brake sensor SSANGYONG NEW ACTYON SPORTS 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 144 of 828

02-70000-00

3. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value ▶

Compression ratio16.5 : 1

Test conditionat normal operating temperature (80˚C)

Compression pressureStandard32 bar

Minimum18 bar

Differential limit between cylindersMaximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston

ring, intake and exhaust vale, cylinder head gasket). This test provides current engine operating

status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping

away from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle. -

-

-

Measurement ▶

<007e0088009900940047009b008f008c0047008c0095008e00900095008c0047009c00970047009b00960047009500960099009400880093004700960097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c00

47004f005f005700b6006a00500055>

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs. -

-

-

Place the diagram sheet to compression

pressure tester and install it into the plug

hole. 1.

Page 306 of 828

15-30000-00

1. ENGINE DATA LIST

Data Unit Value

Coolant temperature℃ 0.436 V (130℃) to 4.896 V (-40℃)

Intake air temperature℃ -40 to 130℃ (varies by ambient air

temperature or engine mode)

Idle speed rpm750 ± 20

Engine load % 18~25%

Mass air flow kg/h 16 to 25 kg/h

Throttle position angle°TA 0° (Full Open) to 78° (Close)

Engine torque Nm varies by engine conditions

Injection time ms 3 to 5ms

Battery voltage V 13.5 V to 14.1 V

Accelerator pedal position 1 V 0.4. to 4.8V

Accelerator pedal position 2 V 0.2 to 2.4 V

Throttle position 1 V 0.3 to 4.6 V

Throttle position 2 V 0.3 to 4.6 V

Oxygen sensor mV 0 to 5 V

A/C compressor switch 1=ON / 0=OFF -

Full load 1=ON / 0=OFF -

Gear selection (A/T) 1=ON / 0=OFF -

Knocking control 1=ON / 0=OFF -

Brake switch 1=ON / 0=OFF -

Cruise control 1=ON / 0=OFF -

Page 310 of 828

15-70000-00

Fuel rail pressure

sensor

(2) Components for ECU Input

CAN

- ABS & ESP

- GCU

- Instrument

cluster

- TCUSwirl valve position

sensor

Differential

pressure sensorE-EGR valve

position sensorCamshaft position

sensorCoolant

temperature senso

r

Exhaust gas

temperature senso

r

HFM sensorOxygen sensorT-MAP sensor

Crankshaft position

sensor

Accelerator pedal

sensorThrottle position

sensorKnock sensor

-Auto cruise switch

- Rear right wheel

speed (without ABS)

- Refrigerant pressure

sensor

- Clutch pedal signal

- Blower switch signal

- Brake pedal signal

Water sensor

Page 312 of 828

15-90000-00

2) ECU Control

(1) Function

a. ECU Function

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston

speed and crankshaft angle based on input data and stored specific map to control the engine

power and emission gas.

Output signal of the ECU microprocessor drives pressure control valve to control the rail pressure

and activates injector solenoid valve to control the fuel injection period and injection timing; so

controls various actuators in response to engine changes. Auxiliary function of ECU has adopted

to reduce emission gas, improve fuel economy and enhance safety, comforts and conveniences.

For example, there are EGR, booster pressure control, autocruise (export only) and immobilizer

and adopted CAN communication to exchange data among electrical systems (automatic T/M

and brake system) in the vehicle fluently. And Scanner can be used to diagnose vehicle status

and defectives.

<00760097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c0047009900880095008e008c00470096008d0047006c006a007c00470090009a0047009500960099009400880093009300a000470054005b005700

47009b009600470052005f005c00b6006a004700880095008b> protected from factors like oil,

water and electromagnetism and there should be no mechanical shocks.

To control the fuel volume precisely under repeated injections, high current should be applied

instantly so there is injector drive circuit in the ECU to generate necessary current during injector

drive stages.

Current control circuit divides current applying time (injection time) into full-in-current-phase and

hold-current-phase and then the injectors should work very correctly under every working

condition.

b. Control Function

Controls by operating stages

To make optimum combustion under every operating stage, ECU should calculate proper

injection volume in each stage by considering various factors.

Starting injection volume control

During initial starting, injecting fuel volume will be calculated by function of temperature and

engine cranking speed. Starting injection continues from when the ignition switch is turned to

ignition position to till the engine reaches to allowable minimum speed.

Driving mode control

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel

and engine rpm and the drive map will be used to match the drivers inputs with optimum

engine power. -

-

-

Page 418 of 828

02-4

Input Signals ▶

NO. Input Signal Name Logic Status

1 IGN1 ON = BAT

(IGN ON or START)

2 IGN2 ON = BAT (IGN ON)

3 ALT_D ON = BAT (engine started)

4 Key reminder switch IN = BAT (key in)

5 Driver's door switch OPEN = GND, CLOSE = OPEN

6 Passenger's door switch OPEN = GND, CLOSE = OPEN

7 Rear door switch - OPEN (one of rear doors) = GND

- CLOSE (all rear doors) = OPEN

8 Hood switch OPEN = GND, CLOSE = OPEN

9 Driver's door lock/unlock switch LOCK = OPEN, UNLOCK = GND

10 Passenger's door lock/unlock switch LOCK = OPEN, UNLOCK = GND

11 Rear door lock/unlock switch - UNLOCK (one of rear doors)

= GND

- LOCK (all rear doors) = OPEN

12 Tailgate lock/unlock switch LOCK = OPEN, UNLOCK = GND

13 Rear defogger switch ON = GND, OFF = OPEN

14 Seat belt switch Unfastened = GND, Fastened = OPEN

15 Sunroof open switch ON = GND, OFF = OPEN

16 Parking brake switch ON = GND, OFF = OPEN

17 Air bag collision sensor ON = 200 ms output (LOW), OFF = OPEN

18 Wiper motor (parking) switch STOP = BAT VOLTAGE, ROTATING = GND

19 Washer switch ON = BAT, OFF = OPEN

20 INT-AUTO switch ON = BAT, OFF = OPEN

21 Auto washer switch ON = BAT, OFF = OPEN

22 Intermittent resistance 0W ~ 51KW (for intermittent wiper)

23 Speed sensor ON = GND (PWM), OFF = OPEN

24 Mirror lock/unlock switch ON = GND, OFF = OPEN

25 Front defogger switch ON = GND, OFF = OPEN

26 Auto hazard switch ON = GND, OFF = OPEN

Page 512 of 828

04-218210-01

ABS Warning Light

This warning light comes on

when the ignition switch is

turned to "ON" position and

should go out if the system is

normal.

The vehicle with ABS performs

self-diagnosis. During this

diagnosis, brake pedal

vibration and noise may be

apparent when the driving

motors discharges the

hydraulic pressure from the

internal hydraulic device.4WD IndicatorLow Fuel Level

Warnig Light

This warning light

comes on when the

fuel will soon be

exhausted. The time

it takes turn on,

however, varies

according to the

gradient of the

vehicle.

4WD HIGH Indicator

The lamp blinks momentarily during

the change of driving mode.

4WD LOW Indicator

The lamp blinks momentarily during

the change of driving mode.

4WD CHECK Warning Light

This indicates that there is

something wrong in the transfer

case system. (check the system) -

-

-

Auto Cruise Control

Indicator

Operating the cruise

control switch turns on

the indicator lamp to

indicate the cruise

control system is

activated.

Water Separator Warning Light

This lamp comes on to warn the driver of

water in the fuel tank which causes the

loss of engine power. When a certain

amount of water is accumulated, the lamp

comes on and a chime sounds.

Engine CHECK Warning Light

This warning light comes on when

the ignition switch is turned to "ON"

position and should go out if the

system related to engine control is

normal.

This comes on when different

sensors and devices related to

engine control are defective.

Winter Mode

Indicator

Pressing the "W" side of the

automatic transmission mode

selector switch switches the

driving mode to winter mode and

turns on the indicator lamp.

Use this mode to drive off

smoothly on icy and slippery

roads.

Charge Warning Light

This warning light comes on when the

ignition switch is turned on and go off

when the engine is started.

If this light doesn't go off after engine

starting, it means there is a malfunction in

the system.

Engine Hood Open Warning Light

When the engine hood is open, this light

comes on to inform the driver.

Page 547 of 828

01-33680-01

1. GENERAL INFORMATION

Six forward speeds

One reverse gear

A toruqe converter with an integral converter

lock-up clutch

Electronic shift and pressure controls

A single planetary gear-set

A double planetary gear-set

Two hydraulically controlled brake bands

Three multi-plate clutches

All hydraulic functions are directed by

electronic solenoids to control -

-

-

-

-

-

-

-

- Automatic transaxle (DSI M78) ▶

TCU ▶

TCU is located under the driver's seat and controls the operations of transmission.

TCU receives the ignition voltage and has three connectors (16-pin, 12-pin, 20-pin).

TCU receives input signals from certain transmission-related sensors, gear select lever and

inhibitor switch. TCU also uses these signals when determining transmission operating strategy.

TCU uses PCAN to communicate with other units. And, TCU communicates with engine ECU,

ESP unit, TCCU and instrument cluster through CAN lines to control the gear shifting and to

recognize the current gear position.

DSI M78 Automatic Transmission is based on the transmission in the vehicle with D20DT engine

for EURO III or EURO IV or EURO V.

Differences: changed some components (torque converter and torque converter housing, some

pinion gears, sun gear), increased torsional damping force.

TCU

Page 555 of 828

01-113680-01

1. OVERVIEW

The six speed automatic (M78) transmission

is available in two variants: four wheel drive

and two wheel drive.

The transmission has the following features:

Six Forward Speeds

One reverse gear

A torque converter with an integral converter lock-up clutch

Electronic shift and pressure controls

A single planetary gear-set

A double planetary gear-set

Two hydraulically controlled brake bands

Three multi-plate clutches

All hydraulic functions are directed by electronic solenoids to control: -

-

-

-

-

-

-

-

-

Engagement feel

Shift feel

Shift scheduling

Modulated torque converter clutch applications ·

·

·

·

The transmission contains fully synthetic automatic transmission fluid (ATF) and is filled for life;

therefore it does not require periodic servicing.

Engine power reaches the transmission via a torque converter with integral converter lock-up

clutch.

The six forward gears and one reverse gear are obtained from a single planetary set, followed by

a double planetary set. This type of gear-set arrangement is commonly known as Lepelletier type

gear-set.

The automatic transmission is electronically controlled. The control system is comprised of the

following elements:

External transmission control unit (TCU)

Internal embedded memory module (EMM)

Input and output speed sensors

Valve body unit comprised of four on/off solenoid valves and six variable bleed solenoids

Torque converter -

-

-

-

-

Page 651 of 828

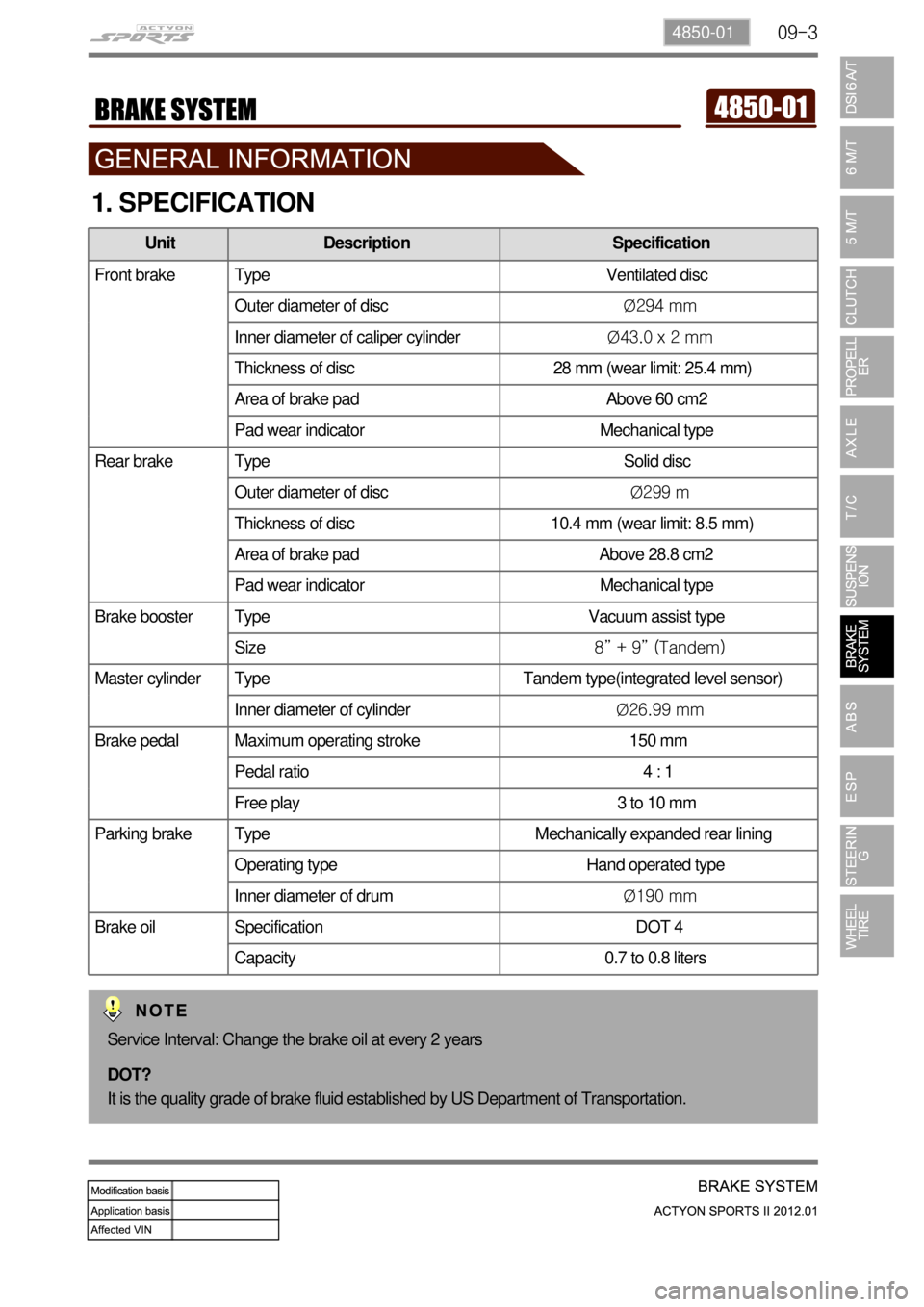

09-34850-01

1. SPECIFICATION

Unit Description Specification

Front brake Type Ventilated disc

Outer diameter of discØ294 mm

Inner diameter of caliper cylinderØ43.0 x 2 mm

Thickness of disc 28 mm (wear limit: 25.4 mm)

Area of brake pad Above 60 cm2

Pad wear indicator Mechanical type

Rear brake Type Solid disc

Outer diameter of discØ299 m

Thickness of disc 10.4 mm (wear limit: 8.5 mm)

Area of brake pad Above 28.8 cm2

Pad wear indicator Mechanical type

Brake booster Type Vacuum assist type

Size8” + 9” (Tandem)

Master cylinder Type Tandem type(integrated level sensor)

Inner diameter of cylinderØ26.99 mm

Brake pedal Maximum operating stroke 150 mm

Pedal ratio 4 : 1

Free play 3 to 10 mm

Parking brake Type Mechanically expanded rear lining

Operating type Hand operated type

Inner diameter of drumØ190 mm

Brake oil Specification DOT 4

Capacity 0.7 to 0.8 liters

Service Interval: Change the brake oil at every 2 years

DOT?

It is the quality grade of brake fluid established by US Department of Transportation.

Page 676 of 828

09-28

Front Brake AssemblyFront Wheel Speed Sensor (4WD)

HECU

2. SYSTEM LAYOUT

Master Cylinder and Booster

Brake Pedal