EGR SSANGYONG TURISMO 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 148 of 796

01-4

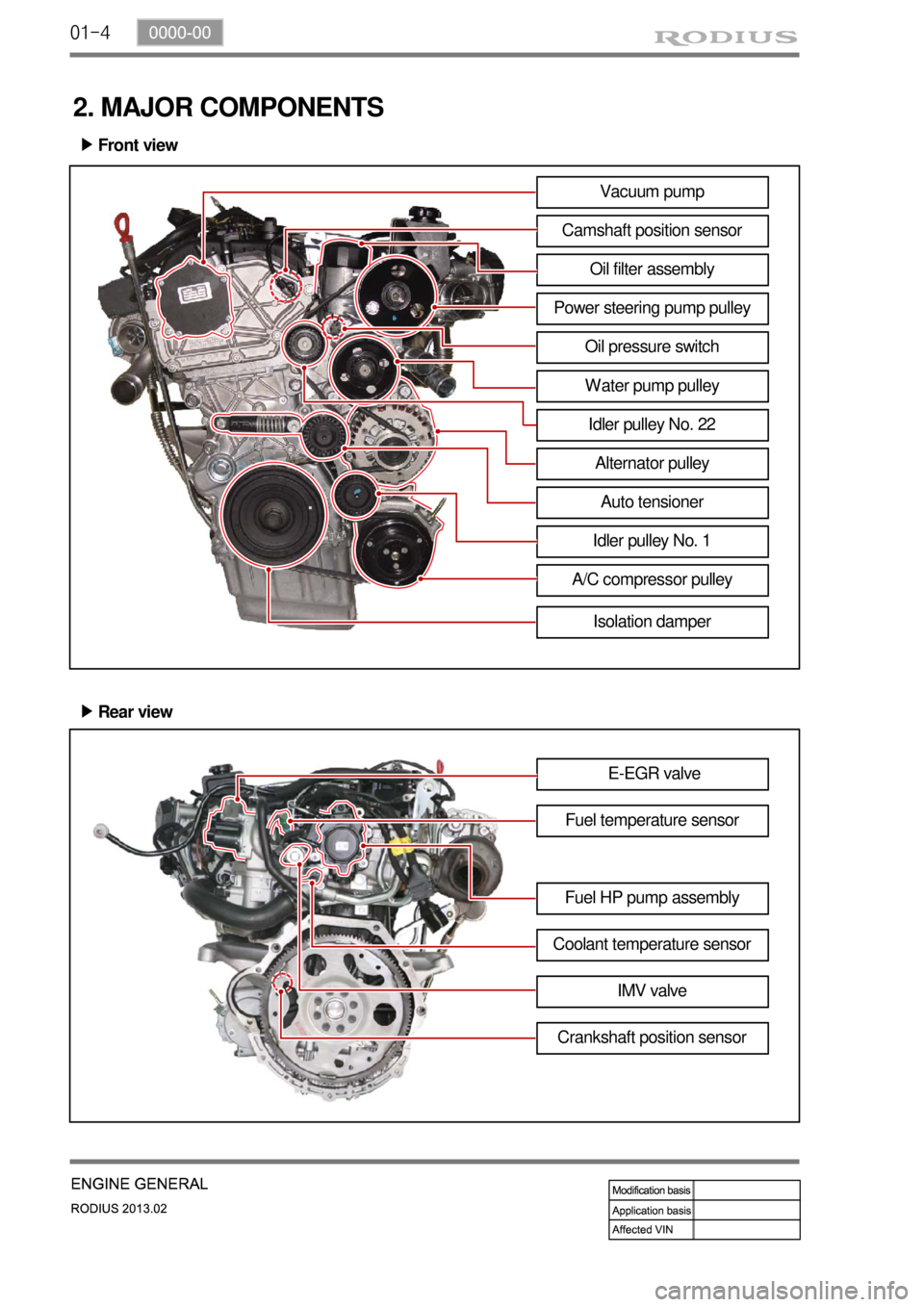

2. MAJOR COMPONENTS

Front view ▶

Vacuum pump

Camshaft position sensor

Oil filter assembly

Power steering pump pulley

Oil pressure switch

Water pump pulley

Idler pulley No. 22

Alternator pulley

Auto tensioner

Idler pulley No. 1

A/C compressor pulley

Rear view ▶

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

Crankshaft position sensorIMV valve

Isolation damper

Page 149 of 796

01-50000-00

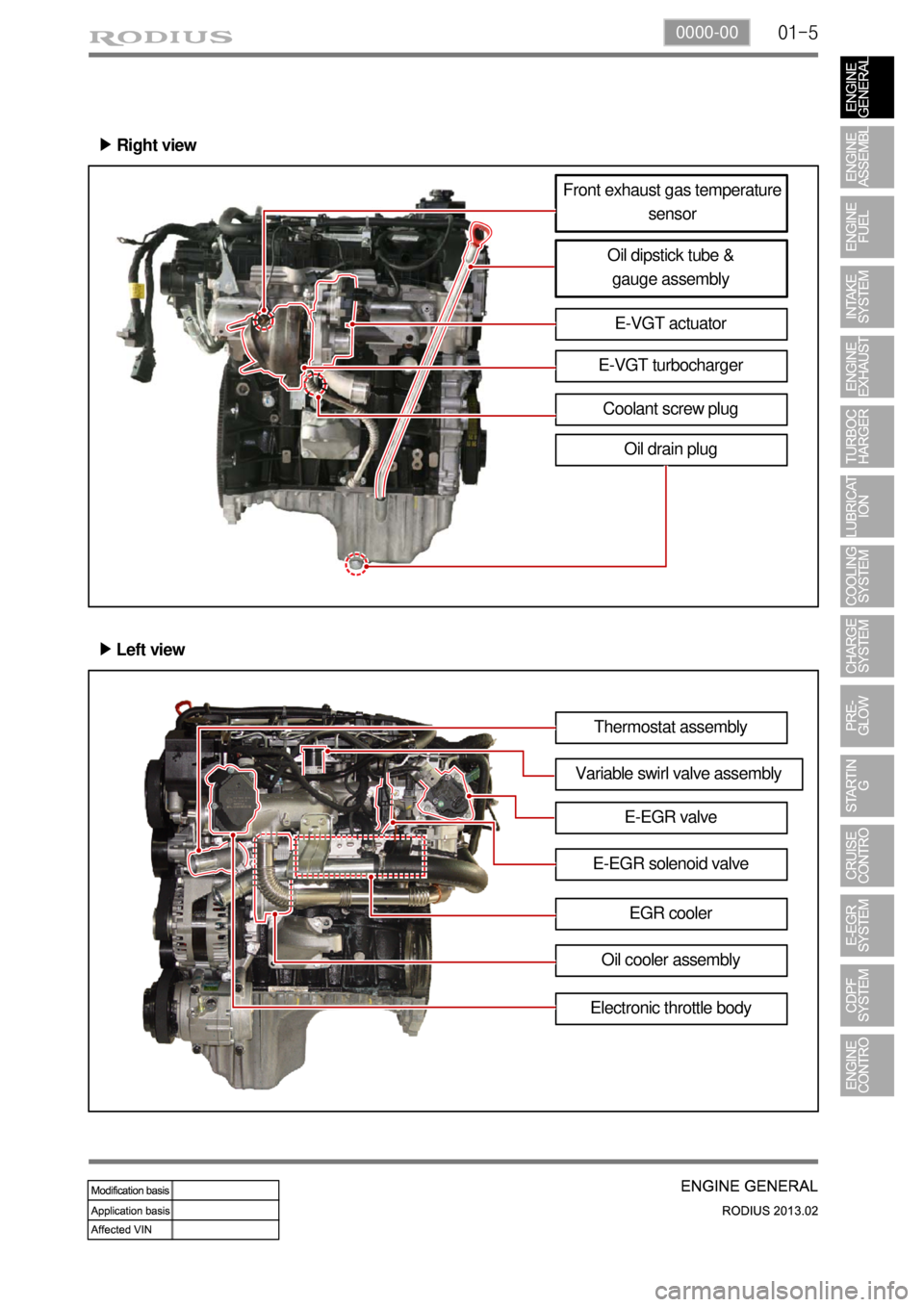

Right view ▶

Front exhaust gas temperature

sensor

Oil dipstick tube &

gauge assembly

E-VGT actuator

E-VGT turbocharger

Coolant screw plug

Oil drain plug

Left view ▶

Thermostat assembly

Variable swirl valve assembly

EGR cooler E-EGR valve

E-EGR solenoid valve

Oil cooler assembly

Electronic throttle body

Page 157 of 796

01-130000-00

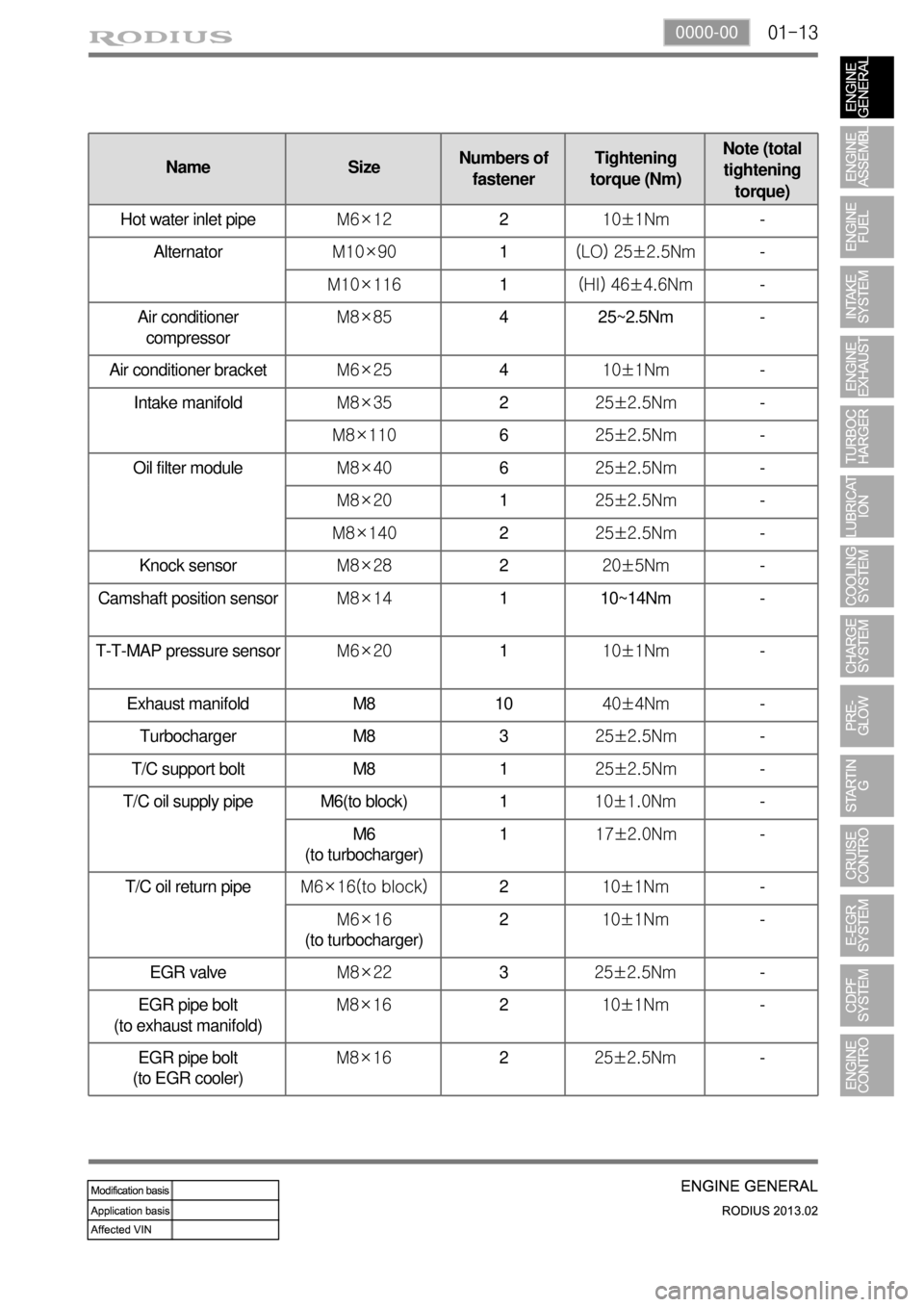

T/C oil supply pipe M6(to block) 1 10±1.0Nm -

M6

(to turbocharger)1 17±2.0Nm-

T/C oil return pipeM6×16(to block)2 10±1Nm -

M6×16

(to turbocharger)210±1Nm -

EGR valveM8×223 25±2.5Nm -

EGR pipe bolt

(to exhaust manifold)M8×16 2 10±1Nm -

EGR pipe bolt

(to EGR cooler)M8×16 2 25±2.5Nm -

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Hot water inlet pipeM6×12210±1Nm-

AlternatorM10×901(LO) 25±2.5Nm -

M10×1161(HI) 46±4.6Nm -

Air conditioner

compressorM8×854 25~2.5Nm -

Air conditioner bracketM6×25410±1Nm-

Intake manifoldM8×35225±2.5Nm-

M8×110625±2.5Nm-

Oil filter moduleM8×40625±2.5Nm-

M8×20125±2.5Nm-

M8×140225±2.5Nm-

Knock sensorM8×28220±5Nm-

Camshaft position sensorM8×141 10~14Nm -

T-T-MAP pressure sensorM6×20110±1Nm-

Exhaust manifold M8 1040±4Nm-

Turbocharger M8 325±2.5Nm-

T/C support bolt M8 125±2.5Nm-

Page 165 of 796

02-6

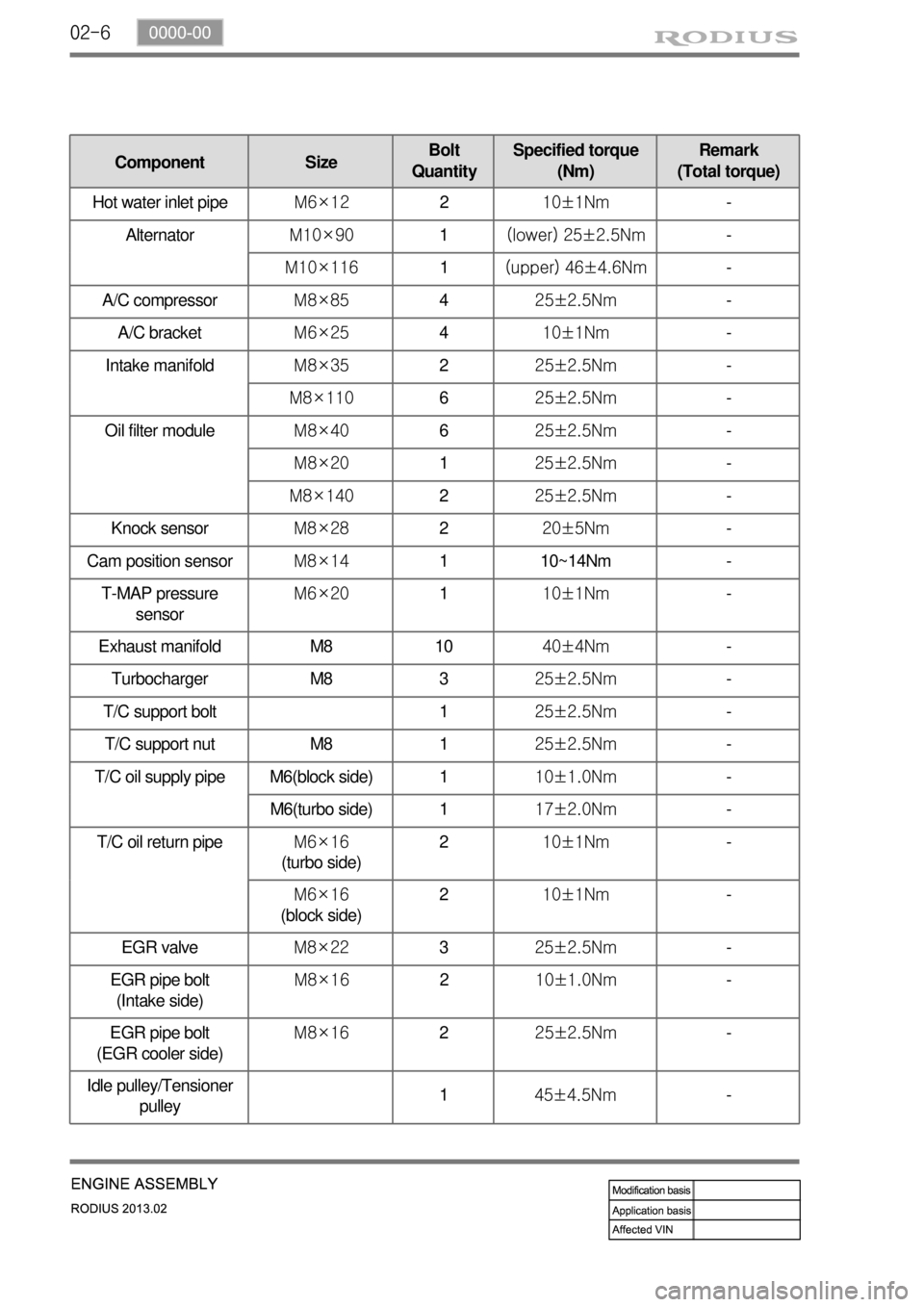

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Hot water inlet pipeM6×12210±1Nm-

AlternatorM10×901(lower) 25±2.5Nm-

M10×1161(upper) 46±4.6Nm-

A/C compressorM8×85425±2.5Nm-

A/C bracketM6×25410±1Nm-

Intake manifoldM8×35225±2.5Nm-

M8×110625±2.5Nm-

Oil filter moduleM8×40625±2.5Nm-

M8×20125±2.5Nm-

M8×140225±2.5Nm-

Knock sensorM8×28220±5Nm-

Cam position sensorM8×141 10~14Nm -

T-MAP pressure

sensorM6×20110±1Nm-

Exhaust manifold M8 1040±4Nm-

Turbocharger M8 325±2.5Nm-

T/C support bolt 125±2.5Nm-

T/C support nut M8 125±2.5Nm-

T/C oil supply pipe M6(block side) 110±1.0Nm-

M6(turbo side) 117±2.0Nm-

T/C oil return pipeM6×16

(turbo side)210±1Nm-

M6×16

(block side)210±1Nm-

EGR valveM8×22325±2.5Nm-

EGR pipe bolt

(Intake side)M8×16210±1.0Nm-

EGR pipe bolt

(EGR cooler side)M8×16225±2.5Nm-

Idle pulley/Tensioner

pulley145±4.5Nm -

Page 177 of 796

02-18

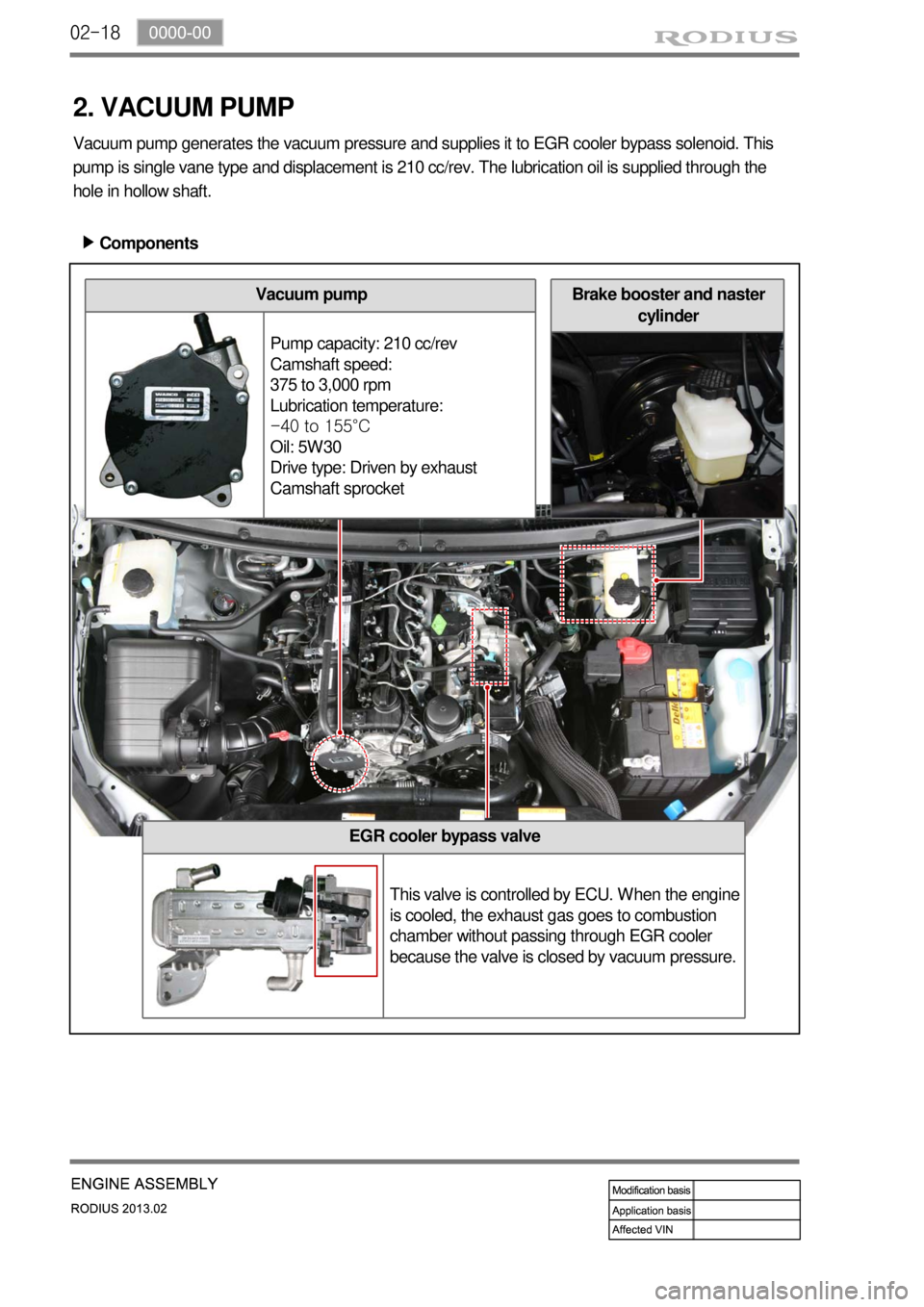

Vacuum pump

Pump capacity: 210 cc/rev

Camshaft speed:

375 to 3,000 rpm

Lubrication temperature:

-40 to 155°C

Oil: 5W30

Drive type: Driven by exhaust

Camshaft sprocket

EGR cooler bypass valve

This valve is controlled by ECU. When the engine

is cooled, the exhaust gas goes to combustion

chamber without passing through EGR cooler

because the valve is closed by vacuum pressure.

2. VACUUM PUMP

Vacuum pump generates the vacuum pressure and supplies it to EGR cooler bypass solenoid. This

pump is single vane type and displacement is 210 cc/rev. The lubrication oil is supplied through the

hole in hollow shaft.

Components ▶

Brake booster and naster

cylinder

Page 181 of 796

02-22

4. INTAKE/EXHAUST MANIFOLD

1) Intake Manifold

Intake manifold is installed on the cylinder head with 8 bolts. The variable swirl valve is introduced to

improve the EGR gas mixture and turbulence in combustion chamber and to decrease the exhaust gas.

2) Exhaust Manifold

Exhaust manifold is installed on the cylinder head with 10 stud bolts and nuts. EGR port is integrated in

cylinder head.Components ▶

Components ▶For detailes, refer to Chapter "Intake System". *

For detailes, refer to Chapter "Exhaust System".

*

Exhaust manifold

Intake manifold

Page 185 of 796

02-26

Location of Expansion Plugs

1) Cylinder Head

(1) Overview

The cylinder is made by gravity casting and the water jacket is integrated type.

The cylinder oil passage is drilled and sealed by cap.

The Camshaft bearing cap is also made by casting and installed on the cylinder head.

(2) Features

Front

Oil gallery expansion plug (M10)

Coolant expansion plug (M21)

Intake side

Rear

Page 209 of 796

02-50

The bottom side of water jacket is desgined as sine wave to strengthen the structure of crankcase. The

main flow of coolant starts from outlet port of water pump and goes along the longitudinal direction of

engine. The coolant passage from cylinder head to inlet port of water pump is integrated in cylinder

head.

The engine oil from oil pump is supplied to the main oil gallery through oil channel, oil filter module and

cross bore in cylinder block without using external pipes. This oil is supplied to main bearing, cylinder

head and MBU. And, it is sprayed to the chain through the chain tensioner connected to cross bore.

Crankcase cross bore for oil supply

Water jacket core

Page 210 of 796

03-32210-01

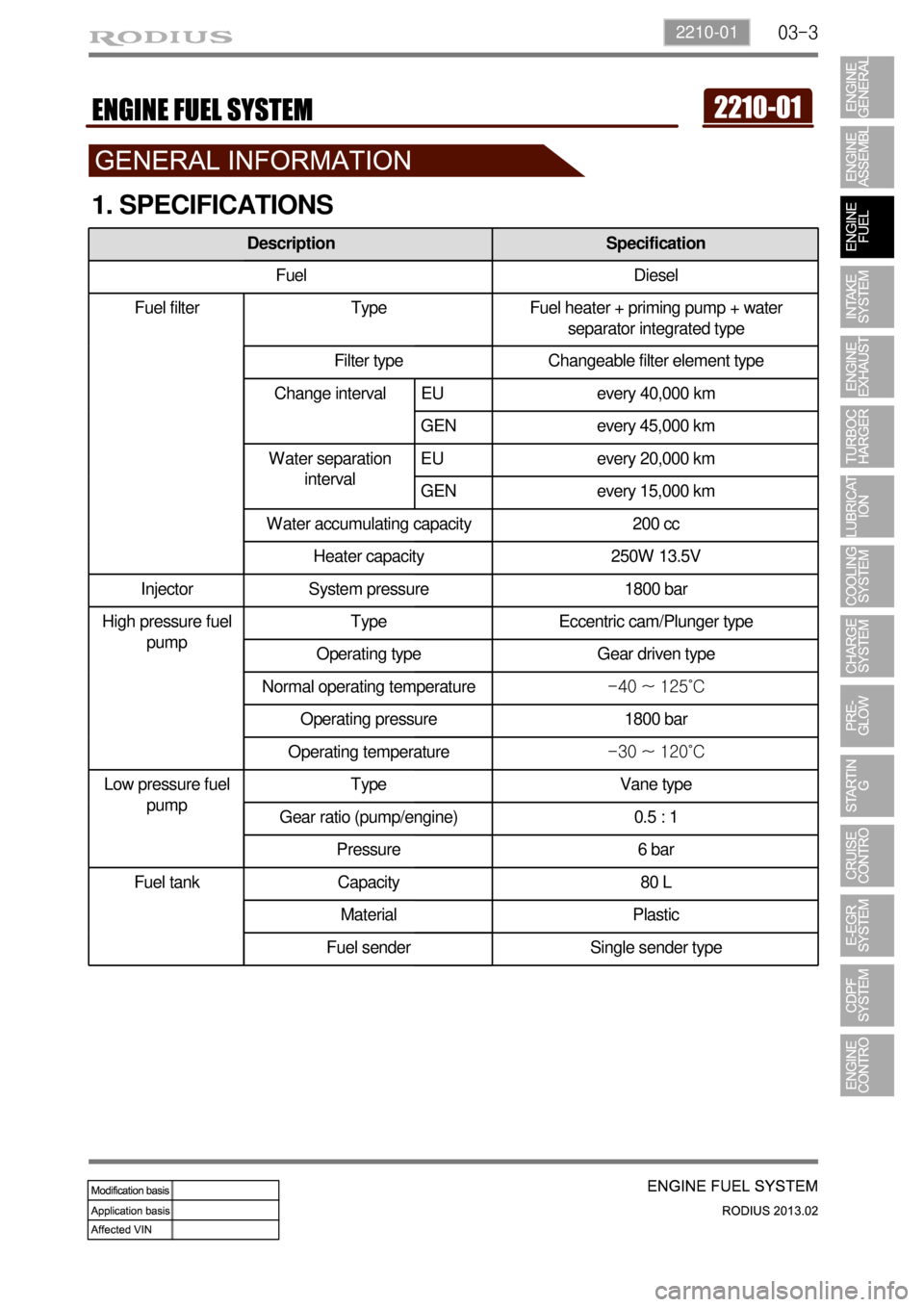

1. SPECIFICATIONS

Description Specification

Fuel Diesel

Fuel filter Type Fuel heater + priming pump + water

separator integrated type

Filter type Changeable filter element type

Change interval EU every 40,000 km

GEN every 45,000 km

Water separation

intervalEU every 20,000 km

GEN every 15,000 km

Water accumulating capacity 200 cc

Heater capacity 250W 13.5V

Injector System pressure 1800 bar

High pressure fuel

pumpType Eccentric cam/Plunger type

Operating type Gear driven type

Normal operating temperature-40 ~ 125˚C

Operating pressure 1800 bar

Operating temperature-30 ~ 120˚C

Low pressure fuel

pumpType Vane type

Gear ratio (pump/engine) 0.5 : 1

Pressure 6 bar

Fuel tank Capacity 80 L

Material Plastic

Fuel sender Single sender type

Page 233 of 796

03-26

The engine ECU calculates the accelerator pedal based on the input signals from various sensors, and

controls the overall operation of the vehicle.

The ECU receives the signals from various sensor through data line, and performs effective air-fuel ratio

control based on these signals.

The crankshaft speed (position) sensor measures the engine speed, and the camshaft speed (position)

sensor determines the order of injections, and the ECU detects the amount of the accelerator pedal

depressed (driver's will) by receiving the electrical signals from the accelerator pedal sensor.

The mass air flow sensor detects the volume of intake air and sends the value to the ECU.

The major function of the ECU is controlling air-fuel ratio to reduce the emission level (EGR valve

control) by detecting instantaneous air flow change with the signals from the mass air flow sensor.

Also, the ECU uses the signals from the coolant temperature & air temperature sensors, booster

pressure sensor, atmospheric pressure sensor to: a) determine injection starting point and set value for

pilot injection, and b) deal with various operations and variable conditions.