fuel filter SSANGYONG NEW REXTON 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 186 of 600

0000-00

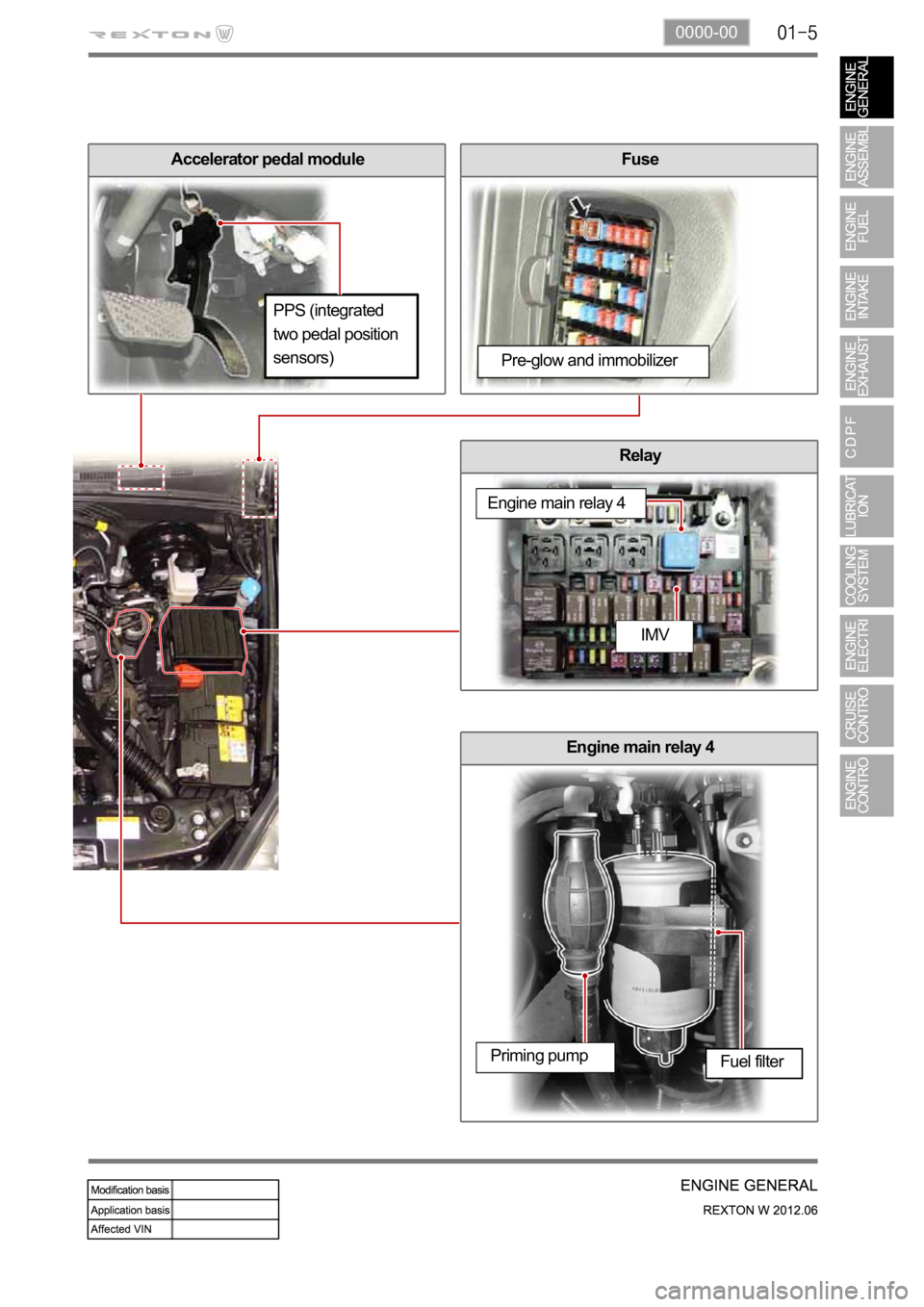

Accelerator pedal moduleFuse

Relay

Engine main relay 4

PPS (integrated

two pedal position

sensors)

Pre-glow and immobilizer

Engine main relay 4

IMV

Priming pumpFuel filter

Page 195 of 600

InjectorFuel filter and priming pump

8. LAYOUT OF FUEL SYSTEM

Components

IMV connector

Pressure sensor

in fuel rail

High pressure

fuel pipe

Fuel pipe

Common rail IMV connector

HP pump

Priming pumpFuel filter

Connector

Returned fuel

from HP pumpFuel filter

Fuel tank

HP pump

Fuel tank

Fuel return port

Low pressure fuel supply portVenturi

Fuel return portFuel temperature

sensor

IMV valve

IMV connectorHigh pressure fuel

supply port

(with orifice)

Page 213 of 600

0000-00

HP PumpFuel Line

Injector (7-way Injection and C3I Coding)Fuel filter Priming Pump

Common Rail

2. COMPONENTS OF FUEL SYSTEM

Fuel nozzle

holes (7)

Injector

Fuel pipe

High pressure fuel pip Fuel rail pressure sensor

Fuel filter

Connector

Priming

pump

Fuel from

HP pumpFuel filter

HP pumpFuel tank

Fuel tank

Common rail

Fuel return

port

Low pressure

fuel supply port

Venturi

High pressure

fuel supply port

(orifice included)

Fuel

temperature

sensor

IMV valve

Fuel return

port

IMV

connector

Page 225 of 600

1533-01

2.CDPF (EURO IV) SYSTEM CONTROL

1) General Description

As the soot is filtered in the CDPF, it is burnt and removed, and the CDPF is returned to the initial state to

collect the soot. Therefore, the burning procedures in the CDPF can be called as regeneration.

The CDPF assembly is integrated with DOC (at front side) and DPF (at rear side).

The DPF burns the soot with high-temperature exhaust gas (over

The rear exhaust gas

temperature sensor monitors the temperature of DPF section. If this temperature is below the

regeneration temperature, the ECU increases the post injection period to increase the fuel injection

amount, and consequently to increase the exhaust gas temperature.

Front exhaust gas temperature sensor

(Measuring temperature of exhaust gas in

exhaust manifold)

Rear exhaust gas temperature sensor

(Measuring temperature of exhaust gas

escaping DOC)

Normally, when the vehicle is driven for 600 ~ 1,200 km, the enough amount of soot to be burnt is

filtered and accumulated in the CDPF. The ECU increase the amount of post injection to increase

the tempeature of exhaust gas up to

so that the soot is burnt. The soot is burnt for

15 ~ 20 minutes. -

Page 226 of 600

2) System Composition for Soot Combustion

When the engine is running in low load range, the temperature of exhaust gas is decreased as the

amount of fuel supplied is decreased. To burn the soot filtered in the CDPF, the control system should

be installed to check the operating range and increase the temperature of exhaust gas by controlling the

amount of fuel supplied and intake air.

Two temperature sensors and one differential pressure sensor monitor the CDPF's operating range.

According to these sensors' information, the throttle flap decreases the intake air entered to the throttle

body. Also, the fuel injection pattern is added to increase the temperature of exhaust gas for soot

combustion.

There are three fuel injection patterns (pilot injection, pre-injection and main injection). As the CDPF is

installed, the post injection pattern is added.

3) Post Injection and Air Mass Control

When the differential pressure sensor detects the pressure difference between the front and the rear

side of CDPF, the sensor sends signal indicating the soot is acumulated and the post injection is

performed to raise the temperature of exhaust gas. The amount of fuel injected is determined according

to the temperature of exhaust gas detected by the rear temperature sensor. If the temperature is below

the amount of fuel injected is increased to raise the temperature. If the temperature is over

the amount of fuel injected is decreased or not controlled.

When the engine is running in low load range, the amount of post injection and the amount of intake ai

r

are controlled. It is to raise the temperature by increasing the amount of fuel while decreasing the

amount of intake air.

Page 258 of 600

2. MAJOR COMPONENTS

Front view

Vacuum pump

Camshaft position sensor

Oil filter assembly

Power steering pump pulley

Oil pressure switch

Idler pulley No. 2

Water pump pulley

Alternator pulley

Auto tensioner

Idler pulley No. 1

A/C compressor pulley

Rear view

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

IMV valve Crankshaft position sensor

Isolation damper

Page 261 of 600

0000-00

1) Service Interval

DescriptionDaily

inspectionWeekly

inspectionService interval

Engine oil & oil

filterInspection - EU Change every 20,000 km or 12 months

(The service interval should be

shortened under severe conditions)

General Change every 15,000 km or 12 months

(The service interval should be

shortened under severe conditions)

Coolant Inspection - Change every 200,000 km or 5 years

Air cleaner

element- Inspection Diesel EU Change every 20,000 km

(The service interval should

be shortened under severe

conditions)

General Clean every 7,500 km,

change every 15,000 km

(The service interval should

be shortened under severe

conditions)

Gasoline Clean every 15,000 km, replace every

60,000 km (The service interval should

be shortened under severe conditions)

Fuel filter - - EU Change every 40,000 km (Draining

water from fuel filter: whenever replacing

the engine oil)

General Change every 45,000 km (Draining

water from fuel filter: whenever replacing

the engine oil)

Page 268 of 600

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Idler pulley/tensioner

pulley1

-

Glow plug M5 4

-

Vacuum pump

3 -

Timing gear case cover

7 -

1 -

3 -

Cylinder head cover

21 -

Oil dipstick gauge cover

1 -

Oil filter cap 1

-

Fuel rail

2 -

Injector clamp bolt

2 -

High pressure pipe

(between high pressure

pump and fuel rail

assembly)M17 1

-

High pressure pipe

(between fuel rail

assembly and injector)M17 4

-

Crankshaft position

sensor

1 -

Main wiring

5 -

Intake duct

3 -

Power steering pump

3 -

Cylinder head front cover

5 -

Page 273 of 600

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 4

-

Vacuum pump

3 -

Timing gear case cover

3 -

7 -

1 -

3 -

Cylinder head cover

21 -

Oil gauge tube

1 -

Oil filter cap 1

-

Fuel rail

2 -

Injector clamp bolt

2 -

High pressure pipe

(between HP pump and

fuel rail)M17 1

-

High pressure pipe

(between fuel rail and

injector)M17 4

-

Crank position sensor

1 -

Main wiring

5 -

Intake duct M8x25 4

-

Power steering pump

3 -

Cylinder head front cover

5 -

Ladder frame

5 -

Oil pump

3 -

Page 317 of 600

2210-01

1. SPECIFICATION

Description Specification

Fuel Diesel

Fuel filterType Fuel heater + priming pump + water

separator integrated type

Filter type Changeable filter element type

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature

Operating pressure 1800 bar

Operating temperature

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tankCapacity 75 L

Material Steel

Fuel sender Single sender type

Change interval EU every 40,000 km

GEN every 45,000 km

Water separation

intervalEU every 20,000 km

GEN every 15,000 km