lock SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 693 of 828

10-14

2) Basic Theory of ABS Function

To give you a better understanding of the tasks and functions of ABS, we will first look at the

physics principles.

(1) Stopping distance

(2) Brake force on a wheel

The maximum possible brake force on a wheel depends on the wheel load and the adhesion

coefficient between tire and carriageway. With a low adhesion coefficient the brake force, which

can be obtained is very low. You are bound to know the result already from driving on winter

roads. With a high adhesion coefficient on a dry road, the brake force, which can be obtained, is

considerably higher. The brake force, which can be obtained, can be calculated from below

formula:

Maximum brake force ▶

FBmax = wheel load FR x coefficient of

frictionMh

The braking process cannot be described

sufficiently accurately with the brake forces

calculated. The values calculated only apply if

the wheel is not locked. In the case of a

locking wheel, the static friction turns into

lower sliding friction, with the result that the

stopping distance is increased. This loss of

friction is termed "slip" in specialist literature.

The stopping distance depends on the vehicle weight and initial speed when braking starts. This

also applies for vehicle with ABS, where ABS always tries to set an optimum brake force on each

wheel. As great forces are exerted between the tires and the carriageway when braking, even with

ABS the wheels may scream and rubber is left on the road. With an ABS skid mark one may be

able to clearly recognize the tire profile. The skid mark of an ABS vehicle does not however leave

any hint of the speed of the vehicle in the case of an accident, as it can only be clearly drawn at

the start of braking.

Page 694 of 828

10-154892-01

Slip ▶

The brake slip is the difference between the vehicle speed and the wheel circumference speed. If

the wheel locks, the slip is greatest, that is 100 %. If the wheel is running freely and un-braked,

the slip is the lowest, equal to 0 %. Slip can be calculated from the vehicle speed Vveh and the

wheel speed Vw. The equation for this is:

Vveh = 100 km/h, Vw = 70 km/h

Slip ratio (S) = X 100%

S = 30%Vveh - Vw

Vveh

Typical Slip Curves ▶

For the various road conditions, the friction

coefficients were plotted. The typical course

of the curves is always the same. The only

special feature is shown by the curve for

freshly fallen snow, for this curve increases

at 100 % slip. In a vehicle without ABS, the

wheel locks on braking and therefore

pushes a wedge before it. This wedge of

loose surface or freshly fallen snow means

and increased resistance and as a result the

stopping distance is shorter. This reduction

in stopping distance is not possible with a

vehicle with ABS, as the wheel does not

lock. On these surfaces the stopping

distance with ABS is longer than without

ABS. The reason for this is based in physics

and not in the Anti-Lock System.

However, as mentioned before, ABS is not

about the stopping distance, but

maneuverability and driving stability, for the

vehicle with locking wheels without ABS

cannot be steered. Ex)

Page 695 of 828

10-16

KAMM circle ▶

Before we go into the Kamm circle, you

should know that a tire offers a maximum of

100 % transmissibility. It is all the same for the

tire whether we require 100 % in the direction

of braking or in the direction of the acting

lateral force, e.g. when driving round curves. If

we drive into a curve too fast and the tire

requires 100 % transmissibility as cornering

force, the tire cannot transmit any additional

brake force. In spite of the ABS the car is

carried out of the curve. The relationship

between brake force B and cornering force S

is shown very clearly in the Kamm circle. If we

put a vehicle wheel in this circle, the

relationship becomes even clearer. In this

relationship: as long as the acting forces and

the resulting force remain within the circle, the

vehicle is stable to drive. If a force exceeds

the circle, the vehicle leaves the road.

Brake force

When depressing the brake pedal the brake

force increases to the maximum, then the

brake force decreases until the wheel locks.

Cornering force

The cornering force is a maximum when the

wheel is turning freely with zero slip. When

braking the cornering force falls to zero if the

wheel locks (slip 100 %).

ABS operating range

The operating range starts just before the

maximum brake force and ends in maximum,

for the unstable range then begins, in which

no further modulation is possible. The ABS

controls the regulation of the brake pressure

so that the brake force only becomes great

enough for a sufficient proportion of cornering

force to remain. With ABS we remain in the

Kamm circle as long as the car is driving

sensibly. We will leave driving physics with

these statements and turn to the braking

systems with and without ABS. -

-

- Brake and cornering force ▶

Page 696 of 828

10-174892-01

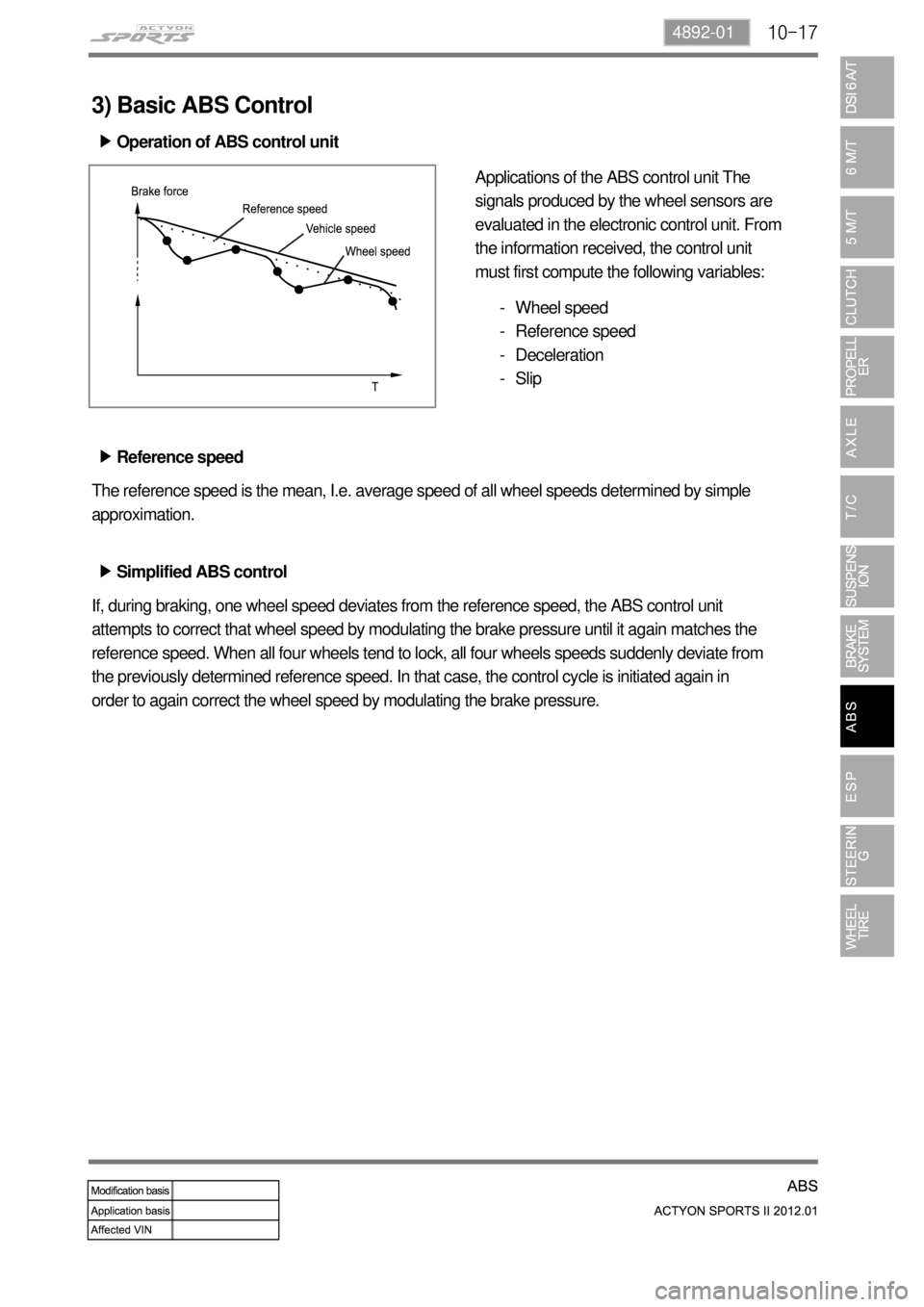

3) Basic ABS Control

Operation of ABS control unit ▶

Applications of the ABS control unit The

signals produced by the wheel sensors are

evaluated in the electronic control unit. From

the information received, the control unit

must first compute the following variables:

Wheel speed

Reference speed

Deceleration

Slip -

-

-

-

Reference speed ▶

The reference speed is the mean, I.e. average speed of all wheel speeds determined by simple

approximation.

Simplified ABS control ▶

If, during braking, one wheel speed deviates from the reference speed, the ABS control unit

attempts to correct that wheel speed by modulating the brake pressure until it again matches the

reference speed. When all four wheels tend to lock, all four wheels speeds suddenly deviate from

the previously determined reference speed. In that case, the control cycle is initiated again in

order to again correct the wheel speed by modulating the brake pressure.

Page 700 of 828

10-214892-01

2) DUMP (ABS is working) Mode

Even when the hydraulic pressure on each circuit is constant, the wheel can be locked as the

wheel speed decreases. This is when the ABS HECU detects the wheel speed and the vehicle

speed and gives the optimized braking without locking the wheels. In order to prevent the

hydraulic pressure from increasing, the inlet valve will be closed, the outlet valve will be opened

and the oil will flow into the low pressure chamber. In addition, the ABS HECU operates the pump

to circulate the oil in the low pressure chamber to the master cylinder. This may make the driver to

feel the brake pedal vibration and some

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Close

ON

Outlet valve - Normal close (NC) valve Open

Page 701 of 828

10-22

3) HOLD (ABS is working) Mode

As hydraulic pressure on each wheel increases, the wheel tends to lock. In order to prevent the

wheel from locking, the hydraulic valve modulator operates the inlet valve control solenoid to stop

increasing the hydraulic pressure by closing the inlet valve. At this moment, the outlet valve is

closed. This procedure helps the wheel to maintain a constant hydraulic pressure.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Close

OFF

Outlet valve - Normal close (NC) valve Close

Page 702 of 828

10-234892-01

4) RISE (ABS is working) Mode

As the wheel speed increases, the inlet valve opens and the wheel's pressure increases due to

the master cylinder pressure. In addition, the pump circulates the oil in the low pressure chamber

to the wheel. As the hydraulic pressure to the wheel increases, the wheel speed will reduce. This

operation continues repetitively until there are no signs that the ABS HECU tends to lock the

wheels. Since the ABS hydraulic pressure control process takes place repeatedly for a short time,

there may be some vibration and noises at the brake pedal.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Open

ON

Outlet valve - Normal close (NC) valve Close

Page 704 of 828

11-34890-10

1. SPECIFICATION

1) Specification of Active Wheel Sensor

Description Specification Remark

Supplying voltage 4.5 ~ 16.0V

Output current (at 2.75 km/h of

vehicle speed)7mA(Lo) ~ 14mA(Hi)

Tightening torqueFront: 7.8 to 11.8 Nm

Rear: 7.8 to 11.8 Nm

Operating temperature-40 ~ 150℃

Operating frequency 1 ~ 2,500Hz

UnitDescription

Specification

ABS ESP

HECU Clock frequency: 32 MHz Clock frequency: 50 MHz

Memory: 128 KB Memory: 256 KB

Wheel speed

sensorActive type Active type Output: 7~14

mA

Steering wheel

angle sensorNone Max. detection angle speed:

1500 °/SecPulse duty:

50±10%

Operating voltage: 9 to 12 V

Sensor cluster None Yaw rate sensor + lateral G

sensor + longitudinal G sensor

(4WD)Mounting

direction should

be kept (CAN

communcation)

Longitudinal G

sensor4WD only None

Pressure

sensorNone HECU integrated

Page 713 of 828

11-12

5. SYSTEM DESCRIPTION

1) Block Diagram of ESP HECU

Page 722 of 828

11-214890-10

2) DUMP (ESP is working) Mode

The pressure decreases just before the wheel speed drops and the wheels are locked.

The inlet valve closes and the outlet valve opens as in the ABS HECU and the oil is gathered at

the low pressure chamber while no additional oil is being supplied. Then the pump operates to

allow fast oil drainage. The shuttle valve and the separation valve do not operate while

decompression.