ENGINE CONTROL SSANGYONG RODIUS 2006 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2006, Model line: RODIUS, Model: SSANGYONG RODIUS 2006Pages: 444, PDF Size: 56.32 MB

Page 25 of 444

CIRCUIT

1491-01/8210-01/3670-01/4891-01/4920-01/4480-01/8810-01/8010-01/7630-02/8710-03/8510-03/4810-10/8510-00/8510-26/8910-01/6810-21/6910-01/6810-30

CIRCUIT

ENGINE

CHASSIS3670-01 TCU (5-SPEED)............................

4891-01 ABS/ESP......................................

4920-01 EPB..............................................

4480-01 EAS..............................................ELECTRIC

8910-01 AUDIO (MULTI VISION)................

8910-01 AUDIO..........................................

6810-21 PTC HEATER (POSITIVE

TEMPERATURE

COEFFICIENT).............................

6910-01 FFH (FUEL FIRED HEATER).........

6810-30 FATC (FULL AUTO TEMP.

CONTROL) CIRCUIT....................

6810-30 AIR-CON (MANUAL).....................

8810-01 AIR-BAG.......................................

8010-01 CLUSTER.....................................

7630-02 CIGAR LIGHTER, POWER

OUTLET......................................

8710-03 STICS..........................................

8510-03 POWER WINDOW CIRCUIT..........

4810-10 STOP & BACK-UP LAMP

CIRCUIT.......................................

8510-00 HEAD LAMP LEVELING DEVICE

CIRCUIT.......................................

8510-26 TURN SIGNAL & HAZARD LAMP

CIRCUIT.......................................7

9

11

12

13

14

17

18

22

23

24

2526

29

30

31

32

35 1491-01 ECU (ENGINE CONTROL UNIT -

D27DT EU IV)...............................

8210-01 DIAGNOSIS CIRCUIT...................3

6

Page 27 of 444

0-3

CIRCUITundefined

1491-01

1491-01

ECU (ENGINE CONTROL UNIT - D27DT EU IV)

1) ENG MAIN RELAY, PEDAL MODULE, HFM SENSOR, VALVE

(1) CONNECTOR INFORMATION

(2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

Page 78 of 444

05-3

ENGINE EXHAUST SYSTEM

RODIUS 2007.07

0000-00

2420-01ENGINE EXHAUST SYSTEM

1. OVERVIEW OF EXHAUST SYSTEM

When you are inspecting or replacing exhaust system components, make sure there is

adequate clearance from all points on the underbody to avoid possible overheating of the

floor panel and possible damage to the passenger compartment insulation and trim

materials.

Check the complete exhaust system and the nearby body areas and trunk lid for broken,

damaged, missing or mispositioned parts, open seams, holes, loose connections, or othe

r

deterioration which could permit exhaust fumes to seep into the trunk may be an indication

of a problem in one of these areas. Any defects should be corrected immediately. -

2. OVERVIEW OF MUFFLER

Aside from the exhaust manifold connection, the exhaust system uses a flange and seal joint

design rather than a slip joint coupling design with clamp and U-bolts.

If hole, open seams, or any deterioration is discovered upon inspection of the front muffler and

pipe assembly, the complete assembly should be replace, the complete assembly should be

replaced.

The same procedure is applicable to the rear muffler assembly. Heat shields for the front and

rear muffler assembly and catalytic converter protect the vehicle and the environment from the

high temperatures that the exhaust system develops.

3. OVERVIEW OF CATALYTIC CONVERTER

When jacking or lifting the vehicle from the body side rails, be certain that the lift pads do

not contact the catalytic converter, as this could damage the catalytic converter. -

Use of anything other than unleaded fuel will damage the catalyst in the catalytic

converter. -

The catalytic converter are emission-control devices added to the exhaust system to

reduce pollutants from the exhaust pipes.

The oxidation catalyst is coated with a catalytic material containing platinum and

palladium, which reduces levels of hydrocarbon (HC) and carbon monoxide (CO) from

the exhaust gas. The three-way catalyst has coatings which contain platinum and

rhodium, which additionally lower the levels of oxides of nitrogen (NOx). ·

·

Page 91 of 444

08-6

RODIUS 2007.07

0000-00

ENGINE ELECTRIC DEVICES

3. IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distributor and coil. It uses a crankshaft

position sensor input to the Engine Control Module (ECM).

The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition

system ignition coil.

This type of distributorless ignition system uses a “waste spark” method of spark

distribution. Each cylinder is paired with the cylinder that is opposite it (2.3L DOHC: 2 - 3 or 1 -

4, 3.2L DOHC: 1 - 6 or 2 - 5 or 3 - 4).

The spark occurs simultaneously in the cylinder coming up on the compression stroke and in

the cylinder coming up on the exhaust stroke.

The cylinder on the exhaust stroke requires very little of the available energy to fire the spark

plug.

The remaining energy is available to the spark plug in the cylinder on the compression stroke.

These systems use the EST signal from the ECM to control the EST.

The ECM uses the following information: Engine load (mass air flow sensor, manifold ai

r

pressure sensor).

Engine coolant temperature.

Intake air temperature.

Crankshaft position.

Engine speed (rpm).

1) Electronic Ignition System Ignition Coil

The Electronic Ignition (EI) system ignition coil is located on the cylinder head cover.

The double ended coils re ceive the signal for the ECM which controls the spark advance.

Each EI system ignition coil provides the high voltage to two spark plugs simultaneously;

3.2L DOHC

T1/1: cylinder 2 and 5

T1/2: cylinder 3 and 4

T1/3: cylinder 1 and 6

The EI system ignition coil is not serviceable and must be replaced as an assembly.

Page 93 of 444

09-3

ENGINE CONTROL SYSTEM

RODIUS 2007.07

0000-00

1522-16ENGINE CONTROL SYSTEM

1. ENGINE DATA DISPLAY TABLE

Page 94 of 444

09-4

RODIUS 2007.07

0000-00

ENGINE CONTROL SYSTEM

2. FASTENER TIGHTENING SPECIFICATIONS

1) TEMPERATURE VS RESISTANCE

Page 143 of 444

0-5

ENGINE FUEL SYSTEM

RODIUS 2007.07

0000-00

3) Fuel Rail - Chrome Color

D27DTP & D27DT (EU IV) * Fuel pipe (Common rail → Injector)

* Fuel high pressure pipe (HP pump →

Common rail)

D27DT * Fuel pipe (Common rail → Injector)

* Fuel high pressure pipe (HP pump →

Common rail) The I.D and O.D of the fuel rail between

HP pump and common rail are increased

according to the increased amount of fuel

injection.

Also, the engine ECU, HFM sensor and

EGR system are changed to control the

fuel injection volume and engine more

precisely.

·

Page 146 of 444

0-3

ENGINE INTAKE SYSTEM

RODIUS 2007.07

0000-00

2321-01ENGINE INTAKE SYSTEM

1. INTAKE SYSTEM LAYOUT

The intake system for the D27DTP (POWER UP) engine is equipped with the throttle body that

has a flap to block the air coming to the engine when the engine is switched off. Therefore, the

structure of the intake manifold has been changed.

Also, the improved HFM sensor (from HFM5.0 to HFM6.0) has been installed to control the

intake air precisely so that the NOx in the exhaust gas can be decreased.

Page 147 of 444

0-3

ENGINE EXHAUST SYSTEM

RODIUS 2007.07

1792-01

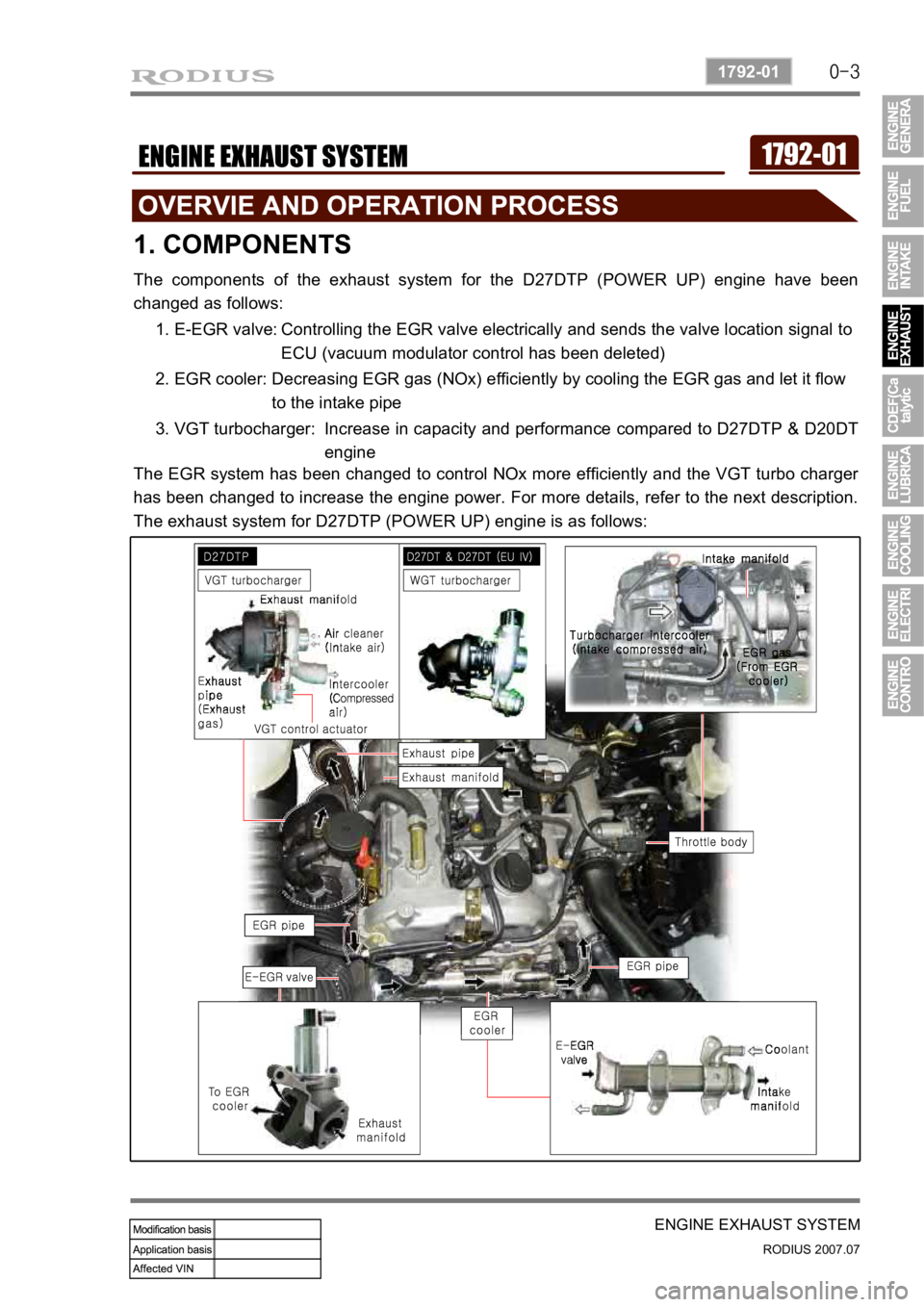

1792-01ENGINE EXHAUST SYSTEM

1. COMPONENTS

The components of the exhaust system for the D27DTP (POWER UP) engine have been

changed as follows:

1. E-EGR valve: Controlling the EGR valve electrically and sends the valve location signal to

ECU (vacuum modulator control has been deleted)

2. EGR cooler: Decreasing EGR gas (NOx) efficiently by cooling the EGR gas and let it flow

to the intake pipe

3. VGT turbocharger: Increase in capacity and performance compared to D27DTP & D20DT

engine

The EGR system has been changed to control NOx more efficiently and the VGT turbo charge

r

has been changed to increase the engine power. For more details, refer to the next description.

The exhaust system for D27DTP (POWER UP) engine is as follows:

Page 154 of 444

0-9

CDEF(Catalytic Disel Particulate Filter)

RODIUS 2007.07

0000-00

2) Sytem Composition for Soot Combustion

When the engine is running in low load range, the temperature of exhaust gas is decreased as

the amount of fuel supplied is decreased. To burnt the soot filtered in the CDPF, the control

system should be installed to check the operating range and increase the temperature o

f

exhaust gas by controlling the amount of fuel supplied and and intake air.

Two temperature sensors and one differential pressure sensor monitor the CDPF's operating

range. According to theses sensors' information, the throttle flap decreases the intake ai

r

entered to the throttle body. Also, the fuel injection pattern is added to increase the temperature

of exhaust gas for soot combustion.

There are two fuel injection patterns (pilot injection and main injection). As the CDPF is

installed, the post injection pattern is added.

3) Post Injection and Air Mass Control

When the differential pressure sensor detects the pressure difference between the front and the

rear side of CDPF, the sensor sends signal indicating the soot is acumulated and the post

injection is performed to raise the temperature of exhaust gas. The amount of fuel injected is

determined according to the temperature of exhaust gas detected by the rear temperature

<009a008c0095009a00960099005500470070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c00470090009a00470089008c00930096009e0047005d0057005700b6006a00530047009b008f008c004700880094009600

9c0095009b00470096008d0047008d009c008c009300470090>njected is increased to

<009900880090009a008c0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c005500470070008d0047009b008f008c0047009b008c00940097008c00990088009b009c0099008c00470090009a00470096009d008c0099004700

5d0057005700b6006a00530047009b008f008c004700880094>ount of fuel injected is

decreased or not controlled.

When the engine is running in low load range, the amount of post injection and the amount of

intake air are controlled.

It is to raise the temperature by increasing the amount of fuel while decreasing the amount of

intake air.