SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1251 of 2870

EN(H4SO)-153

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

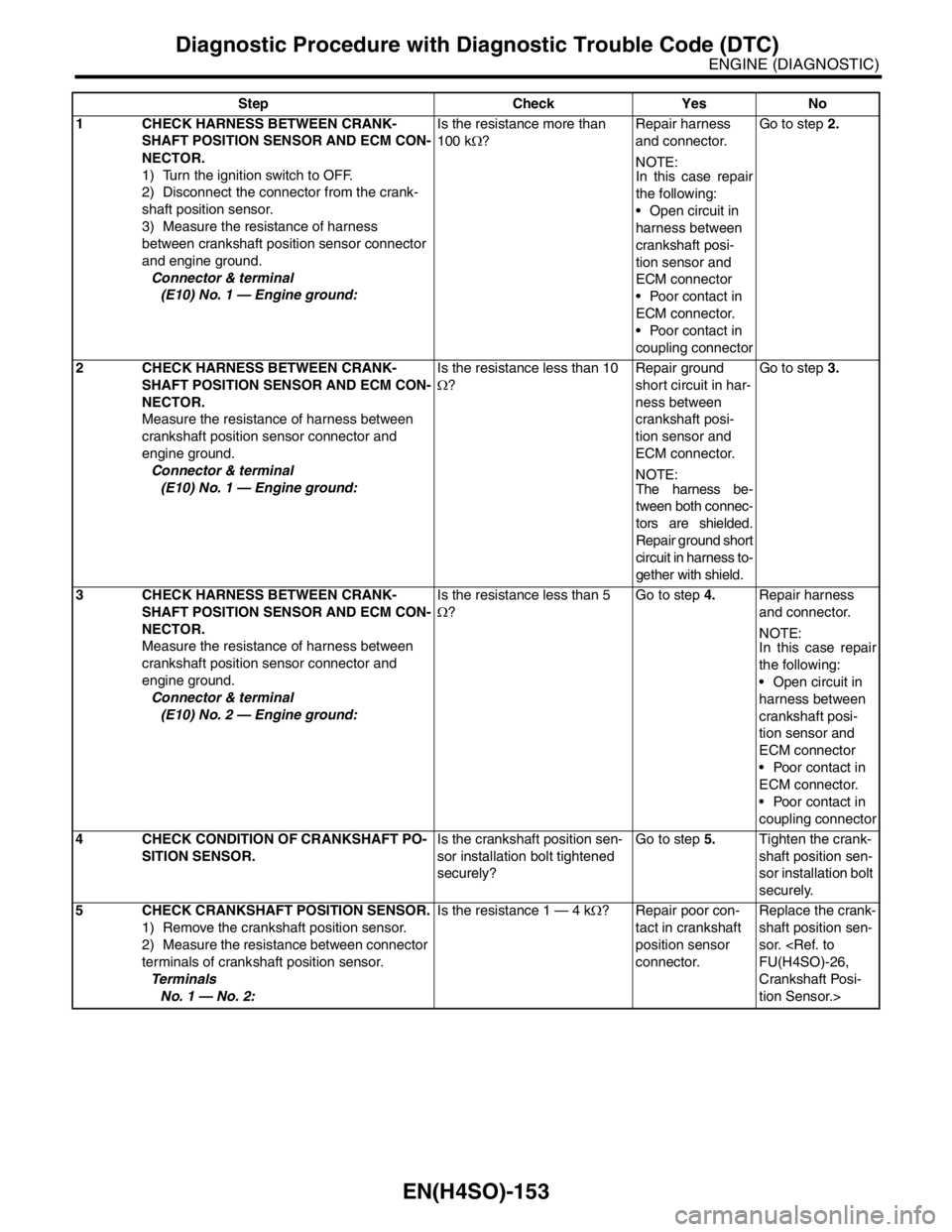

Step Check Yes No

1 CHECK HARNESS BETWEEN CRANK-

SHAFT POSITION SENSOR AND ECM CON-

NECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the crank-

shaft position sensor.

3) Measure the resistance of harness

between crankshaft position sensor connector

and engine ground.

Connector & terminal

(E10) No. 1 — Engine ground:Is the resistance more than

100 kΩ?Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

crankshaft posi-

tion sensor and

ECM connector

Poor contact in

ECM connector.

Poor contact in

coupling connectorGo to step 2.

2 CHECK HARNESS BETWEEN CRANK-

SHAFT POSITION SENSOR AND ECM CON-

NECTOR.

Measure the resistance of harness between

crankshaft position sensor connector and

engine ground.

Connector & terminal

(E10) No. 1 — Engine ground:Is the resistance less than 10

Ω?Repair ground

short circuit in har-

ness between

crankshaft posi-

tion sensor and

ECM connector.

N

OTE:

The harness be-

tween both connec-

tors are shielded.

Repair ground short

circuit in harness to-

gether with shield.Go to step 3.

3 CHECK HARNESS BETWEEN CRANK-

SHAFT POSITION SENSOR AND ECM CON-

NECTOR.

Measure the resistance of harness between

crankshaft position sensor connector and

engine ground.

Connector & terminal

(E10) No. 2 — Engine ground:Is the resistance less than 5

Ω?Go to step 4.Repair harness

and connector.

NOTE:

In this case repair

the following:

Open circuit in

harness between

crankshaft posi-

tion sensor and

ECM connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

4 CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.Is the crankshaft position sen-

sor installation bolt tightened

securely?Go to step 5.Tighten the crank-

shaft position sen-

sor installation bolt

securely.

5 CHECK CRANKSHAFT POSITION SENSOR.

1) Remove the crankshaft position sensor.

2) Measure the resistance between connector

terminals of crankshaft position sensor.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Repair poor con-

tact in crankshaft

position sensor

connector.Replace the crank-

shaft position sen-

sor.

Crankshaft Posi-

tion Sensor.>

Page 1252 of 2870

EN(H4SO)-154

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

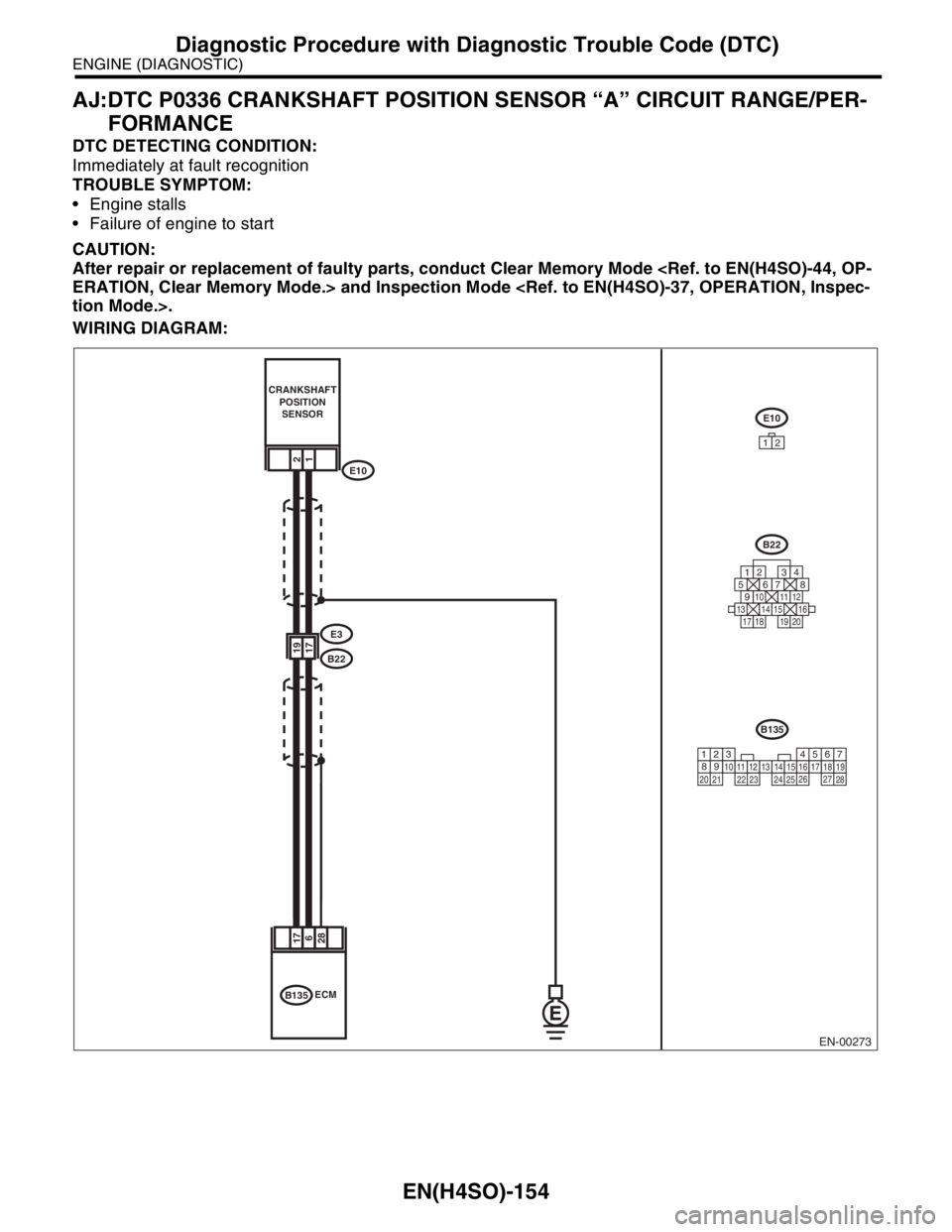

AJ:DTC P0336 CRANKSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PER-

FORMANCE

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Engine stalls

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-00273

12

1917

1728

B22

E3

E10

B22

E10

12

B135ECM CRANKSHAFT

POSITION

SENSOR

125678

131415169101112

34

17181920

6

B135

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

Page 1253 of 2870

EN(H4SO)-155

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

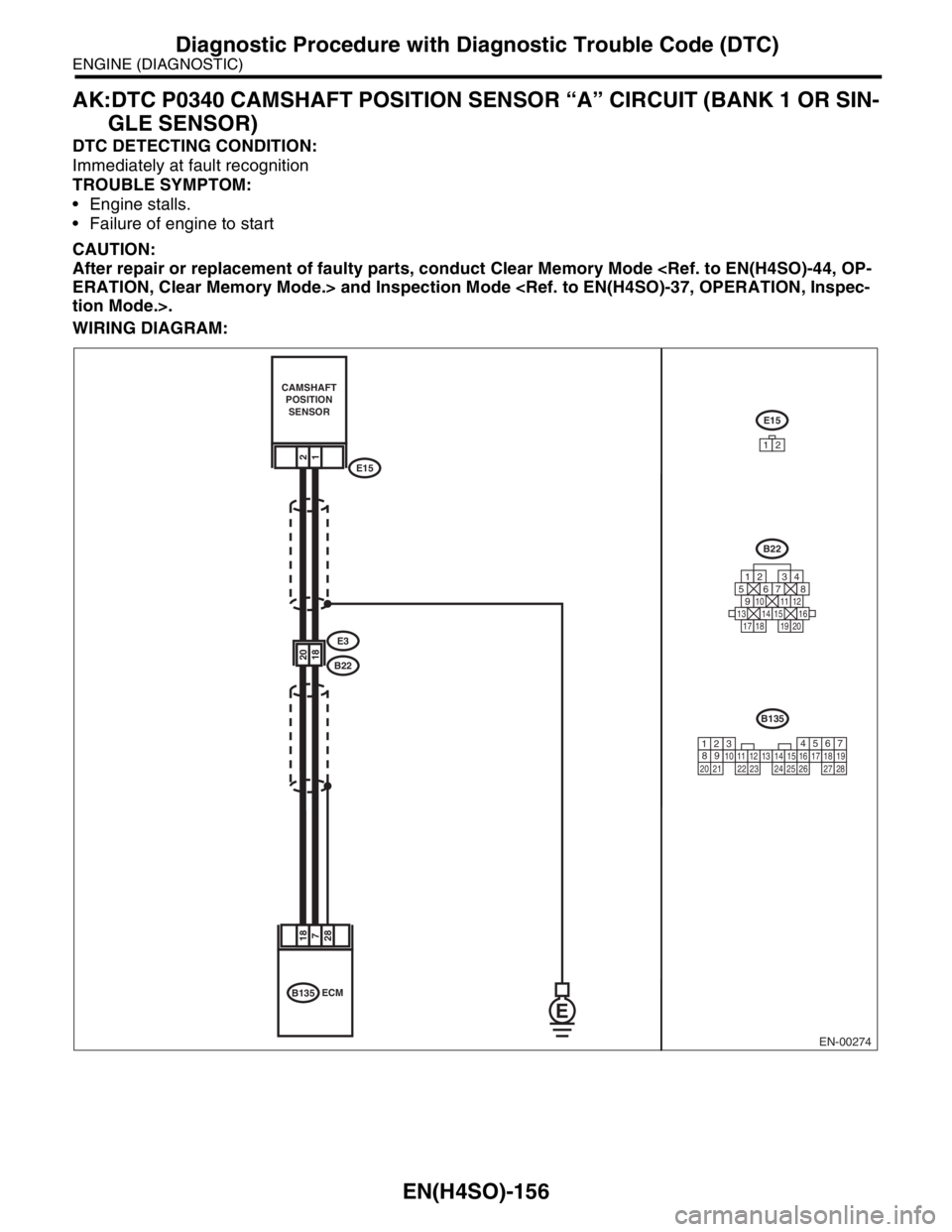

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the DTC

using “List of Diag-

nostic Trouble

Code (DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Turn the ignition switch to OFF.Is the crankshaft position sen-

sor installation bolt tightened

securely?Go to step 3.Tighten the crank-

shaft position sen-

sor installation bolt

securely.

3 CHECK CRANK SPROCKET.

Remove the front belt cover.Are crank sprocket teeth

cracked or damaged?Replace the crank

sprocket.

Crank Sprocket.>Go to step 4.

4 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the crankshaft using ST, and align align-

ment mark on crank sprocket with alignment

mark on cylinder block.

ST 499987500 CRANKSHAFT SOCKETIs the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt.>Replace the crank-

shaft position sen-

sor.

Crankshaft Posi-

tion Sensor.>

Page 1254 of 2870

EN(H4SO)-156

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

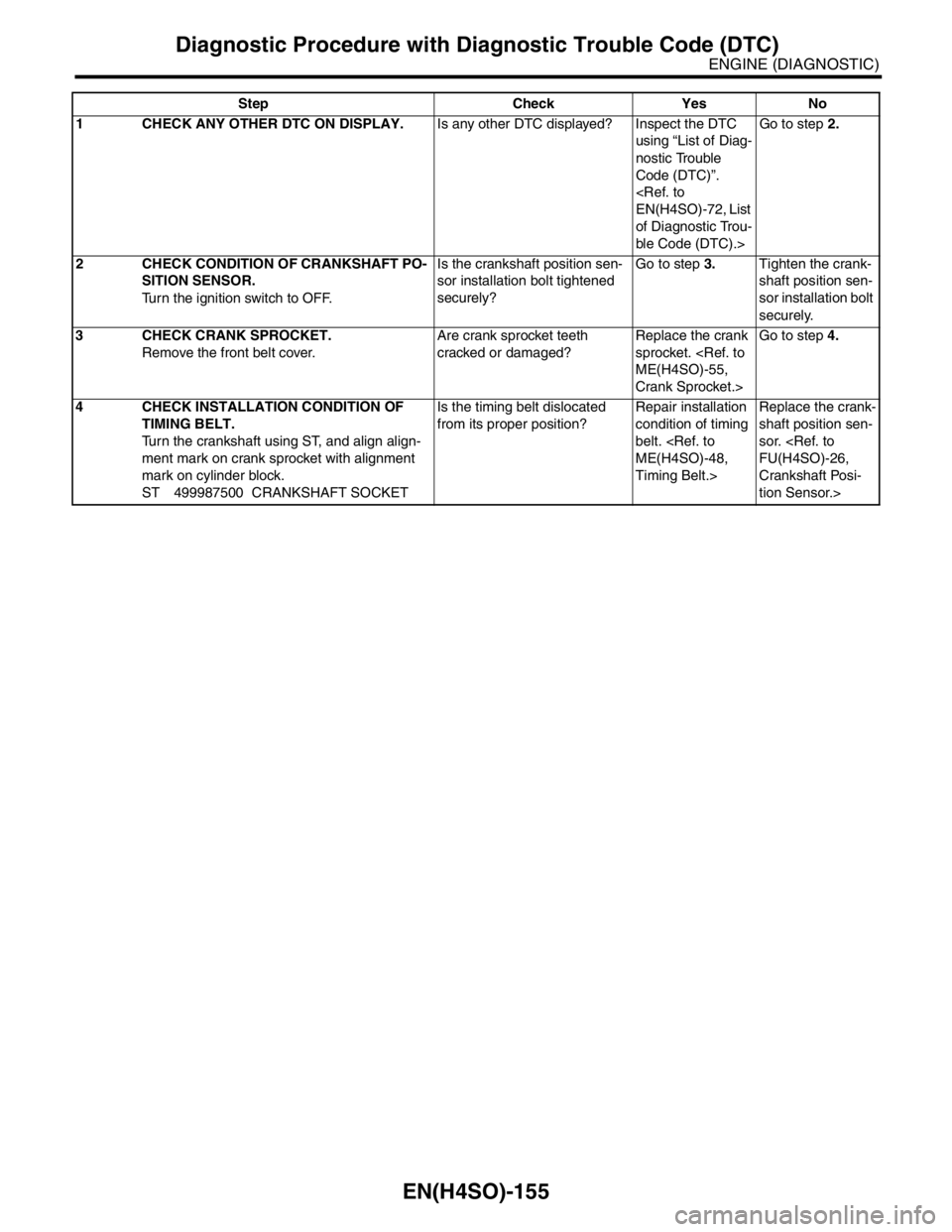

AK:DTC P0340 CAMSHAFT POSITION SENSOR “A” CIRCUIT (BANK 1 OR SIN-

GLE SENSOR)

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Engine stalls.

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-00274

B22

E15

12

125678

131415169101112

34

17181920

12

2018

1828

B22

E3

E15

B135ECM CAMSHAFT

POSITION

SENSOR

7

B135

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

Page 1255 of 2870

EN(H4SO)-157

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

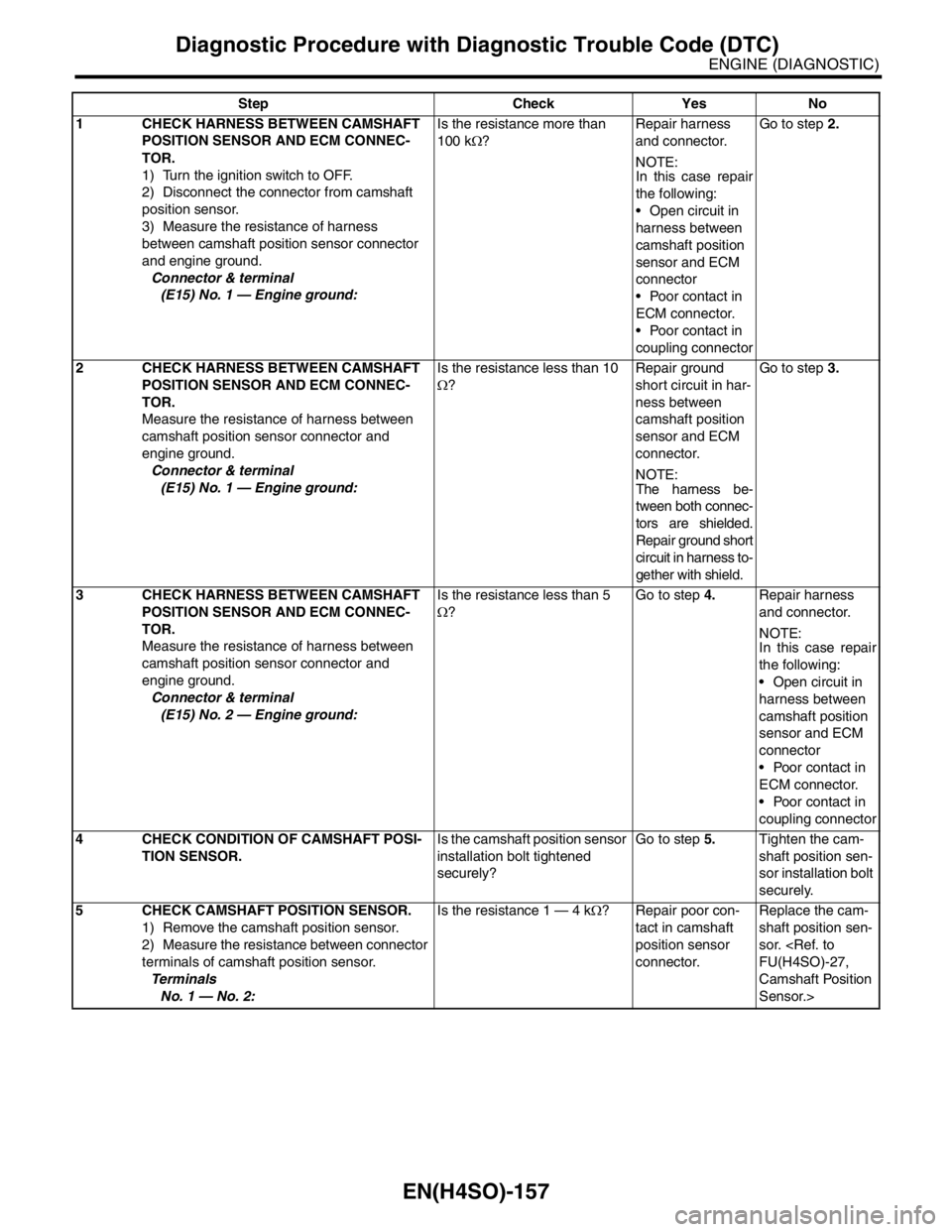

Step Check Yes No

1 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from camshaft

position sensor.

3) Measure the resistance of harness

between camshaft position sensor connector

and engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance more than

100 kΩ?Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor and ECM

connector

Poor contact in

ECM connector.

Poor contact in

coupling connectorGo to step 2.

2 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR AND ECM CONNEC-

TOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance less than 10

Ω?Repair ground

short circuit in har-

ness between

camshaft position

sensor and ECM

connector.

N

OTE:

The harness be-

tween both connec-

tors are shielded.

Repair ground short

circuit in harness to-

gether with shield.Go to step 3.

3 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR AND ECM CONNEC-

TOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 2 — Engine ground:Is the resistance less than 5

Ω?Go to step 4.Repair harness

and connector.

NOTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor and ECM

connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

4 CHECK CONDITION OF CAMSHAFT POSI-

TION SENSOR.Is the camshaft position sensor

installation bolt tightened

securely?Go to step 5.Tighten the cam-

shaft position sen-

sor installation bolt

securely.

5 CHECK CAMSHAFT POSITION SENSOR.

1) Remove the camshaft position sensor.

2) Measure the resistance between connector

terminals of camshaft position sensor.

Te r m i n a l s

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Repair poor con-

tact in camshaft

position sensor

connector.Replace the cam-

shaft position sen-

sor.

Camshaft Position

Sensor.>

Page 1256 of 2870

EN(H4SO)-158

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

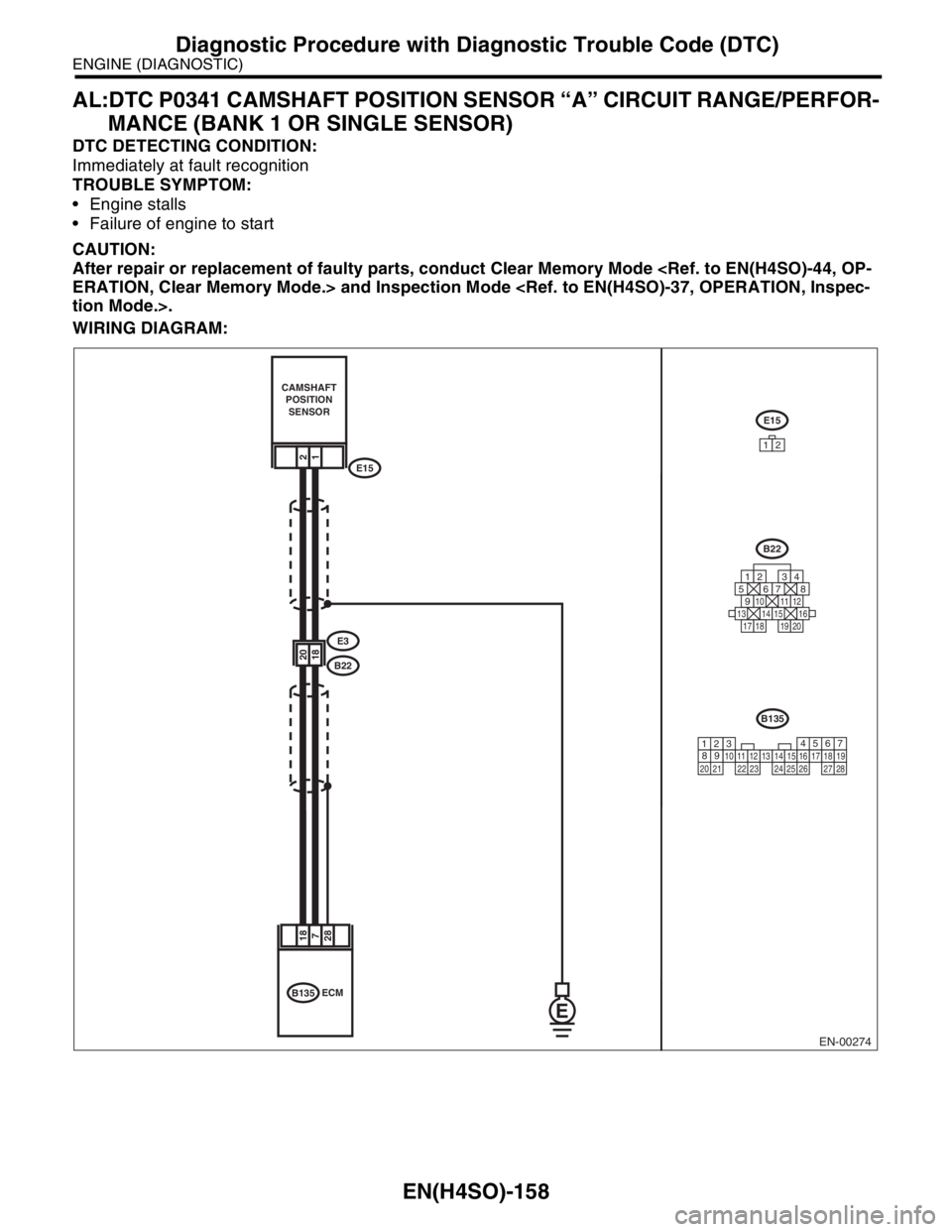

AL:DTC P0341 CAMSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PERFOR-

MANCE (BANK 1 OR SINGLE SENSOR)

DTC DETECTING CONDITION:

Immediately at fault recognition

TROUBLE SYMPTOM:

Engine stalls

Failure of engine to start

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-00274

B22

E15

12

125678

131415169101112

34

17181920

12

2018

1828

B22

E3

E15

B135ECM CAMSHAFT

POSITION

SENSOR

7

B135

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

Page 1257 of 2870

EN(H4SO)-159

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

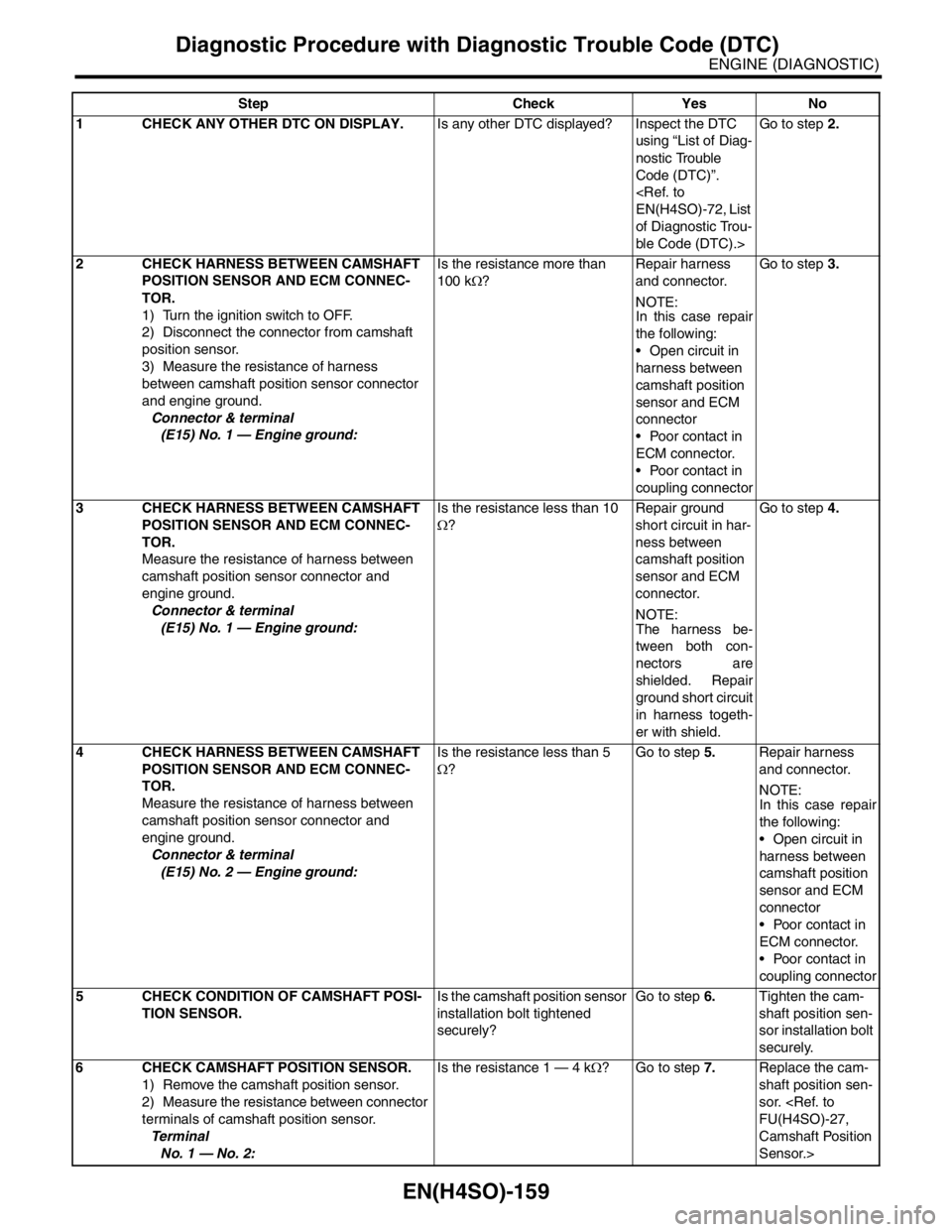

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the DTC

using “List of Diag-

nostic Trouble

Code (DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR AND ECM CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from camshaft

position sensor.

3) Measure the resistance of harness

between camshaft position sensor connector

and engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance more than

100 kΩ?Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor and ECM

connector

Poor contact in

ECM connector.

Poor contact in

coupling connectorGo to step 3.

3 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR AND ECM CONNEC-

TOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 1 — Engine ground:Is the resistance less than 10

Ω?Repair ground

short circuit in har-

ness between

camshaft position

sensor and ECM

connector.

N

OTE:

The harness be-

tween both con-

nectors are

shielded. Repair

ground short circuit

in harness togeth-

er with shield.Go to step 4.

4 CHECK HARNESS BETWEEN CAMSHAFT

POSITION SENSOR AND ECM CONNEC-

TOR.

Measure the resistance of harness between

camshaft position sensor connector and

engine ground.

Connector & terminal

(E15) No. 2 — Engine ground:Is the resistance less than 5

Ω?Go to step 5.Repair harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

camshaft position

sensor and ECM

connector

Poor contact in

ECM connector.

Poor contact in

coupling connector

5 CHECK CONDITION OF CAMSHAFT POSI-

TION SENSOR.Is the camshaft position sensor

installation bolt tightened

securely?Go to step 6.Tighten the cam-

shaft position sen-

sor installation bolt

securely.

6 CHECK CAMSHAFT POSITION SENSOR.

1) Remove the camshaft position sensor.

2) Measure the resistance between connector

terminals of camshaft position sensor.

Te r m i n a l

No. 1 — No. 2:Is the resistance 1 — 4 kΩ? Go to step 7.Replace the cam-

shaft position sen-

sor.

Camshaft Position

Sensor.>

Page 1258 of 2870

EN(H4SO)-160

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

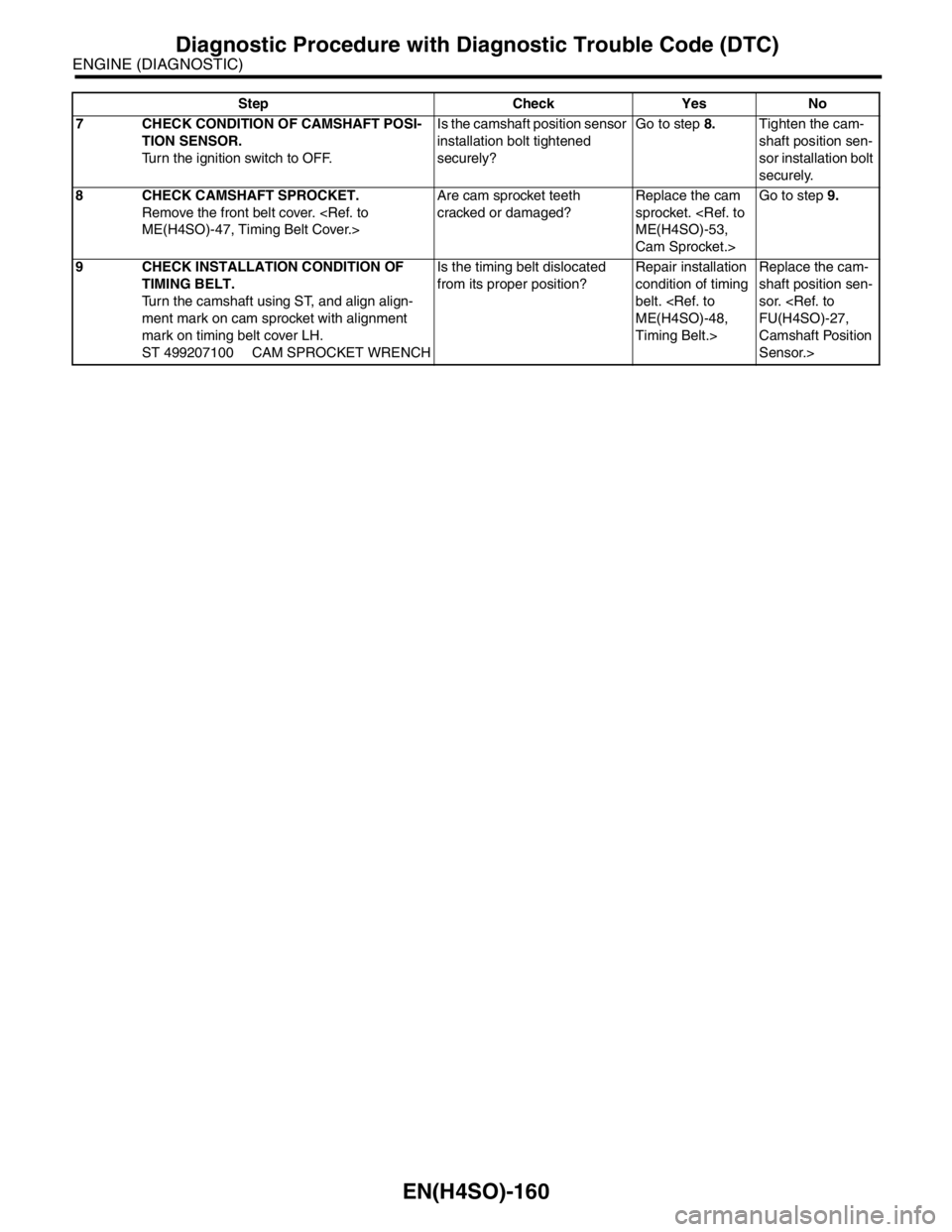

7 CHECK CONDITION OF CAMSHAFT POSI-

TION SENSOR.

Turn the ignition switch to OFF.Is the camshaft position sensor

installation bolt tightened

securely?Go to step 8.Tighten the cam-

shaft position sen-

sor installation bolt

securely.

8 CHECK CAMSHAFT SPROCKET.

Remove the front belt cover.

cracked or damaged?Replace the cam

sprocket.

Cam Sprocket.>Go to step 9.

9 CHECK INSTALLATION CONDITION OF

TIMING BELT.

Turn the camshaft using ST, and align align-

ment mark on cam sprocket with alignment

mark on timing belt cover LH.

ST 499207100 CAM SPROCKET WRENCHIs the timing belt dislocated

from its proper position?Repair installation

condition of timing

belt.

Timing Belt.>Replace the cam-

shaft position sen-

sor.

Camshaft Position

Sensor.> Step Check Yes No

Page 1259 of 2870

EN(H4SO)-161

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

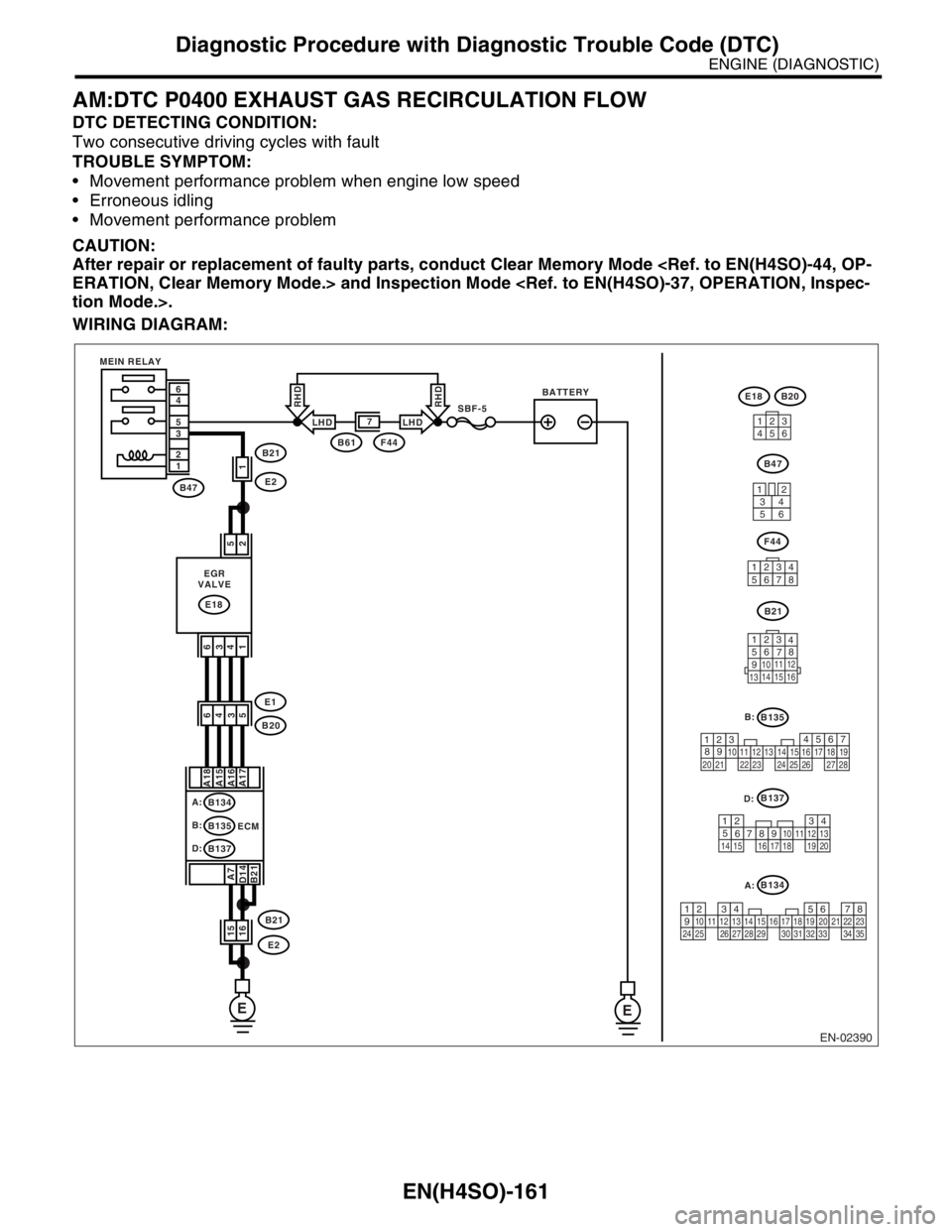

AM:DTC P0400 EXHAUST GAS RECIRCULATION FLOW

DTC DETECTING CONDITION:

Two consecutive driving cycles with fault

TROUBLE SYMPTOM:

Movement performance problem when engine low speed

Erroneous idling

Movement performance problem

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02390

B137

B135

B134

B21

123

4

56

78

9

1011 12

1314 15 16

EE

B47

E18

2 5

1 4 3 6

B21B61F44

E2

B20

E1

B21

E2

6

4

5

3

2

1

1

5 A17 A16 A15 A18

B21 D14A74

3 6

15

16

SBF-5BATTERY MEIN RELAY

EGR

VALVE

A:

B134

B:

B135

D:

B137ECM

B47

F44

E18

3412

56

13

45627

12345678

4

1

53

2618 15 167891011

17 19

20121314

567

82 1

94

310

24 22 23 251112131415

26 27

281617181920 21

1234567891011121314151617181920212223242526272829303132333435

B20

LHDLHD

RHDRHD

A: B:

D:

Page 1260 of 2870

EN(H4SO)-162

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

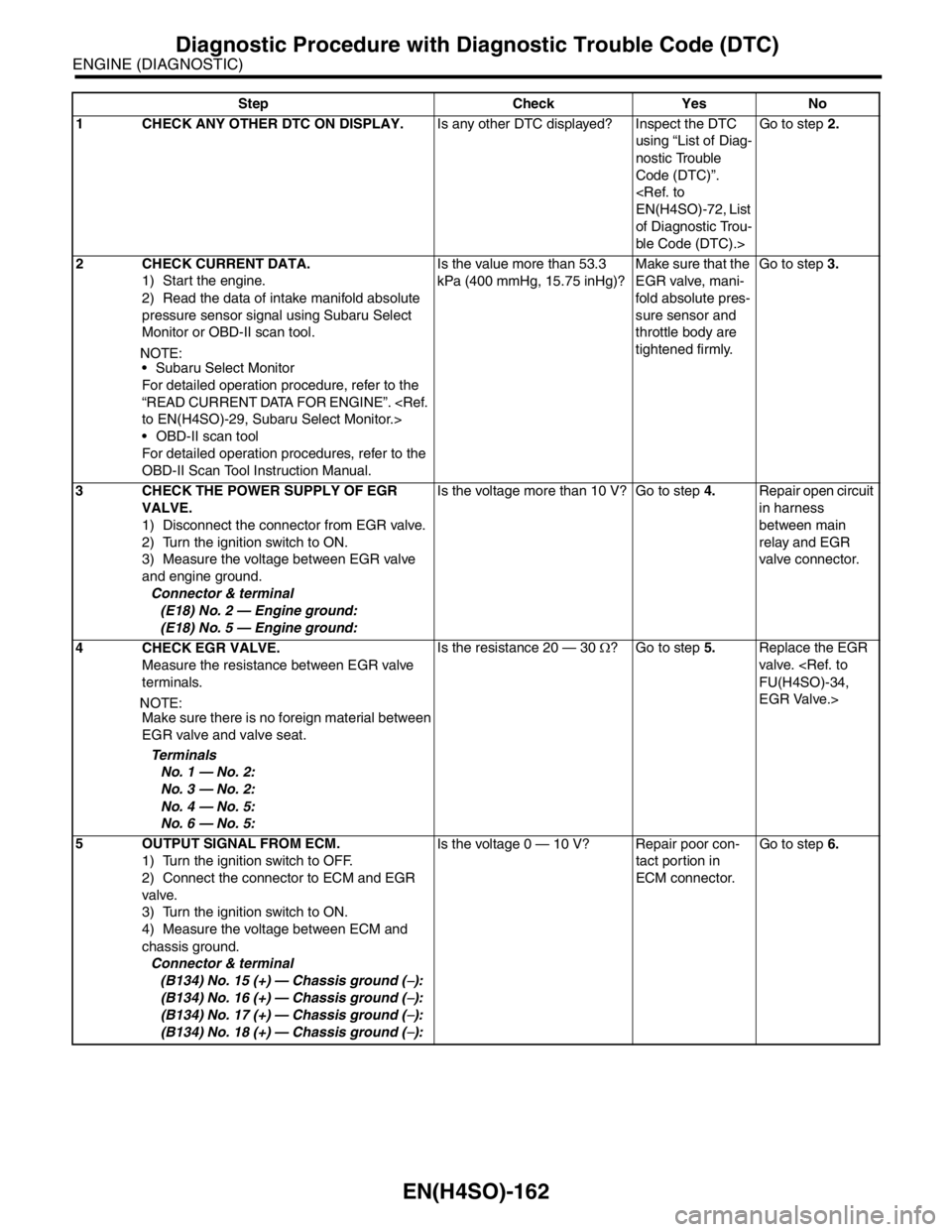

Step Check Yes No

1 CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Inspect the DTC

using “List of Diag-

nostic Trouble

Code (DTC)”.

of Diagnostic Trou-

ble Code (DTC).>Go to step 2.

2 CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of intake manifold absolute

pressure sensor signal using Subaru Select

Monitor or OBD-II scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to the

“READ CURRENT DATA FOR ENGINE”.

OBD-II scan tool

For detailed operation procedures, refer to the

OBD-II Scan Tool Instruction Manual.Is the value more than 53.3

kPa (400 mmHg, 15.75 inHg)?Make sure that the

EGR valve, mani-

fold absolute pres-

sure sensor and

throttle body are

tightened firmly.Go to step 3.

3 CHECK THE POWER SUPPLY OF EGR

VALVE.

1) Disconnect the connector from EGR valve.

2) Turn the ignition switch to ON.

3) Measure the voltage between EGR valve

and engine ground.

Connector & terminal

(E18) No. 2 — Engine ground:

(E18) No. 5 — Engine ground:Is the voltage more than 10 V? Go to step 4.Repair open circuit

in harness

between main

relay and EGR

valve connector.

4 CHECK EGR VALVE.

Measure the resistance between EGR valve

terminals.

N

OTE:

Make sure there is no foreign material between

EGR valve and valve seat.

Te r m i n a l s

No. 1 — No. 2:

No. 3 — No. 2:

No. 4 — No. 5:

No. 6 — No. 5:Is the resistance 20 — 30 Ω? Go to step 5.Replace the EGR

valve.

EGR Valve.>

5 OUTPUT SIGNAL FROM ECM.

1) Turn the ignition switch to OFF.

2) Connect the connector to ECM and EGR

valve.

3) Turn the ignition switch to ON.

4) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B134) No. 15 (+) — Chassis ground (

−):

(B134) No. 16 (+) — Chassis ground (

−):

(B134) No. 17 (+) — Chassis ground (

−):

(B134) No. 18 (+) — Chassis ground (

−):Is the voltage 0 — 10 V? Repair poor con-

tact portion in

ECM connector.Go to step 6.