automatic SSANGYONG NEW ACTYON SPORTS 2012 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2012Pages: 828, PDF Size: 91.28 MB

Page 559 of 828

01-153680-01

2) Mode “M” (Manual Shift Mode)

This allows the driver to define the highest possible gear by selecting "+" or "-" on the gear

selector when the lever is in the "M" position. When the lever is first moved to the manual "M"

position the transmission will select the lowest possible gear.

When maximum engine rpm is reached the transmission will upshift automatically regardless of

the driver selected limit. 4WD models with low range will not automatically upshift when low range

is selected.

1st gear position ▶

2nd gear position ▶

3st gear position ▶

4th gear position ▶

5th gear position ▶

6th gear position ▶Use on a rugged road, mountain path and steep hill. Engine braking effect on steep hill is

available. -

Use on a long and gentle slope. 2-1 automatic kickdown shift is available. Engine braking

effect is available. -

Use on a long and gentle slope. 3-2 and 2-1 automatic kickdown shift is available.

Engine braking effect is available. -

Use on a long and gentle slope. 4-3, 4-2 and 4-1 automatic kickdown shift is available. -

5-4 and 5-3 automatic kickdown shift is available. -

6-5 and 6-4 automatic kickdown shift is available. -

Kickdown Function

If you need to accelerate rapidly, depress the accelerator pedal completely to the floor.

Then, a one- or two-lever gear will automatically be engaged. This is called the Kickdown

function.

Page 560 of 828

01-16

4. LIMP HOME MODE

In case of transmission malfunction ▶

If a serious fault occurs in the automatic transmission, the TCU enters the limp home

mode to secure safe driving and protect the automatic transmission.

As power is no longer supplied to the solenoid, the current basic function (P, R, N, D) is

maintained and the 4th gear can be maintained only by the operation of the hydraulic

system without electrical operation.

The ECU communicates with other electric modules with CAN. If a serious fault occurs, the

transmission automatically enters the limp home mode for service.

The TCU monitors all factors which can affect to the performance of the transmission and

diagnose the system according to OBD II regulation. 1.

2.

3.

4.

In case of overheated transmission ▶

The TCU enters the limp home mode when the batter voltage drops below 8 V.

If the transmission is overheated, the shift pattern is changed to the hot mode to cool the

transmission more efficiently.

While the transmission is overheated, the selector lever symbol and engine temperature

warning lamp on the instrument cluster blink until the transmission is cooled down to the

normal operation temperature. If the transmission is excessively overheated, the gear

cannot be shifted but remains in the neutral position. 1.

2.

3.

Towing the vehicle with A/T ▶

The best way to transport the vehicle is to load it to a truck and transport it, especially if the

vehicle is 4WD.

If towing the vehicle with the propeller shaft connected, the transmission or oil pump of

transfer case may malfunction, resulting in internal damage due to poor lubrication. -

Page 561 of 828

01-173680-01

5. ELECTRONIC CONTROL SYSTEM

1) Overview

The transmission control unit (TCU) and its input/output networks control the operations of

transmission:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

In addition, the TCU receives input signals from certain transmission-related sensors and

switches. The TCU also uses these signals when determining transmission operating strategy.

Using all of these input signals, the TCU can determine when the time and conditions are right for

a shift, or when to apply or release the torque converter clutch. It will also determine the pressure

needed to optimise shift feel. To accomplish this, the TCU operates six variable bleed control

solenoids and four ON/OFF solenoids to control the operations of transmission.

2) Transmission Control Unit (TCU)

The transmission control unit (TCU) is mounted under the driver's seat and controls the operation

of the transmission.

TCU processes the analog information from the internal sensors and the digital information

through CAN communication lines. TCU monitors all the input and output signals. If there is any

<008d008800900093009c0099008c00530047007b006a007c0047008a008f00880095008e008c009a0047009b008f008c0047009a00a0009a009b008c00940047009b0096004702c800730090009400970047006f00960094008c004700740096008b008c02

c9004700880095008b004700880093008c0099009b009a0047>to the driver through the

warning lamp on the instrument cluster.

(1) Hard-wired (Analog) Input/Output

Input/Output Data between TGS Lever and TCU ▶

Position and conditions of gear select lever

Driving moded (Winter or Standard) -

-

Position of inhibitor switch - Input/Output Data between Inhibitor and TCU ▶

6 control signals for variable bleed solenoid

4 control signals for ON/OFF solenoid

Transmission input speed

Transmission output speed

Transmission oil temperature

EMM (Embeded Memory Module) -

-

-

-

-

- Input/Output Data between Automatic Transmission and TCU ▶

Input/Output Data between Self Diagnostic Connector and TCU ▶

Various DTC codes and TCU information -

Page 565 of 828

01-213680-01

Pressure Modulation ▶

To provide a higher level of shift comfort and durability, the hydraulic pressure in the shift related

friction elements of the transmission must be matched accurately to the input torque to

transmission. This hydraulic pressure is composed of a hydraulically pre-set basic pressure and a

control pressure which is set by one of the variable bleed solenoids.

The transmission input torque can be directly calculated from the following operating parameters:

engine torque signals

engine speed or any signal transmitted from ECU through CAN lines

converter slip -

-

-

Separate pressure characteristics for each gear change make it possible to adapt precisely to the

particular shift operation.

5) Shift Mode Selection by TCU

The driver can select Standard (S) or Winter mode (W) with the mode switch. TCU automatically

changes the shift mode according to the transmission oil temperature, uphill or downhill gradient,

and altitude to keep the good driving conditions.

Standard Mode (S) ▶

Uphii and Downhill Mode ▶

Altitude Mode ▶ Standard Mode is selected when setting the mode switch in Standard (S) position with the gear

<009a008c0093008c008a009b00470093008c009d008c0099004700900095004702c8006b02c9004700880095008b0047009b008f008c0047009b009900880095009a00940090009a009a00900096009500470096009000930047009b008c00940097008c00

990088009b009c0099008c0047009000950047009500960099>mal operating range. Proper shift

timing provides the optimized fuel economy and good driving conditions.

In this mode, the operating points of torque converter lock-up clutch and the shifting points are

adjusted according to the vehicle weight.

In this mode, the shifting points are automatically adjusted according to the altitude to compensate

the engine torque changes due to barometric pressure and temperature.

Page 616 of 828

03-8

Variant Coding Options

(2) Detects the position of the shifting lever for the HDC operation

among ABS functions.

The HDC function operates only if the M/T shift lever is in forward or reverse position. Please refer

to the ABS section for the specific information related to the HDC.

Variant Coding Related to N Switch ▶

The N switch transmits information to the ECU through the CAN communication while New Rexton

is connected to the ECU through wires. Thus, if you set the variant coding in the engine ECU, you

must do it differently, and you must set the variant coding differently according to the vehicle

category and specification as below.

Neutral Signal Input None / Wire / CANWire /

Actyon & Kyron models with

manual transmission

New Rexton model with manual

transmission Manufactured

after 04.09.15

BODY IN: after 154600

Automatic transmission & Rodius

model with automatic

transmission before 2006

Page 629 of 828

07-53240-01

Operation ▶

Description Mode Conditions

Driving

mode2H 2 Wheel drive

(rear wheel)Rear-wheel drive mode. This is used under

normal or high-speed driving conditions on

public roads or highways.

4H 4 Wheel drive

(high speed)This is used under sandy, muddy or snow-

covered road conditions

4L 4 Wheel drive

(low speed)This is used for maximum traction.

When cornering with low speed in 4WD

condition, there could be tire dragging, some

mechanical shocks and resistances in

vehicle’s drive train. These are normal

conditions due to internal resistance in the

drive train when the 4WD system is properly

working

Mode change2H←4H2 Wheel drive

↔4 Wheel driveShifting is possible while driving at the speed

of 70 km/h or less

2H,

4H↔4L2 Wheel drive,

4 Wheel drive (high

speed)

↔4 Wheel drive

(low speed)For Automatic Transmission:

For Manual Transmission:

Stop the vehicle on level ground and

move the gear selector lever into the

“N” position. Turn the switch to the

desired position. ·

Stop the vehicle on level ground and

move the gear selector lever into the

“N” position. Then turn the switch to

the desired position while depressing

the clutch pedal. ·

To make the mode change easily, stop

the vehicle on level ground and turn the

mode switch to the desired position and

move the shift lever to "N"-"R"-"N" while

depressing the brake pedal.

Page 630 of 828

07-6

2. LAYOUT

Front axle

Front locking hub system (IWE)

Front propeller shaft

DSI 6-speed automatic

transmission

Part-time transfer case

Rear propeller shaft

Rear axle

Page 645 of 828

08-94411-01

Under View (4WD, Automatic Transmission)

Rear suspension

1. SUSPENSION

The suspension is the device to connect the axle and vehicle. It absorbs the vibrations and

impacts from road surface, which enhances the comforts, driving force, braking force and

drivability.

Front suspension

Page 652 of 828

09-4

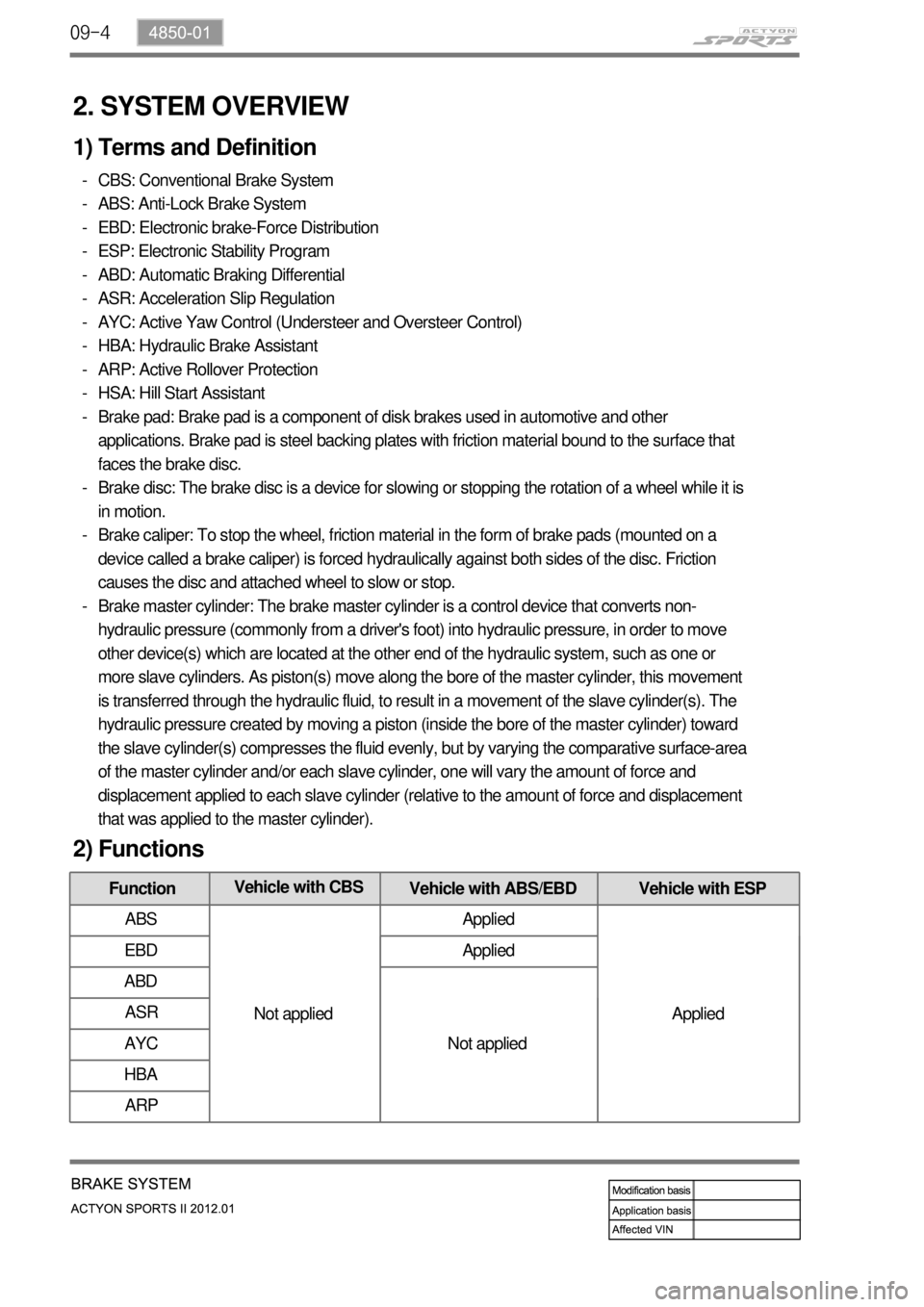

2. SYSTEM OVERVIEW

1) Terms and Definition

CBS: Conventional Brake System

ABS: Anti-Lock Brake System

EBD: Electronic brake-Force Distribution

ESP: Electronic Stability Program

ABD: Automatic Braking Differential

ASR: Acceleration Slip Regulation

AYC: Active Yaw Control (Understeer and Oversteer Control)

HBA: Hydraulic Brake Assistant

ARP: Active Rollover Protection

HSA: Hill Start Assistant

Brake pad: Brake pad is a component of disk brakes used in automotive and other

applications. Brake pad is steel backing plates with friction material bound to the surface that

faces the brake disc.

Brake disc: The brake disc is a device for slowing or stopping the rotation of a wheel while it is

in motion.

Brake caliper: To stop the wheel, friction material in the form of brake pads (mounted on a

device called a brake caliper) is forced hydraulically against both sides of the disc. Friction

causes the disc and attached wheel to slow or stop.

Brake master cylinder: The brake master cylinder is a control device that converts non-

hydraulic pressure (commonly from a driver's foot) into hydraulic pressure, in order to move

other device(s) which are located at the other end of the hydraulic system, such as one or

more slave cylinders. As piston(s) move along the bore of the master cylinder, this movement

is transferred through the hydraulic fluid, to result in a movement of the slave cylinder(s). The

hydraulic pressure created by moving a piston (inside the bore of the master cylinder) toward

the slave cylinder(s) compresses the fluid evenly, but by varying the comparative surface-area

of the master cylinder and/or each slave cylinder, one will vary the amount of force and

displacement applied to each slave cylinder (relative to the amount of force and displacement

that was applied to the master cylinder). -

-

-

-

-

-

-

-

-

-

-

-

-

-

FunctionVehicle with CBS

Vehicle with ABS/EBD Vehicle with ESP

ABS

Not appliedApplied

Applied EBD Applied

ABD

Not applied ASR

AYC

HBA

ARP

2) Functions

Page 656 of 828

09-8

Problem Possible Cause Action

Increased pedal stroke Air in brake line Bleed air

Oil leak Repair

Worn brake pad Replace

Excessive clearance between push rod and master

cylinderAdjust

Worn or damaged piston seal Replace

Brake dragging Parking brake is not fully released Release

Incorrect adjustment of parking brake Adjust

Incorrectly adjusted clearance of parking brake

shoeAdjust

Faulty brake pedal return spring Replace

Incorrectly adjusted free play of brake pedal Adjust

Faulty master cylinder Replace

Lack of lubrication in sliding parts Lubricate

Faulty brake booster (vacuum leak) Repair

Wear, hardening or poor contact of brake pad Replace

Oil or water on lining Repair or replace

Fixed or broken parking brake cable Replace

Excessive stroke of brake lever Adjust notch

Faulty auto clearance adjuster Repair

Poor parking

brake

Increased stroke of

parking brake leverLoosened parking brake cable Adjust or replace

Incorrectly adjusted parking brake cable Adjus

Defective automatic lining clearance adjuster Repair or replace

Worn brake lining Replace