SSANGYONG MUSSO 2003 Service Manual

MUSSO 2003

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57511/w960_57511-0.png

SSANGYONG MUSSO 2003 Service Manual

Trending: air conditioning, instrument panel, diagnostic menu, service indicator, spare tire, drain bolt, warning lights

Page 781 of 1574

SECTION 3D

REAR DRIVE AXLE

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 3D-1 General Specifications . . . . . . . . . . . . . . . . . . 3D-1

Fastener Tightening Specifications . . . . . . . . . 3D-2

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-3 Noise (During Straight Driving) . . . . . . . . . . . . 3D-3

Oil Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-3

Noise (During Turning) . . . . . . . . . . . . . . . . . . 3D-3

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-3

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-4 Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3D-4

Component Locator . . . . . . . . . . . . . . . . . . . 3D-5

Maintenance and Repair . . . . . . . . . . . . . . . 3D-6

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 3D-6

Axle Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-6

Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3D-9

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 3D-11 Axle Housing . . . . . . . . . . . . . . . . . . . . . . . . . 3D-11

LSD (Limited Slip Diffrential) . . . . . . . . . . . . . 3D-16

SPECIFICATIONS

GENERAL SPECIFICATIONS

Axle Shaft Type

Axle Housing TypeDifferential Reduction Ratio

Type Gear M/T M/TA/T (MB)M/TA/T (BTRA) M/T A/T (BTRA)

Description

Semi - floating

Salibury (Build-up)

Conventional Type Hypoid Gear

4.55 4.55 3.73 4.555.384.274.89Application

661NA 662NA 661LA 662LA

Page 782 of 1574

3D-2 REAR DRIVE AXLEFASTENER TIGHTENING SPECIFICATIONS

Application

Inner Bracket Mounting Nut Propeller Shaft to Rear Axle Input ShaftLower Arm Mounting Nut Lower Shock Absorber to Axle Housing Upper Arm Mounting NutStabilizer Bar Mounting BoltLateral Rod Mounting NutDrive Pinion Lock Nut Oil Drain Plug Ring Gear Mounting BoltOil Filler Plug

N

m

50 - 65 70 - 80

150 - 180 50 - 65

150 - 180 30 - 45

150 - 180240 - 310 28 - 4275 - 9028 - 42

4.55 4.554.55 4.27 5.863.733.734.89

1.9 L

SEA 80W/90, API GL - 5

M/TA/T (MB) M/T A/T (MB)A/T (BTRA)M/TA/T (MB) A/T (BTRA)

Oil Capacity Oil Specification

Application Description

GENERAL SPECIFICATIONS(CONT'D)

E20 E23 E32

Reduction Ratio

Page 783 of 1574

REAR DRIVE AXLE 3D-3

Checks

Worn or Damaged Tooth of Pinion or Side Gear Worn Pinion Shaft Excessive Backlash of Pinion Gear and Side Gear Excessive End-play of Rear Axle ShaftIncorrect Contact of Side Gear and Differential CaseAxle Housing CrackBent or Poor Installation of Drive Pinion Oil Seal

Damaged or Torn Drive Pinion Oil Seal Loosened Bearing CollarWorn or Damaged Universal JointWorn or Damaged Axle Shaft Bearing Checks

Excessive OilFaulty Seal of Carrier Contact Surface Axle Housing Crack Worn or Damaged Oil Seal Checks

Lack of OilLow Viscosity of OilInsufficient Oil Excessive Backlash of Ring Gear

Worn or Damaged Tooth of Ring and Pinion GearWorn or Damaged Drive Pinion BearingBent Axle HousingBent Differential Case Worn Pinion Shaft Incorrect Drive Pinion PreloadIncorrect Contact of Ring Gear and Pinion DIAGNOSIS

NOISE (DURING STRAIGHT DRIVING)

Action

Replenish

Replace Replace

Adjust

ReplaceReplaceReplaceReplace Replace Adjust

Retightening

OIL LEAKAGE

Action Adjust

Repair

Replace Replace

NOISE (DURING TURNING)

Action

Replace Replace Replace Adjust

Replace ReplaceReplace Replace ReplaceReplaceReplace

HEATING

Checks

Lack of Oil Insufficient Backlash of GearsExcessive Preload of Bearing Action

Replenish AdjustAdjust

Page 784 of 1574

3D-4 REAR DRIVE AXLEVIBRATION

Checks

Faulty Connection of Sliding Joint Bent Propeller ShaftSymmetry of Universal Joint Snap Ring

Loosened Yoke Bolts Action

Adjust

Replace Adjust

Tighten

NOISE

Checks

Worn or Damaged Universal Joint Bearing Fallen Off Universal Joint Snap Ring

Loosened Yoke ConnectionWorn Sliding Joint SplineInsufficient Grease Action

Replace

Adjust or Replace Tighten

Replace

Apply as Necessary

Page 785 of 1574

REAR DRIVE AXLE 3D-5

1 Spring Seat

2 Coil Spring

3 Lateral Rod

4 Shock Absorber5 Upper Arm

6 Lower Arm

7 Connecting Link

8 Stabilizer Bar

COMPONENT LOCATOR

Page 786 of 1574

3D-6 REAR DRIVE AXLEMAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

AXLE SHAFT

1 Brake Disc

2 Dust Plug

3 Rear Axle Shaft

4 Nut ....................................................... 50-65 Nm

5 Washer

6 Parking Brake Cable

7 Parking Brake Lining and Back Plate Assembly

8 Caliper Assembly

9 Gasket

10 Bolt .................................................... 85-100 Nm

11 Rear Axle Housing

Page 787 of 1574

REAR DRIVE AXLE 3D-7

Removal & Installation Procedure

1. Remove the tire.Installation Notice

2. Release the parking brake. Steel Wheel

Aluminum Wheel

Tightening Torque

3. Remove the bolts and the brake caliper.

Installation Notice Be careful not to damage the brake hose.

Tightening Torque 85 - 100 Nm

4. Remove the brake disc. Notice

To remove the disc, install the bolts (M8 x 1.25) into the service hole and uniformly tighten the bolts.

5. Disconnect the parking brake cable.

80 - 120 Nm

110 - 130 Nm

Page 788 of 1574

3D-8 REAR DRIVE AXLE

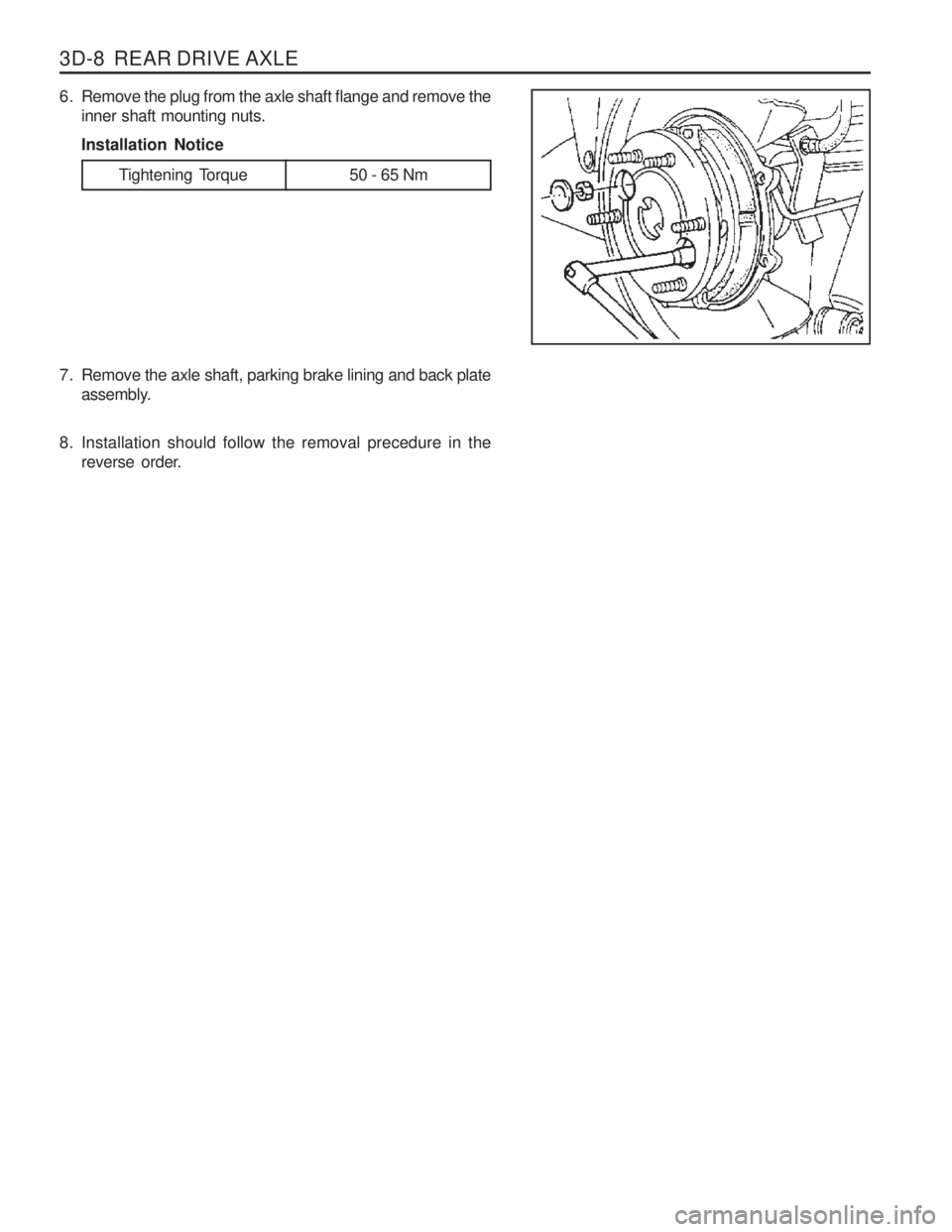

Tightening Torque 50 - 65 Nm

6. Remove the plug from the axle shaft flange and remove theinner shaft mounting nuts. Installation Notice

7. Remove the axle shaft, parking brake lining and back plate assembly.

8. Installation should follow the removal precedure in the reverse order.

Page 789 of 1574

REAR DRIVE AXLE 3D-9

AXLE Removal & Installation Procedure

1. Lift up the vehicle and support the frame safely.

2. Remove the axle shaft.

Tightening Torque 150 - 180 Nm

3. Remove the propeller shaft from the rear axle input shaft.

Installation Notice Notice Place alignment marks before removal.

Tightening Torque 81 - 89 Nm

4. Disconnect the parking brake cable and brake hose.

5. Remove the lower arm mounting nuts and remove the lower arm from the axle housing. Installation Notice

Page 790 of 1574

3D-10 REAR DRIVE AXLE

6. Separate the lower shock absorber from the axle housing.Installation Notice

7. Remove the upper arm mounting nuts and remove the upper arm form the axle housing. Installation Notice

Tightening Torque 50 - 65 Nm

8. Remove the stabilizer bar. Installation Notice

Tightening Torque 150 - 180 Nm

9. Remove the lateral rod mounting nuts and remove the lateral rod from the axle housing. Installation Notice

Tightening Torque 30 - 45 Nm

10. Lowering the axle housing slowly, remove the coil springs and spring seats.

11. Installation should follow the removal precedure in the reverse order.

Tightening Torque 150 - 180 Nm

Trending: lock, wiring, remote control, steering, electrical, transmission fluid, heating