brake sensor SSANGYONG NEW ACTYON SPORTS 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 677 of 828

09-294850-01

Rear Wheel Speed Sensor (4WD)

Rear Brake Assembly

ABS/EBD Indicators

Parking Brake Lever

Parking Brake

Page 688 of 828

10-94892-01

Front wheel speed sensor (4WD)

Located on the hub assembly.

Front discFront caliper assembly (2WD/4WD)

Located on the knuckle.

ABS hydraulic device and control unit

Located near the brake booster in engine compartment.

Page 689 of 828

10-10

3. ABS CONTROL LOGIC

The principal ABS control logic is the determination of the reference speed by choosing one

wheel meeting a certain condition, while sensing the speed information from 4 wheel speed

sensors when the vehicle is being driven.

For example, when the comparison of the reference speed with front right wheel speed shows a

slip, the control signal is determined according to whether it's deceleration or acceleration. If the

control conditions are met, the brake for the front right wheel will be got under control.

Page 691 of 828

10-12

2) EBD (Electronic Brake-force Distribution) Warning Lamp

EBD warning lamps (brake warning lamp and ABS warning lamp) come on when the system

performs the self diagnosis and when it detects the malfunction of EBD system. However, the

brake warning lamp comes on regardless of EBD system when the parking brake is applied.

EBD warning lamp ON:

When turning the ignition switch to ON position, ABS warning lamp and the brake warning

lamp comes on for 3 seconds for self diagnosis and goes off if the system is OK

(initialization mode).

When applying the parking brake, the brake warning lamp comes on.

When the brake fluid is not sufficient, the brake warning lamp comes on.

When disengaging the connector, the warning lamp comes on.

When the system is defective, ABS warning lamp and the brake warning lamp come on

simultaneously. A.

B.

C.

D.

E.

When the solenoid valve is defective

When one or more wheel sensors are defective

When ABS HECU is defective

When the voltage is abnormal

When valve relay is defective a.

b.

c.

d.

e.

When the communication between warning lamp CAN modules in meter cluster is failed,

the warning lamp comes on. F.

Page 696 of 828

10-174892-01

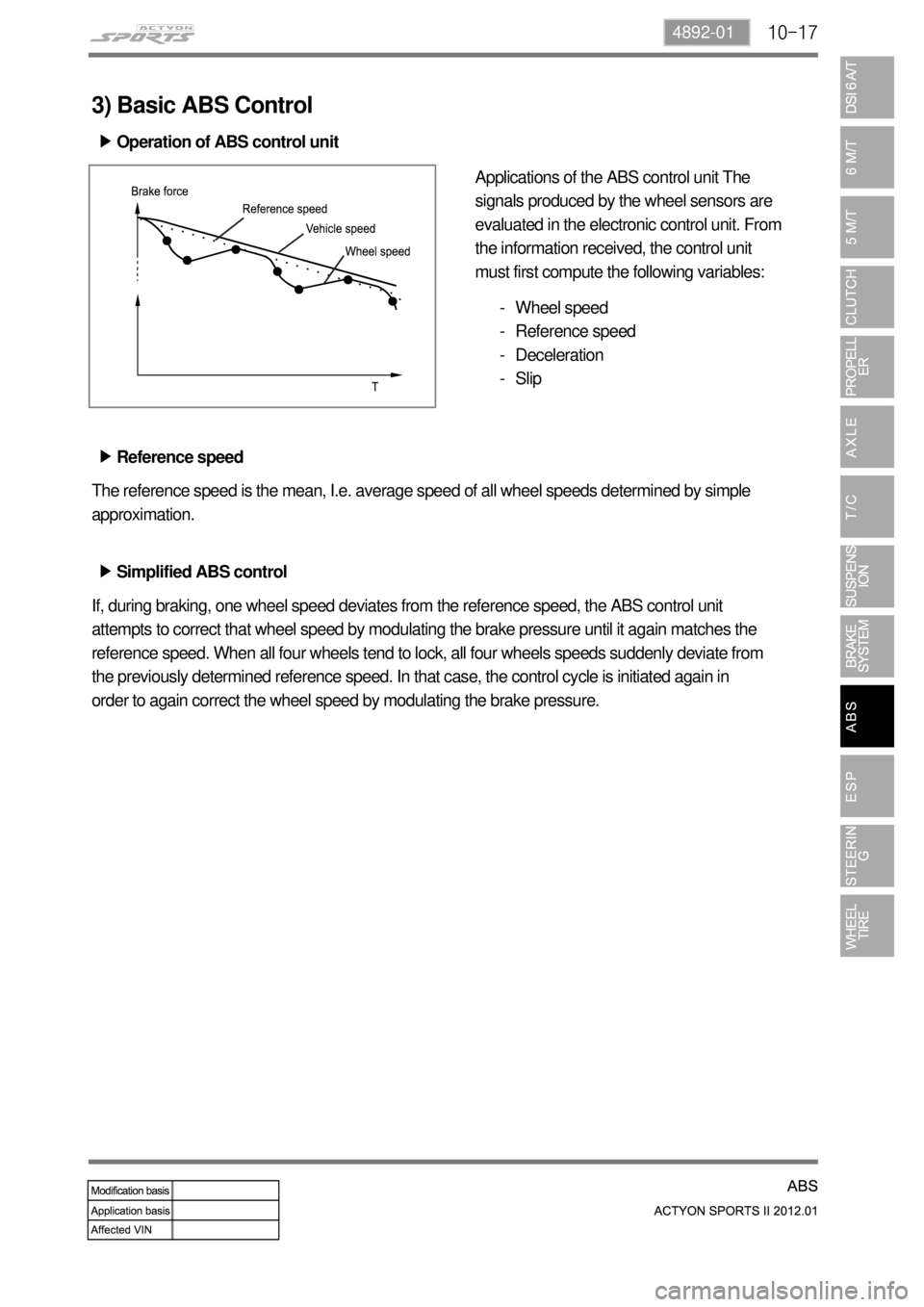

3) Basic ABS Control

Operation of ABS control unit ▶

Applications of the ABS control unit The

signals produced by the wheel sensors are

evaluated in the electronic control unit. From

the information received, the control unit

must first compute the following variables:

Wheel speed

Reference speed

Deceleration

Slip -

-

-

-

Reference speed ▶

The reference speed is the mean, I.e. average speed of all wheel speeds determined by simple

approximation.

Simplified ABS control ▶

If, during braking, one wheel speed deviates from the reference speed, the ABS control unit

attempts to correct that wheel speed by modulating the brake pressure until it again matches the

reference speed. When all four wheels tend to lock, all four wheels speeds suddenly deviate from

the previously determined reference speed. In that case, the control cycle is initiated again in

order to again correct the wheel speed by modulating the brake pressure.

Page 698 of 828

10-194892-01

5) EBD (Electronic Brake Force Distribution) System

System description ▶

As an add-on logic to the ABS base algorithm, EBD works in a range in which the intervention

thresholds for ABS control are not reached yet.

EBD ensures that the rear wheels are sensitively monitored for slip with respect to the front axle. If

slip is detected, the inlet valves for the rear wheels are switched to pressure hold to prevent a

further increase in pressure at the rear-wheel breaks, thus electronically reproducing

a pressure-reduction function at the rear-wheel brakes.

ABS features an enhanced algorithm which includes control of the brake force distribution

between the front and rear axles. This is called Electronic Brake Distribution. In an unloading car

condition the brake efficiency is comparable to the conventional system but for a fully loaded

vehicle the efficiency of the EBD system is higher due to the better use of rear axle braking

capability.

Advantages ▶

Elimination of conventional proportioning

valve EBD utilizes the existing rear axle

wheel speed sensor to monitor rear wheel

slip.

Based on many variables in algorithm a

pressure hold, increase and/or decrease

pulsetrain may be triggered at the rear

wheels insuring vehicle stability.

Vehicle approaches the ideal brake force

distribution (front to rear).

Constant brake force distribution during

vehicle lifetime.

EBD function is monitored via ABS safety

logic (conventional proportioning valves are

not monitorable). -

-

-

-

-

Ideal distribution

EBD start point

Cut-in point

Fixed distribution 1.

2.

3.

4.

Page 709 of 828

11-8

ESP OFF switch

Located on the left side of

instrument panel.

Rear wheel speed sensor

Located on the both ends of

rear axle.Front wheel speed sensor

Located on the hub

assembly.Sensor cluster

Located at the bottom of

center fascia panel.

Steering wheel angle sensor

Located on column shaft with

contact coil.HECU assembly

Located near the brake

booster in engine

compartment and contains

the pressure sensor.

2. COMPONENTS

Page 712 of 828

11-114890-10

2) EBD (Electronic Brake-force Distribution) Warning Lamp (Brake

Warning Lamp)

EBD warning lamp when the system perform the self diagnosis and when it detects the

malfunction of EBD system. However, the brake warning lamp comes on regardless of EBD

when the parking brake is applied.

EBD warning lamp ON:

When turning the ignition switch to ON position, ABS warning lamp and the brake warning

lamp comes on for 3 seconds for self diagnosis and goes off if the system is OK

(initialization mode).

When applying the parking brake, the brake warning lamp comes on.

When the brake fluid is not sufficient, the brake warning lamp comes on.

When disengaging the connector, the warning lamp comes on.

When the system is defective, ABS warning lamp and the brake warning lamp come on

simultaneously. 1.

2.

3.

4.

5.

When the solenoid valve is defective

When one or more wheel sensors are defective

When ABS HECU is defective

When the voltage is abnormal

When valve relay is defective a.

b.

c.

d.

e.

When the communication between warning lamp CAN module in meter cluster, the

warning lamp comes on. 6.

3) ESP OFF Indicator

ESP OFF indicator ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for

self diagnosis and goes off if the system is OK (initialization mode).

When the ESP OFF switch is pressed to turn off ESP function, ESP OFF indicator comes on. 1.

2.

4) ESP Warning Lamp

ESP warning lamp ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds

for self diagnosis and goes off if the system is OK (initialization mode).

When the system is defective, the warning lamp comes on.

When the ESP function is activated, ESP warning lamp blinks with the interval of 2 Hz.

When the communication between warning lamp CAN module in meter cluster, the warning

lamp comes on. 1.

2.

3.

4.

5.

5) ESP OFF Switch

If ESP OFF switch is pressed, ESP function is deactivated and the ESP OFF indicator in the

instrument cluster comes on.

To resume the ESP function, press the switch again. At this time, ESP OFF indicator goes out.

Page 717 of 828

11-16

4) HBA (Hydraulic Brake Assist System)

(1) Purpose

HBA (Hydraulic Brake Assist) system helps in an emergency braking situation when the driver

applies the brake fast, but not with sufficient pressure, which leads to dangerously long braking

distance. ECU recognizes the attempt at full braking and transmits the signal calling for full brake

pressure from the hydraulic booster. An inexperienced, elderly or physically weak driver may suffer

from the accident by not fully pressing the brake pedal when hard braking is required under

emergency. The HBA System increases the braking force under urgent situations to enhance the

inputted braking force from the driver. Based on the fact that some drivers depress the brake

pedal too soft even under when hard braking is necessary, the HECU system is a safety

supplementary system that builds high braking force during initial braking according to pressure

value of the brake pressure sensor and the pressure changes of the pressure sensor intervals.

When the system is designed to apply high braking force when brake pedal is depressed softly by

an elderly or physically weak driver, the vehicle will make abrupt stopping under normal braking

situation due to high braking pressure at each wheels.

(2) Operation

The brake pressure value and the changed value of the pressure sensor are the conditions in

which the HBA System operates. There are 2 pressure sensors under the master cylinder. When

the ESP ECU system determines that emergency braking is present, the pump operates, the

brake fluid in the master cylinder is sent to the pump and the braking pressure is delivered to the

wheels via the inlet valves . If the drive depress the brake pedal slowly, the pressure change is not

high. In this case, only the conventional brake system with booster is activated.

(3) Operating conditions

Sensor pressure: over 40 bar

Pressure changes: over 850 bar/sec

Vehicle speed: over 30 km/h -

-

-

Page 718 of 828

11-174890-10

5) ARP (Active Roll-Over Protection

The ARP (Active Roll-over Protection) system is a safety assistant device that minimizes, by

controlling brakes and the engine, the physical tendency of the vehicle rollover during sharp lane

changes or U-turns. For the system, software is added to the existing ESP system and no

additional device or switch is needed. One must note that the ARP system, just as general

assistant devices including the ABS, is only a safety assistant device using the ESP system and its

function is useless when the situation overcomes the physical power. Following picture shows

how the ARP compensates the vehicle position by varying each wheel's braking power to

overcome the physical tendency of the vehicle rollover during sharp turns.

Lateral sensor

(In sensor cluster)

Vehicle speedBrake force

Radius

The vehicle driving condition is controlled by the internally programmed logic according to the

input signals from wheel speed sensor, steering angle sensor and lateral sensor.

During the ARP operation, vehicle safety (rollover prevention) takes the first priority and thus,

stronger engine control is in effect. Consequently, the vehicle speed decreases rapidly, so the

driver must take caution for the vehicle may drift away from the lane.