engine SSANGYONG MUSSO 2003 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 78 of 1574

1B1-42 M162 ENGINE MECHANICAL1 Center Bolt (M18 x 50) ......1st step 200- 220 Nm

2nd step 90 °+10 °

2 Vibration Damper Disk

3 Bolt (M6 x 20, 6 pieces) .....................7.7-9.5 Nm

BELT PULLEY AND VIBRATION DAMPER Preceding Work : Removal of cooling fan and viscous clutch

Removal of fan shroud Removal of drive belt

4 Vibration Damper Assembly

5 Woodruff Key

6 Bolt (M6 x 12, 4 pieces) ......................... 9-11 Nm

7 Cooling Fan Pulley

Page 79 of 1574

M162 ENGINE MECHANICAL 1B1-43

Components

1 Center Bolt (M18 x 50)

2 Center Bolt Washer

3 Vibration Damper and Pulley Assembly

4 Key

5 Crankshaft Front Seal

6 Timing Gear Case Cover

7 Crankshaft Sprocket (Camshaft Driven)

8 Crankshaft Sprocket (Oil pump Driven)

9 Crankshaft

10 Oil Pan 11 Oil Pan Gasket

12 Oil Pan Mounting Bolt (M6 x 22)

Service Data Standard

Permissble Deviation of The Vibration Damper Radial Runout

Axial Runout0.6 mm 0.6 mm

Tools Required

103 589 00 33 00 Puller

001 589 65 09 00 Socket Wrench Insert

602 589 00 40 00 Engine Lock Removal & Installation Procedure

1. Adjust the piston of number 1 cylinder to the TDC.

Page 80 of 1574

1B1-44 M162 ENGINE MECHANICALEngine Lock 602 589 00 40 00

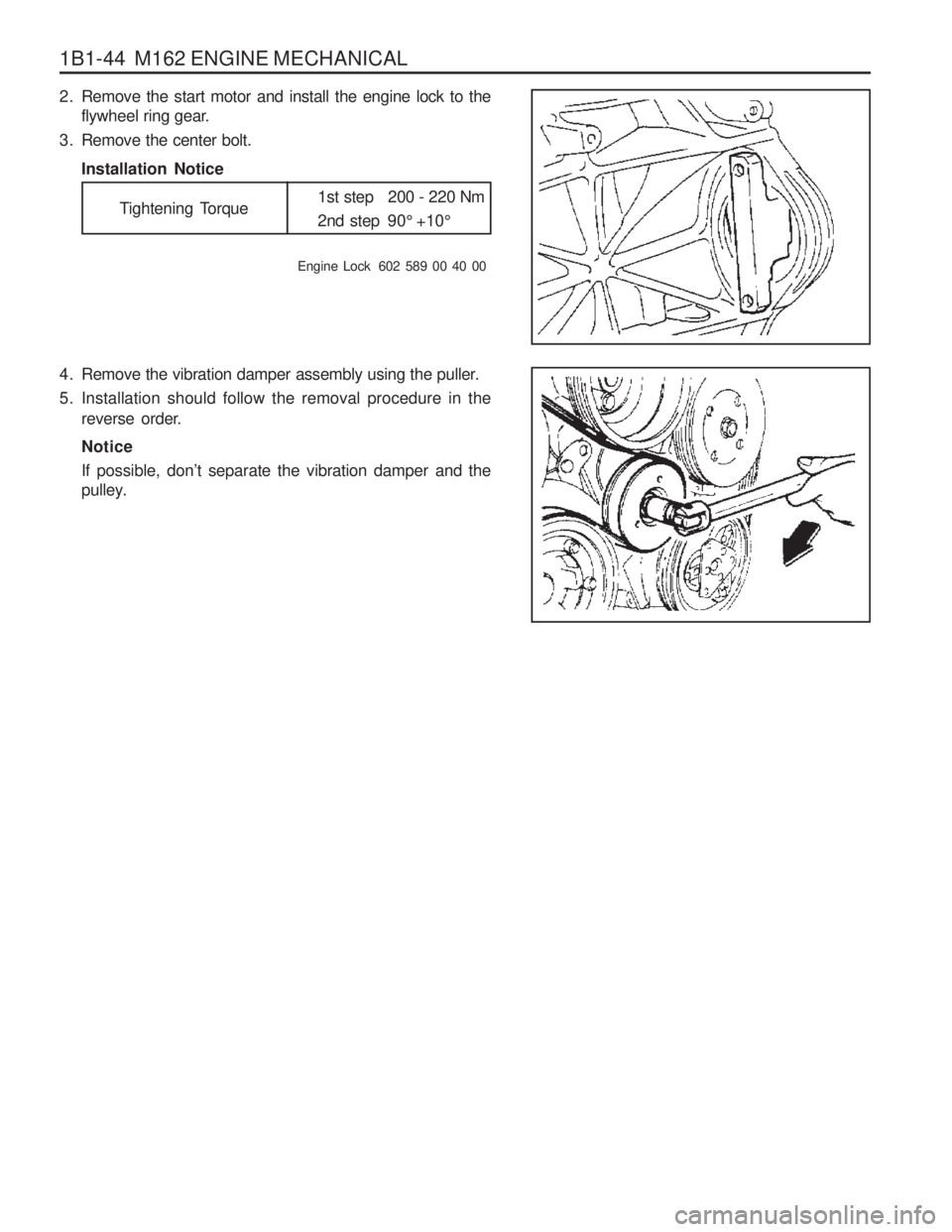

2. Remove the start motor and install the engine lock to the

flywheel ring gear.

3. Remove the center bolt.

Installation Notice

Tightening Torque 1st step 200 - 220 Nm

2nd step 90

° +10 °

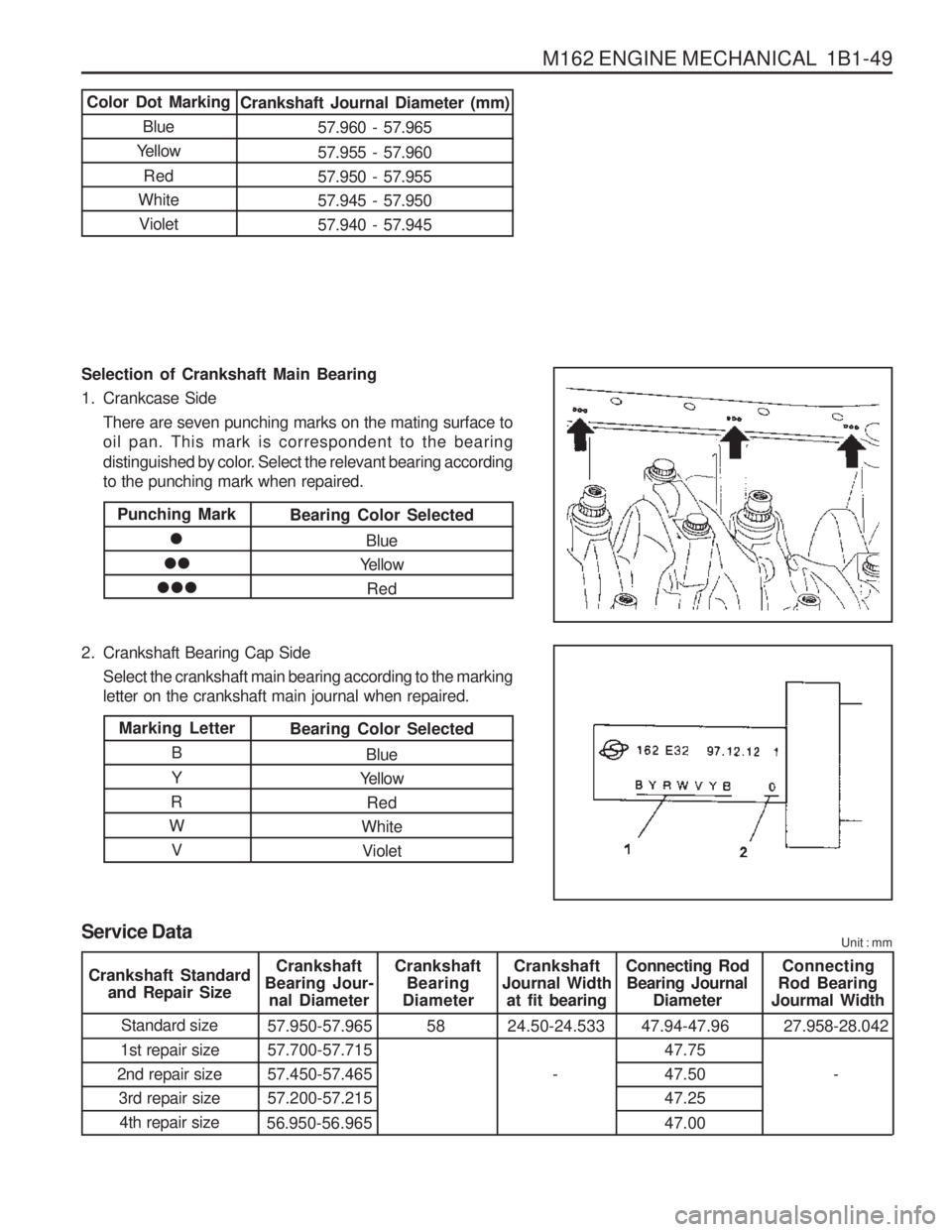

4. Remove the vibration damper assembly using the puller.

5. Installation should follow the removal procedure in the

reverse order. Notice If possible, don ’t separate the vibration damper and the

pulley.

Page 81 of 1574

M162 ENGINE MECHANICAL 1B1-45

CRANKSHAFT FRONT RADIAL SEAL Preceding Work : Removal of belt pulley and vibration damper

1 Center Bolt (M18 x 50)................................ 1st step 200-220 Nm

2nd step 90 ° +10 °

2 Center Bolt Washer

3 Sleeve (Special Tool)

4 Crankshaft Front Seal

5 Key

Tools Required

601 589 03 14 00 Sleeve Replacement Procedure

1. Remove the radial seal with a screw driver.

Notice Use a clean cloth not to damage the radial seal mounting hole and the crankshaft.

5. Remove the sleeve and install the belt pulley and thevibration damper.

6. Check for leaks while operating the engine.

2. Coat the radial sealing lip with engine oil.

3. Using the sleeve, assemble the radial seal .

4. Align the sleeve groove and the woodruff key and tighten

the center bolt until the center bolt and the damper disk stop in the movement. Installation Notice

Tightening Torque 1st step 200 - 220Nm

2nd step 90

° + 10 °

Page 82 of 1574

1B1-46 M162 ENGINE MECHANICAL CRANKSHAFT REAR RADIAL SEAL Preceding Work : Removal of flywheel or drive plate

1 Special Tool

2 Special Tool3 Crankshaft Rear Seal

Tools Required

601 589 03 43 00 Sleeve Replacement Proceudre

1. Remove the radial seal with a screw driver.

Notice Use a clean cloth not to damage the radial seal mounting hole and the crankshaft.

2. Install the special tool (2) to the crankshaft.

3. Apply the engine oil on the special tool (2).

NoticeDo not use the grease.

4. Install the radial seal on the inner parts assembler.

5. Press in the special tool (1) until the radial seal is stopped.

6. Check for leaks while operating the engine.

Page 83 of 1574

M162 ENGINE MECHANICAL 1B1-47

CRANKSHAFT Preceding Work : Removal of engine assemblyRemoval of timing gear case cover Removal of cylinder head Removal of oil pumpRemoval of oil shield

1 12-sided Stretch Bolt ........ 55 Nm x 90°, Iubricate

2 Crank Shaft Bearing Cap

3 Crank Shaft Low Main Bearing

4 Lower Thrust Bearing

5 Crank Shaft

Page 84 of 1574

1B1-48 M162 ENGINE MECHANICAL Arrangement of the Thrust Bearing and the Main Bearing

1 - 12 Weight Balance/Color Marking Point

j1 - j7 Journal Main Bearing #1 - #7� Color Dot Marking

The color dot marking are put on the 1 , 2 , 4 , 6 , 8

, 10 ,12 and it indicates the diameter of crankshaft journal

by color as below. A Crankcase Side

B Bearing Cap Side (Oil Pan Side)

C Axial Fit Bearing (Number 5 Bearing Point)

D Radial Bearing

1 Upper Main Bearing

2 Upper Thrust Bearing

3 Crankshaft

4 Lower Main Bearing

5 Lower Thrust Bearing

Page 85 of 1574

M162 ENGINE MECHANICAL 1B1-49

Selection of Crankshaft Main Bearing

1. Crankcase SideThere are seven punching marks on the mating surface to oil pan. This mark is correspondent to the bearing

distinguished by color. Select the relevant bearing according to the punching mark when repaired.

2. Crankshaft Bearing Cap Side Select the crankshaft main bearing according to the markingletter on the crankshaft main journal when repaired.

Color Dot Marking

Blue

Yellow

Red

White VioletCrankshaft Journal Diameter (mm)

57.960 - 57.965 57.955 - 57.960 57.950 - 57.95557.945 - 57.95057.940 - 57.945

Punching Mark

Bearing Color Selected

Blue

Yellow

Red

Marking Letter

B Y

R

W VBearing Color Selected

Blue

Yellow

Red

White Violet

Service Data Unit : mm

Crankshaft

Bearing Jour- nal Diameter Crankshaft

Bearing

Diameter Crankshaft

Journal Width at fit bearing Connecting Rod

Bearing Journal Diameter Connecting

Rod Bearing

Jourmal Width

Standard size

1st repair size

2nd repair size 3rd repair size4th repair size 57.950-57.965 57.700-57.71557.450-57.46557.200-57.215

56.950-56.965 58 24.50-24.533

-47.94-47.96

47.7547.5047.25 47.00 27.958-28.042

-

Crankshaft Standard

and Repair Size

Page 86 of 1574

1B1-50 M162 ENGINE MECHANICALInstallation Notice

�Make sure the crankshaft bearing cap properly seated in place in the crankcase side. When perfectly installed,the projected part (arrow) locates in the left side (intakemanifold side).

� Assemble so that the projected part of the cap andcrankcase face the same direction.

Removal & Installation Procedure

1. Unscrew the connecting rod bearing cap bolt and remove

the bearing cap. Installation Notice

2. Unscrew the crankshaft bearing cap bolts and separate the upper and lower bearing shells and thrust washers. Installation Notice

�Remove the bearing cap from front (pulley side) to rear.

� Make sure that the upper and lower bearing shells do not change each other and coat with engine oil.

� The oil grooves (arrows) in the thrust washers must faceoutward and insert the thrust bearing into the bearingcap.

� There are five kinds of thrust washers by thickness. Selectthe proper washer when repaired.

3. Remove the crankshaft.

4. Installation should follow the removal procedure in the reverse order.

5. After completion of the installation, check for the rotating condition of the crankshaft.�

Make sure that the upper and lower bearing shells do

not change each other.

� Coat the bearing shell with engine oil.

� Install the bearing cap according to the consecutive

number.

Part No. : 601 030 00 622.15 mm

Part No. : 601 030 01 62 2.20 mm

Part No. : 601 030 02 62 2.25 mm

Part No. : 601 030 03 62 2.30 mm

Part No. : 601 030 04 62 2.40 mm

Tightening Torque 40 Nm + 90 °

Tightening Torque 55 Nm + 90°

Page 87 of 1574

M162 ENGINE MECHANICAL 1B1-51

Inspection

1. If the length ‘L’ of the crankshaft bearing cap bolt exceeds

63.8mm, replace it.

2. Make sure the crankshaft bearing cap is properly seated on the cylinder block (arrows).

3. Measure and record the inner diameter of the crankshaftbearing. Notice

�Measure at 2 points (1, 2).

� Measure ‘A’,‘B’and ‘C’ as shown. If average value of ‘B’

and ‘C’is less than value ‘A’, then the average value of

‘B’ and ‘C’ is actual average value. If average value of

‘B’ and ‘C’ is more than value ‘A’is actual average value.

4. Measure and record the diameter of the crankshaft bearing journal. Notice

� Record the mean value when measured at 3 points (A,

B, C).

� Measure the inner diameter of bearing and the diameter

of journal and if it is out of the standard data, replace the bearing shell.