charging SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 132 of 751

06-18

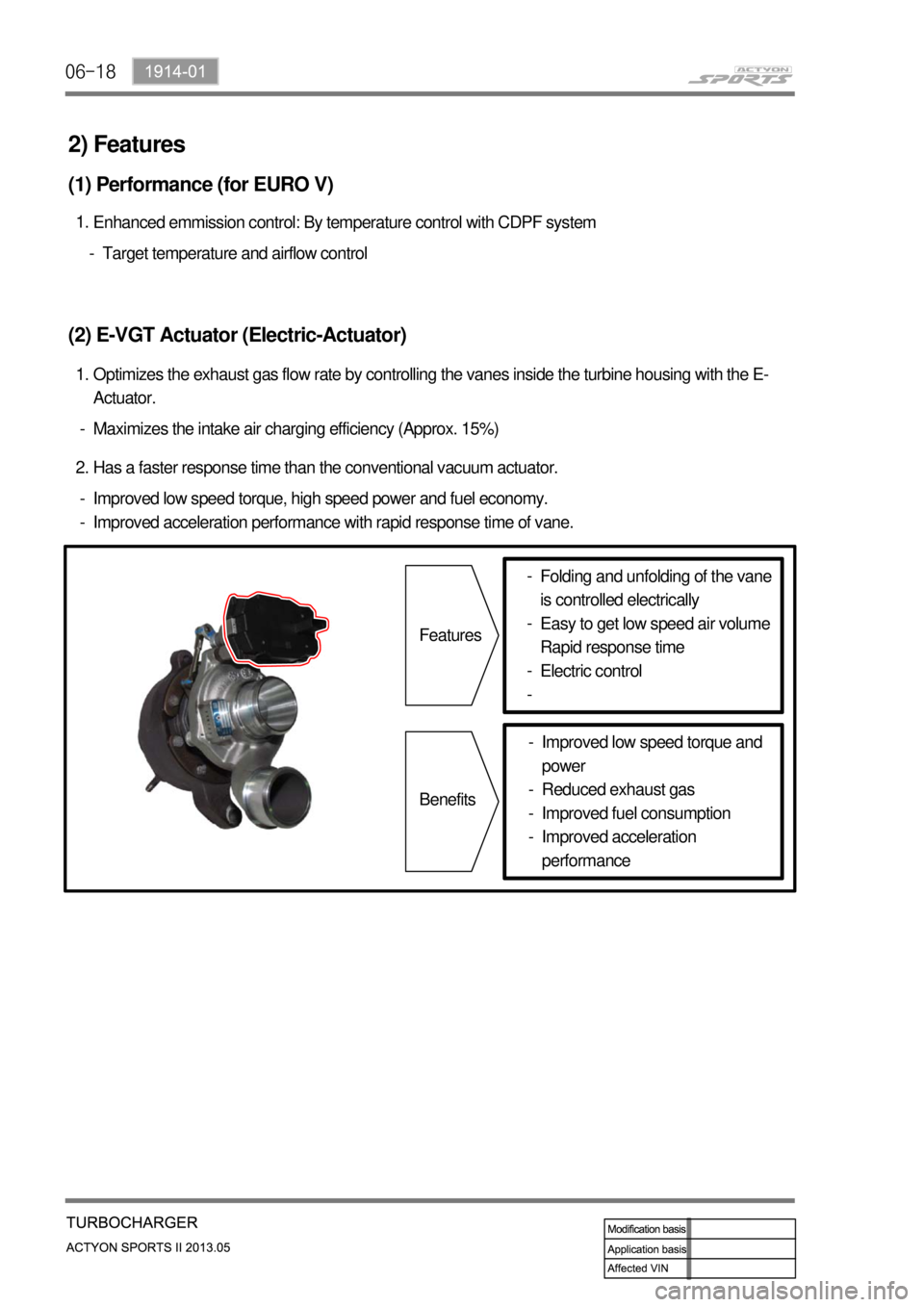

Maximizes the intake air charging efficiency (Approx. 15%) -Optimizes the exhaust gas flow rate by controlling the vanes inside the turbine housing with the E-

Actuator. 1.

(2) E-VGT Actuator (Electric-Actuator)

Target temperature and airflow control -Enhanced emmission control: By temperature control with CDPF system 1.

(1) Performance (for EURO V)

Has a faster response time than the conventional vacuum actuator. 2.

Improved low speed torque, high speed power and fuel economy.

Improved acceleration performance with rapid response time of vane. -

-

2) Features

Features

BenefitsFolding and unfolding of the vane

is controlled electrically

Easy to get low speed air volume

Rapid response time

Electric control -

-

-

-

Improved low speed torque and

power

Reduced exhaust gas

Improved fuel consumption

Improved acceleration

performance -

-

-

-

Page 152 of 751

09-71451-01

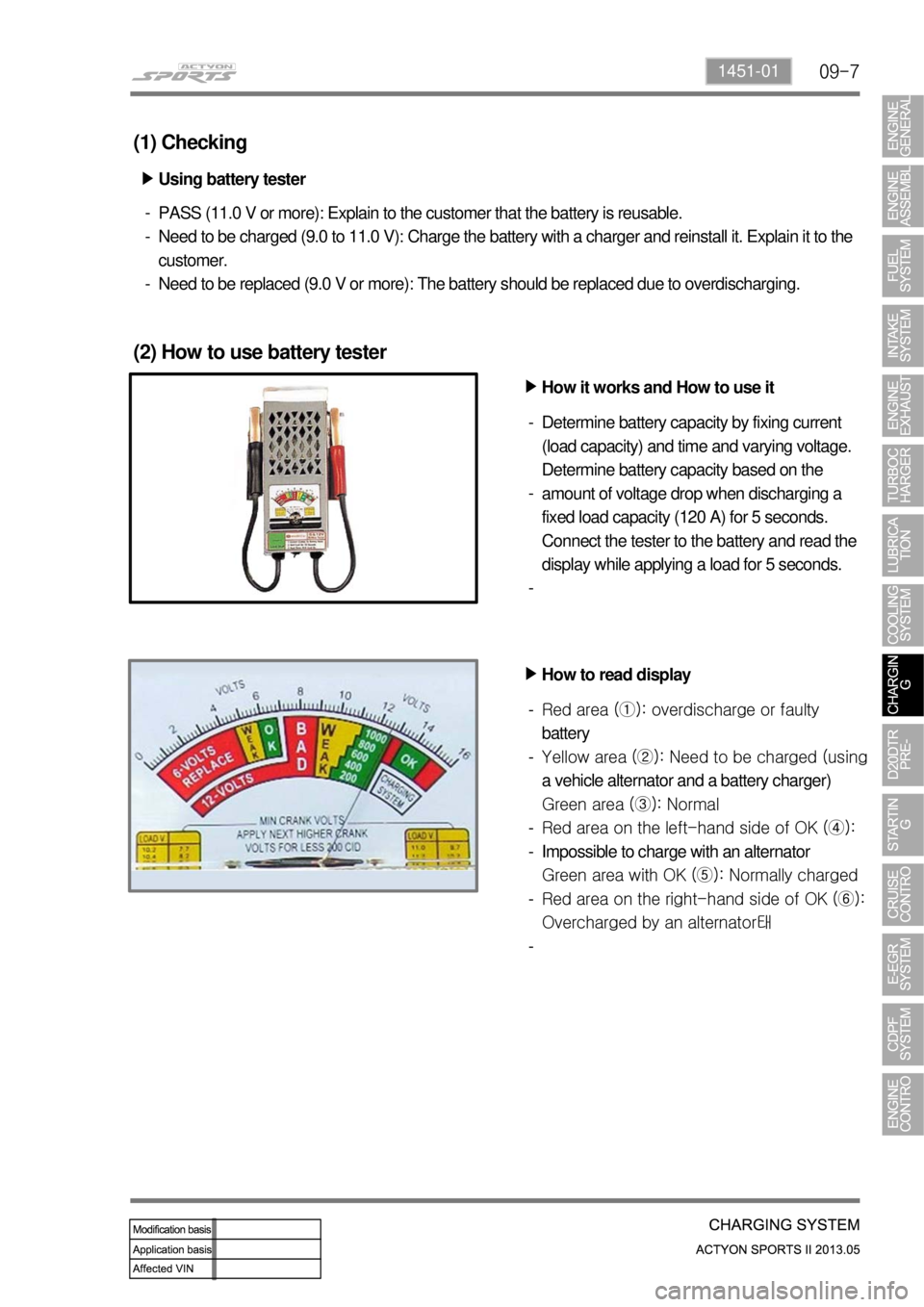

(1) Checking

Using battery tester ▶

PASS (11.0 V or more): Explain to the customer that the battery is reusable.

Need to be charged (9.0 to 11.0 V): Charge the battery with a charger and reinstall it. Explain it to the

customer.

Need to be replaced (9.0 V or more): The battery should be replaced due to overdischarging. -

-

-

(2) How to use battery tester

How it works and How to use it ▶

Determine battery capacity by fixing current

(load capacity) and time and varying voltage.

Determine battery capacity based on the

amount of voltage drop when discharging a

fixed load capacity (120 A) for 5 seconds.

Connect the tester to the battery and read the

display while applying a load for 5 seconds. -

-

-

How to read display ▶

Red area (①): overdischarge or faulty

battery

Yellow area (②): Need to be charged (using

a vehicle alternator and a battery charger)

Green area (③): Normal

Red area on the left-hand side of OK (④):

Impossible to charge with an alternator

Green area with OK (⑤): Normally charged

Red area on the right-hand side of OK (⑥):

Overcharged by an alternator태 -

-

-

-

-

-

Page 156 of 751

09-111451-01

2. OPERATING PROCESS

1) Charging Flow

Page 157 of 751

09-12

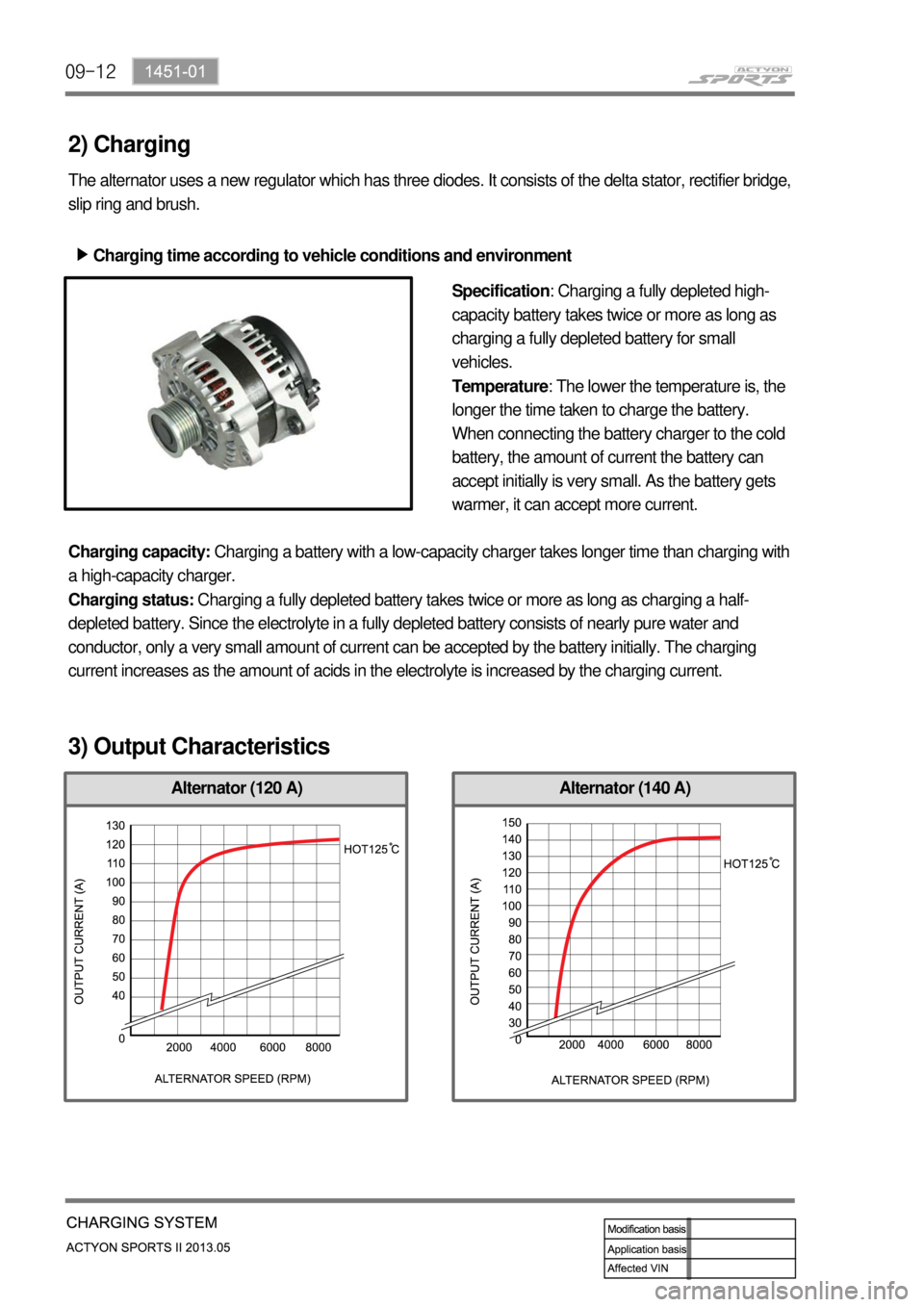

Alternator (140 A)Alternator (120 A)

2) Charging

The alternator uses a new regulator which has three diodes. It consists of the delta stator, rectifier bridge,

slip ring and brush.

Charging time according to vehicle conditions and environment ▶

Specification: Charging a fully depleted high-

capacity battery takes twice or more as long as

charging a fully depleted battery for small

vehicles.

Temperature: The lower the temperature is, the

longer the time taken to charge the battery.

When connecting the battery charger to the cold

battery, the amount of current the battery can

accept initially is very small. As the battery gets

warmer, it can accept more current.

Charging capacity: Charging a battery with a low-capacity charger takes longer time than charging with

a high-capacity charger.

Charging status: Charging a fully depleted battery takes twice or more as long as charging a half-

depleted battery. Since the electrolyte in a fully depleted battery consists of nearly pure water and

conductor, only a very small amount of current can be accepted by the battery initially. The charging

current increases as the amount of acids in the electrolyte is increased by the charging current.

3) Output Characteristics

Page 295 of 751

07-6

(2) Cold Cranking Amperage

The cold cranking amperage test is expressed at a battery temperature of -18°C(0°F).

The current rating is the minimum amperage, which must be maintained by the battery for 30 seconds at

the specified temperature, while meeting a minimum voltage requirement of 7.2 volts.

This rating is a measure of cold cranking capacity.

The battery is not designed to last indefinitely. However, with proper care, the battery will provide many

years of service. If the battery tests well, but fails to perform satisfactorily in service for no apparent

reason, the following factors may point to the cause of the trouble:

Vehicle accessories are left on overnight.

Slow average driving speeds are used for short periods.

The vehicle's electrical load is more than the generator output, particularly with the addition o

f

aftermarket equipment.

Defects in the charging system, such as electrical shorts, a slipping generator belt, a faulty generator,

or a faulty voltage regulator.

Battery abuse, including failure to keep the battery cable terminals clean and tight or a loose battery

hold-down clamp.

Mechanical problems in the electrical system, such as shorted or pinched wires. ·

·

·

·

·

·

3) Charging Time Required

The time required to charge a battery will vary depending upon the following factors:

Size of Battery - A Completely discharged large heavy-duty battery required more than twice the

recharging time as a completely discharged small passenger car battery. ▶

<007b008c00940097008c00990088009b009c0099008c00470054004700680047009300960095008e008c00990047009b00900094008c0047009e00900093009300470089008c00470095008c008c008b008c008b0047009b00960047008a008f0088009900

8e008c00470088009500a0004700890088009b009b008c0099>y at -18°C(0°F) than at

27°C(80°F).

When a fast charger is connected to a cold battery, the current accepted by the battery will be very

low at first.

The battery will accept a higher current rate as the battery warms. ▶

Charger Capacity - A charger which can supply only 5 amperes will require a much longer charging

period than a charger that can supply 30 amperes or more. ▶

State-of-Charge - A completely discharged battery requires more than twice as much charge as a

onehalf charged battery.

Because the electrolyte is nearly pure water and a poor conductor in a completely discharged

battery, the current accepted by the battery is very low at first. Later, as the charging current causes

the electrolyte acid content to increase, the charging current will likewise increase. ▶

Page 296 of 751

07-71452-01

4) Charging a Completely Discharged Battery (Off the Vehicle)

Unless this procedure is properly followed, a perfectly good battery may be needlessly replaced.

The following procedure should be used to recharge a completely discharged battery:

Measure the voltage at the battery terminals with an accurate voltmeter.

If the reading is below 10 volts, the charge current will be very low, and it could take some

time before the battery accepts the current in excess of a few milliamperes.

Refer to "Charging Time Required" in this section, which focuses on the factors affecting both the

charging time required. Such low current may not be detectable on ammeters available in the field.

Set the battery charger on the high setting. 1.

2.

Continue to charge the battery until the charge current is measurable. Battery chargers vary in the

amount of voltage and current provided. The time required for the battery to accept a measurable

charger current at various voltages may be as follows: 3.

If the charge current is not measurable at the end of the above charging times, the battery

should be replaced.

If the charge current is measurable during the charging time, the battery is good, and charging

should be completed in the normal manner. ·

·

If the charge current is still not measurable after using the charging time calculated by the above

method, the battery should be replaced. ·

It is important to remember that a completely discharged battery must be recharged for a sufficient

number of ampere hours (AH) to restore the battery to a usable state.

Page 297 of 751

07-8

5) Jump Starting Procedure

Position the vehicle with the charged battery so that the jumper cables will reach from the charged

battery to the battery that requires charging.

Turn off the ignition, all the lights, and all the electrical loads in both vehicles.

Leave the hazard flasher on if jump starting where there may be other traffic and any other lights

needed for the work area.

Apply the parking brake firmly in both vehicles. 1.

2.

3.

4.

Shift an automatic transmission to PARK. 5.

Clamp one end of the first jumper cable to the positive terminal on the booster battery. Make sure it

does not touch any other metal parts.

Clamp the other end of the same cable to the positive terminal on the discharged battery. Never

connect the other end to the negative terminal of the discharged battery. 6.

7.

Clamp one end of the second cable to the negative terminal of the booster battery.

Make the final connection to a solid engine ground, such as the engine lift bracket at least 450

millimeters (18 inches) from the discharged battery.

Start the engine of the vehicle with the good battery.

Run the engine at a moderate speed for several minutes.

Then start the engine of the vehicle with the discharged battery.

Remove the jumper cables by reversing the above sequence exactly, removing the negative cable

from the vehicle with the discharged battery first.

While removing each clamp, take care that it does not touch any other metal while the other end

remains attached. 8.

9.

10.

11.

12.In order to avoid damaging the vehicle make sure the cables are not on or near pulleys, fans, or

other parts that will move when the engine starts.

In order to avoid injury, do not use cables that have loose or missing insulation.

Page 298 of 751

07-91452-01

6) Alternator

Alternators are equipped with internal regulators.

Unlike three-wire generators, the alternator may be used with only two connections: battery positive and

an "D+" terminal to the charge indicator lamp.

As with other charging systems, the charge indicator lamp lights when the ignition switch is turned to

RUN, and goes out when the engine is running.

If the charge idicator is on with the engine running, a charging system defect is indicated. This indicato

r

light will glow at full brilliance for several kinds of defects as well as when the system voltage is too high

or too low.

The regulator voltage setting varies with temperature and limits the system voltage by controlling roto

r

field current.

Achieve correct average field current for proper system voltage control by varying the on-off time. At high

speeds, the on-time may be 10 percent and the off-time 90 percent.

At low speeds, with high electrical loads, the on-time may be 90 percent and the off-time 10 percent.

7) Charging System

Generators use a new type of regulator that incorporates a diode trio.

A Delta stator, a rectifier bridge, and a rotor with slip rings and brushes are electrically similar

to earlier generators.

A conventional pulley and fan are used.

There is no test hole.

8) Starter

Wound field starter motors have pole pieces, arranged around the armature, which are energized by

wound field coils.

Enclosed shift lever cranking motors have the shift lever mechanism and the solenoid plunger enclosed

in the drive housing, protecting them from exposure to dirt, icy conditions, and splashes.

In the basic circuit, solenoid windings are energized when the switch is closed.

The resulting plunger and shift lever movement causes the pinion to engage the engine flywheel ring

gear.

The solenoid main contacts close. Cranking then takes place.

When the engine starts, pinion overrun protects the armature from excessive speed until the switch is

opened, at which time the return spring causes the pinion to disengage.

To prevent excessive overrun, the switch should be released immediately after the engine starts.

Page 650 of 751

12-214610-01

1. SYSTEM DESCRIPTION

The power steering has been designed to make the wheel move more easily than in a manual steering

system. The hydraulic power assists the process utilizing hydraulic fluid. The fluid increases pressure in

the power steering pump and aids the movement of the steering mechanism. The power steering

system consists of pump, oil reservoir, rack and gear box. The power steering pump is a vane type and

delivers hydraulic pressure to operate the power steering system. The pressure relief valve in the pump

controls the discharging pressure. The rotary valve in the rack and the pinion gear directs the oil from the

power steering pump to one side of the rack piston. The integrated rack piston converts the hydraulic

pressure to linear movement. The operating force of the rack moves the wheels through the tie rod, the

tie rod end and the steering knuckle. Even though the hydraulic pressure cannot be generated, a driver

can steer the vehicle without power assist but it needs very high steering force. In this case, the

operating force of the steering wheel is conveyed to the pinion, and the movement of the pinion moves

the rack through the pinion gear combined to the rack gear.