relay SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 23 of 751

01-6

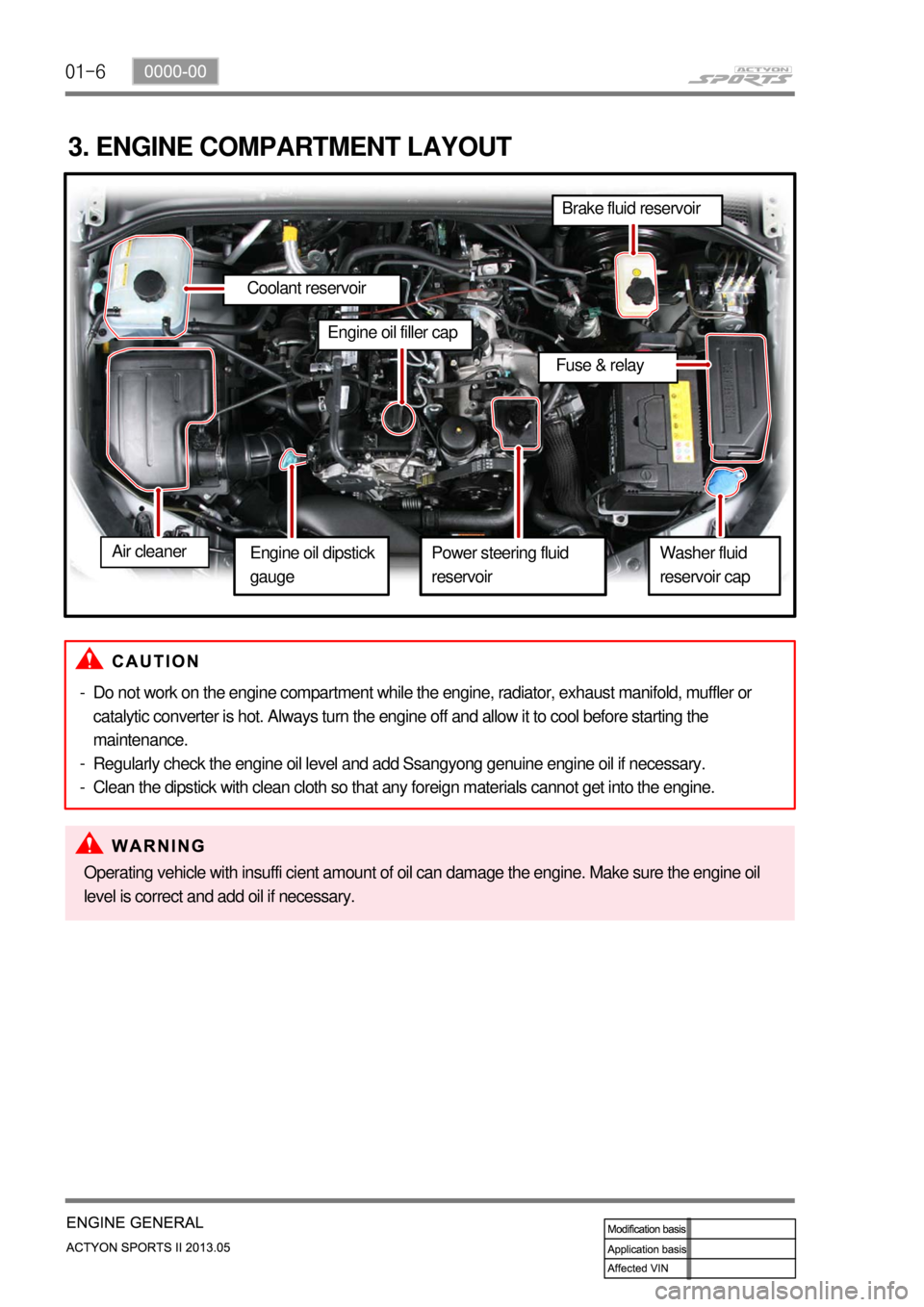

3. ENGINE COMPARTMENT LAYOUT

Do not work on the engine compartment while the engine, radiator, exhaust manifold, muffler or

catalytic converter is hot. Always turn the engine off and allow it to cool before starting the

maintenance.

Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary.

Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine. -

-

-

Power steering fluid

reservoirBrake fluid reservoir

Fuse & relay

Engine oil dipstick

gaugeWasher fluid

reservoir cap Engine oil filler cap

Air cleaner

Operating vehicle with insuffi cient amount of oil can damage the engine. Make sure the engine oil

level is correct and add oil if necessary.

Coolant reservoir

Page 31 of 751

01-14

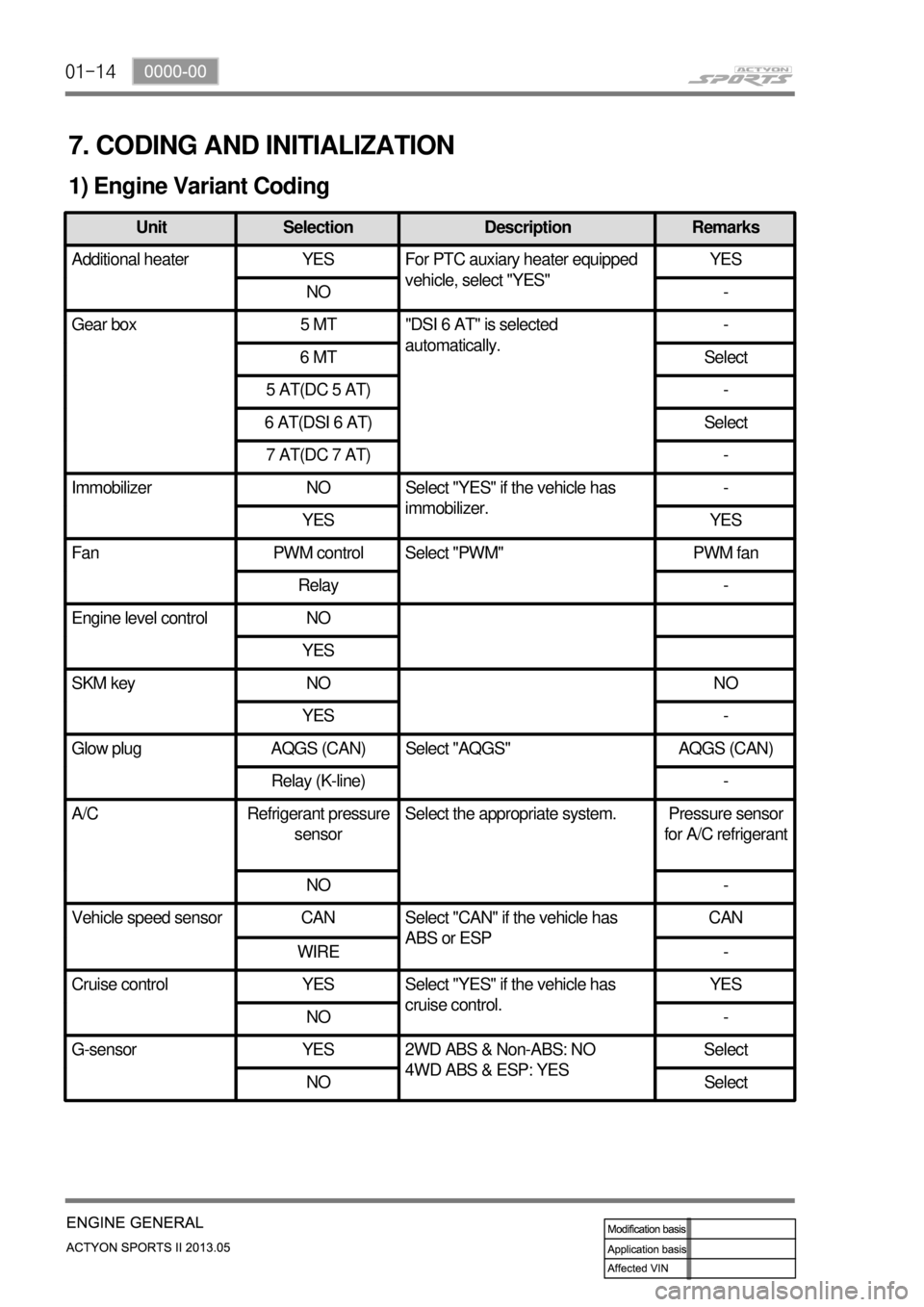

7. CODING AND INITIALIZATION

1) Engine Variant Coding

Unit Selection Description Remarks

Additional heater YES For PTC auxiary heater equipped

vehicle, select "YES"YES

NO -

Gear box 5 MT "DSI 6 AT" is selected

automatically.-

6 MT Select

5 AT(DC 5 AT) -

6 AT(DSI 6 AT) Select

7 AT(DC 7 AT) -

Immobilizer NO Select "YES" if the vehicle has

immobilizer.-

YES YES

Fan PWM control Select "PWM" PWM fan

Relay -

Engine level control NO

YES

SKM key NO NO

YES -

Glow plug AQGS (CAN) Select "AQGS" AQGS (CAN)

Relay (K-line) -

A/C Refrigerant pressure

sensorSelect the appropriate system. Pressure sensor

for A/C refrigerant

NO -

Vehicle speed sensor CAN Select "CAN" if the vehicle has

ABS or ESPCAN

WIRE -

Cruise control YES Select "YES" if the vehicle has

cruise control.YES

NO -

G-sensor YES 2WD ABS & Non-ABS: NO

4WD ABS & ESP: YESSelect

NO Select

Page 204 of 751

15-4

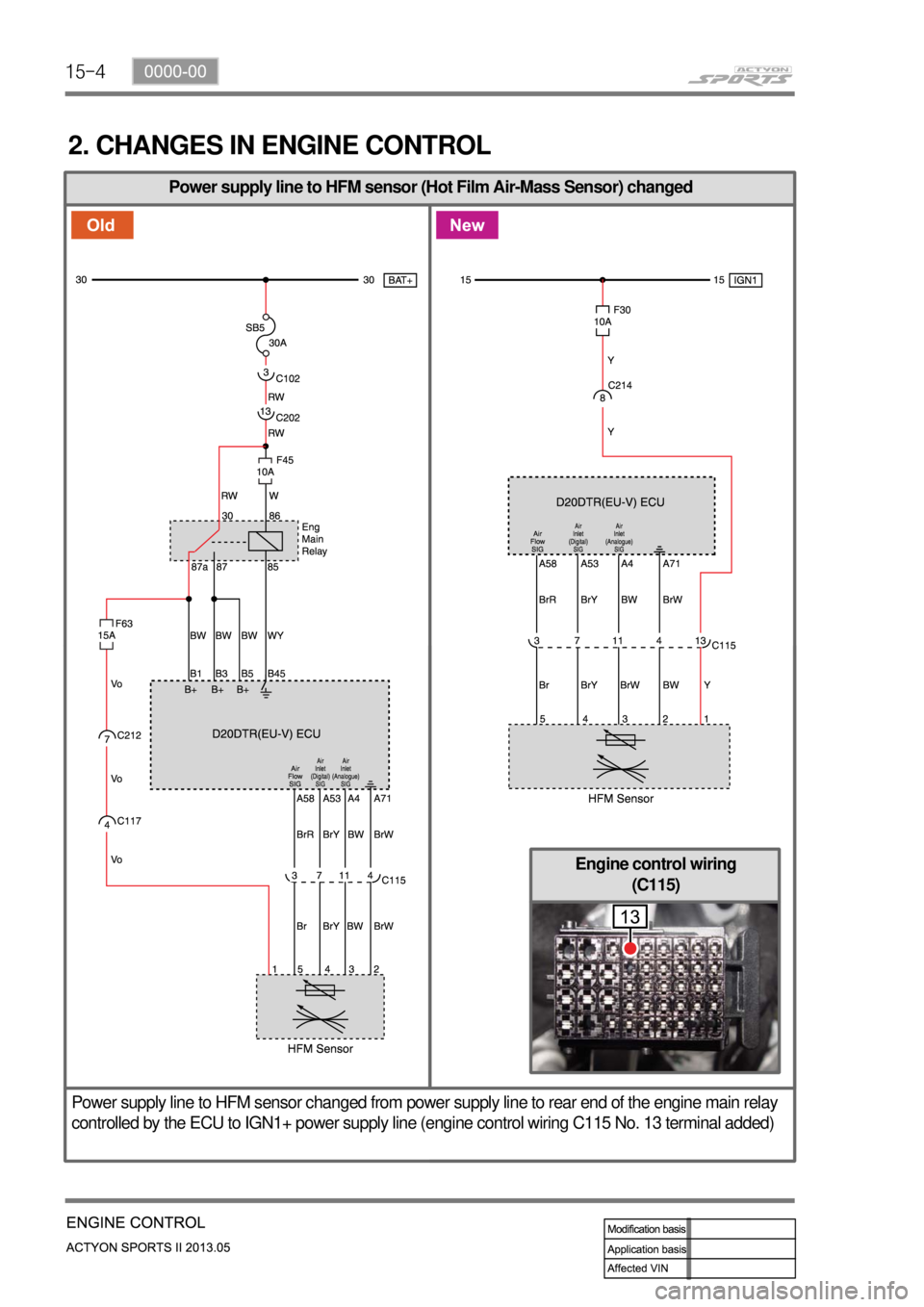

Power supply line to HFM sensor (Hot Film Air-Mass Sensor) changed

Power supply line to HFM sensor changed from power supply line to rear end of the engine main relay

controlled by the ECU to IGN1+ power supply line (engine control wiring C115 No. 13 terminal added)

2. CHANGES IN ENGINE CONTROL

Engine control wiring

(C115)

Page 239 of 751

15-390000-00

HFM (intake air

temperature)Cooling fan

module

DSI 6 A/T (ATF

temperature)Coolant

temperature

sensor

Refrigerant

pressure sensor

Relay box

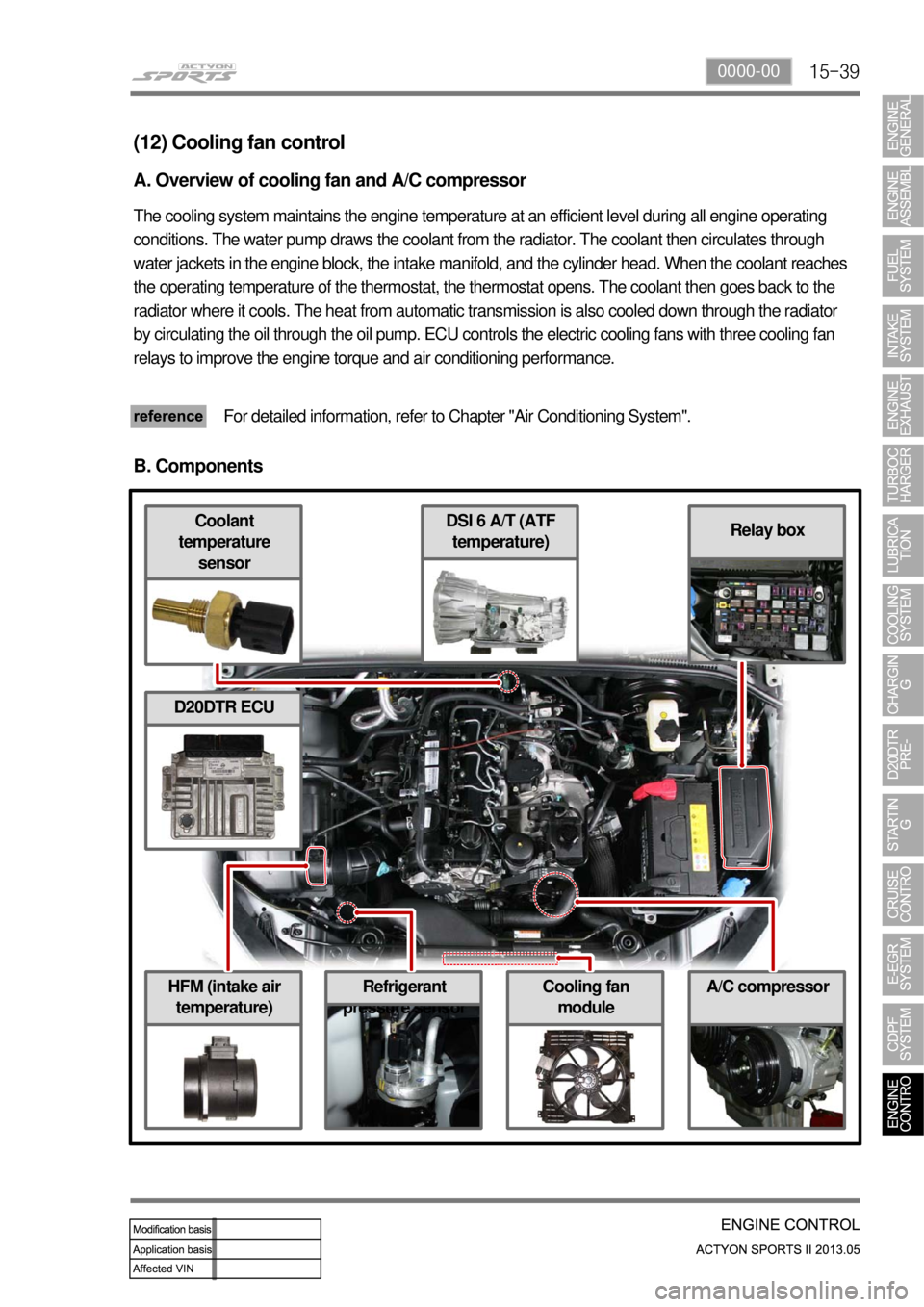

(12) Cooling fan control

A. Overview of cooling fan and A/C compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transmission is also cooled down through the radiator

by circulating the oil through the oil pump. ECU controls the electric cooling fans with three cooling fan

relays to improve the engine torque and air conditioning performance.

For detailed information, refer to Chapter "Air Conditioning System".

B. Components

A/C compressor

D20DTR ECU

Page 241 of 751

15-410000-00

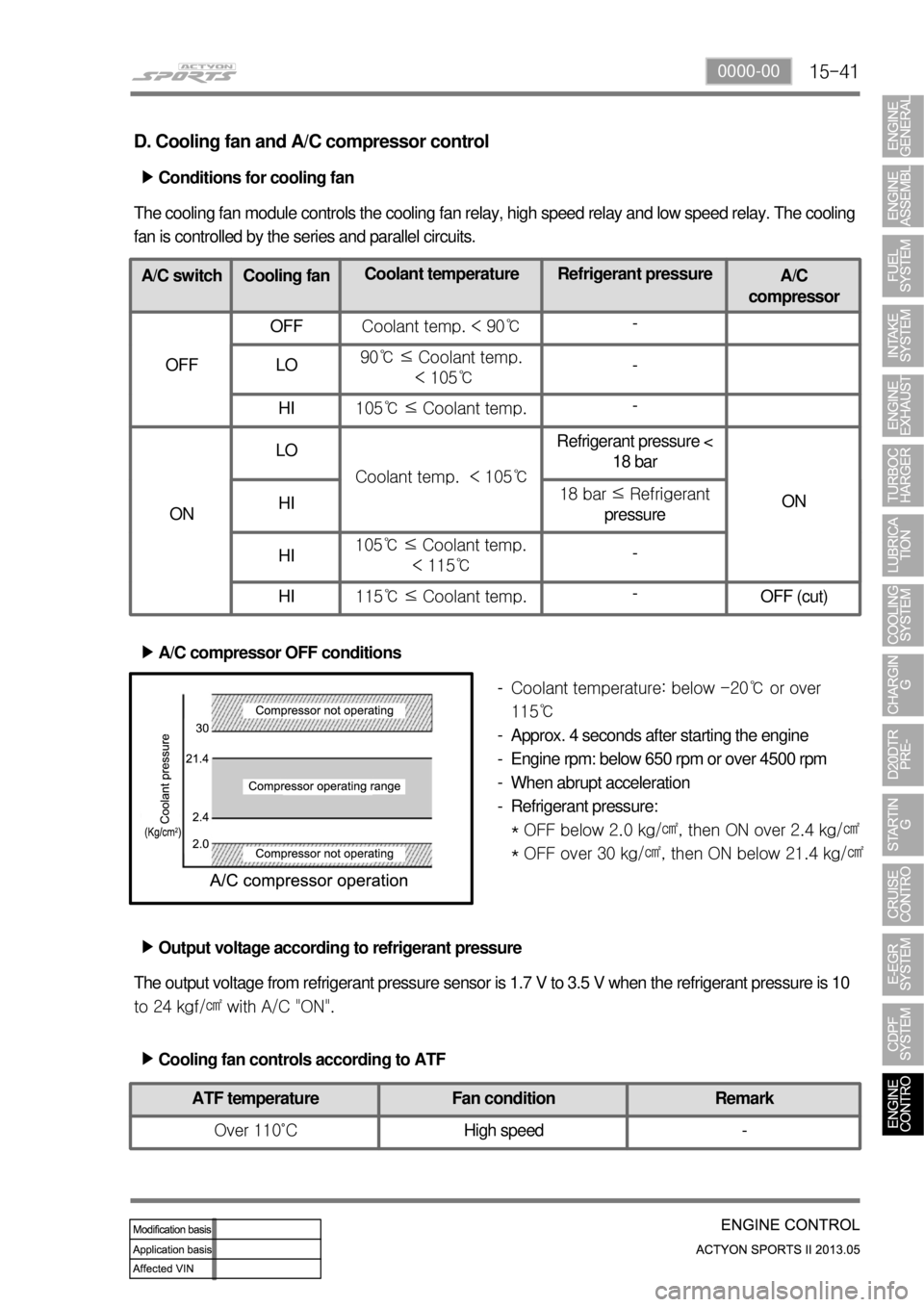

D. Cooling fan and A/C compressor control

Conditions for cooling fan ▶

The cooling fan module controls the cooling fan relay, high speed relay and low speed relay. The cooling

fan is controlled by the series and parallel circuits.

A/C switch Cooling fanCoolant temperature Refrigerant pressure

A/C

compressor

OFF OFF Coolant temp. < 90℃ -

LO 90℃ ≤ Coolant temp.

< 105℃-

HI 105℃ ≤ Coolant temp. -

ONLO

Coolant temp. < 105℃Refrigerant pressure <

18 bar

ON

HI 18 bar ≤ Refrigerant

pressure

HI 105℃ ≤ Coolant temp.

< 115℃-

HI115℃ ≤ Coolant temp. -

OFF (cut)

A/C compressor OFF conditions ▶

Coolant temperature: below -20℃ or over

115℃

Approx. 4 seconds after starting the engine

Engine rpm: below 650 rpm or over 4500 rpm

When abrupt acceleration

Refrigerant pressure:

* OFF below 2.0 kg/㎠, then ON over 2.4 kg/㎠

* OFF over 30 kg/㎠, then ON below 21.4 kg/㎠ -

-

-

-

-

The output voltage from refrigerant pressure sensor is 1.7 V to 3.5 V when the refrigerant pressure is 10

to 24 kgf/㎠ with A/C "ON".Output voltage according to refrigerant pressure ▶

Cooling fan controls according to ATF ▶

ATF temperature Fan condition Remark

Over 110˚CHigh speed -

Page 242 of 751

15-42

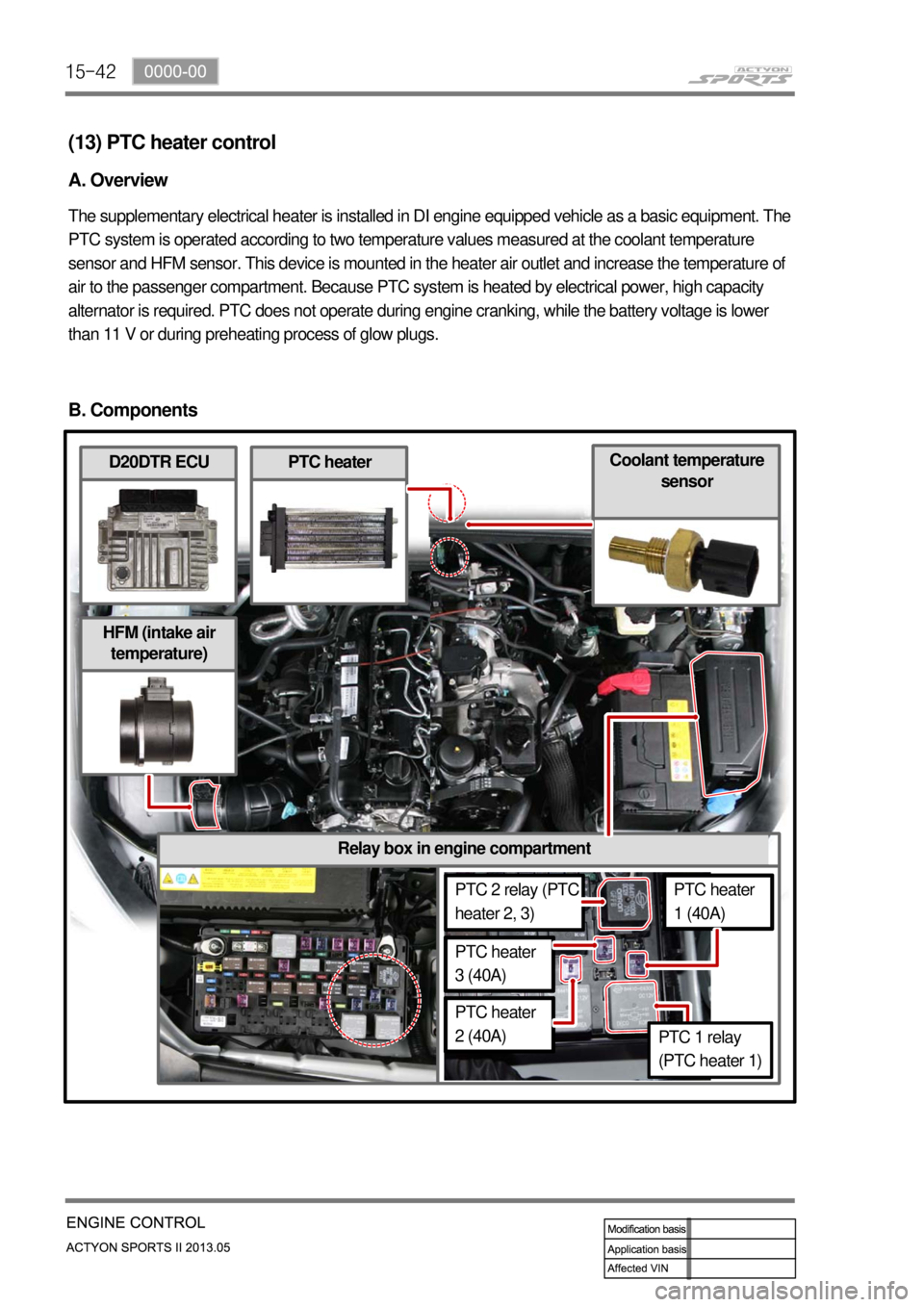

Relay box in engine compartment

(13) PTC heater control

A. Overview

The supplementary electrical heater is installed in DI engine equipped vehicle as a basic equipment. The

PTC system is operated according to two temperature values measured at the coolant temperature

sensor and HFM sensor. This device is mounted in the heater air outlet and increase the temperature of

air to the passenger compartment. Because PTC system is heated by electrical power, high capacity

alternator is required. PTC does not operate during engine cranking, while the battery voltage is lower

than 11 V or during preheating process of glow plugs.

B. Components

HFM (intake air

temperature)

Coolant temperature

sensorPTC heater

PTC 2 relay (PTC

heater 2, 3)

PTC heater

3 (40A)

PTC heater

2 (40A)

PTC heater

1 (40A)

D20DTR ECU

PTC 1 relay

(PTC heater 1)

Page 243 of 751

15-430000-00

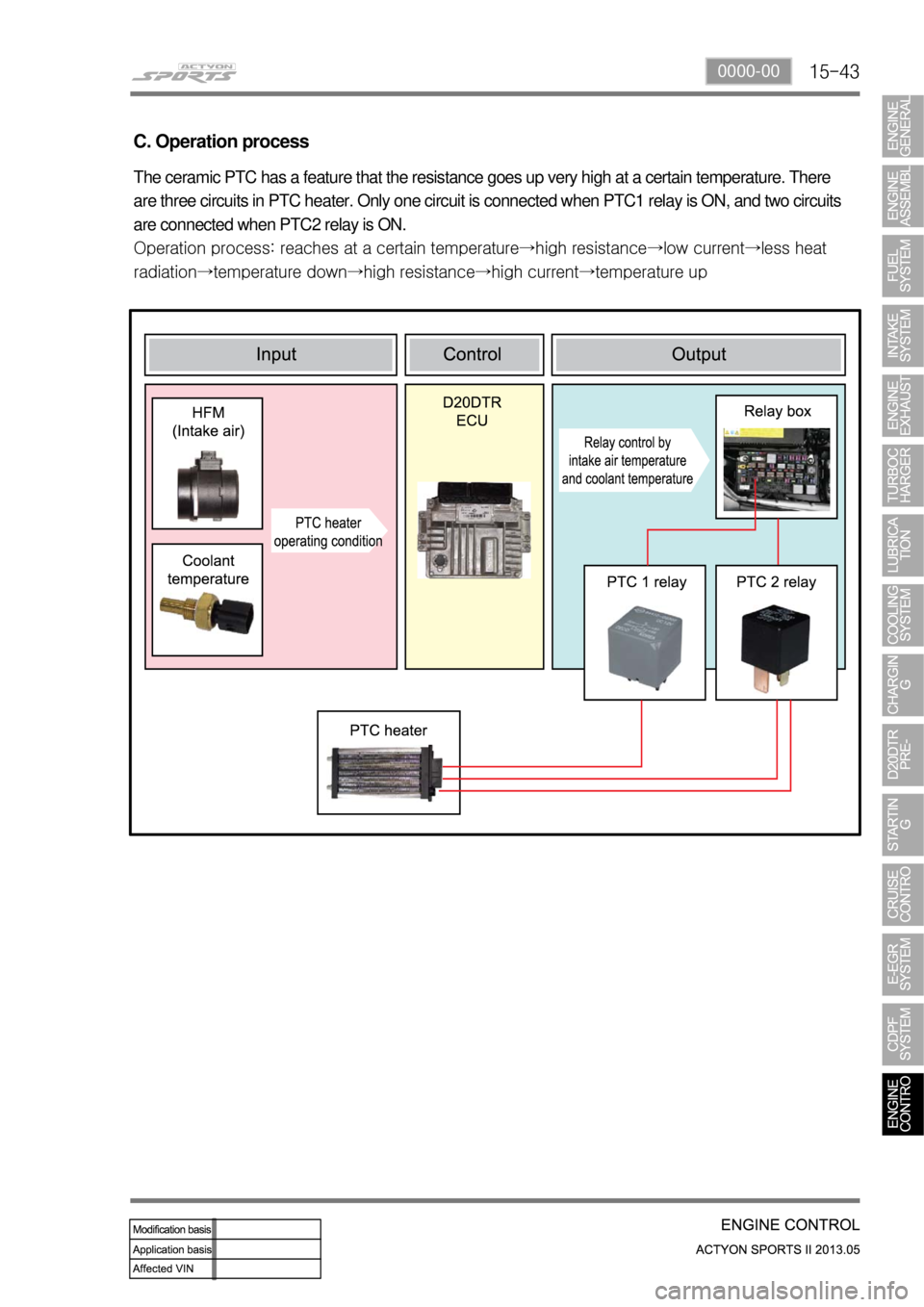

C. Operation process

The ceramic PTC has a feature that the resistance goes up very high at a certain temperature. There

are three circuits in PTC heater. Only one circuit is connected when PTC1 relay is ON, and two circuits

are connected when PTC2 relay is ON.

<00760097008c00990088009b0090009600950047009700990096008a008c009a009a006100470099008c0088008a008f008c009a00470088009b004700880047008a008c0099009b0088009000950047009b008c00940097008c00990088009b009c009900

8c02e7008f0090008e008f00470099008c009a0090009a009b>ance→low current→less heat

<00990088008b00900088009b00900096009502e7009b008c00940097008c00990088009b009c0099008c0047008b0096009e009502e7008f0090008e008f00470099008c009a0090009a009b00880095008a008c02e7008f0090008e008f0047008a009c00

990099008c0095009b02e7009b008c00940097008c00990088>ture up

Page 275 of 751

02-6

1) Starting Mode

When the ignition is turned ON, the ECM turns the fuel pump relay on for 1 second. The fuel pump then

builds fuel pressure. The ECM also checks the Engine Coolant Temperature (ECT) sensor and the

Throttle Position (TP) sensor and determines the proper air/fuel ratio for starting the engine. This ranges

from1.5 to 1 at -36 °C (-33 °F) coolant temperature to 14.7 to 1 at 94 °C (201 °F) coolant

temperature. The ECM controls the amountof fuel delivered in the starting mode by changing how long

the fuel injector is turned on and off. This is done by ''pulsing" the fuel injectors for very short times.

2) Run Mode

The run mode has two conditions called ''open loop" and ''closed loop".

3) Open Loop

When the engine is first started and it is above 690 rpm, the system goes into "open loop" operation. In

"open loop", the ECM ignores the signal from the HO2S and calculates the air/fuel ratio based on inputs

from the ECT sensor and the MAF sensor. The ECM stays in "open loop" until the following conditions

are met:

The O2 has a varying voltage output, showing that it is hot enough to operate properly.

The ECT sensor is above a specified temperature (22.5 °C).

A specific amount of time has elapsed after starting the engine. -

-

-

4) Closed Loop

The specific values for the above conditions vary with different engines and are stored in the

Electronically Erasable Programmable Read-Only Memory (EEPROM).

When these conditions are met, the system goes into "closed loop" operation. In "closed loop", the ECM

calculates the air/fuel ratio (fuel injector on- time) based on the signals from the O2 sensors. This allows

the air/fuel ratio to stay very close to 14.7 to 1.

5) Acceleration Mode

The ECM responds to rapid changes in throttle position and airflow and provides extra fuel.

6) Deceleration Mode

The ECM responds to changes in throttle position and airflow and reduces the amount of fuel. When

deceleration is very fast, the ECM can cut off fuel completely for short periods of time.

Page 288 of 751

06-8

The cooling fans are mounted behind the radiator in the engine compartment. The electric cooling fans

increase the flow of air across the radiator fins and across the condenser on air conditioned (A/C)-

equipped vehicles.

This helps to speed cooling when the vehicle is at idle or moving at low speeds.

All models have two fans. The main fan is 320 mm (12. 6 inches) in diameter with seven blades to aid

the airflow through the radiator and the condenser. An electric motor attached to the radiator support

drives the fan.

The auxiliary fan is 320 mm (12.6 inches) in diameter.

A/C Off or Non-AC Model ▶

The cooling fans are actuated by the engine control module (ECM) using a low-speed cooling

fan relay, a high-speed cooling fan relay and a cooling fan motor relay.

The ECM will turn the cooling fans on at low speed when the coolant temperature reaches

95°C(203°F) and at high speed when the coolant temperature reaches 105°C(221°F).

The ECM will change the cooling fans from high peed to low speed at 100°C(212°F) and

will turn the cooling fans off at 90°C (194°F). -

-

-

A/C On ▶

The ECM will turn the cooling fans on at low speed when the A/C system is on. The ECM will

change to high speed when the high side A/C pressure reaches 1860 kPa (269.8 psi).

The cooling fans will return to low speed when the high side A/C pressure reaches 1378 kPa

(199.8 psi). -

-

7) Engine Coolant Temperature Sensor

The Engine Coolant Temperature (ECT) sensor uses a temperature to control the signal voltage to the

Engine Control Module (ECM).

8) Coolant Temperature Gauge

The coolant temperature gauge controls the instrument panel temperature indicator. The coolant

temperature gauge is located with ECT sensor.

Page 302 of 751

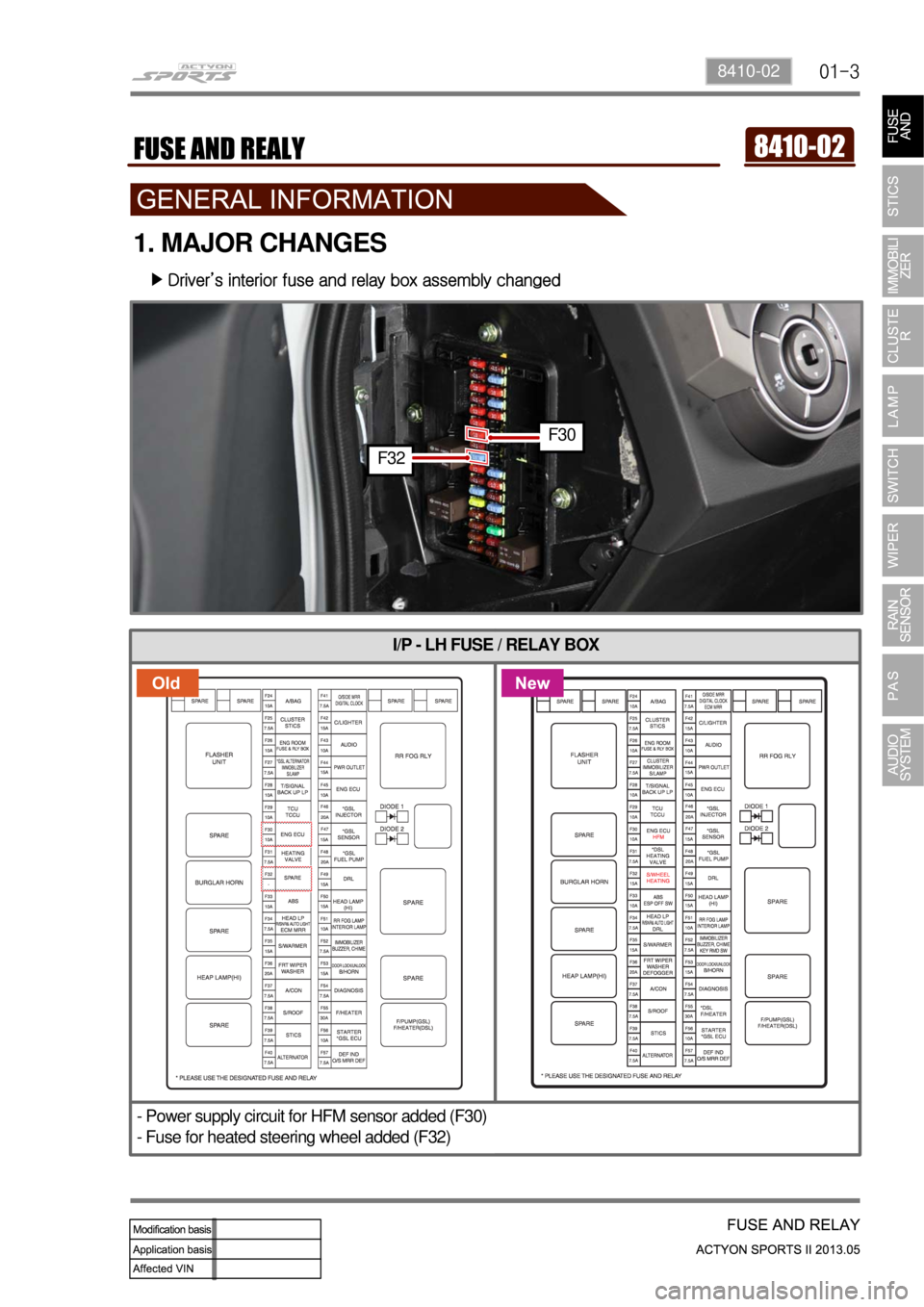

01-38410-02

I/P - LH FUSE / RELAY BOX

- Power supply circuit for HFM sensor added (F30)

- Fuse for heated steering wheel added (F32)

1. MAJOR CHANGES

Driver’s interior fuse and relay box assembly changed ▶

F32

F30