NUMBER OF CONNECTOR

- Terminal number is given based on Female Terminal Connector ex) Terminal Number 4 of C901 connection

Locking Terminal Number 4

of total 6 pins

Male Connector

(W/H Fuel Tank)

4 C901

Female Connector (W/H Floor)

C901

W/H Floor 13

2

46 5