SSANGYONG RODIUS 2012 Service Manual

RODIUS 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57525/w960_57525-0.png

SSANGYONG RODIUS 2012 Service Manual

Trending: roof rack, Bolt, fuel, oil additives, lock, lights, clock

Page 131 of 715

01-16

5. RECOMMENDED FLUIDS AND LUBRICANTS

- Use only Ssangyong recommended fluids and lubricants.

- Keep the specified levels when adding or replacing the fluids.

- Do not mix any different types or brands of oils or fluids. This may cause damages.

Page 132 of 715

01-170000-00

Front: Double wishbone Rear: Multi Link

6. JACK POINTS

Page 133 of 715

01-18

The diagnostic connector is located at bottom of instrument panel. It consists of 16 pins.

The REKES key should be coded by the scan tool.

Connector Pin ▶

Diagnostic connector

Pin No. Function

1 -

2 -

3 STICS "A2"(Coding)

4 Ground

5 Ground

6 CAN HI S205 "12"

7 GSL ECU "58"

8 ABS/ESP unit “2”

9 Air bag unit “9”

10 -

11 TCU "A18"

12 -

13 TCCU "21"

14 CAN LO S205 "5"

15 STICS "B16" (Diagnosis)

16 B+

7. PIN ARRANGEMENT OF DIAGNOSTIC CONNECTOR

Page 134 of 715

01-190000-00

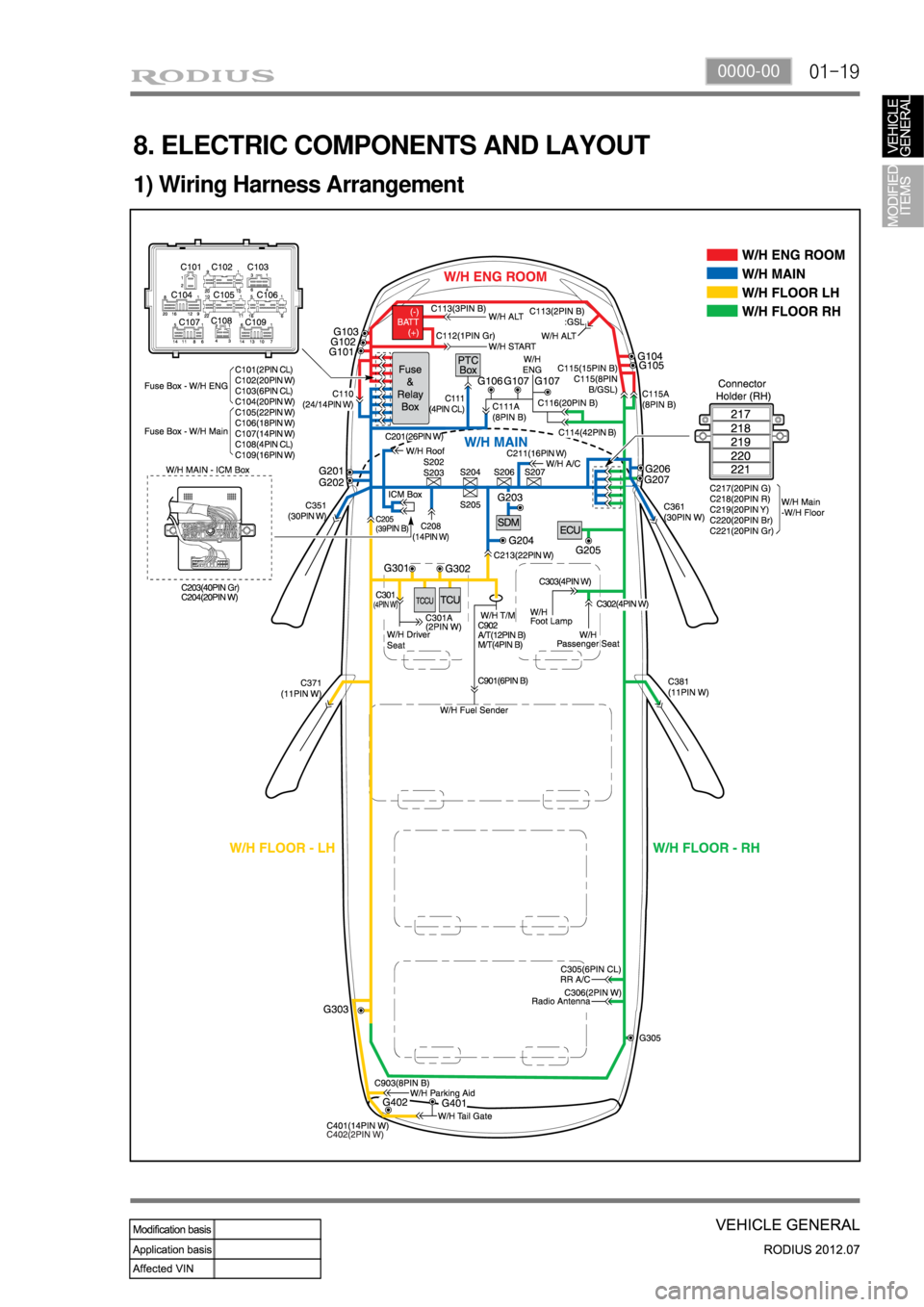

8. ELECTRIC COMPONENTS AND LAYOUT

1) Wiring Harness Arrangement

Page 135 of 715

01-20

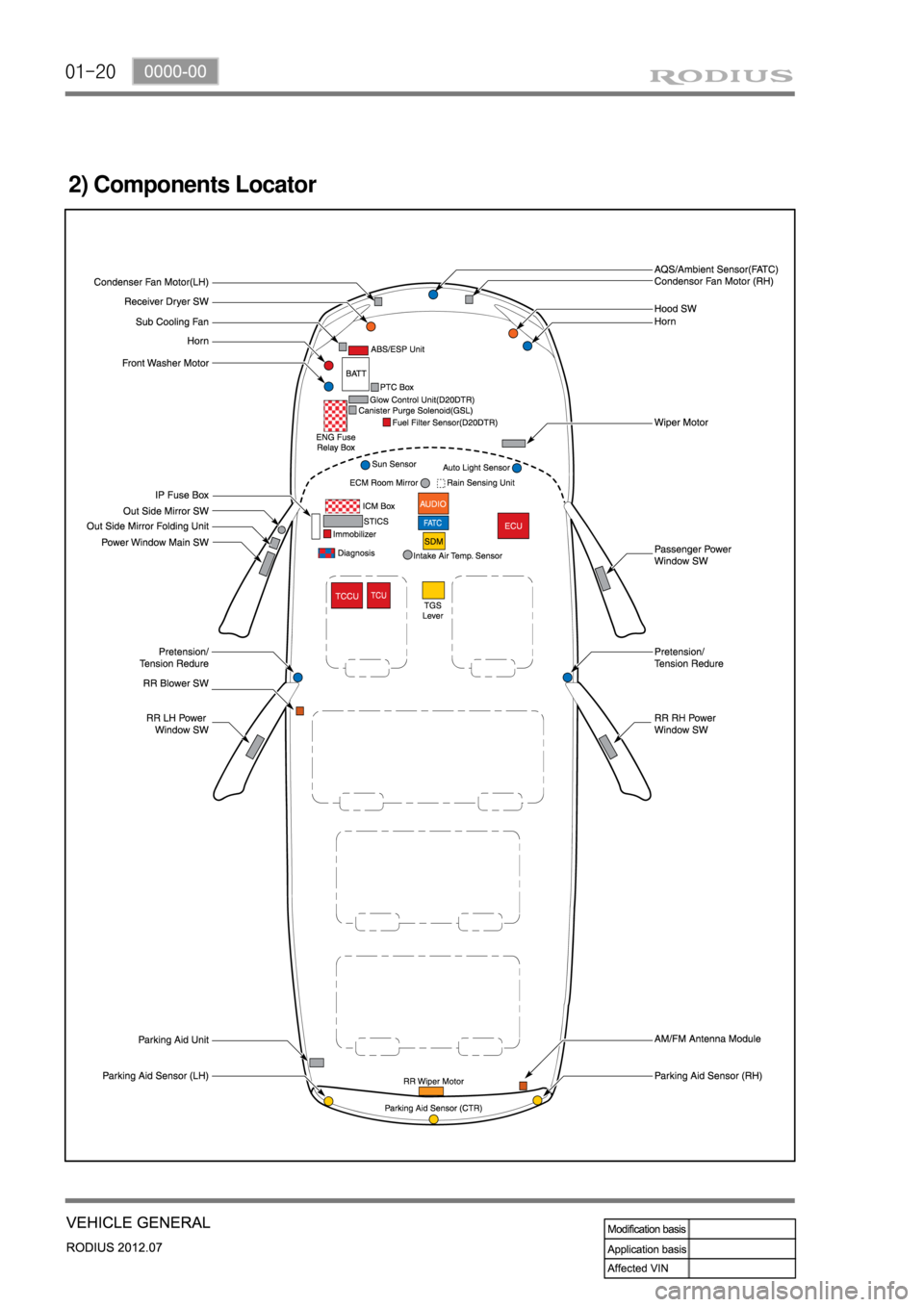

2) Components Locator

Page 136 of 715

01-210000-00

9. TIGHTENING TORQUE OF STANDARD BOLTS

Tightening Torque By Bolt Specification ▶

Metric bolt strength is embossed on the head

of each bolt. The strength of bolt can be

classified as 4T, 7T, 8.8T, 10.9T, 11T and

12.9T in general.

Observe standard tightening torque during

bolt tightening works and can adjust torque to

be proper within 15 % if necessary. Try not to

over max. allowable tightening torque if not

required to do so. 1.

2.Determine extra proper tightening torque if

tightens with washer or packing.

If tightens bolts on the below materials, be

sure to determine the proper torque. 3.

4.

Aluminum alloy: Tighten to 80 % o

f

above torque table.

Plastics: Tighten to 20 % of above torque

table. ·

·

Page 137 of 715

Page 138 of 715

02-2

2130-13 Coolant Reservoir

- Changed housing design and added

de-aeration port (engine head to coolant

reservoir)

1. ENGINE COMPARTMENT (DIESEL ENGINE)

De-aeration

port

HFM6 HFM7

1115-00 Engine

- Deleted D27DT (Euro4) engine and

introduced D20DTR (Euro5) engine.

2330-08HFM (Hot Film Air-Mass Sensor)

- Changed HFM sensor

2130-02 Air Cleaner

- Changed the material of air cleaner

element (paper filer to felt)2313-01Air cleaner Housing and Snorke

- Changed design according to installation

of new engine

Page 139 of 715

02-30000-00

2232-01 Fuel Filter Assembly

- Changed fuel filter

2112-02 PWM Cooling Fan

- To increase the cooling performance,

PWM cooling fan has been introduced.

Newly Installed Equipment

Water detection

sensor

Priming pump

Front RHFront LH

Electric fan

Front RHFront LH

PWM electric fan

1990-01 Engine Mounting Insulator

- Changed design according to installation

of new engine

2330-01 Intercooler

- To increase the cooling performance,

made the cooling capacity bigger and

changed the design.

Page 140 of 715

02-4

2. CHASSIS I

4012-01 Front Sub Frame

- Changed sub frame

4420-01 Front Stabilizer

- Improved rolling capacity

Newly Installed Equipment

2412-02CDPF (Catalyst & Diesel

Particulate Filter)

- Installed CDPF according to Euro 5

regulation

Sub frame bushing

Engine side

Mounting

bracket

assembly

Stabilizer linkStabilizer bar

Stabilizer bar

Mounting

bracket

assembly

Stabilizer link

Changed stabilizer mounting

Changed front axle mounting height

Trending: c 202, diagram, transmission, oil, glove box, automatic transmission, tire pressure