check engine SUBARU FORESTER 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: FORESTER, Model: SUBARU FORESTER 1999Pages: 345, PDF Size: 5.6 MB

Page 10 of 345

4. Diagnostics Chart for On-

board Diagnostic System

A: BASIC DIAGNOSTICS

PROCEDURE

4A1 : CHECK AIRBAG WARNING LIGHT

ILLUMINATES.

1) Turn ignition switch to ON (engine OFF).

2) Check airbag warning light illuminates.

:Does airbag warning light stay ON

after about 7 seconds or remain OFF,

or come back ON after 30 seconds?

: Repair and replace.

: Go to step4A2.

4A2 : CHECK TROUBLE CODE INDICATES.

Perform ON-BOARD DIAGNOSTICS.

:Does trouble code indicate?

: Repair and replace.

: Repair and replace.

4A3 : CHECK AIRBAG WARNING LIGHT

ILLUMINATES.

1) Turn ignition switch to ON (engine OFF).

2) Check airbag warning light illuminates.

:Does airbag warning light stay ON

after about 7 seconds or come back

ON after 30 seconds?

: Repair and replace.

: Go to step4A4.4A4 : CHECK AIRBAG WARNING LIGHT

ILLUMINATES.

Check airbag warning light illuminates.

:Does airbag warning light come ON

for about 7 seconds, then go out and

stay out?

: Perform clear memory.

: Go to step4A1.

B: ON-BOARD DIAGNOSTIC

When the airbag system is in functioning condition,

the airbag warning light will remain on for about 7

seconds and go out when the ignition switch is set

to ON.

If there is any malfunction, the airbag warning light

will either stay on or off continuously. In such

cases, perform on-board diagnostic in accordance

with the specified procedure to determine trouble

codes.

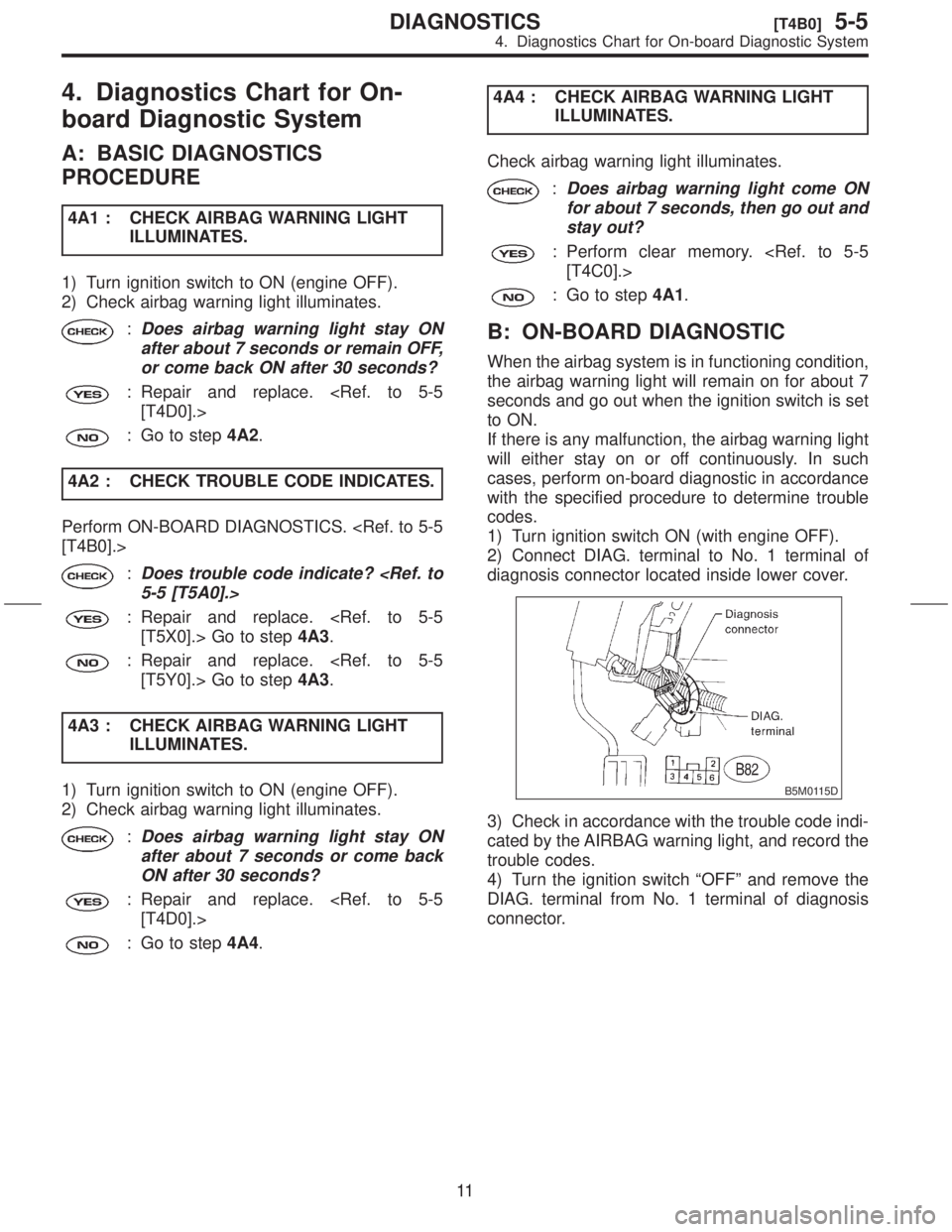

1) Turn ignition switch ON (with engine OFF).

2) Connect DIAG. terminal to No. 1 terminal of

diagnosis connector located inside lower cover.

B5M0115D

3) Check in accordance with the trouble code indi-

cated by the AIRBAG warning light, and record the

trouble codes.

4) Turn the ignition switch ªOFFº and remove the

DIAG. terminal from No. 1 terminal of diagnosis

connector.

11

[T4B0]5-5DIAGNOSTICS

4. Diagnostics Chart for On-board Diagnostic System

Page 11 of 345

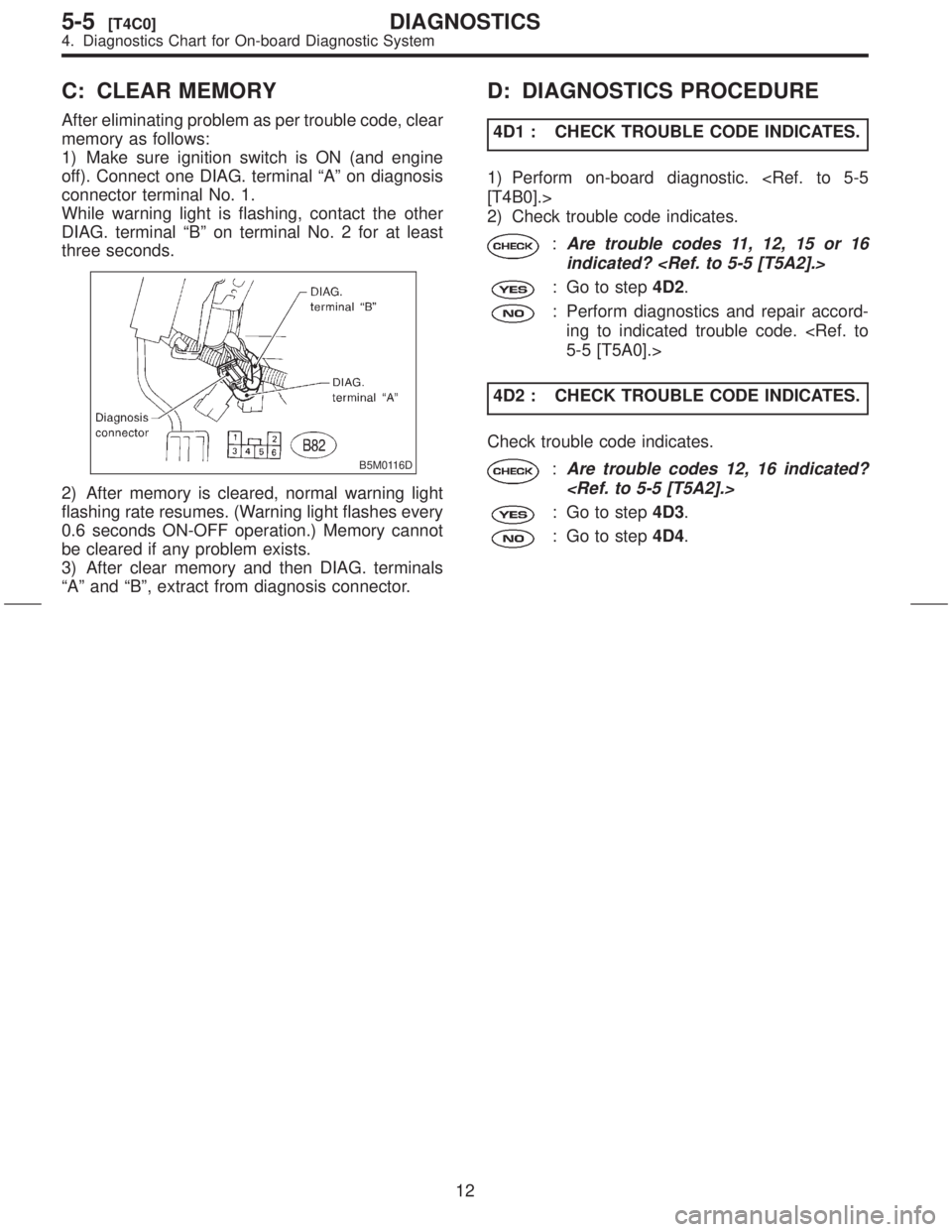

C: CLEAR MEMORY

After eliminating problem as per trouble code, clear

memory as follows:

1) Make sure ignition switch is ON (and engine

off). Connect one DIAG. terminal ªAº on diagnosis

connector terminal No. 1.

While warning light is flashing, contact the other

DIAG. terminal ªBº on terminal No. 2 for at least

three seconds.

B5M0116D

2) After memory is cleared, normal warning light

flashing rate resumes. (Warning light flashes every

0.6 seconds ON-OFF operation.) Memory cannot

be cleared if any problem exists.

3) After clear memory and then DIAG. terminals

ªAº and ªBº, extract from diagnosis connector.

D: DIAGNOSTICS PROCEDURE

4D1 : CHECK TROUBLE CODE INDICATES.

1) Perform on-board diagnostic.

2) Check trouble code indicates.

:Are trouble codes 11, 12, 15 or 16

indicated?

: Go to step4D2.

: Perform diagnostics and repair accord-

ing to indicated trouble code.

4D2 : CHECK TROUBLE CODE INDICATES.

Check trouble code indicates.

:Are trouble codes 12, 16 indicated?

: Go to step4D3.

: Go to step4D4.

12

5-5[T4C0]DIAGNOSTICS

4. Diagnostics Chart for On-board Diagnostic System

Page 55 of 345

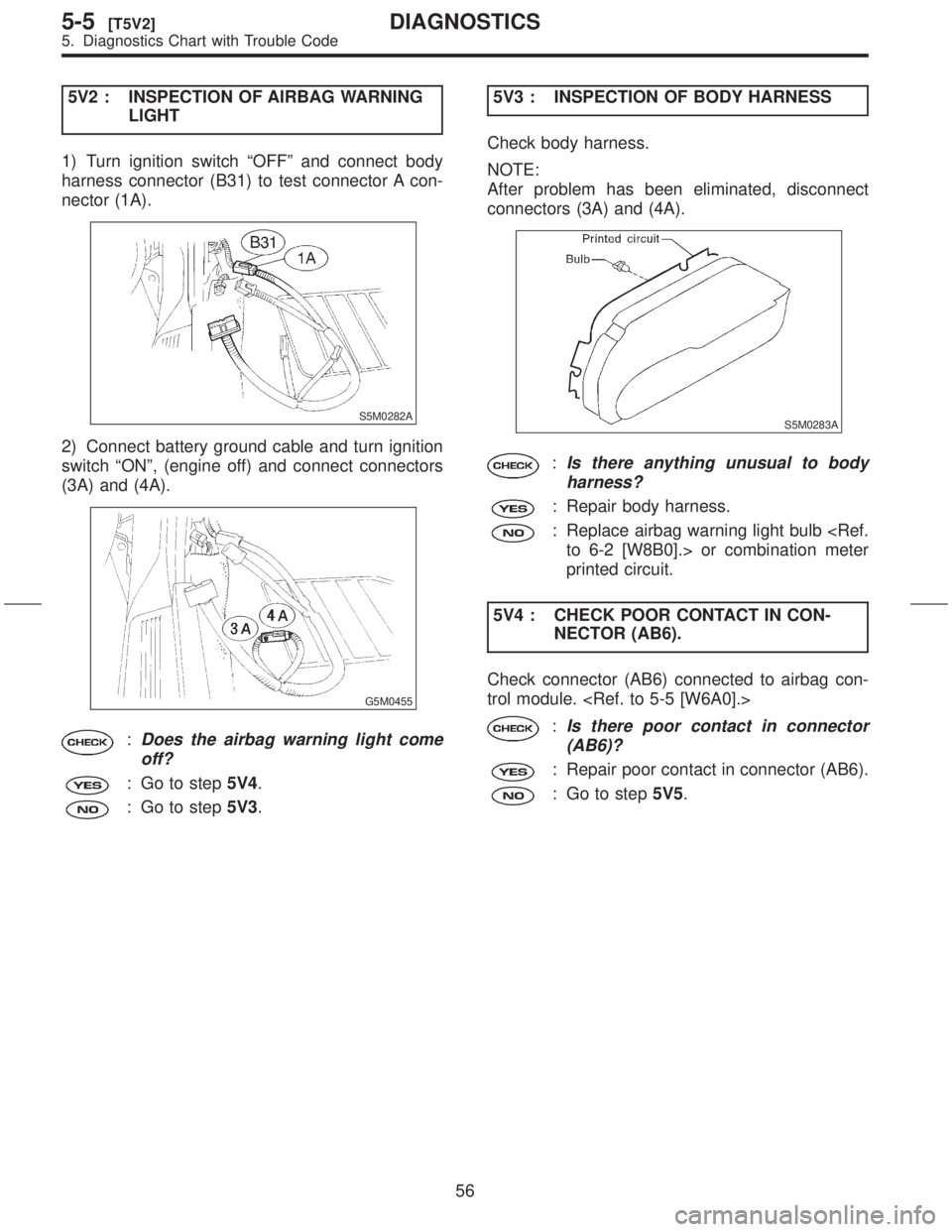

5V2 : INSPECTION OF AIRBAG WARNING

LIGHT

1) Turn ignition switch ªOFFº and connect body

harness connector (B31) to test connector A con-

nector (1A).

S5M0282A

2) Connect battery ground cable and turn ignition

switch ªONº, (engine off) and connect connectors

(3A) and (4A).

G5M0455

:Does the airbag warning light come

off?

: Go to step5V4.

: Go to step5V3.5V3 : INSPECTION OF BODY HARNESS

Check body harness.

NOTE:

After problem has been eliminated, disconnect

connectors (3A) and (4A).

S5M0283A

:Is there anything unusual to body

harness?

: Repair body harness.

: Replace airbag warning light bulb

printed circuit.

5V4 : CHECK POOR CONTACT IN CON-

NECTOR (AB6).

Check connector (AB6) connected to airbag con-

trol module.

:Is there poor contact in connector

(AB6)?

: Repair poor contact in connector (AB6).

: Go to step5V5.

56

5-5[T5V2]DIAGNOSTICS

5. Diagnostics Chart with Trouble Code

Page 57 of 345

![SUBARU FORESTER 1999 Service Repair Manual 5V8 : INSPECTION OF AIRBAG MAIN HAR-

NESS

1) Connect connectors (AB1) and (B31). Discon-

nect connector (AB6) from airbag control module

<Ref. to 5-5 [W6A0].>, and connect it to test har-

ness I or I2 SUBARU FORESTER 1999 Service Repair Manual 5V8 : INSPECTION OF AIRBAG MAIN HAR-

NESS

1) Connect connectors (AB1) and (B31). Discon-

nect connector (AB6) from airbag control module

<Ref. to 5-5 [W6A0].>, and connect it to test har-

ness I or I2](/img/17/57427/w960_57427-56.png)

5V8 : INSPECTION OF AIRBAG MAIN HAR-

NESS

1) Connect connectors (AB1) and (B31). Discon-

nect connector (AB6) from airbag control module

ness I or I2 connector (1I).

2) Measure resistance between each test harness

I or I2 connector (2I) terminal and chassis ground.

Connector & terminal

(2I) No. 9 (+) Ð Chassis ground (þ):

S5M0271B

:Is resistance less than 10W?

: Go to step5V9.

: Replace airbag main harness.

5V9 : INSPECTION OF AIRBAG MAIN HAR-

NESS

Measure resistance between each test harness I

or I2 connector (2I) terminal and chassis ground.

Connector & terminal

(2I) No. 10 (+) Ð Chassis ground (þ):

S5M0272B

:Is resistance less than 10W?

: Replace airbag control module.

: Replace airbag main harness.

W: AIRBAG WARNING LIGHT

REMAINS OFF.

DIAGNOSIS:

IFuse No. 5 (in main fuse box) is blown.

IBody harness circuit is open.

IAirbag warning light is faulty.

IAirbag main harness is faulty.

IAirbag control module is faulty.

CAUTION:

Before performing diagnostics on airbag

system, turn ignition switch ªOFFº, disconnect

battery ground terminal, and then wait at least

20 seconds.

5W1 : FUSE NO. 5 (IN MAIN FUSE BOX)

INSPECTION

Remove and visually check fuse No. 5 (In main

fuse box).

S5M0273A

:Is fuse No. 5 blown?

: Replace fuse No. 5. If fuse No. 5 blows

again, Go to step5W2.

: Go to step5W2.

5W2 : BODY HARNESS INSPECTION

Turn ignition switch ªONº (engine off) to make sure

other warning lights (in combination meter) illumi-

nate.

:Do all the warning lights (in combina-

tion meter) except airbag warning

light come on?

: Go to step5W3.

: Repair body harness.

58

5-5[T5V8]DIAGNOSTICS

5. Diagnostics Chart with Trouble Code

Page 62 of 345

5Y7 : WARNING LIGHT ILLUMINATION

CHECK

Turn ignition switch ªONº (engine off) and observe

airbag warning light.

:Does the airbag warning light come

on for about 7 seconds, then go out

and stay out?

: Perform clear memory.

: Go to ªDIAGNOSTICS PROCEDUREº.

63

[T5Y7]5-5DIAGNOSTICS

5. Diagnostics Chart with Trouble Code

Page 65 of 345

1A4 : CHECK TRANSMISSION TYPE.

:Is the transmission type MT?

: Go to step1A5.

: Go to step1A9.

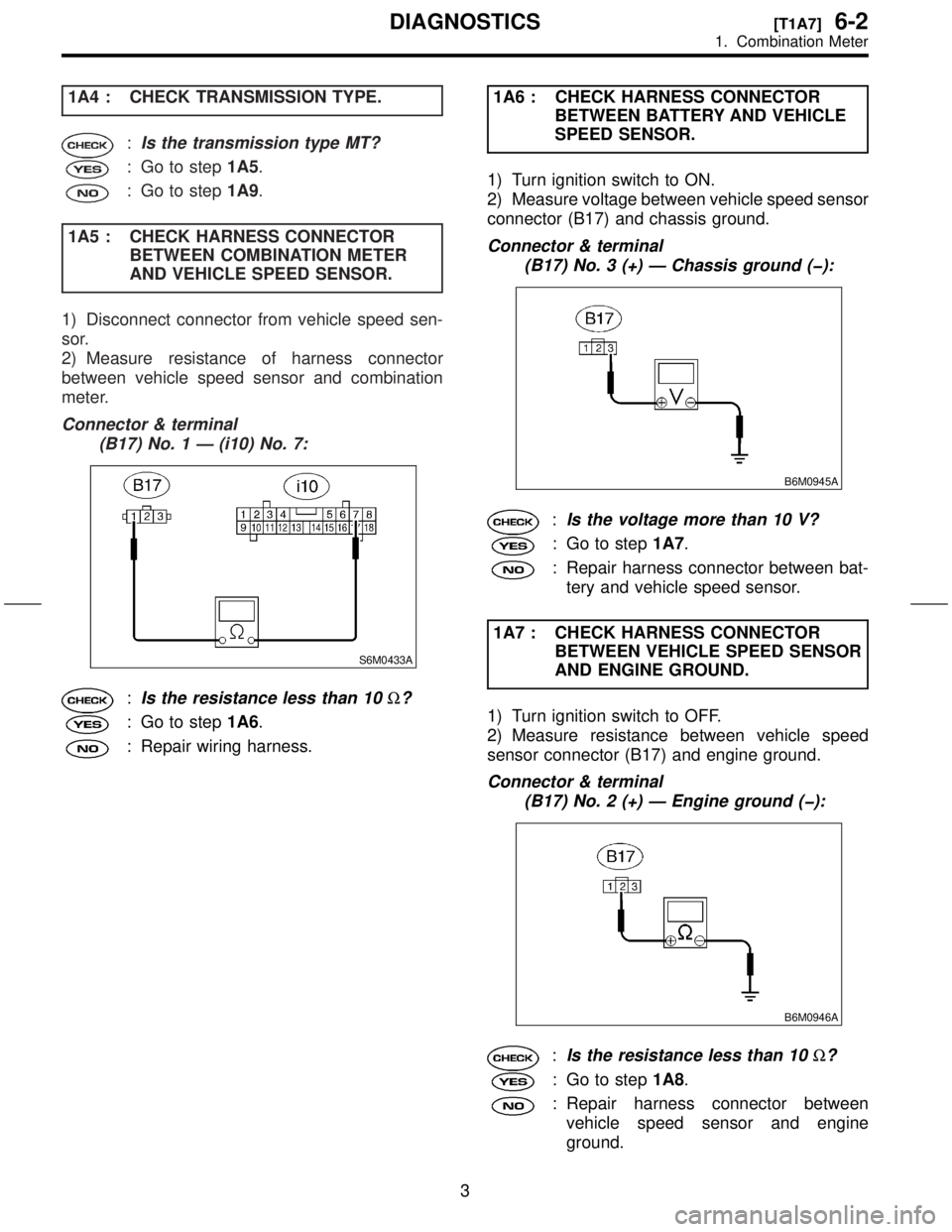

1A5 : CHECK HARNESS CONNECTOR

BETWEEN COMBINATION METER

AND VEHICLE SPEED SENSOR.

1) Disconnect connector from vehicle speed sen-

sor.

2) Measure resistance of harness connector

between vehicle speed sensor and combination

meter.

Connector & terminal

(B17) No. 1 Ð (i10) No. 7:

S6M0433A

:Is the resistance less than 10W?

: Go to step1A6.

: Repair wiring harness.1A6 : CHECK HARNESS CONNECTOR

BETWEEN BATTERY AND VEHICLE

SPEED SENSOR.

1) Turn ignition switch to ON.

2) Measure voltage between vehicle speed sensor

connector (B17) and chassis ground.

Connector & terminal

(B17) No. 3 (+) Ð Chassis ground (þ):

B6M0945A

:Is the voltage more than 10 V?

: Go to step1A7.

: Repair harness connector between bat-

tery and vehicle speed sensor.

1A7 : CHECK HARNESS CONNECTOR

BETWEEN VEHICLE SPEED SENSOR

AND ENGINE GROUND.

1) Turn ignition switch to OFF.

2) Measure resistance between vehicle speed

sensor connector (B17) and engine ground.

Connector & terminal

(B17) No. 2 (+) Ð Engine ground (þ):

B6M0946A

:Is the resistance less than 10W?

: Go to step1A8.

: Repair harness connector between

vehicle speed sensor and engine

ground.

3

[T1A7]6-2DIAGNOSTICS

1. Combination Meter

Page 82 of 345

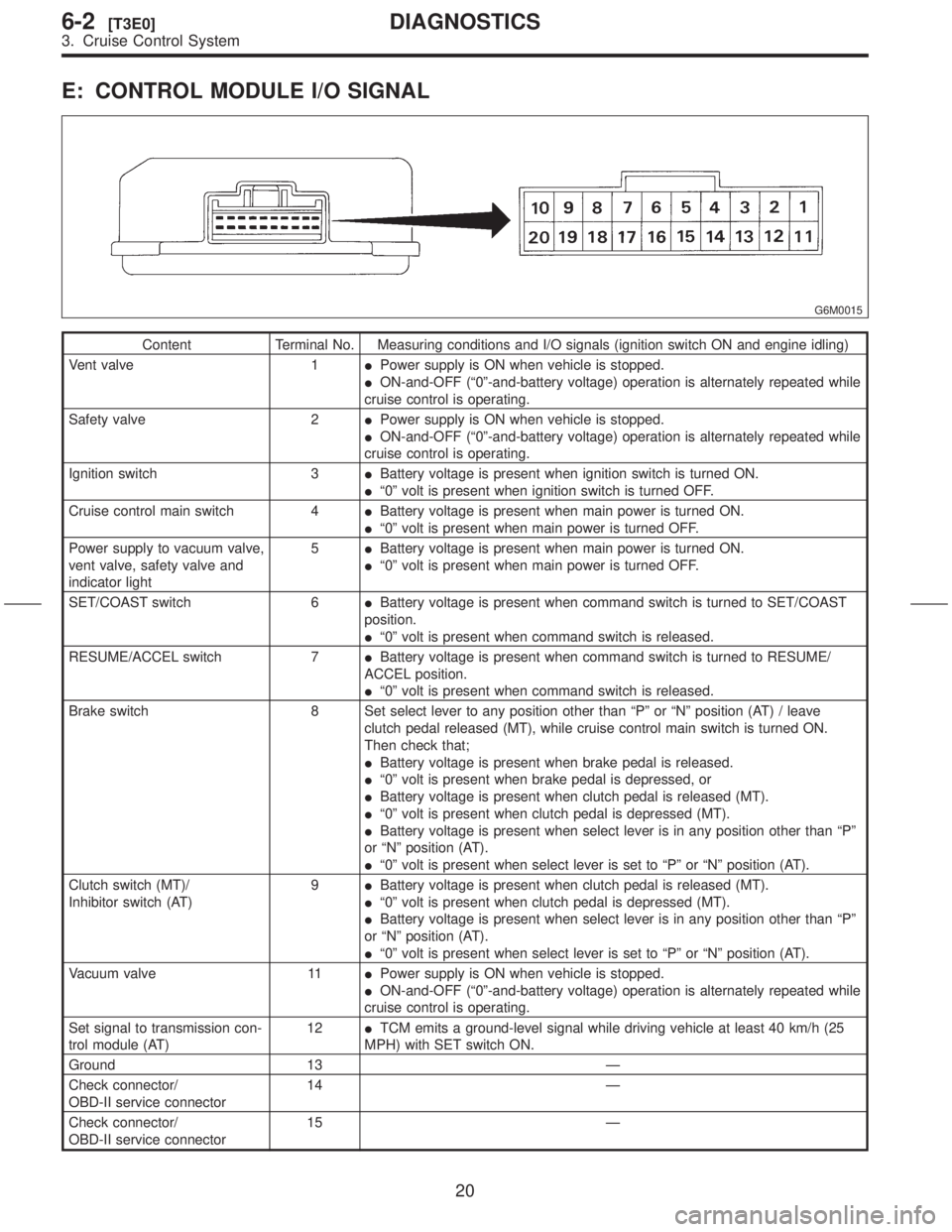

E: CONTROL MODULE I/O SIGNAL

G6M0015

Content Terminal No. Measuring conditions and I/O signals (ignition switch ON and engine idling)

Vent valve 1IPower supply is ON when vehicle is stopped.

ION-and-OFF (ª0º-and-battery voltage) operation is alternately repeated while

cruise control is operating.

Safety valve 2IPower supply is ON when vehicle is stopped.

ION-and-OFF (ª0º-and-battery voltage) operation is alternately repeated while

cruise control is operating.

Ignition switch 3IBattery voltage is present when ignition switch is turned ON.

Iª0º volt is present when ignition switch is turned OFF.

Cruise control main switch 4IBattery voltage is present when main power is turned ON.

Iª0º volt is present when main power is turned OFF.

Power supply to vacuum valve,

vent valve, safety valve and

indicator light5IBattery voltage is present when main power is turned ON.

Iª0º volt is present when main power is turned OFF.

SET/COAST switch 6IBattery voltage is present when command switch is turned to SET/COAST

position.

Iª0º volt is present when command switch is released.

RESUME/ACCEL switch 7IBattery voltage is present when command switch is turned to RESUME/

ACCEL position.

Iª0º volt is present when command switch is released.

Brake switch 8 Set select lever to any position other than ªPº or ªNº position (AT) / leave

clutch pedal released (MT), while cruise control main switch is turned ON.

Then check that;

IBattery voltage is present when brake pedal is released.

Iª0º volt is present when brake pedal is depressed, or

IBattery voltage is present when clutch pedal is released (MT).

Iª0º volt is present when clutch pedal is depressed (MT).

IBattery voltage is present when select lever is in any position other than ªPº

or ªNº position (AT).

Iª0º volt is present when select lever is set to ªPº or ªNº position (AT).

Clutch switch (MT)/

Inhibitor switch (AT)9IBattery voltage is present when clutch pedal is released (MT).

Iª0º volt is present when clutch pedal is depressed (MT).

IBattery voltage is present when select lever is in any position other than ªPº

or ªNº position (AT).

Iª0º volt is present when select lever is set to ªPº or ªNº position (AT).

Vacuum valve 11IPower supply is ON when vehicle is stopped.

ION-and-OFF (ª0º-and-battery voltage) operation is alternately repeated while

cruise control is operating.

Set signal to transmission con-

trol module (AT)12ITCM emits a ground-level signal while driving vehicle at least 40 km/h (25

MPH) with SET switch ON.

Ground 13 Ð

Check connector/

OBD-II service connector14 Ð

Check connector/

OBD-II service connector15 Ð

20

6-2[T3E0]DIAGNOSTICS

3. Cruise Control System

Page 83 of 345

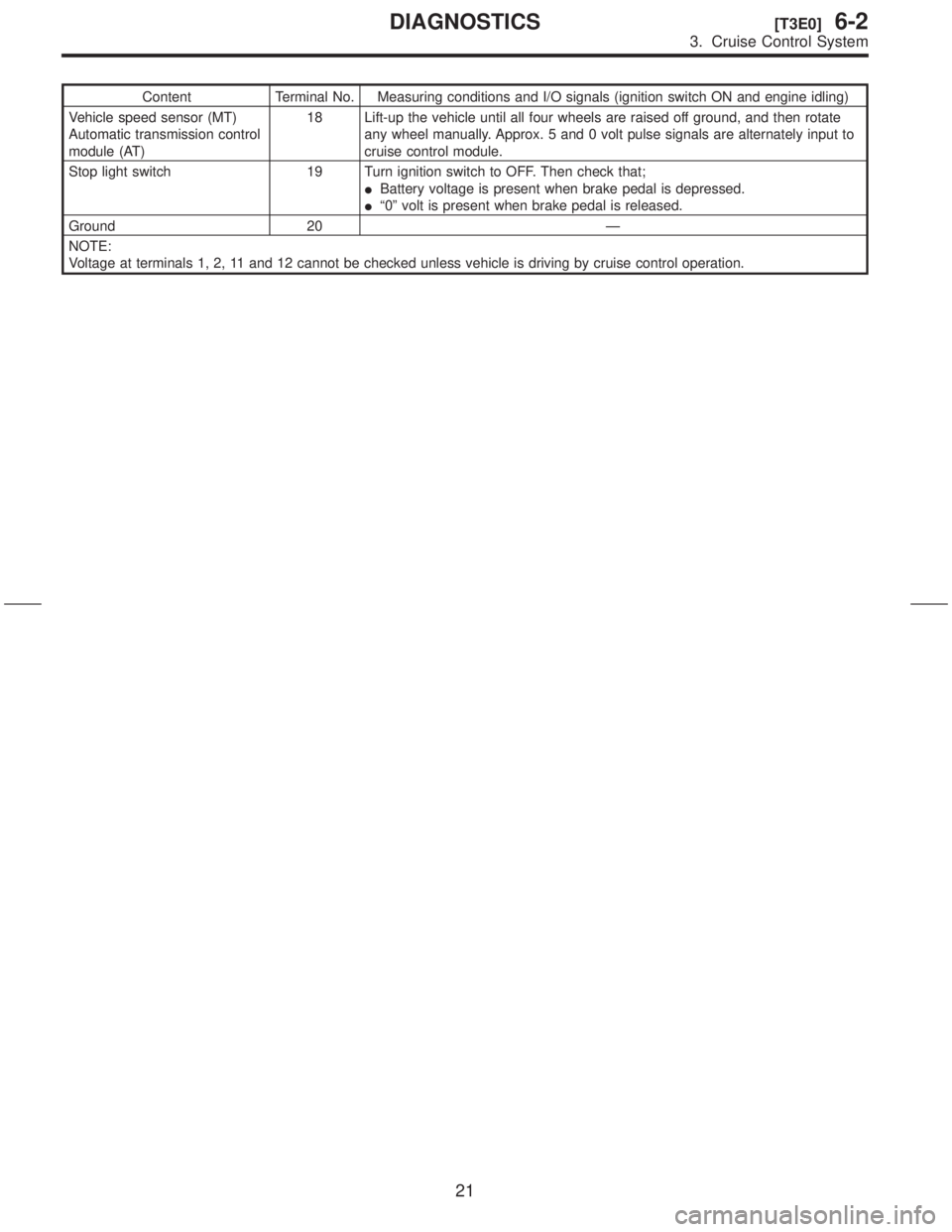

Content Terminal No. Measuring conditions and I/O signals (ignition switch ON and engine idling)

Vehicle speed sensor (MT)

Automatic transmission control

module (AT)18 Lift-up the vehicle until all four wheels are raised off ground, and then rotate

any wheel manually. Approx. 5 and 0 volt pulse signals are alternately input to

cruise control module.

Stop light switch 19 Turn ignition switch to OFF. Then check that;

IBattery voltage is present when brake pedal is depressed.

Iª0º volt is present when brake pedal is released.

Ground 20 Ð

NOTE:

Voltage at terminals 1, 2, 11 and 12 cannot be checked unless vehicle is driving by cruise control operation.

21

[T3E0]6-2DIAGNOSTICS

3. Cruise Control System

Page 85 of 345

2. ON-BOARD DIAGNOSIS WITH SELECT

MONITOR

IGeneral

The on-board diagnosis function of the cruise con-

trol system uses an external select monitor.

The on-board diagnosis function operates in two

categories, which are used depending on the type

of problems;

NOTE:

Select monitor part No.:

1) Cruise cancel conditions diagnosis

(1) This category of diagnosis requires actual

vehicle driving in order to determine the cause,

(as when cruise speed is cancelled during driv-

ing although cruise cancel condition is not

entered).

(2) Cruise control module memory stores the

cancel condition (Code No.) which occurred

during driving. When there are plural cancel

conditions (Code No.), they are shown on the

select monitor.

CAUTION:

IThe cruise control memory stores not only

the cruise ªcancelº which occurred (although

ªcancelº operation is not entered by the

driver), but also the ªcancelº condition input by

the driver.

IThe content of memory is cleared when igni-

tion switch or cruise main switch is turned OFF.

2) Real-time diagnosis

The real-time diagnosis function is used to deter-

mine whether or not the input signal system is in

good order, according to signal emitted from

switches, sensors, etc.

(1) Vehicle cannot be driven at cruise speed

because problems occurs in the cruise control

system or its associated circuits.

(2) Monitor the signal conditions from switches

and sensors.

ICruise Cancel Conditions Diagnosis

1) Connect select monitor.

2) Start the engine and turn cruise control main

switch to ON.

3) Set select monitor in ªAll System Diagnosisº

mode.

NOTE:

The diagnostic code is also shown in the ªEach

System Checkº mode. This mode is called up on

the ªCruise Control Diagnosisº screen by selecting

the item ªCancel Code(s) Displayº.

4) Drive vehicle at least 40 km/h (25 MPH) with

cruise speed set.5) If cruise speed is canceled itself (without doing

any cancel operations), a diagnostic code will

appear on select monitor display.

CAUTION:

IA diagnostic code will also appear when

cruise cancel is effected by driver. Do not con-

fuse.

IHave a co-worker ride in vehicle to assist in

diagnosis during driving.

NOTE:

Diagnostic code will be cleared by turning ignition

switch or cruise control main switch to OFF.

IReal-Time Diagnosis

1) Connect select monitor.

2) Turn ignition switch and cruise control main

switch to ON.

3) Select the ªCurrent Data Display & Saveº mode

on the select monitor ªCruise Control Diagnosisº

screen.

4) Ensure that normal indication is displayed when

controls are operated as indicated below:

IDepress/release the brake pedal. (Stop light

switch and brake switch turn ON.)

ITurn ON the ªSET/COASTº switch.

ITurn ON the ªRESUME/ACCELº switch.

IDepress/release the clutch pedal. (MT)

ISet the select lever to P or N. (AT)

23

[T3F2]6-2DIAGNOSTICS

3. Cruise Control System

Page 101 of 345

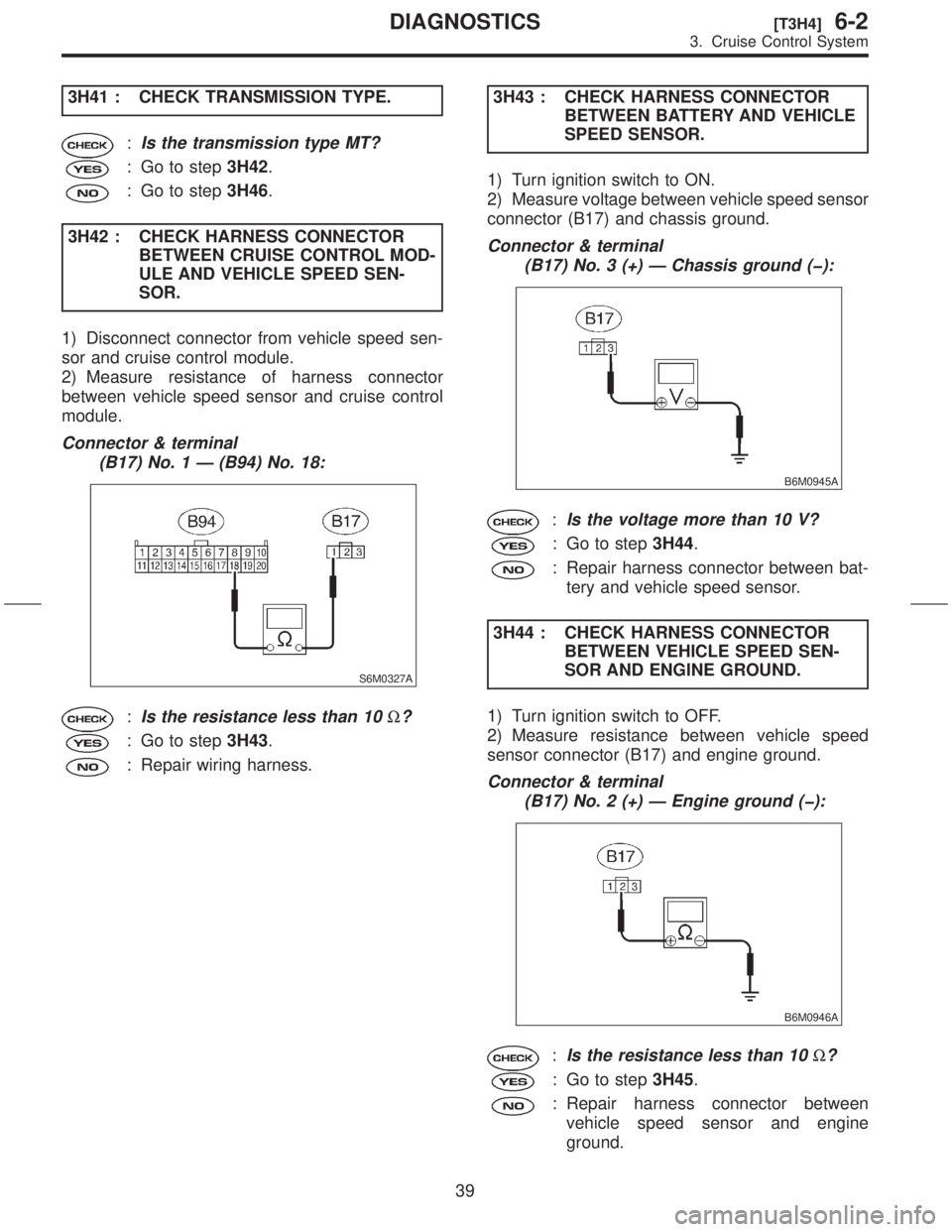

3H41 : CHECK TRANSMISSION TYPE.

:Is the transmission type MT?

: Go to step3H42.

: Go to step3H46.

3H42 : CHECK HARNESS CONNECTOR

BETWEEN CRUISE CONTROL MOD-

ULE AND VEHICLE SPEED SEN-

SOR.

1) Disconnect connector from vehicle speed sen-

sor and cruise control module.

2) Measure resistance of harness connector

between vehicle speed sensor and cruise control

module.

Connector & terminal

(B17) No. 1 Ð (B94) No. 18:

S6M0327A

:Is the resistance less than 10W?

: Go to step3H43.

: Repair wiring harness.3H43 : CHECK HARNESS CONNECTOR

BETWEEN BATTERY AND VEHICLE

SPEED SENSOR.

1) Turn ignition switch to ON.

2) Measure voltage between vehicle speed sensor

connector (B17) and chassis ground.

Connector & terminal

(B17) No. 3 (+) Ð Chassis ground (þ):

B6M0945A

:Is the voltage more than 10 V?

: Go to step3H44.

: Repair harness connector between bat-

tery and vehicle speed sensor.

3H44 : CHECK HARNESS CONNECTOR

BETWEEN VEHICLE SPEED SEN-

SOR AND ENGINE GROUND.

1) Turn ignition switch to OFF.

2) Measure resistance between vehicle speed

sensor connector (B17) and engine ground.

Connector & terminal

(B17) No. 2 (+) Ð Engine ground (þ):

B6M0946A

:Is the resistance less than 10W?

: Go to step3H45.

: Repair harness connector between

vehicle speed sensor and engine

ground.

39

[T3H4]6-2DIAGNOSTICS

3. Cruise Control System