brake SSANGYONG RODIUS 2012 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: RODIUS, Model: SSANGYONG RODIUS 2012Pages: 715, PDF Size: 79.36 MB

Page 633 of 715

10-4

2) Maximum Brake Force

FBmax = wheel load FR x coefficient of friction (Mh)

The braking process cannot be described

sufficiently accurately with the brake forces

calculated. The values calculated only apply if

the wheel is not locked. In the case of a locking

wheel, the static friction turns into lower sliding

friction, with the result that the stopping distance

is increased. This loss of friction is termed "slip"

in specialist literature.

Page 636 of 715

10-74891-01

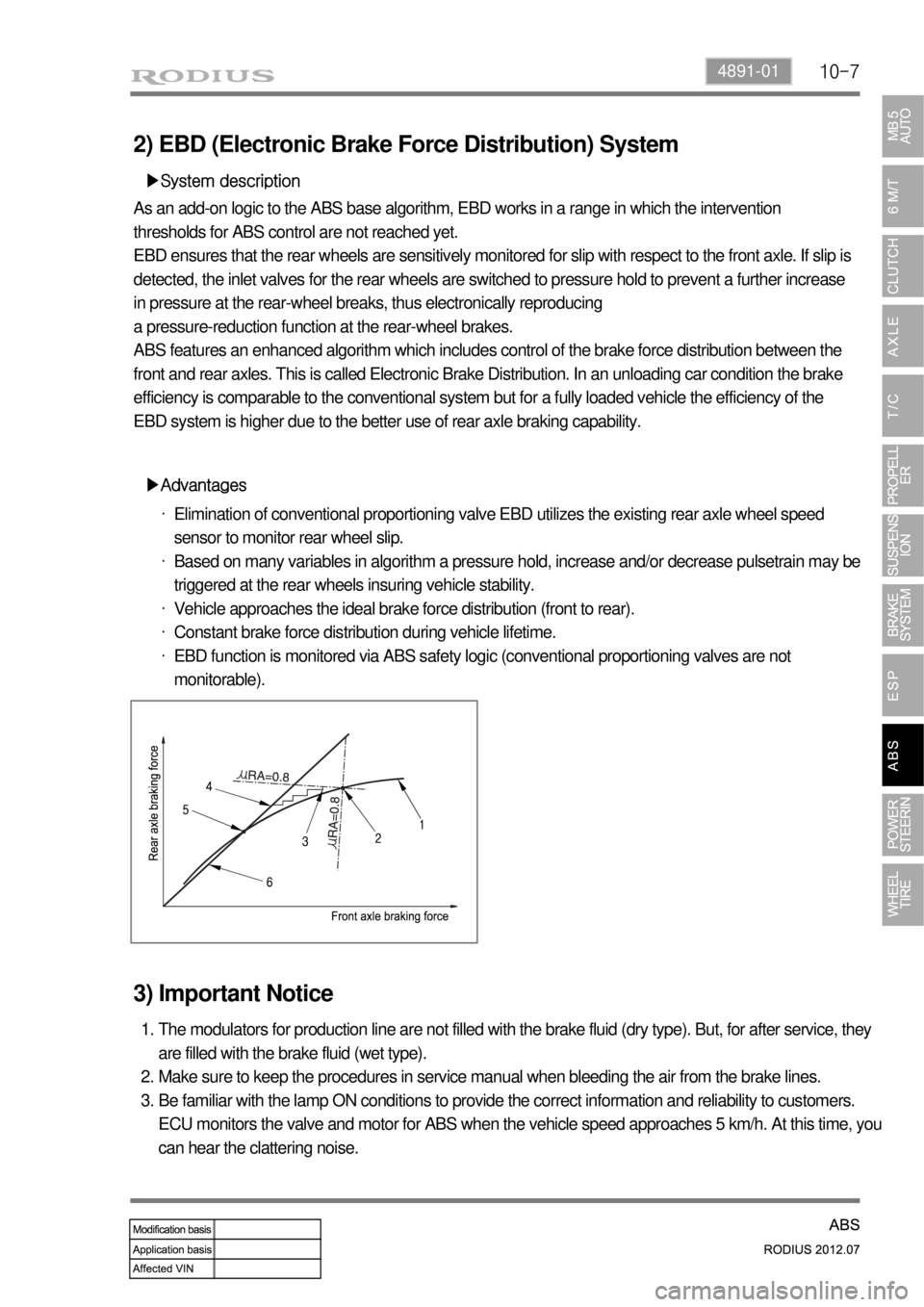

2) EBD (Electronic Brake Force Distribution) System

▶System description

As an add-on logic to the ABS base algorithm, EBD works in a range in which the intervention

thresholds for ABS control are not reached yet.

EBD ensures that the rear wheels are sensitively monitored for slip with respect to the front axle. If slip is

detected, the inlet valves for the rear wheels are switched to pressure hold to prevent a further increase

in pressure at the rear-wheel breaks, thus electronically reproducing

a pressure-reduction function at the rear-wheel brakes.

ABS features an enhanced algorithm which includes control of the brake force distribution between the

front and rear axles. This is called Electronic Brake Distribution. In an unloading car condition the brake

efficiency is comparable to the conventional system but for a fully loaded vehicle the efficiency of the

EBD system is higher due to the better use of rear axle braking capability.

▶Advantages

Elimination of conventional proportioning valve EBD utilizes the existing rear axle wheel speed

sensor to monitor rear wheel slip.

Based on many variables in algorithm a pressure hold, increase and/or decrease pulsetrain may be

triggered at the rear wheels insuring vehicle stability.

Vehicle approaches the ideal brake force distribution (front to rear).

Constant brake force distribution during vehicle lifetime.

EBD function is monitored via ABS safety logic (conventional proportioning valves are not

monitorable). ·

·

·

·

·

3) Important Notice

The modulators for production line are not filled with the brake fluid (dry type). But, for after service, they

are filled with the brake fluid (wet type).

Make sure to keep the procedures in service manual when bleeding the air from the brake lines.

Be familiar with the lamp ON conditions to provide the correct information and reliability to customers.

ECU monitors the valve and motor for ABS when the vehicle speed approaches 5 km/h. At this time, you

can hear the clattering noise. 1.

2.

3.

Page 637 of 715

10-8

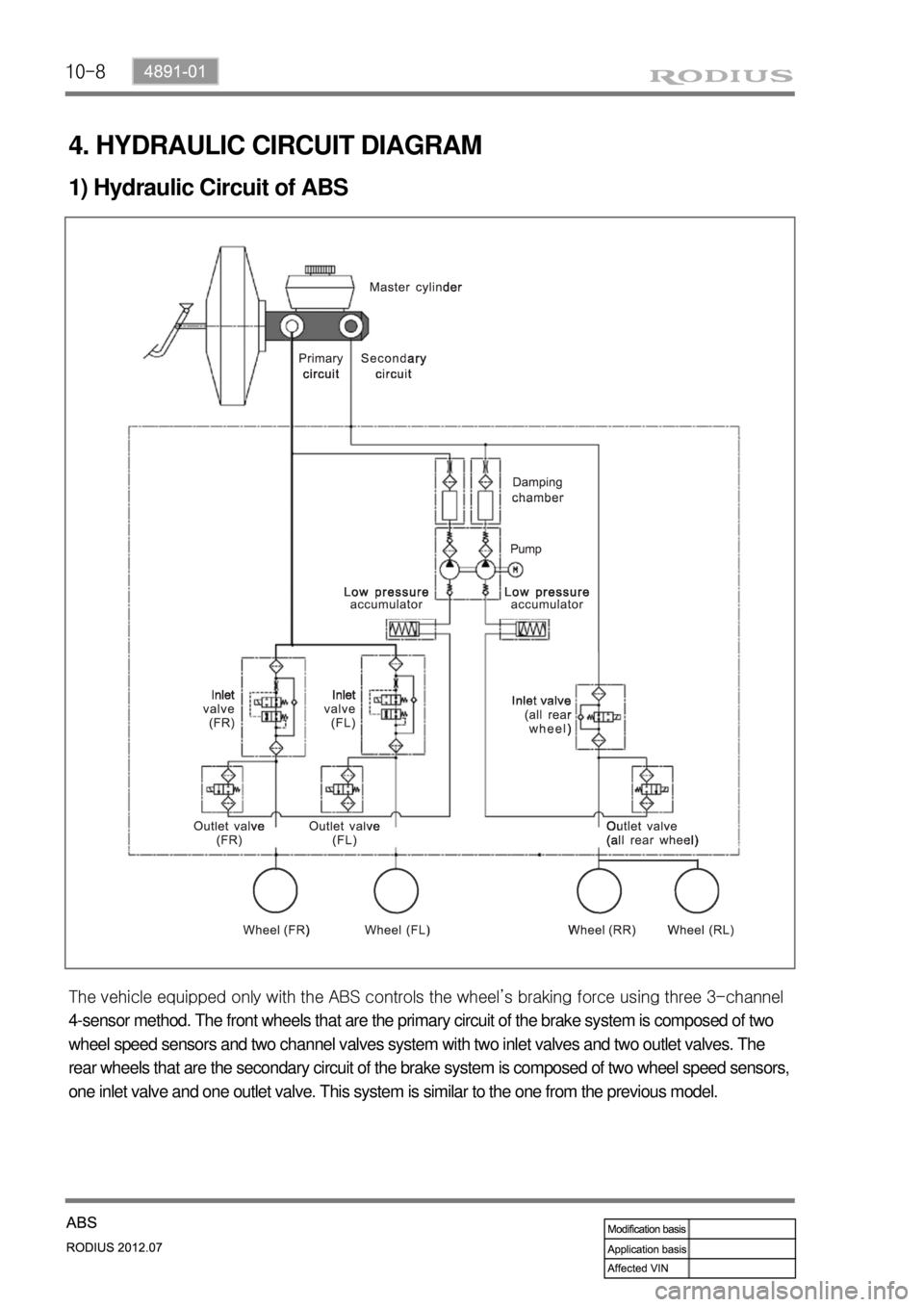

4. HYDRAULIC CIRCUIT DIAGRAM

1) Hydraulic Circuit of ABS

The vehicle equipped only with the ABS controls the wheel’s braking force using three 3-channel

4-sensor method. The front wheels that are the primary circuit of the brake system is composed of two

wheel speed sensors and two channel valves system with two inlet valves and two outlet valves. The

rear wheels that are the secondary circuit of the brake system is composed of two wheel speed sensors,

one inlet valve and one outlet valve. This system is similar to the one from the previous model.

Page 639 of 715

10-10

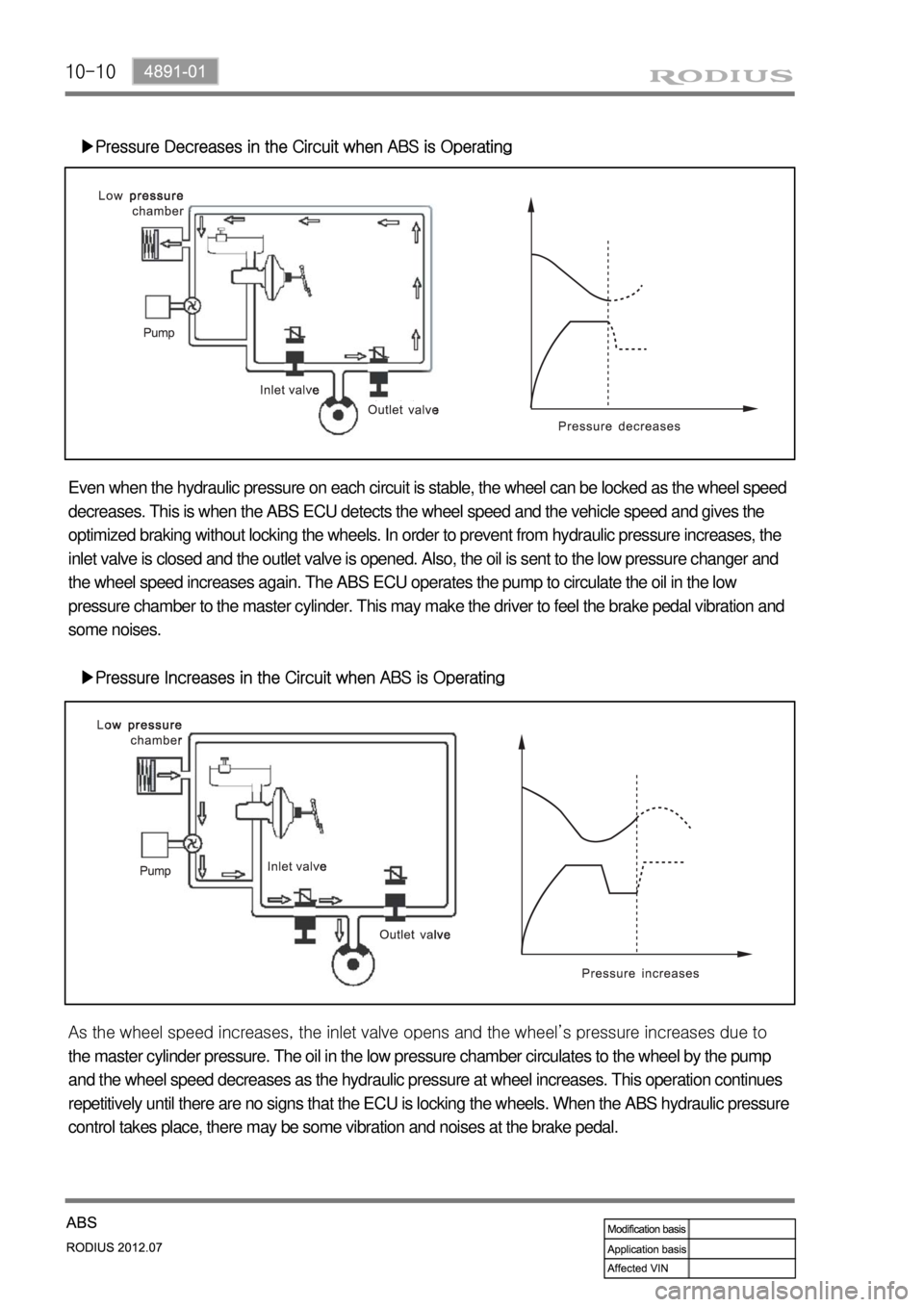

▶Pressure Decreases in the Circuit when ABS is Operating

Even when the hydraulic pressure on each circuit is stable, the wheel can be locked as the wheel speed

decreases. This is when the ABS ECU detects the wheel speed and the vehicle speed and gives the

optimized braking without locking the wheels. In order to prevent from hydraulic pressure increases, the

inlet valve is closed and the outlet valve is opened. Also, the oil is sent to the low pressure changer and

the wheel speed increases again. The ABS ECU operates the pump to circulate the oil in the low

pressure chamber to the master cylinder. This may make the driver to feel the brake pedal vibration and

some noises.

▶Pressure Increases in the Circuit when ABS is Operating

<0068009a0047009b008f008c0047009e008f008c008c00930047009a0097008c008c008b004700900095008a0099008c0088009a008c009a00530047009b008f008c0047009000950093008c009b0047009d00880093009d008c004700960097008c009500

9a004700880095008b0047009b008f008c0047009e008f008c>el’s pressure increases due to

the master cylinder pressure. The oil in the low pressure chamber circulates to the wheel by the pump

and the wheel speed decreases as the hydraulic pressure at wheel increases. This operation continues

repetitively until there are no signs that the ECU is locking the wheels. When the ABS hydraulic pressure

control takes place, there may be some vibration and noises at the brake pedal.

Page 643 of 715

11-54610-00

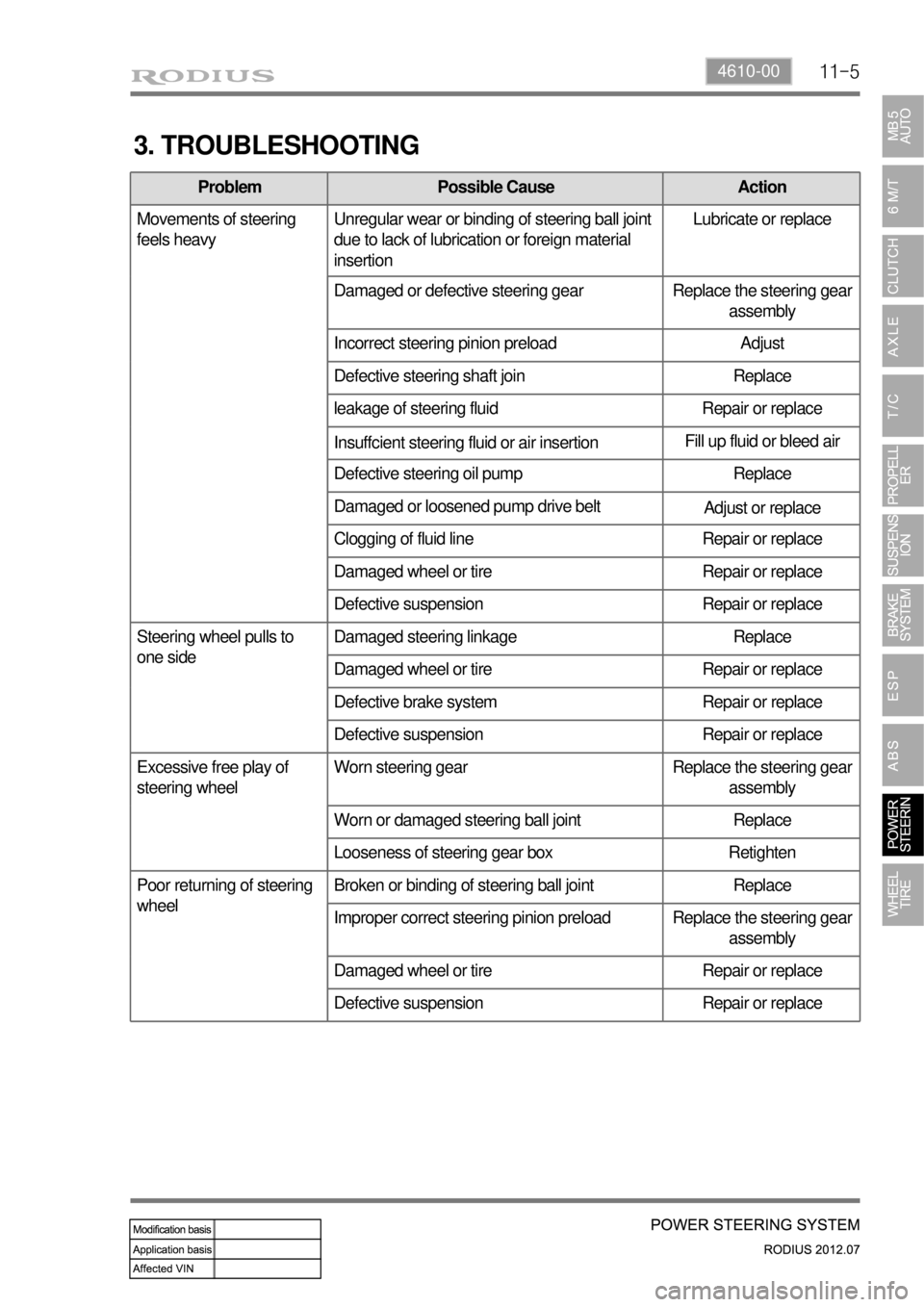

3. TROUBLESHOOTING

Problem Possible Cause Action

Movements of steering

feels heavyUnregular wear or binding of steering ball joint

due to lack of lubrication or foreign material

insertionLubricate or replace

Damaged or defective steering gear Replace the steering gear

assembly

Incorrect steering pinion preload Adjust

Defective steering shaft join Replace

leakage of steering fluid Repair or replace

Insuffcient steering fluid or air insertionFill up fluid or bleed air

Defective steering oil pump Replace

Damaged or loosened pump drive belt

Adjust or replace

Clogging of fluid line Repair or replace

Damaged wheel or tire Repair or replace

Defective suspension Repair or replace

Steering wheel pulls to

one sideDamaged steering linkage Replace

Damaged wheel or tire Repair or replace

Defective brake system Repair or replace

Defective suspension Repair or replace

Excessive free play of

steering wheelWorn steering gear Replace the steering gear

assembly

Worn or damaged steering ball joint Replace

Looseness of steering gear box Retighten

Poor returning of steering

wheelBroken or binding of steering ball joint Replace

Improper correct steering pinion preload Replace the steering gear

assembly

Damaged wheel or tire Repair or replace

Defective suspension Repair or replace

Page 648 of 715

11-10

Oil Pump Pressure Check ▶

Check the oil pump pressure to locate any defect

in oil pump.

Before checking the pressure, check the oil

level and belt tension. Prepare the empty

container to collect the spilled oil during the

service.

Unscrew the pressure line fitting in power

steering pump.

Install the pressure gauge between the

power steering pump and the power steering

oil pressure line.

Place the shift lever to neutral position. Apply

the parking brake.

Open the valve in pressure gauge. Start the

engine and let it run at idle speed.

Turn the steering wheel several times so that

the oil temperature reaches to normal

operating level. A.

B.

C.

D.

E.

Fully close the valve in pressure gauge and

measure the oil pressure. F.

To prevent internal damage, do not close the

gauge valve over 10 seconds.

Keep the oil temperature at proper range. -

-

Relief pressure90 ± 3 bar

Page 652 of 715

12-4

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct

line from one bead to the other across the tread. In addition, a radial tire has a belt overwrap

under the tread surface to provide greater structural stability. The belt overwrap of a radial tire

distortion while the radial structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

<009d008c008f0090008a0093008c02c5009a004700940096009d008c0094008c0095009b0055004700700095004700960099008b008c00990047009b00960047008a0096009400970093008c009b008c0047009a009c008a008f0047009b0088009a009200

9a0053004700880047009b00900099008c00470094009c009a>t be structured to be a resilient

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6

mm from the groove bottom. This wear limit mark is not seen from the outside so there is

additional "▲" mark on the shoulder to let the driver find the wear mark easily. To measure the tire

groove depth, measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire

inflation pressure, changed tire location, etc.

1) Structure of Tire

Tread

This thick layer of rubber provides the

interface between the tire and the road.

Wear-resistant rubber is used to protect the

carcass and belt against fractures and

impacts and to deliver a long driving life.

Shoulder

Located between the tread and sidewall, the

shoulder rubber is the thickest so that the

design must allow for the easy diffusion of

heat generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the

flexible sidewall protects the carcass and

enhances the ride. A tire’s type, size,

structure, pattern, manufacturing company,

product name and various characters are

indicated here. Bead

The bead attaches the tire to the rim and

wraps the end of the cord fabric. Comprised

of the bead wire, core, flipper and other parts,

the bead is generally designed to be slightly

tight around the rim so that in the case of a

sudden drop in inflation pressure, the tire will

not fall off the rim.

Carcass

As the most important framework of a tire, the

entire inner layer of cord fabric is called the

carcass. The carcass acts to support air

pressure, vertical load and absorb shocks.

Valve

Belt

Bead core

Page 655 of 715

12-74170-01

When the vehicle is driven on a road surface covered with water at high speed, tires do not

contact with the road surface but rotate floating on a thin film of water.

It causes brake failure, lower traction force and losing the steering performance.

To prevent this, increase the tire inflation pressure, use tires with leaf shape tread which is not

worn. However, it is a best measure to drive slowly.

2) Hydro Planing