sensor SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 814 of 2870

FU(H4SO)-32

FUEL INJECTION (FUEL SYSTEM)

Intake Air Temperature Sensor

10.Intake Air Temperature Sen-

sor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Disconnect the connector from the intake air

temperature sensor.

3) Remove the intake air temperature sensor from

air cleaner case.

B: INSTALLATION

Install in the reverse order of removal.

FU-00009

FU-00297

Page 822 of 2870

FU(H4SO)-40

FUEL INJECTION (FUEL SYSTEM)

Front Oxygen (A/F) Sensor

14.Front Oxygen (A/F) Sensor

A: REMOVAL

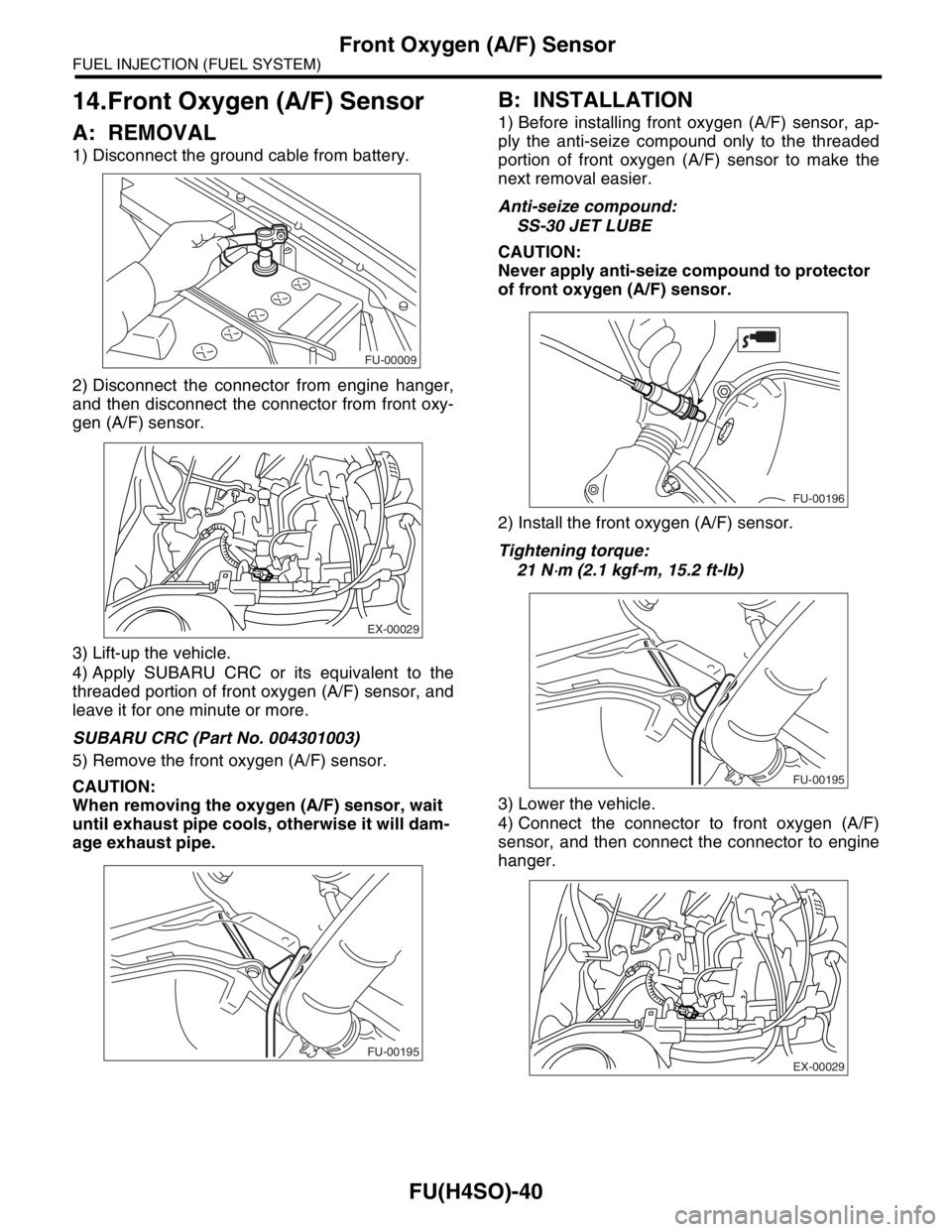

1) Disconnect the ground cable from battery.

2) Disconnect the connector from engine hanger,

and then disconnect the connector from front oxy-

gen (A/F) sensor.

3) Lift-up the vehicle.

4) Apply SUBARU CRC or its equivalent to the

threaded portion of front oxygen (A/F) sensor, and

leave it for one minute or more.

SUBARU CRC (Part No. 004301003)

5) Remove the front oxygen (A/F) sensor.

CAUTION:

When removing the oxygen (A/F) sensor, wait

until exhaust pipe cools, otherwise it will dam-

age exhaust pipe.

B: INSTALLATION

1) Before installing front oxygen (A/F) sensor, ap-

ply the anti-seize compound only to the threaded

portion of front oxygen (A/F) sensor to make the

next removal easier.

Anti-seize compound:

SS-30 JET LUBE

CAUTION:

Never apply anti-seize compound to protector

of front oxygen (A/F) sensor.

2) Install the front oxygen (A/F) sensor.

Tightening torque:

21 N

⋅m (2.1 kgf-m, 15.2 ft-lb)

3) Lower the vehicle.

4) Connect the connector to front oxygen (A/F)

sensor, and then connect the connector to engine

hanger.

FU-00009

EX-00029

FU-00195

FU-00196

FU-00195

EX-00029

Page 823 of 2870

FU(H4SO)-41

FUEL INJECTION (FUEL SYSTEM)

Front Oxygen (A/F) Sensor

5) Connect the battery ground cable to battery.

FU-00009

Page 824 of 2870

FU(H4SO)-42

FUEL INJECTION (FUEL SYSTEM)

Rear Oxygen Sensor

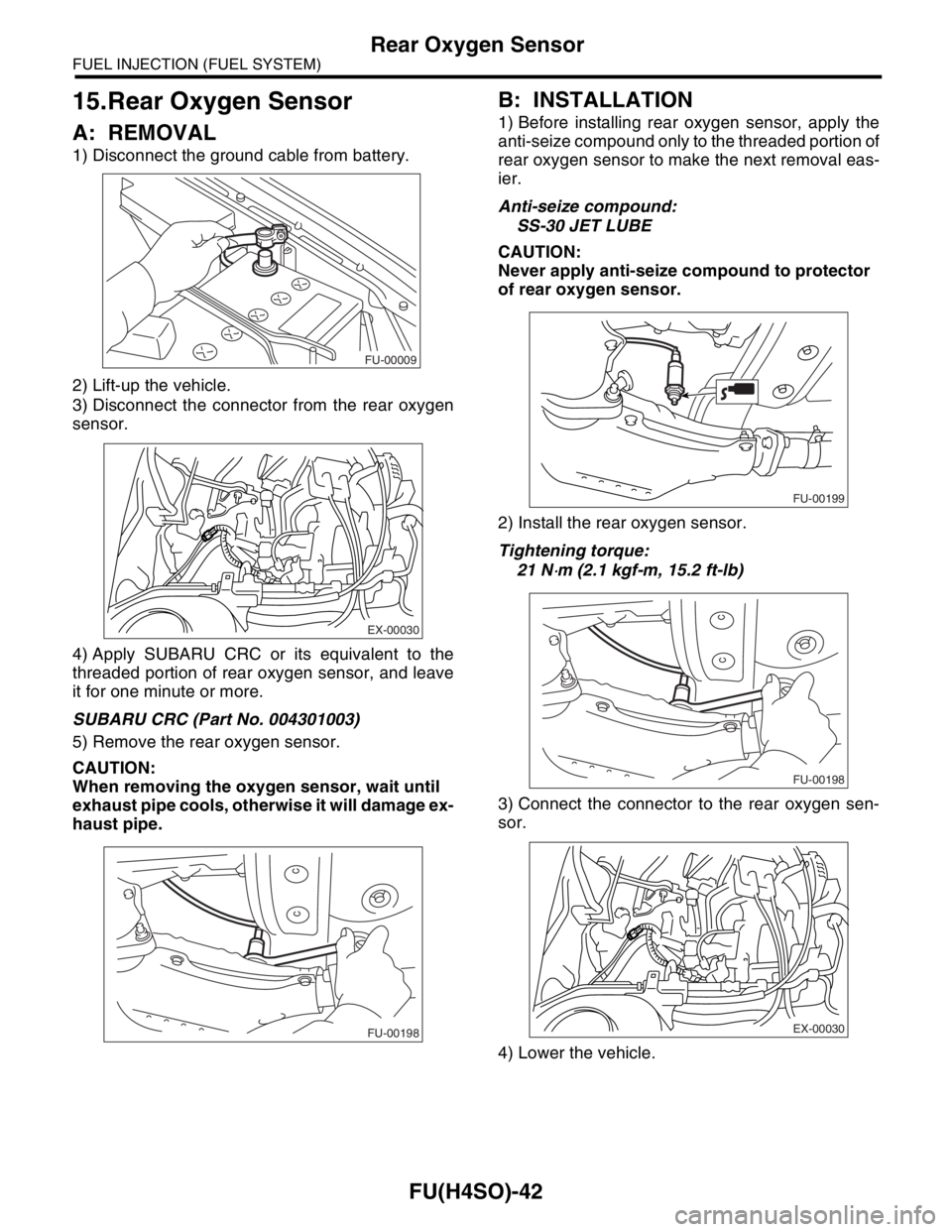

15.Rear Oxygen Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Lift-up the vehicle.

3) Disconnect the connector from the rear oxygen

sensor.

4) Apply SUBARU CRC or its equivalent to the

threaded portion of rear oxygen sensor, and leave

it for one minute or more.

SUBARU CRC (Part No. 004301003)

5) Remove the rear oxygen sensor.

CAUTION:

When removing the oxygen sensor, wait until

exhaust pipe cools, otherwise it will damage ex-

haust pipe.

B: INSTALLATION

1) Before installing rear oxygen sensor, apply the

anti-seize compound only to the threaded portion of

rear oxygen sensor to make the next removal eas-

ier.

Anti-seize compound:

SS-30 JET LUBE

CAUTION:

Never apply anti-seize compound to protector

of rear oxygen sensor.

2) Install the rear oxygen sensor.

Tightening torque:

21 N

⋅m (2.1 kgf-m, 15.2 ft-lb)

3) Connect the connector to the rear oxygen sen-

sor.

4) Lower the vehicle.

FU-00009

EX-00030

FU-00198

FU-00199

FU-00198

EX-00030

Page 825 of 2870

FU(H4SO)-43

FUEL INJECTION (FUEL SYSTEM)

Rear Oxygen Sensor

5) Connect the battery ground cable to battery.

FU-00009

Page 837 of 2870

FU(H4SO)-55

FUEL INJECTION (FUEL SYSTEM)

Fuel Pump

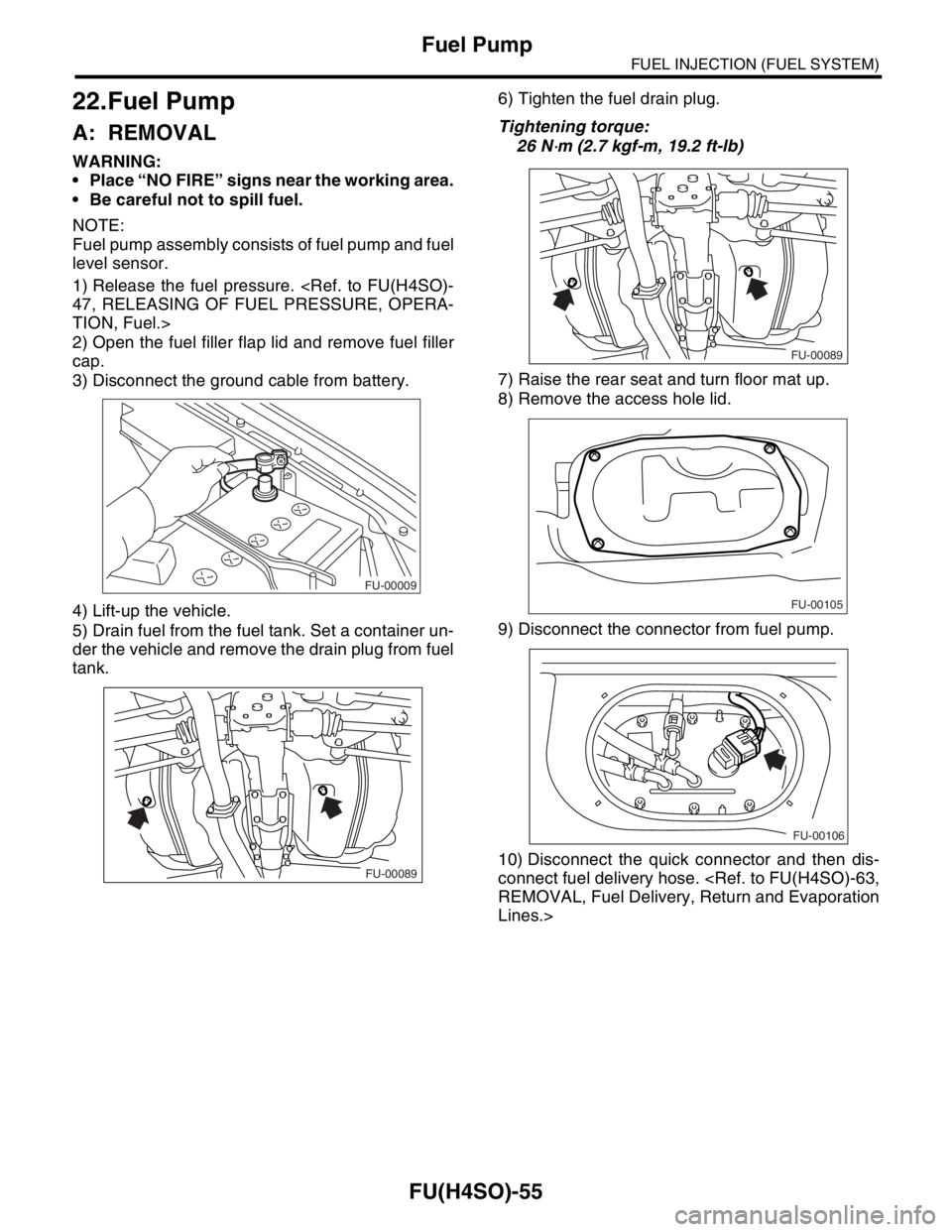

22.Fuel Pump

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel.

NOTE:

Fuel pump assembly consists of fuel pump and fuel

level sensor.

1) Release the fuel pressure.

TION, Fuel.>

2) Open the fuel filler flap lid and remove fuel filler

cap.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Drain fuel from the fuel tank. Set a container un-

der the vehicle and remove the drain plug from fuel

tank.6) Tighten the fuel drain plug.

Tightening torque:

26 N

⋅m (2.7 kgf-m, 19.2 ft-lb)

7) Raise the rear seat and turn floor mat up.

8) Remove the access hole lid.

9) Disconnect the connector from fuel pump.

10) Disconnect the quick connector and then dis-

connect fuel delivery hose.

Lines.>

FU-00009

FU-00089

FU-00089

FU-00105

FU-00106

Page 839 of 2870

FU(H4SO)-57

FUEL INJECTION (FUEL SYSTEM)

Fuel Level Sensor

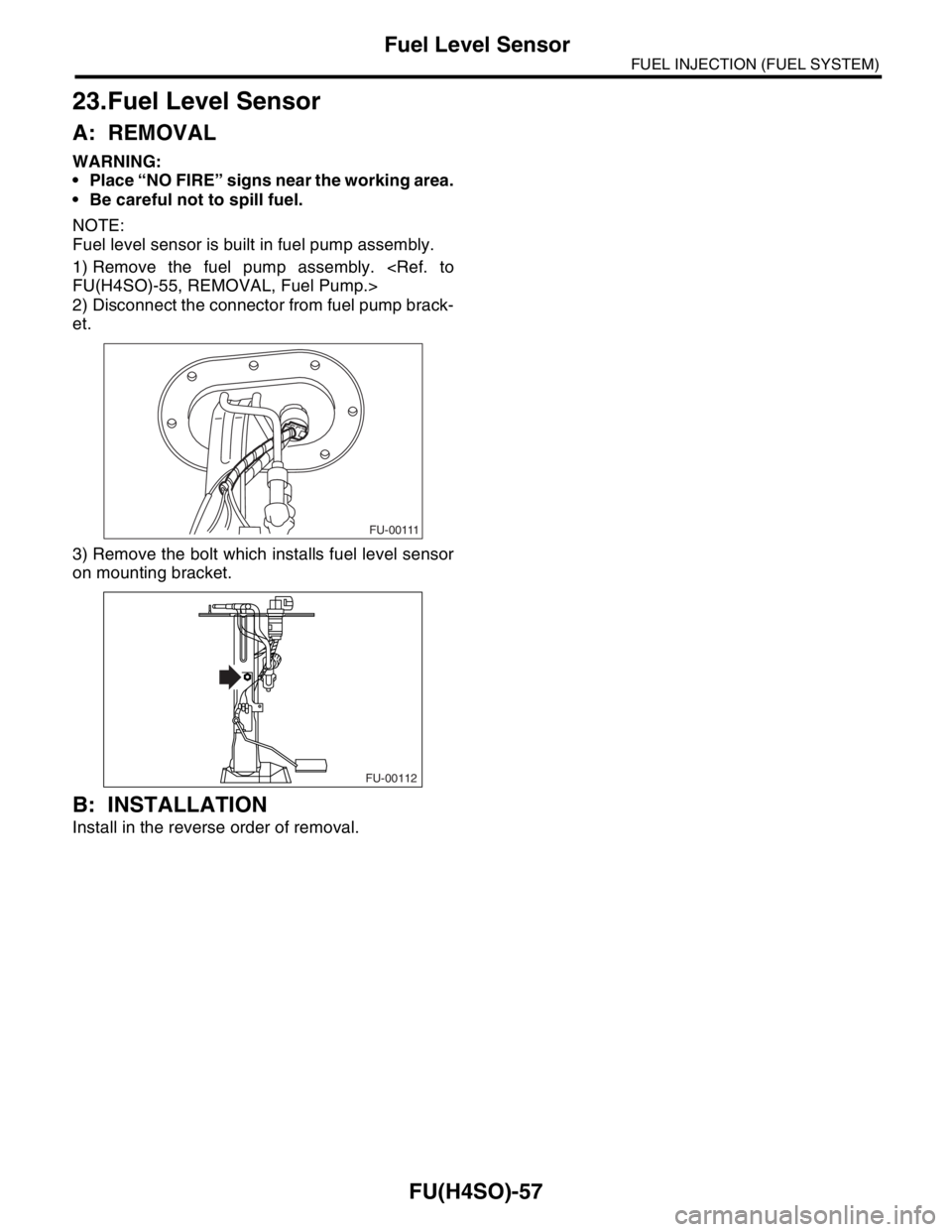

23.Fuel Level Sensor

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel.

NOTE:

Fuel level sensor is built in fuel pump assembly.

1) Remove the fuel pump assembly.

2) Disconnect the connector from fuel pump brack-

et.

3) Remove the bolt which installs fuel level sensor

on mounting bracket.

B: INSTALLATION

Install in the reverse order of removal.

FU-00111

FU-00112

Page 840 of 2870

FU(H4SO)-58

FUEL INJECTION (FUEL SYSTEM)

Fuel Sub Level Sensor

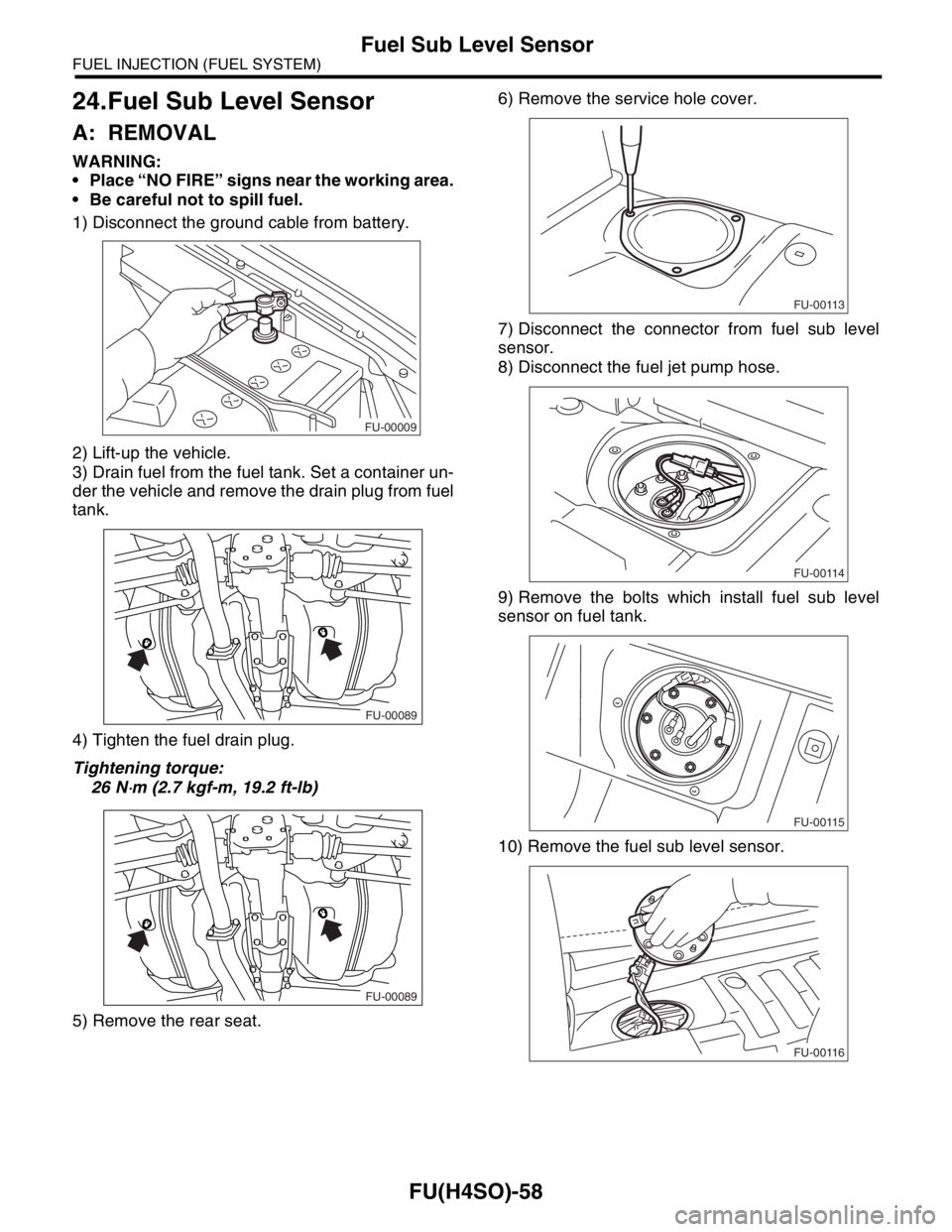

24.Fuel Sub Level Sensor

A: REMOVAL

WARNING:

Place “NO FIRE” signs near the working area.

Be careful not to spill fuel.

1) Disconnect the ground cable from battery.

2) Lift-up the vehicle.

3) Drain fuel from the fuel tank. Set a container un-

der the vehicle and remove the drain plug from fuel

tank.

4) Tighten the fuel drain plug.

Tightening torque:

26 N

⋅m (2.7 kgf-m, 19.2 ft-lb)

5) Remove the rear seat.6) Remove the service hole cover.

7) Disconnect the connector from fuel sub level

sensor.

8) Disconnect the fuel jet pump hose.

9) Remove the bolts which install fuel sub level

sensor on fuel tank.

10) Remove the fuel sub level sensor.

FU-00009

FU-00089

FU-00089

FU-00113

FU-00114

FU-00115

FU-00116

Page 841 of 2870

FU(H4SO)-59

FUEL INJECTION (FUEL SYSTEM)

Fuel Sub Level Sensor

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

4.4 N

⋅m (0.45 kgf-m, 3.3 ft-lb)

FU-00115

Page 848 of 2870

FU(H4SO)-66

FUEL INJECTION (FUEL SYSTEM)

Fuel System Trouble in General

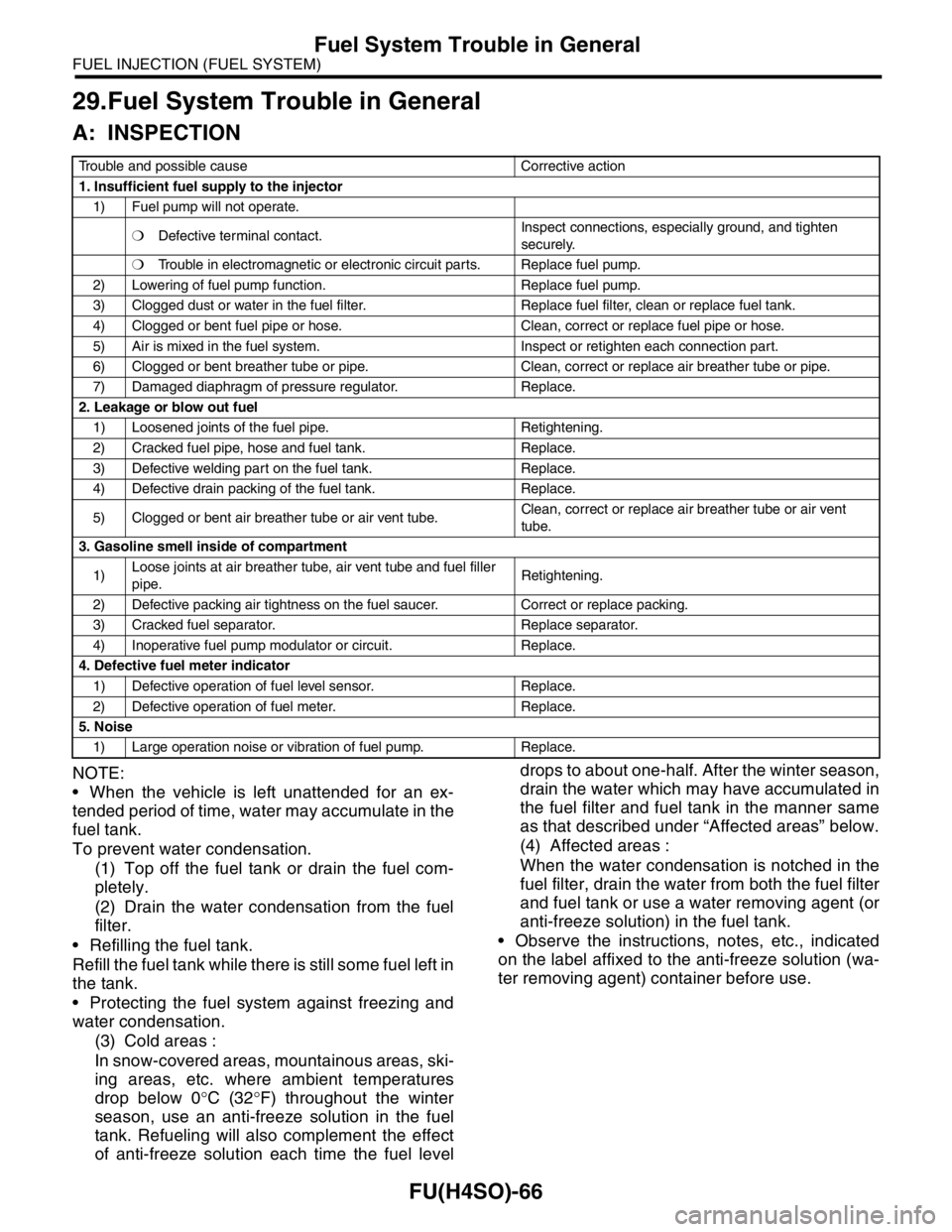

29.Fuel System Trouble in General

A: INSPECTION

NOTE:

When the vehicle is left unattended for an ex-

tended period of time, water may accumulate in the

fuel tank.

To prevent water condensation.

(1) Top off the fuel tank or drain the fuel com-

pletely.

(2) Drain the water condensation from the fuel

filter.

Refilling the fuel tank.

Refill the fuel tank while there is still some fuel left in

the tank.

Protecting the fuel system against freezing and

water condensation.

(3) Cold areas :

In snow-covered areas, mountainous areas, ski-

ing areas, etc. where ambient temperatures

drop below 0°C (32°F) throughout the winter

season, use an anti-freeze solution in the fuel

tank. Refueling will also complement the effect

of anti-freeze solution each time the fuel leveldrops to about one-half. After the winter season,

drain the water which may have accumulated in

the fuel filter and fuel tank in the manner same

as that described under “Affected areas” below.

(4) Affected areas :

When the water condensation is notched in the

fuel filter, drain the water from both the fuel filter

and fuel tank or use a water removing agent (or

anti-freeze solution) in the fuel tank.

Observe the instructions, notes, etc., indicated

on the label affixed to the anti-freeze solution (wa-

ter removing agent) container before use.

Trouble and possible cause Corrective action

1. Insufficient fuel supply to the injector

1) Fuel pump will not operate.

❍Defective terminal contact.Inspect connections, especially ground, and tighten

securely.

❍Trouble in electromagnetic or electronic circuit parts. Replace fuel pump.

2) Lowering of fuel pump function. Replace fuel pump.

3) Clogged dust or water in the fuel filter. Replace fuel filter, clean or replace fuel tank.

4) Clogged or bent fuel pipe or hose. Clean, correct or replace fuel pipe or hose.

5) Air is mixed in the fuel system. Inspect or retighten each connection part.

6) Clogged or bent breather tube or pipe. Clean, correct or replace air breather tube or pipe.

7) Damaged diaphragm of pressure regulator. Replace.

2. Leakage or blow out fuel

1) Loosened joints of the fuel pipe. Retightening.

2) Cracked fuel pipe, hose and fuel tank. Replace.

3) Defective welding part on the fuel tank. Replace.

4) Defective drain packing of the fuel tank. Replace.

5) Clogged or bent air breather tube or air vent tube.Clean, correct or replace air breather tube or air vent

tube.

3. Gasoline smell inside of compartment

1)Loose joints at air breather tube, air vent tube and fuel filler

pipe.Retightening.

2) Defective packing air tightness on the fuel saucer. Correct or replace packing.

3) Cracked fuel separator. Replace separator.

4) Inoperative fuel pump modulator or circuit. Replace.

4. Defective fuel meter indicator

1) Defective operation of fuel level sensor. Replace.

2) Defective operation of fuel meter. Replace.

5. Noise

1) Large operation noise or vibration of fuel pump. Replace.