sensor SSANGYONG TURISMO 2013 Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 374 of 796

15-46

(15) CDPF control

A. Overview

As the solution for environmental regulations and PM Particle Material) of diesel engine, the low

emission vehicle is getting popular. This vehicle is equipped with an extra filter to collect the soot and

burn it again so that the amount of PM in the exhaust gas passed through the DOC (Diesel Oxidation

Catalyst) is reduced. The CDPF (Catalyst & Diesel Particulate Filter) is an integrated filter including

DOC (Diesel Oxidation Catalyst) and DPF (Diesel Particulate Filter).

For details, refer to Chapter "CDPF".

B. Components

Oxygen sensorFront

EGT sensorCDPF

(DOC + DPF)Rear

EGT sensor

Differential pressure

sensorD20DTR ECUElectric throttle body

Page 376 of 796

15-48

Rear EGT sensor:

Measure DPF temp

Diff. pres. sensor:

Measure pressure

between front side and

rear side of CDPFElectronic throttle

body: Control intake

air mass

ECU (DCM 3.7)

Injector: Control post

injection

D. Operation process

When the differential pressure sensor detects the pressure difference between the front and the rear

side of CDPF, the sensor sends signal indicating the soot is accumulated and the post injection is

performed to raise the temperature of exhaust gas. The amount of fuel injected is determined

according to the temperature of exhaust gas detected by the rear temperature sensor. If the

tem

perature is below 600°C, the amount of fuel injected is increased to raise the temperature. If

the tem

perature is over 600°C, the amount of fuel injected is decreased or not controlled. When

the engine is running in low load range, the amount of post injection and the amount of intake air are

controlled. It is to raise the temperature by increasing the amount of fuel while decreasing the amount

of intake air.

Front EGT sensor:

Measure DOC temp

T-MAP sensor

Intake air

mass

Exceed PM

limitBooster

pressure/

temperaturePost injection

Control intake

air mass

Page 380 of 796

01-50000-00

No. FUNCTION No. FUNCTION

1 HFM sensor 12 Intake manifold

2 Intake air duct 13 Connecting rod

3 Resonance flap 14 Exhaust manifold

4 Cylinder head cover 15 Crankshaft

5 Exhaust camshaft 16 Engine mounting

6 Intake camshaft 17 Starter

7 Cylinder head 18 Crankcase

8 Spark plug connector 19 Oil pump sprocket

9 Valve tappe

t20 Oil strainer

10 Injector 21 Oil pan

11 Exhaust valve 22 Drain plug

Front View ▶

Page 404 of 796

08-6

3. IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distributor and coil. It uses a crankshaft position

sensor input to the Engine Control Module (ECM).

The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition system

ignition coil.

This type of distributor less ignition system uses a "waste spark" method of spark distribution. Each

cylinder is paired with the cylinder that is opposite it (2.3L DOHC: 2 - 3 or 1 - 4, 3.2L DOHC: 1 - 6 or 2 -

5 or 3 - 4).

The spark occurs simultaneously in the cylinder coming up on the compression stroke and in the

cylinder coming up on the exhaust stroke.

The cylinder on the exhaust stroke requires very little of the available energy to fire the spark plug.

The remaining energy is available to the spark plug in the cylinder on the compression stroke. These

systems use the EST signal from the ECM to control the EST.

The ECM uses the following information: Engine load (mass air flow sensor, manifold air pressure

sensor).

Engine coolant temperature.

Intake air temperature.

Crankshaft position.

Engine speed (rpm).

1) Electronic Ignition System Ignition Coil

The Electronic Ignition (EI) system ignition coil is located on the cylinder head cover.

The double ended coils receive the signal for the ECM which controls the spark advance. Each

EI system ignition coil provides the high voltage to two spark plugs simultaneously;

3.2L DOHC

T1/1: cylinder 2 and 5

T1/2: cylinder 3 and 4

T1/3: cylinder 1 and 6

The EI system ignition coil is not serviceable and must be replaced as an assembly.

Page 416 of 796

01-38410-02

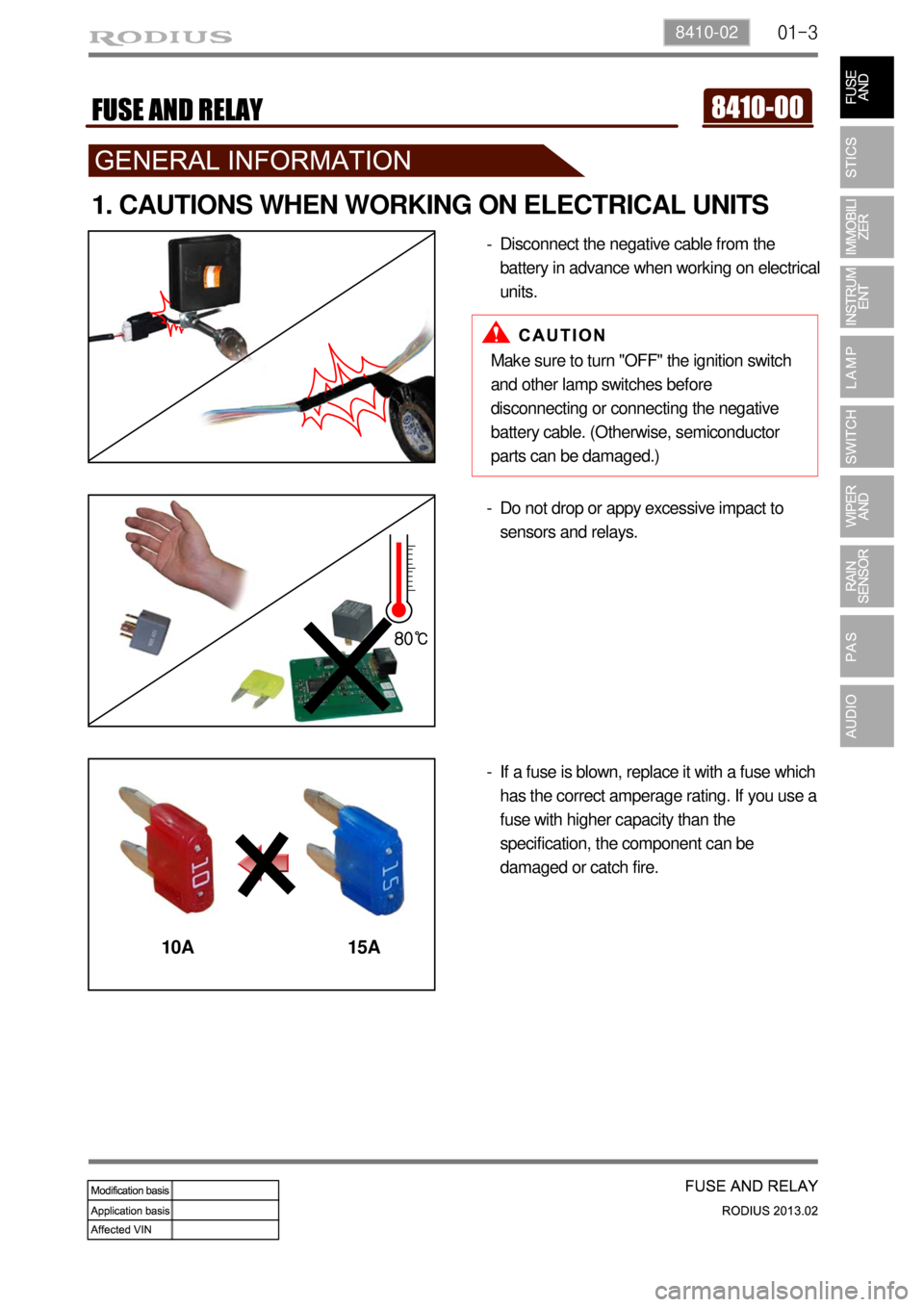

1. CAUTIONS WHEN WORKING ON ELECTRICAL UNITS

80℃

10A 15A

Disconnect the negative cable from the

battery in advance when working on electrical

units. -

Make sure to turn "OFF" the ignition switch

and other lamp switches before

disconnecting or connecting the negative

battery cable. (Otherwise, semiconductor

parts can be damaged.)

Do not drop or appy excessive impact to

sensors and relays. -

If a fuse is blown, replace it with a fuse which

has the correct amperage rating. If you use a

fuse with higher capacity than the

specification, the component can be

damaged or catch fire. -

Page 439 of 796

02-8

(2) Rain Sensor Coupled Wiper

▶ System layout

This vehicle has a different wiper control logic compared to other models. As shown in the system

diagram, the rain sensor unit does not control wiper directly. The rain sensor unit sends infrared rays

signal through LED and then receives it with photo diode and then sends the returned signal to STICS

and the STICS controls the wipers directly.

For more details, refer to rain sensing wiper section in this manual.

Page 440 of 796

02-98710-01

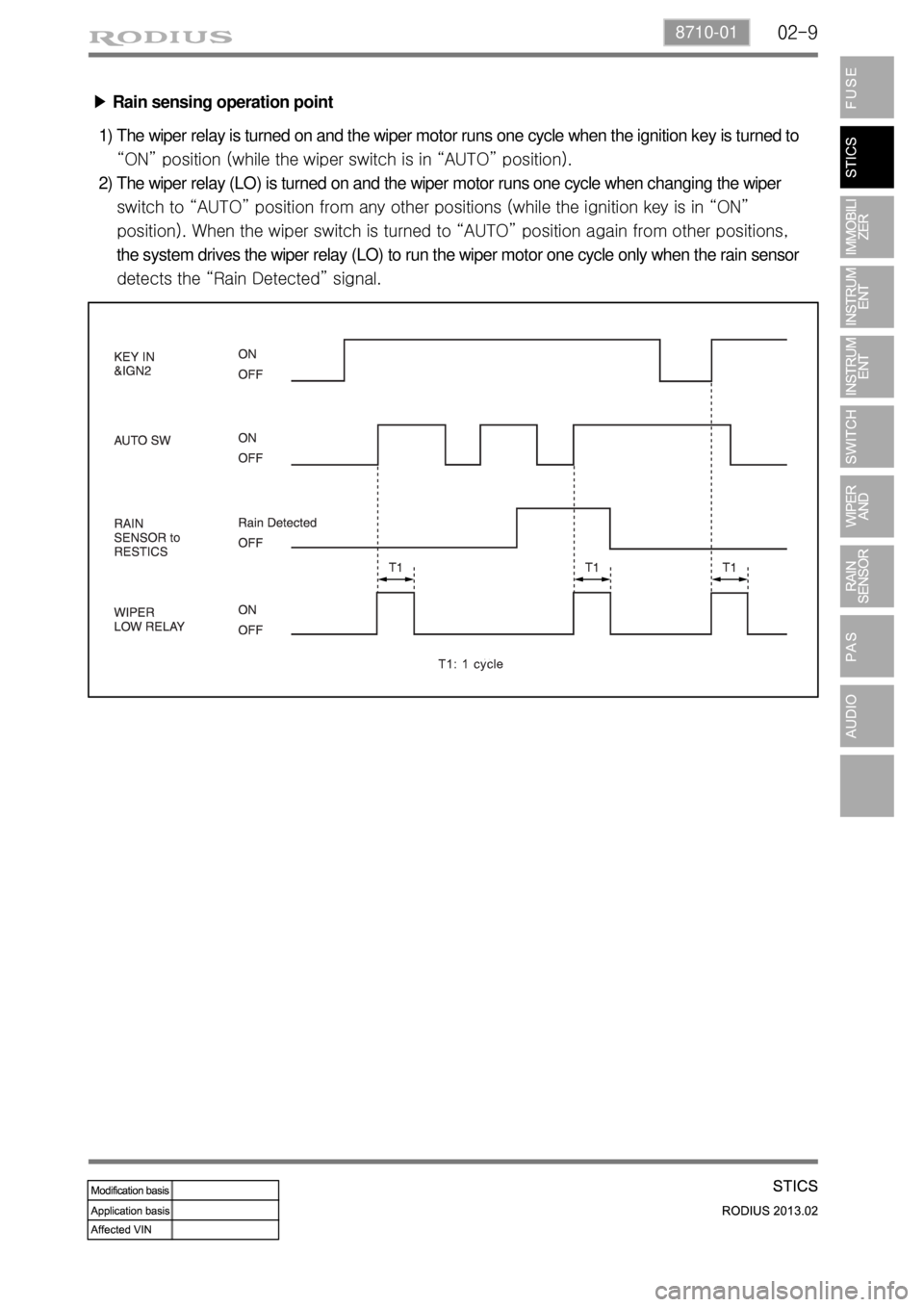

▶ Rain sensing operation point

The wiper relay is turned on and the wiper motor runs one cycle when the ignition key is turned to

“ON” position (while the wiper switch is in “AUTO” position).

The wiper relay (LO) is turned on and the wiper motor runs one cycle when changing the wiper

switch to “AUTO” position from any other positions (while the ignition key is in “ON”

position). When the wiper switch is turned to “AUTO” position again from other positions,

the system drives the wiper relay (LO) to run the wiper motor one cycle only when the rain sensor

detects the “Rain Detected” signal. 1)

2)

Page 441 of 796

02-10

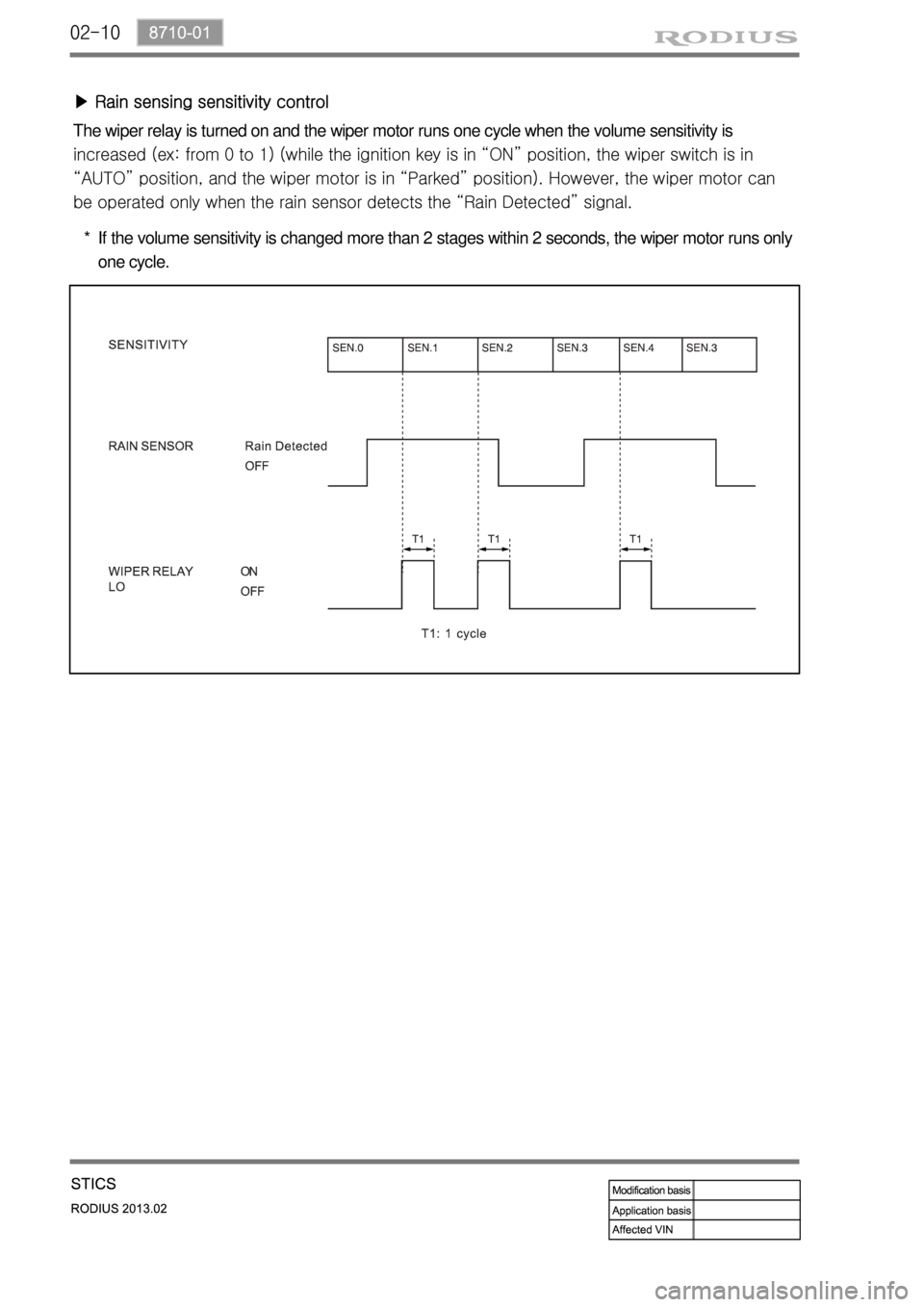

The wiper relay is turned on and the wiper motor runs one cycle when the volume sensitivity is

increased (ex: from 0 to 1) (while the ignition key is in “ON” position, the wiper switch is in

“AUTO” position, and the wiper motor is in “Parked” position). However, the wiper motor can

be operated only when the rain sensor detects the “Rain Detected” signal.

▶ Rain sensing sensitivity control

If the volume sensitivity is changed more than 2 stages within 2 seconds, the wiper motor runs only

one cycle. *

Page 442 of 796

02-118710-01

The wiper system continuously outputs the parking signal of current sensitivity when the parking

terminal is grounded (while the ignition key is in “ON” position and the wiper switch is in

“AUTO” position). 1)

※ The wiper motor runs only when the rain sensor requires.

When the parking terminal is fixed to IGN (HIGH), the wiper system outputs the operating signal of

current sensitivity for 2 seconds, then continuously outputs the parking signal of current sensitivity. 2)

※ The wiper motor runs only when the rain sensor requires.

▶ Wiper operation when the wiper parking terminal is grounded

Page 443 of 796

02-12

The wiper relay (LO) is turned on and the wiper motor runs one cycle when the wiper sensitivity is

changed to 2 from 3 during receiving the malfunction signal (1) from the rain sensor. However, the

wiper motor can be operated only when the rain sensor detects the "Rain Detected" signal. 1)

If the volume sensitivity is changed more than 2 stages within 2 seconds, the wiper motor runs

only one cycle. ▶ Defective rain sensor