EGR SSANGYONG TURISMO 2013 Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: TURISMO, Model: SSANGYONG TURISMO 2013Pages: 796, PDF Size: 78.99 MB

Page 533 of 796

09-6

Shift lever (R position)

Sends reverse signal to PAS unit

1. Overview

The parking aid system (PAS) is a supplementary device which detects the distance to any obstacle

with the ultrasonic sensors equipped to the rear bumper and warns the driver with alarm sounds, when

the vehicle is moving backward.

The system emits the ultrasonic wave signals from the sensors on the rear bumper with a specific

interval and detects the reflected signals from obstacles.

The alarm interval becomes shorter as the obstacle approaches to assure the safety distance and to

facilitate parking of the vehicle.

2. Layout

ICM box

Buzzer integrated into ICM box

(indicates distance as alarm interval)

Page 545 of 796

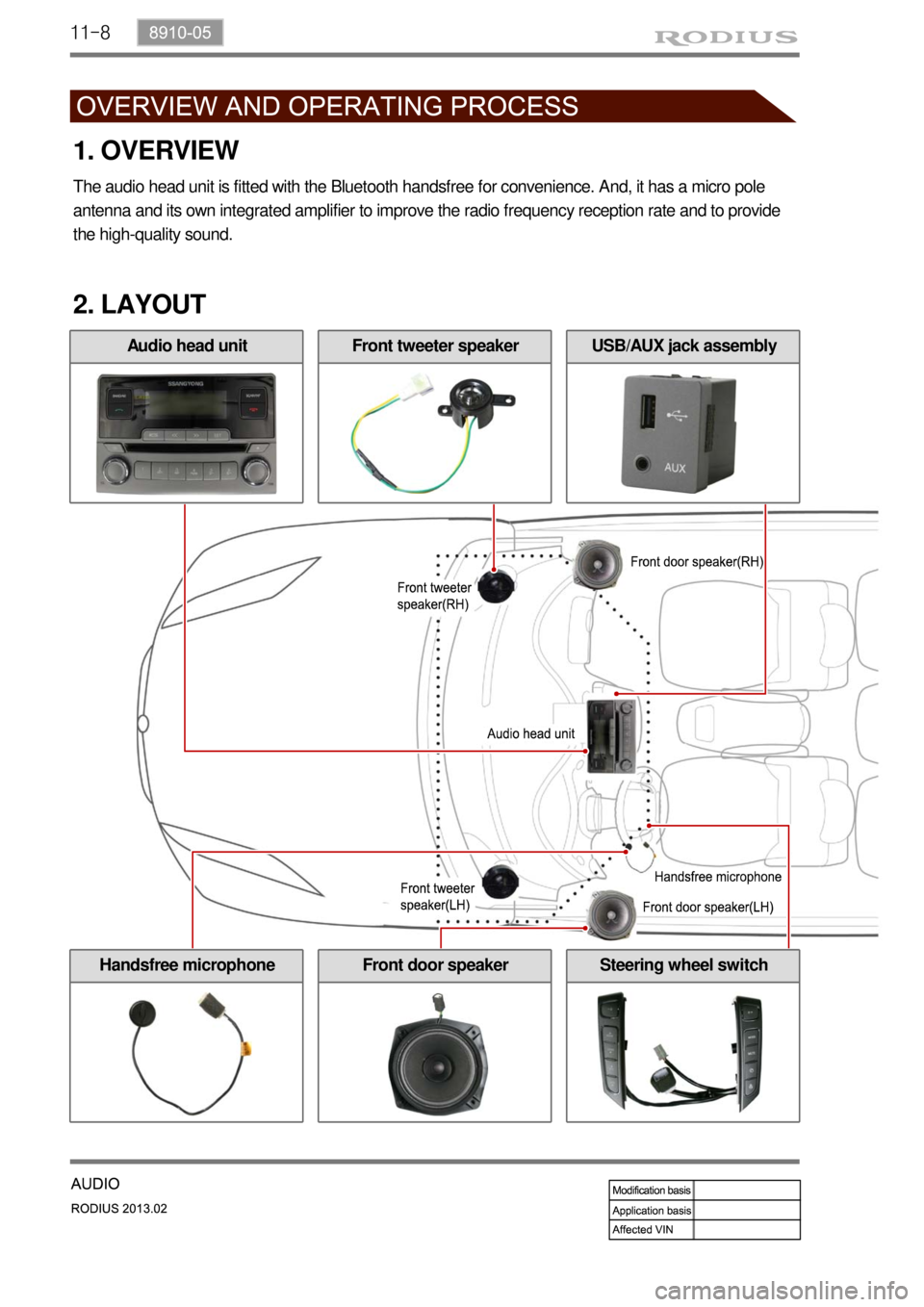

11-8

Front door speaker

2. LAYOUT

Handsfree microphoneSteering wheel switch

1. OVERVIEW

The audio head unit is fitted with the Bluetooth handsfree for convenience. And, it has a micro pole

antenna and its own integrated amplifier to improve the radio frequency reception rate and to provide

the high-quality sound.

Audio head unitFront tweeter speakerUSB/AUX jack assembly

Page 594 of 796

03-8

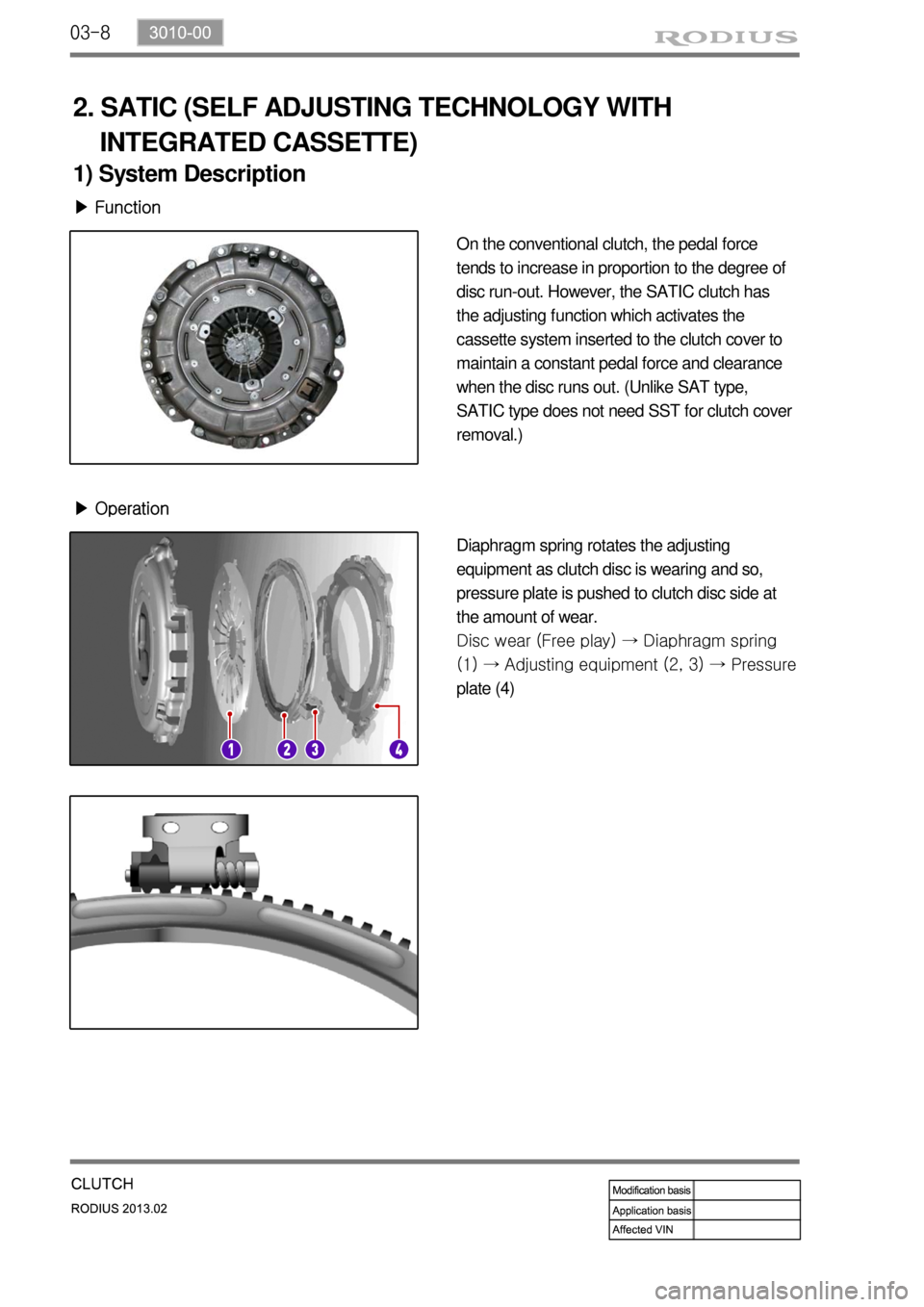

2. SATIC (SELF ADJUSTING TECHNOLOGY WITH

INTEGRATED CASSETTE)

1) System Description

▶ Function

On the conventional clutch, the pedal force

tends to increase in proportion to the degree of

disc run-out. However, the SATIC clutch has

the adjusting function which activates the

cassette system inserted to the clutch cover to

maintain a constant pedal force and clearance

when the disc runs out. (Unlike SAT type,

SATIC type does not need SST for clutch cover

removal.)

▶ Operation

Diaphragm spring rotates the adjusting

equipment as clutch disc is wearing and so,

pressure plate is pushed to clutch disc side at

the amount of wear.

Disc wear (Free play) → Diaphragm spring

(1) → Ad

justing equipment (2, 3) → Pressure

plate (4)

Page 608 of 796

05-93240-01

4. IWE LOCKING HUB SYSTEM

1) Overview

The vacuum locking hub uses the IWE (Integrated Wheel End) system, and in this system, the

vacuum is generated only within the hub actuator.

It is structured to transmit power to the front section after the actuator hub is engaged following

the release of vacuum from the drive shaft end gear and the hub end gear.

Booster

Vacuum pump

Vacuum generation process in front hub actuator ▶

Page 630 of 796

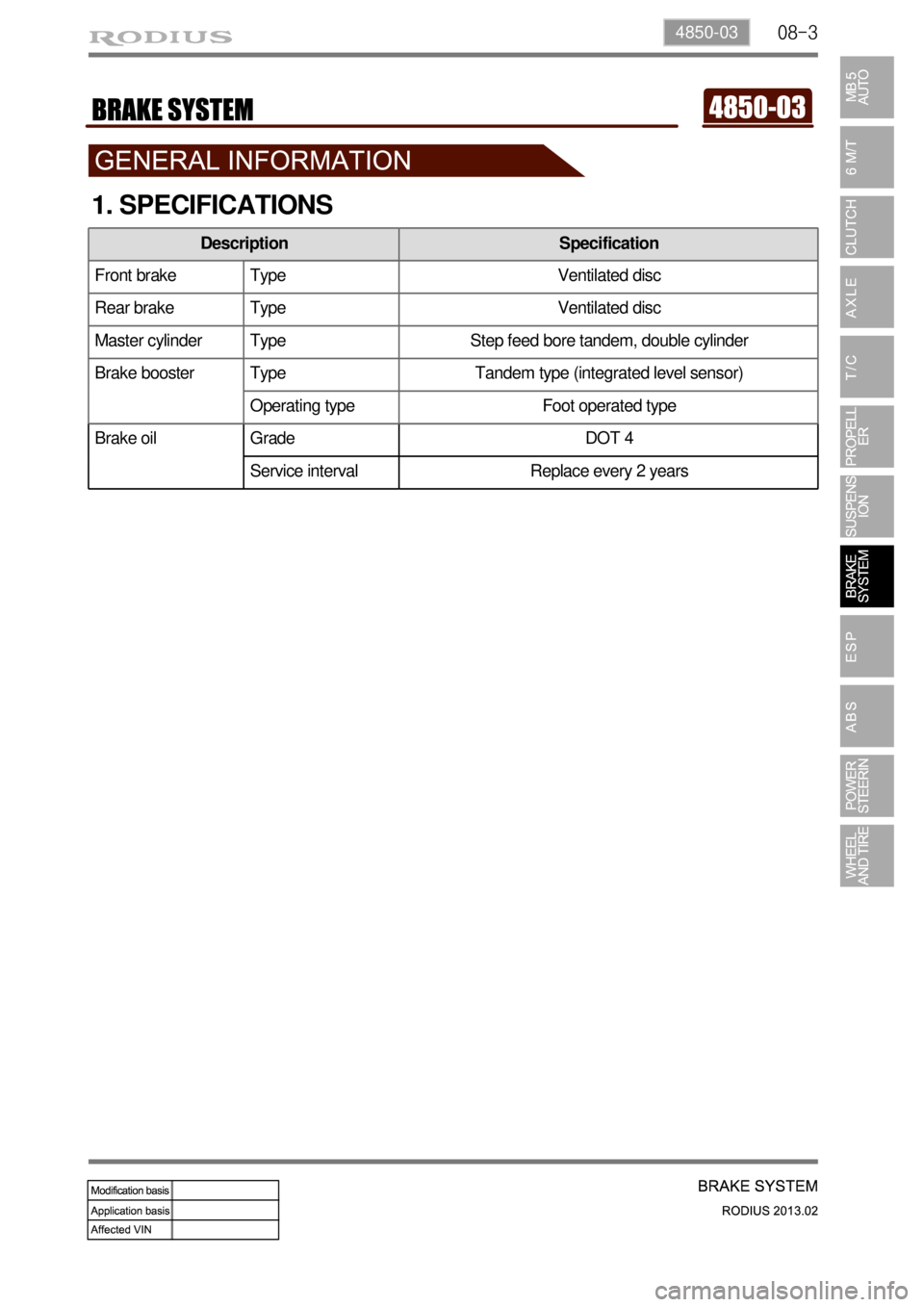

08-34850-03

Brake oil Grade DOT 4

Service interval Replace every 2 years

1. SPECIFICATIONS

Description Specification

Front brake Type Ventilated disc

Rear brake Type Ventilated disc

Master cylinder Type Step feed bore tandem, double cylinder

Brake booster Type Tandem type (integrated level sensor)

Operating type Foot operated type

Page 649 of 796

09-34891-01

1. SPECIFICATIONS

1) Pressure Sensor

UnitDescription

Location

ABS ESP

HECU

(Hydraulic &

Electronic Control

Unit) CPU:MCU60 (32bit)

Clock Frequency:

28 MHz

Memory: 128~256 KB CPU:MCU60 (32bit)

Clock Frequency:

28 MHz

Memory:256~512 KB Under the front washer

reservoir

Wheel Speed

SensorActive type wheel speed

sensorActive type wheel speed

sensorOn each wheel

Front air gap:

0.3 ~ 1.3mm,

Rear air gap:

0.3 ~ 1.3 mm

Steering Wheel

Angle SensorN/AMaximum angular speed:

1500°/sec

Operating voltage:

9~16 VUnder the steering

wheel

Sensor ClusterN/AIntegrated with yaw rate

sensor and lateral sensorUnder the audio

assembly

Pressure Sensor

N/A Analog outputUnder the master

cylinder

Description Specification

Supplying voltage approx. 5 V (4.75~5.25 V)

Max. pressure 350 bar

Page 652 of 796

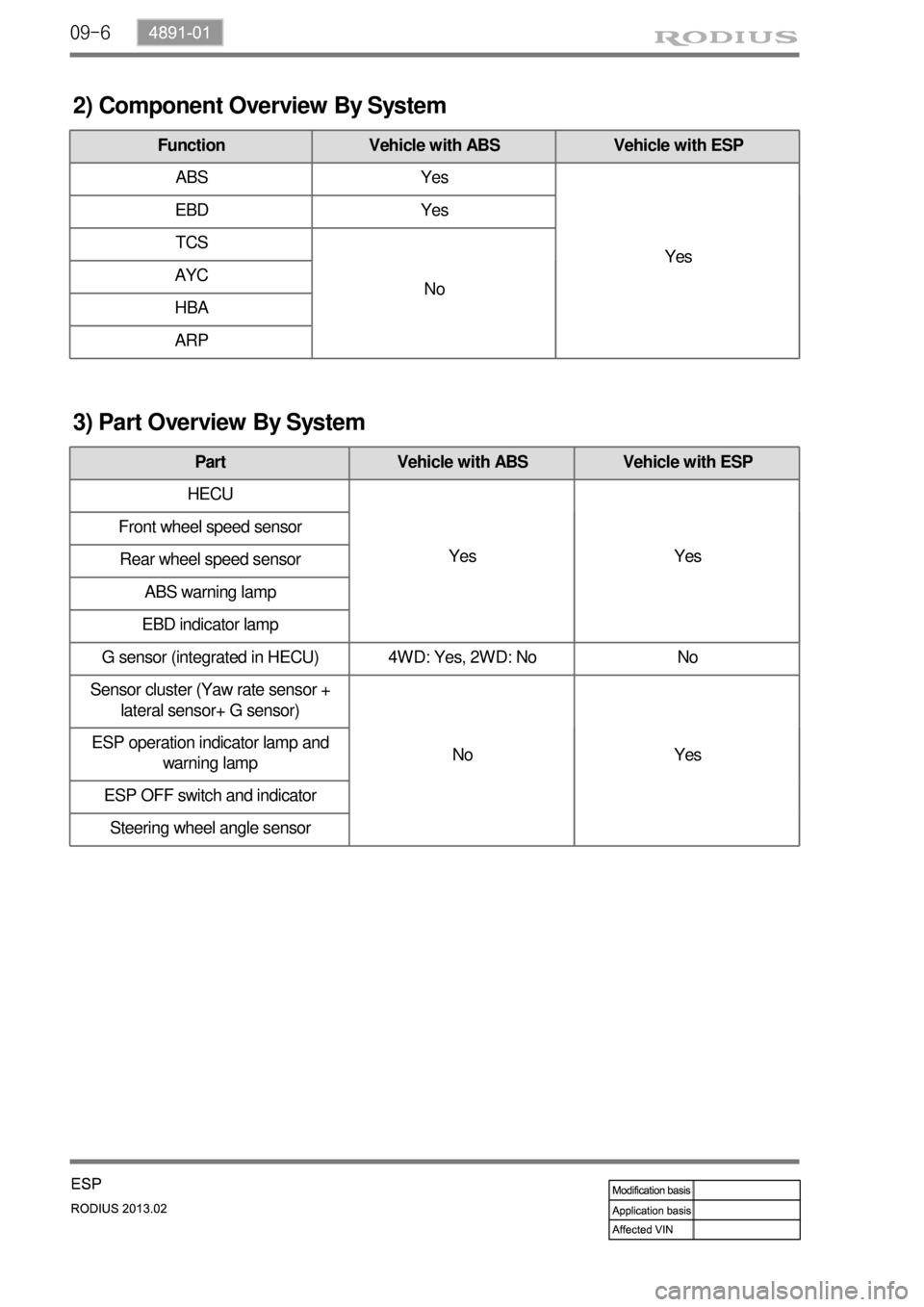

09-6

2) Component Overview By System

Function Vehicle with ABS Vehicle with ESP

ABS Yes

Yes EBD Yes

TCS

No AYC

HBA

ARP

3) Part Overview By System

Part Vehicle with ABS Vehicle with ESP

HECU

Yes Yes Front wheel speed sensor

Rear wheel speed sensor

ABS warning lamp

EBD indicator lamp

G sensor (integrated in HECU) 4WD: Yes, 2WD: No No

Sensor cluster (Yaw rate sensor +

lateral sensor+ G sensor)

No Yes ESP operation indicator lamp and

warning lamp

ESP OFF switch and indicator

Steering wheel angle sensor

Page 655 of 796

09-94891-01

1. ESP (Electronic Stability Program)

As the single-track vehicle model used for the calculations is only valid for a vehicle moving forward,

ESP intervention never takes place during backup.

The ESP system includes the ABS/EBD and ASR systems allowing the system to be able to operate

depending to the vehicle driving conditions.

1) Overview

For example, when the brakes are applied during cornering at the speed of 100 km/h, the ABS will

operate at the same time the ASR or ABD systems operate to reduce the power from the slipping

wheel. And when yaw rate sensor detects the rate exceeding 4 degree/seconds, the ESP system

is activated to apply the brake force to the corresponding wheel to compensate the yaw moment

with the vehicle stability control function. This may cause a problem in vehicle control system due

to multi-operation of systems, thus there is a priority as below:

TCS (ASR or ABD) > ESP > ABS (This is subject to the driving and vehicle conditions.)

Page 695 of 796

11-134610-00

1. OVERVIEW

The power steering has been designed to make the wheel move more easily than in a manual steering

system. The hydraulic power assists the process utilizing hydraulic fluid. The fluid increases pressure

in the power steering pump and aids the movement of the steering mechanism. The power steering

system consists of pump, oil reservoir, rack and gear box. The power steering pump is a vane type

and delivers hydraulic pressure to operate the power steering system. The pressure relief valve in the

pump controls the discharging pressure. The rotary valve in the rack and the pinion gear directs the oil

from the power steering pump to one side of the rack piston. The integrated rack piston converts the

hydraulic pressure to linear movement. The operating force of the rack moves the wheels through the

tie rod, the tie rod end and the steering knuckle. Even though the hydraulic pressure cannot be

generated, a driver can steer the vehicle without power assist but it needs very high steering force. In

this case, the operating force of the steering wheel is conveyed to the pinion, and the movement of the

pinion moves the rack through the pinion gear combined to the rack gear.

Page 700 of 796

12-54170-01

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct line

from one bead to the other across the tread. In addition, a radial tire has a belt overwrap under the

tread surface to provide greater structural stability. The belt overwrap of a radial tire distortion while the

radial structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

vehicle’s movement. In order to complete such tasks, a tire must be structured to be a resilient

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6 mm

from the groove bottom. This wear limit mark is not seen from the outside so there is additional

"▲" mark on the shoulder to let the driver find the wear mark easily. To measure the tire groove

depth, measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire inflation

pressure, changed tire location, etc.

1) Structure of Tire

Tread

This thick layer of rubber provides the interface

between the tire and the road. Wear-resistant

rubber is used to protect the carcass and belt

against fractures and impacts and to deliver a

long driving life.

Shoulder

Located between the tread and sidewall, the

shoulder rubber is the thickest so that the

design must allow for the easy diffusion of heat

generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the

flexible sidewall protects the carcass and

enhances the ride. A tire’s type, size,

structure, pattern, manufacturing company,

product name and various characters are

indicated here. Bead

The bead attaches the tire to the rim and wraps

the end of the cord fabric. Comprised of the bead

wire, core, flipper and other parts, the bead is

generally designed to be slightly tight around the

rim so that in the case of a sudden drop in

inflation pressure, the tire will not fall off the rim.

Carcass

As the most important framework of a tire, the

entire inner layer of cord fabric is called the

carcass. The carcass acts to support air

pressure, vertical load and absorb shocks.

Valve

Belt

Bead core