SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

NEW ACTYON SPORTS 2013

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57512/w960_57512-0.png

SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

Trending: alternator belt, wiring, instrument cluster, fuse box, AUTO TRANS, sunroof, length

Page 521 of 751

04-53010-01

2. SATIC (SELF ADJUSTING TECHNOLOGY WITH

INTEGRATED CASSETTE)

1) System Description

Function ▶

On the conventional clutch, the pedal force tends

to increase in proportion to the degree of disc

run-out. However, the SATIC clutch has the

adjusting function which activates the cassette

system inserted to the clutch cover to maintain a

constant pedal force and clearance when the

disc runs out. (Unlike SAT type, SATIC type does

not need SST for clutch cover removal.)

Operation ▶

Diaphragm spring rotates the adjusting

equipment as clutch disc is wearing and so,

pressure plate is pushed to clutch disc side at the

amount of wear.

Disc wear (Free

play) → Diaphragm spring (1)

→ Adjusting equipment (2, 3) → Pressure

plate (4)

Page 522 of 751

04-6

2) Overview

Driving elements ▶

The driving elements consist of two flat surfaces machined to a smooth finish.

One of these is the rear face of the engine flywheel and the other is the clutch pressure plate. The clutch

pressure plate is fitted into a clutch steel cover, which is bolted to the flywheel.

Driven elements ▶

The driven element is the clutch disc with a splined hub which is free to slide lengthwise along the splines

of the input shaft.

The driving and driven elements are held in contact by spring pressure. This pressure is exerted by a

diaphragm spring in the clutch cover pressure plate assembly.

Operating Elements ▶

The clutch "release" system consists of the clutch pedal and clutch release cylinder.

This system directly releases the clutch by using hydraulic pressure while the conventional clutch system

releases the clutch by using release lever and release fork. This system provides higher efficiency than

conventional clutch system, and its durability is superior.

Clutch master cylinder (mounted on clutch pedal)

Concentric slave cylinder pipe (mounted inside of transmission) -

-

Page 523 of 751

04-73010-01

3) Layout

Clutch discClutch cover assembly

Dual mass flywheel (DMF)Concentric slave cylinder

Centering pin

Page 524 of 751

04-8

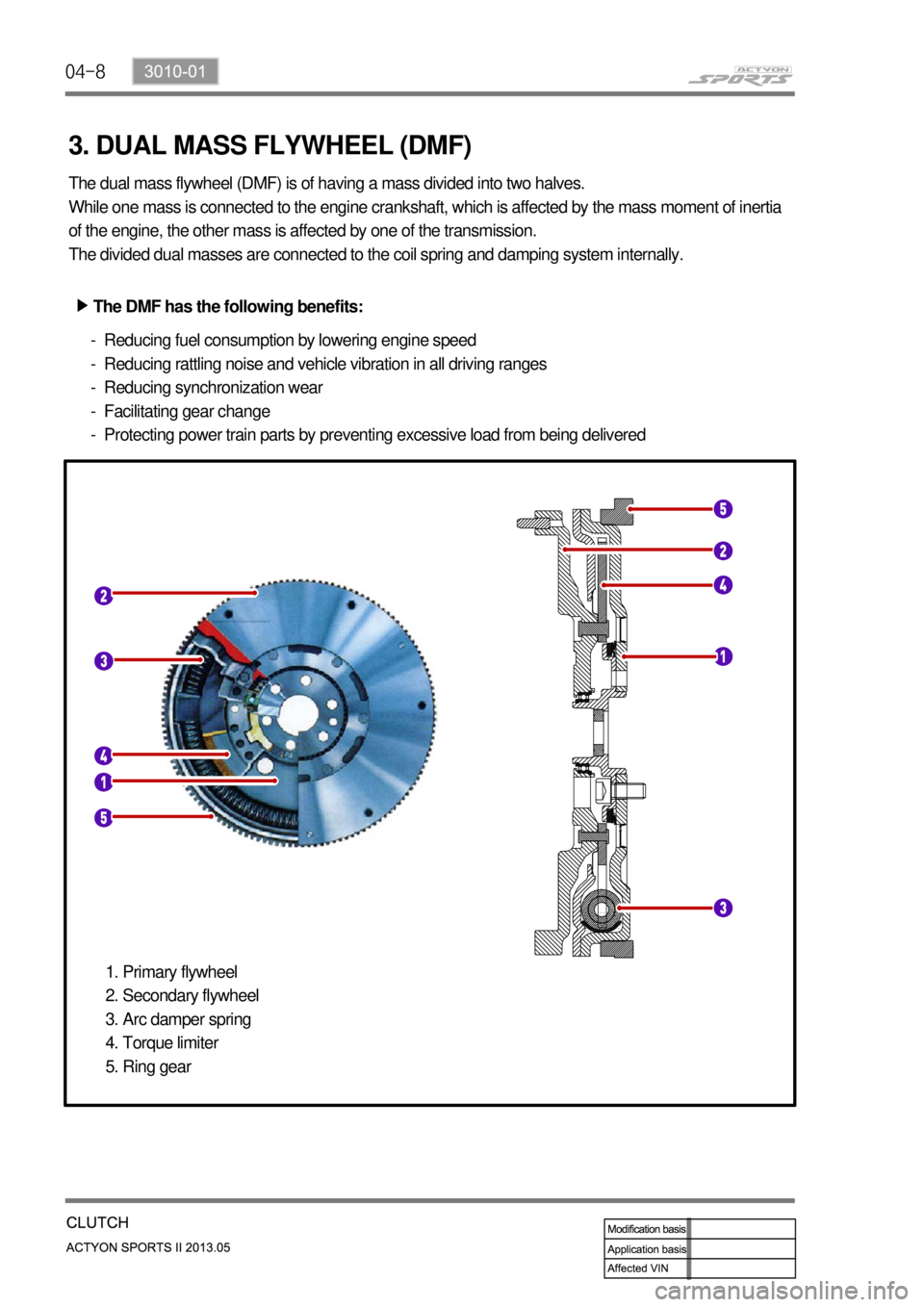

3. DUAL MASS FLYWHEEL (DMF)

The dual mass flywheel (DMF) is of having a mass divided into two halves.

While one mass is connected to the engine crankshaft, which is affected by the mass moment of inertia

of the engine, the other mass is affected by one of the transmission.

The divided dual masses are connected to the coil spring and damping system internally.

The DMF has the following benefits: ▶

Reducing fuel consumption by lowering engine speed

Reducing rattling noise and vehicle vibration in all driving ranges

Reducing synchronization wear

Facilitating gear change

Protecting power train parts by preventing excessive load from being delivered -

-

-

-

-

Primary flywheel

Secondary flywheel

Arc damper spring

Torque limiter

Ring gear 1.

2.

3.

4.

5.

Page 525 of 751

05-33310-00

1. SPECIFICATION

Description Specification

Structure Universal joint with yoke arm and spider

Number of spiders Front Part time T/C Two

Rear Three

Runout Max. 0.3mm

Unbalance Max. 18 g.cm / 4,500 rpm

Dimension of front

propeller shaft (Length x

Dia.) (mm)A/T 552.3*Φ63.5 (Compressed)

M/T 603.8*Φ63.5 (Compressed)

Dimension of front

propeller shaft (Length x

Dia.) (mm)2WD Front1136.0*Φ63.5

Rear743.*Φ63.5(Compressed)

4WD(M/T) Front785.1*Φ63.5

Rear743.*Φ63.5(Compressed)

4WD(A/T) Front836.8*Φ63.5

Rear743.*Φ63.5(Compressed)

2. TIGHTENING TORQUE

Fastener Tightening torque

Mounting bolts for front/rear axle 66.7 ~ 73.5Nm

Mounting bolts for T/M and T/C 79.4 ~ 87.2Nm

Mounting bolts for center bearing 78.4 ~93.1Nm

Page 526 of 751

05-4

1. OVERVIEW

The propeller shaft transfers the power through the transmission and transfer case to the front/rear axle

differential carrier (final reduction gear).

It is manufactured by a thin rounded steel pipe to have the strong resisting force against the torsion and

bending.

Both ends of propeller shaft are connected to the spider and the center of propeller shaft is connected to

the spline to accommodate the changes of the height and length.

The rubber bushing that covers the intermediate bearing keeps the balance of rear propeller shaft and

absorbs its vibration.

Function of propeller shaft ▶

Transmits driving torque.

Compensates the angle change (universal joint / CV joint).

Compensates the axial length change (splines for the slip joint). -

-

-

Front propeller shaft

Rear propeller shaft

Page 527 of 751

06-2

1. SPECIFICATIONS

Location Front Axle Rear Axle

GearType Hypoid←←←

SizeØ182.8 mm ← Ø228.6 mm ←

Offset28.58 mm

(DYMOS)

35 mm(Tongil)←30 mm -

Housing Steel←Steel casting←

OilTypeSAE 80W/90, API

GL-5←SAE 80W/90, API

GL-5←

Capacity 1.4 L←

2.0L

←

Length 448.0 mm←469.0 mm←

Witdh 681.9 mm←1,717.7 mm←

Weight 45 kg←90 kg←

Specification M/T A/T M/T A/T

Gear ratio4.55R(5MT DSL)

4.89R(5MT GSL)3.54(5AT DSL)

3.91(6AT DSL)4.55R(5MT DSL)

4.89R(5MT GSL)3.54(5AT DSL)

3.91(6AT DSL)

Page 528 of 751

07-33240-01

1. SPECIFICATIONS

Description Specifications

Type Part-time transfer case

Total length 343 mm

Mating surface of front flange 40 mm

Weight 32.4 kg (including oil)

Oil capacity 1.4 L

Oil type ATF DEXRON III

Location Transfer case

Major element Housing Part-time & TOD

Bolt 11 ea, M8 x 1.25

Input shaft A/T: outer spline

M/T: inner spline

Page 529 of 751

07-4

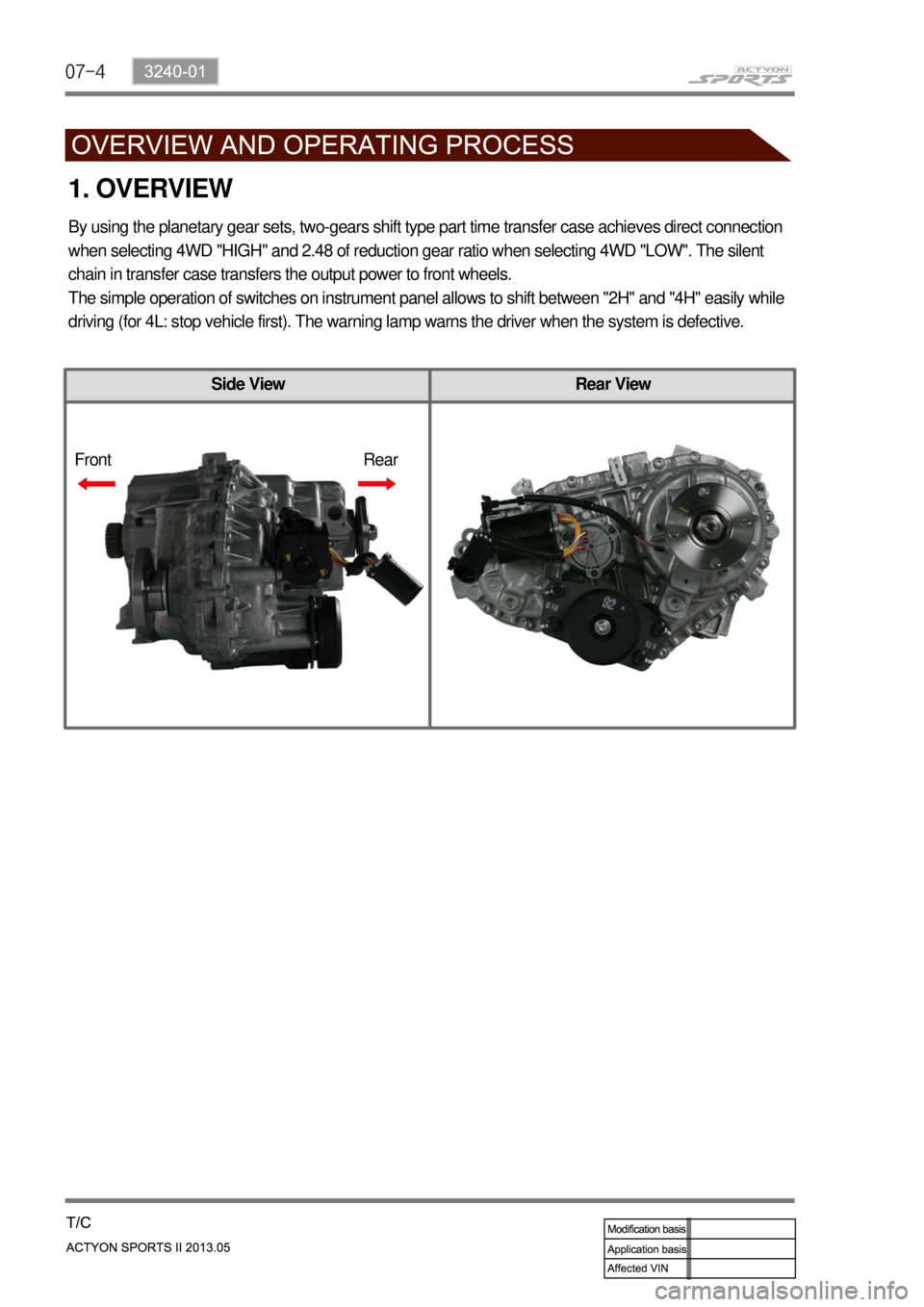

Side View Rear View

1. OVERVIEW

By using the planetary gear sets, two-gears shift type part time transfer case achieves direct connection

when selecting 4WD "HIGH" and 2.48 of reduction gear ratio when selecting 4WD "LOW". The silent

chain in transfer case transfers the output power to front wheels.

The simple operation of switches on instrument panel allows to shift between "2H" and "4H" easily while

driving (for 4L: stop vehicle first). The warning lamp warns the driver when the system is defective.

Front Rear

Page 530 of 751

07-53240-01

Operation ▶

Description Mode Conditions

Driving

mode2H 2 Wheel drive

(rear wheel)Rear-wheel drive mode. This is used under

normal or high-speed driving conditions on

public roads or highways.

4H 4 Wheel drive

(high speed)This is used under sandy, muddy or snow-

covered road conditions

4L 4 Wheel drive

(low speed)This is used for maximum traction.

When cornering with low speed in 4WD

condition, there could be tire dragging, some

mechanical shocks and resistances in

vehicle’s drive train. These are normal

conditions due to internal resistance in the drive

train when the 4WD system is properly working

Mode change2H←4H2 Wheel drive

↔4 Wheel driveShifting is possible while driving at the speed of

70 km/h or less

2H,

4H↔4L2 Wheel drive,

4 Wheel drive (high

speed)

↔4 Wheel drive

(low speed)For Automatic Transmission:

For Manual Transmission:

Stop the vehicle on level ground and

move the gear selector lever into the

“N” position. Turn the switch to the

desired position. ·

Stop the vehicle on level ground and

move the gear selector lever into the

“N” position. Then turn the switch to

the desired position while depressing the

clutch pedal. ·

To make the mode change easily, stop the

vehicle on level ground and turn the mode

switch to the desired position and move the

shift lever to "N"-"R"-"N" while depressing

the brake pedal.

Trending: air conditioning, Torque, mirror controls, parking brake, fuel pressure, tires, load capacity