torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1491 of 2870

ME(H4DOTC)-35

MECHANICAL

Engine Oil Pressure

6. Engine Oil Pressure

A: INSPECTION

1) Remove the oil pressure switch from engine cyl-

inder block.

2) Connect the oil pressure gauge hose to cylinder

block.

3) Connect the battery ground cable to battery.

4) Start the engine, and then measure the oil pres-

sure.

Oil pressure:

98 kPa (1.0 kg/cm

2, 14 psi) or more at 800 rpm

294 kPa (3.0 kg/cm2, 43 psi) or more at 5,000

rpm

If the oil pressure is out of specification, check oil

pump, oil filter and lubrication line.

System Trouble in General.>

If the oil pressure warning light is turned ON and

oil pressure is in specification, replace the oil pres-

sure switch.

NOTE:

The specified data is based on an engine oil tem-

perature of 80°C (176°F).

5) After measuring the oil pressure, install the oil

pressure switch.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

FU-00009

ME-00009

Page 1495 of 2870

ME(H4DOTC)-39

MECHANICAL

Valve Clearance

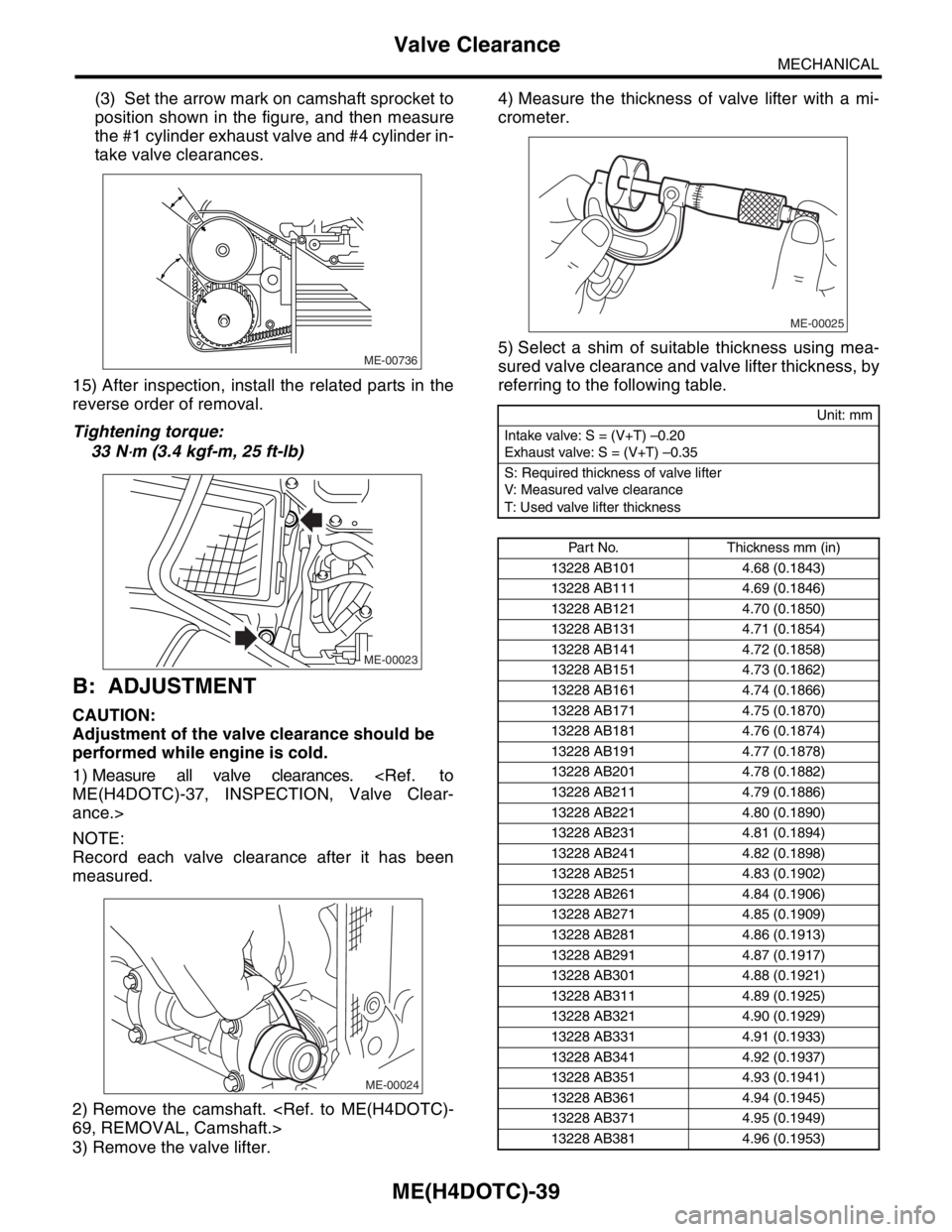

(3) Set the arrow mark on camshaft sprocket to

position shown in the figure, and then measure

the #1 cylinder exhaust valve and #4 cylinder in-

take valve clearances.

15) After inspection, install the related parts in the

reverse order of removal.

Tightening torque:

33 N

⋅m (3.4 kgf-m, 25 ft-lb)

B: ADJUSTMENT

CAUTION:

Adjustment of the valve clearance should be

performed while engine is cold.

1) Measure all valve clearances.

ance.>

NOTE:

Record each valve clearance after it has been

measured.

2) Remove the camshaft.

3) Remove the valve lifter.4) Measure the thickness of valve lifter with a mi-

crometer.

5) Select a shim of suitable thickness using mea-

sured valve clearance and valve lifter thickness, by

referring to the following table.

ME-00736

ME-00023

ME-00024

Unit: mm

Intake valve: S = (V+T) –0.20

Exhaust valve: S = (V+T) –0.35

S: Required thickness of valve lifter

V: Measured valve clearance

T: Used valve lifter thickness

Part No. Thickness mm (in)

13228 AB101 4.68 (0.1843)

13228 AB111 4.69 (0.1846)

13228 AB121 4.70 (0.1850)

13228 AB131 4.71 (0.1854)

13228 AB141 4.72 (0.1858)

13228 AB151 4.73 (0.1862)

13228 AB161 4.74 (0.1866)

13228 AB171 4.75 (0.1870)

13228 AB181 4.76 (0.1874)

13228 AB191 4.77 (0.1878)

13228 AB201 4.78 (0.1882)

13228 AB211 4.79 (0.1886)

13228 AB221 4.80 (0.1890)

13228 AB231 4.81 (0.1894)

13228 AB241 4.82 (0.1898)

13228 AB251 4.83 (0.1902)

13228 AB261 4.84 (0.1906)

13228 AB271 4.85 (0.1909)

13228 AB281 4.86 (0.1913)

13228 AB291 4.87 (0.1917)

13228 AB301 4.88 (0.1921)

13228 AB311 4.89 (0.1925)

13228 AB321 4.90 (0.1929)

13228 AB331 4.91 (0.1933)

13228 AB341 4.92 (0.1937)

13228 AB351 4.93 (0.1941)

13228 AB361 4.94 (0.1945)

13228 AB371 4.95 (0.1949)

13228 AB381 4.96 (0.1953)

ME-00025

Page 1502 of 2870

ME(H4DOTC)-44

MECHANICAL

Engine Assembly

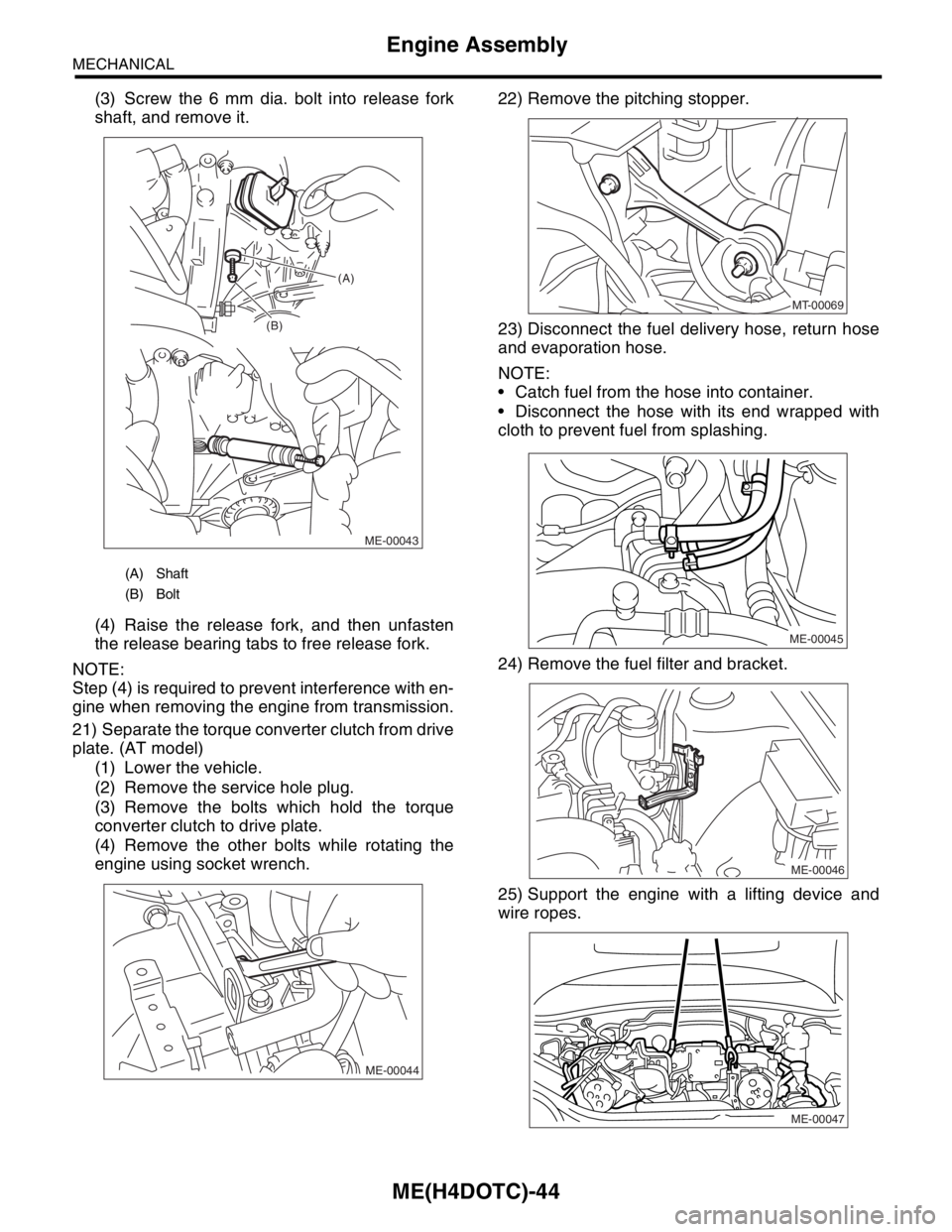

(3) Screw the 6 mm dia. bolt into release fork

shaft, and remove it.

(4) Raise the release fork, and then unfasten

the release bearing tabs to free release fork.

NOTE:

Step (4) is required to prevent interference with en-

gine when removing the engine from transmission.

21) Separate the torque converter clutch from drive

plate. (AT model)

(1) Lower the vehicle.

(2) Remove the service hole plug.

(3) Remove the bolts which hold the torque

converter clutch to drive plate.

(4) Remove the other bolts while rotating the

engine using socket wrench.22) Remove the pitching stopper.

23) Disconnect the fuel delivery hose, return hose

and evaporation hose.

NOTE:

Catch fuel from the hose into container.

Disconnect the hose with its end wrapped with

cloth to prevent fuel from splashing.

24) Remove the fuel filter and bracket.

25) Support the engine with a lifting device and

wire ropes.

(A) Shaft

(B) Bolt

ME-00043 (B)(A)

ME-00044

MT-00069

ME-00045

ME-00046

ME-00047

Page 1503 of 2870

ME(H4DOTC)-45

MECHANICAL

Engine Assembly

26) Support the transmission with a garage jack.

NOTE:

Before moving the engine away from transmission,

check to be sure no work has been overlooked. Do-

ing this is very important in order to facilitate re-in-

stallation and because transmission lowers under

its own weight.

27) Separation of the engine and transmission.

(1) Remove the starter.

(2) Install the ST to torque converter clutch

case. (AT model)

ST 498277200 STOPPER SET

(3) Remove the bolts which hold the right upper

side of transmission to engine.

28) Remove the engine from vehicle.

(1) Slightly raise the engine.

(2) Raise the transmission with garage jack.

(3) Move the engine horizontally until the main-

shaft is withdrawn from clutch cover.

(4) Slowly move the engine away from engine

compartment.NOTE:

Be careful not to damage adjacent parts or body

panels with crank pulley, oil pressure gauge, etc.

29) Remove the front cushion rubbers.

B: INSTALLATION

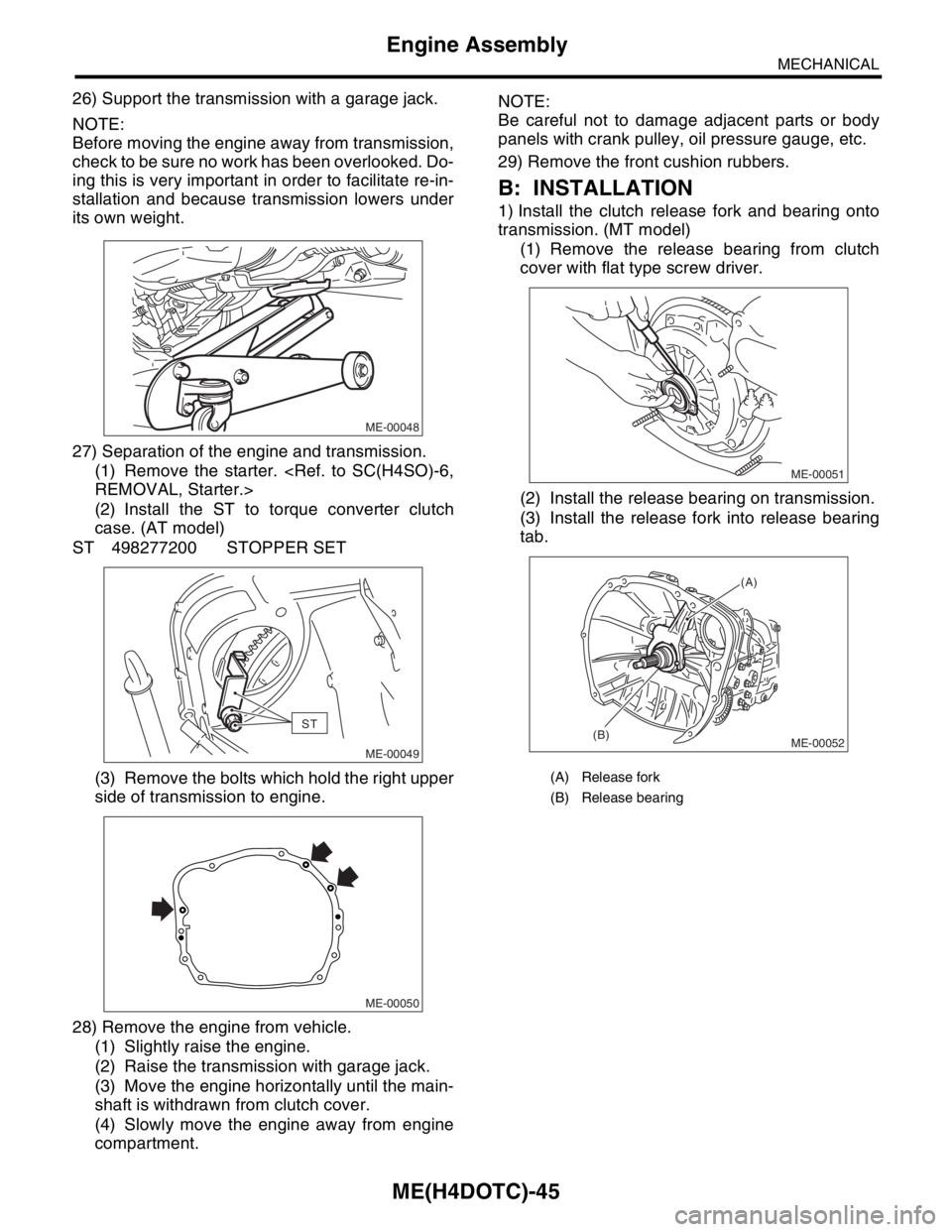

1) Install the clutch release fork and bearing onto

transmission. (MT model)

(1) Remove the release bearing from clutch

cover with flat type screw driver.

(2) Install the release bearing on transmission.

(3) Install the release fork into release bearing

tab.

ME-00048

ST

ME-00049

ME-00050

(A) Release fork

(B) Release bearing

ME-00051

ME-00052

(A)

(B)

Page 1504 of 2870

ME(H4DOTC)-46

MECHANICAL

Engine Assembly

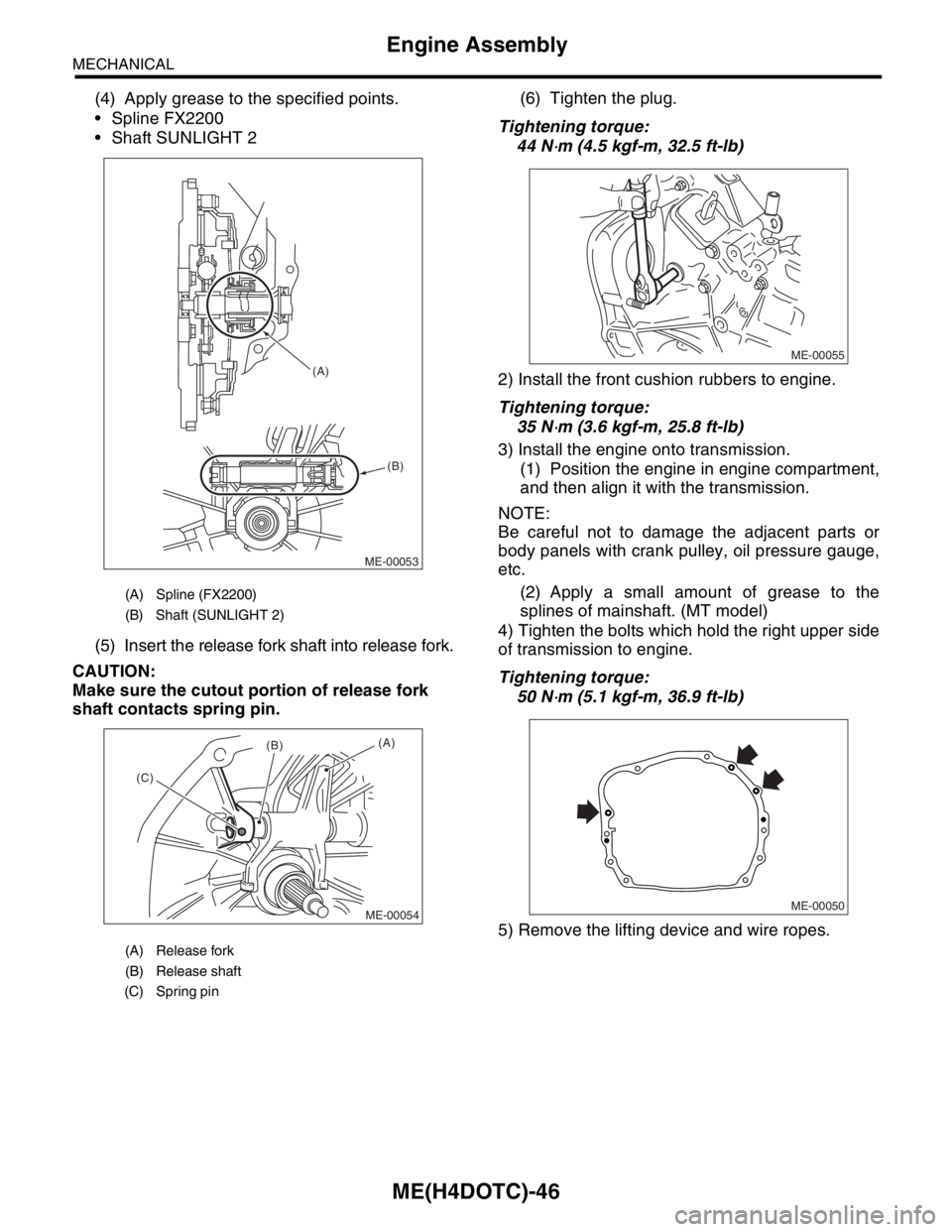

(4) Apply grease to the specified points.

Spline FX2200

Shaft SUNLIGHT 2

(5) Insert the release fork shaft into release fork.

CAUTION:

Make sure the cutout portion of release fork

shaft contacts spring pin.(6) Tighten the plug.

Tightening torque:

44 N

⋅m (4.5 kgf-m, 32.5 ft-lb)

2) Install the front cushion rubbers to engine.

Tightening torque:

35 N

⋅m (3.6 kgf-m, 25.8 ft-lb)

3) Install the engine onto transmission.

(1) Position the engine in engine compartment,

and then align it with the transmission.

NOTE:

Be careful not to damage the adjacent parts or

body panels with crank pulley, oil pressure gauge,

etc.

(2) Apply a small amount of grease to the

splines of mainshaft. (MT model)

4) Tighten the bolts which hold the right upper side

of transmission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

5) Remove the lifting device and wire ropes.

(A) Spline (FX2200)

(B) Shaft (SUNLIGHT 2)

(A) Release fork

(B) Release shaft

(C) Spring pin

ME-00053 (A)

(B)

ME-00054

(A)(B)

(C)ME-00055

ME-00050

Page 1505 of 2870

ME(H4DOTC)-47

MECHANICAL

Engine Assembly

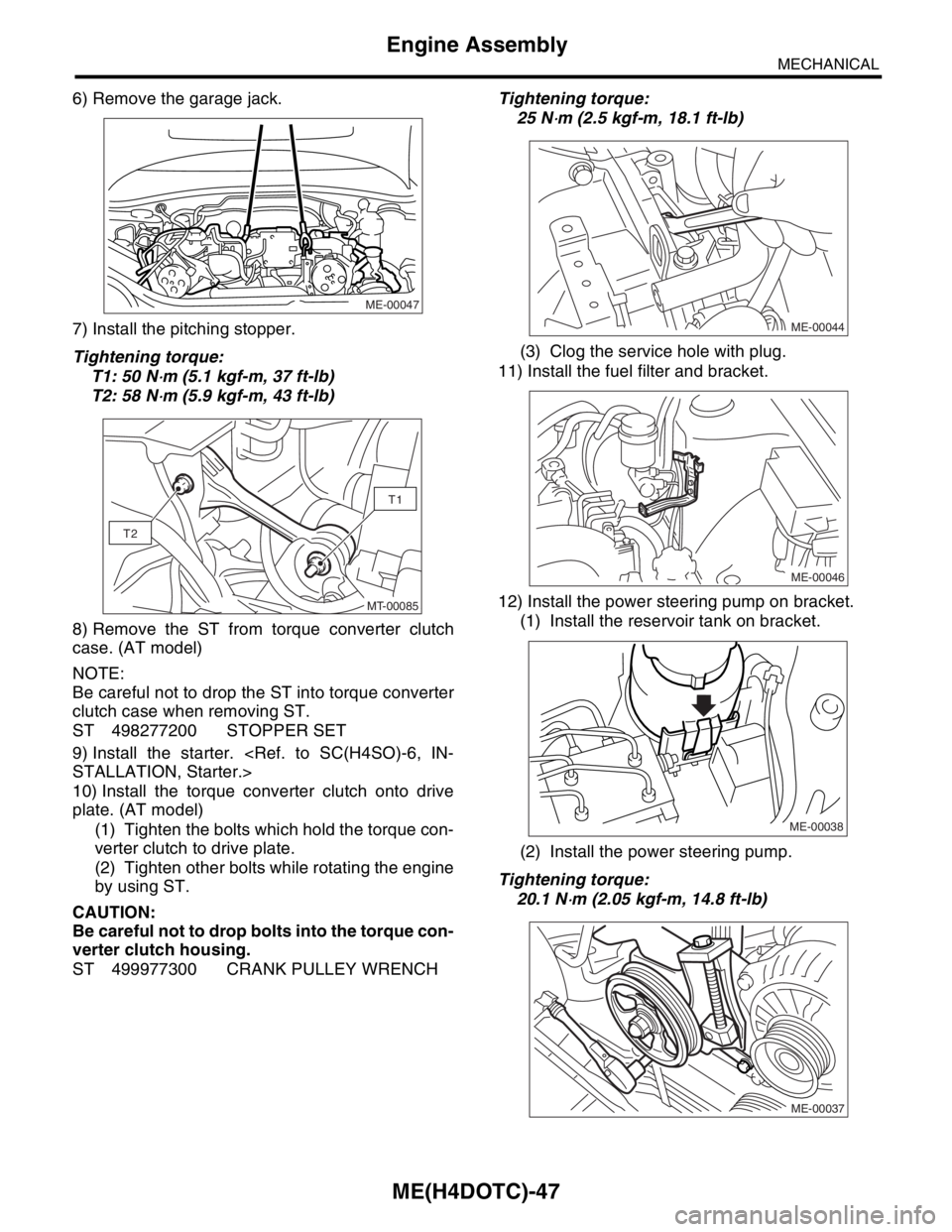

6) Remove the garage jack.

7) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

8) Remove the ST from torque converter clutch

case. (AT model)

NOTE:

Be careful not to drop the ST into torque converter

clutch case when removing ST.

ST 498277200 STOPPER SET

9) Install the starter.

10) Install the torque converter clutch onto drive

plate. (AT model)

(1) Tighten the bolts which hold the torque con-

verter clutch to drive plate.

(2) Tighten other bolts while rotating the engine

by using ST.

CAUTION:

Be careful not to drop bolts into the torque con-

verter clutch housing.

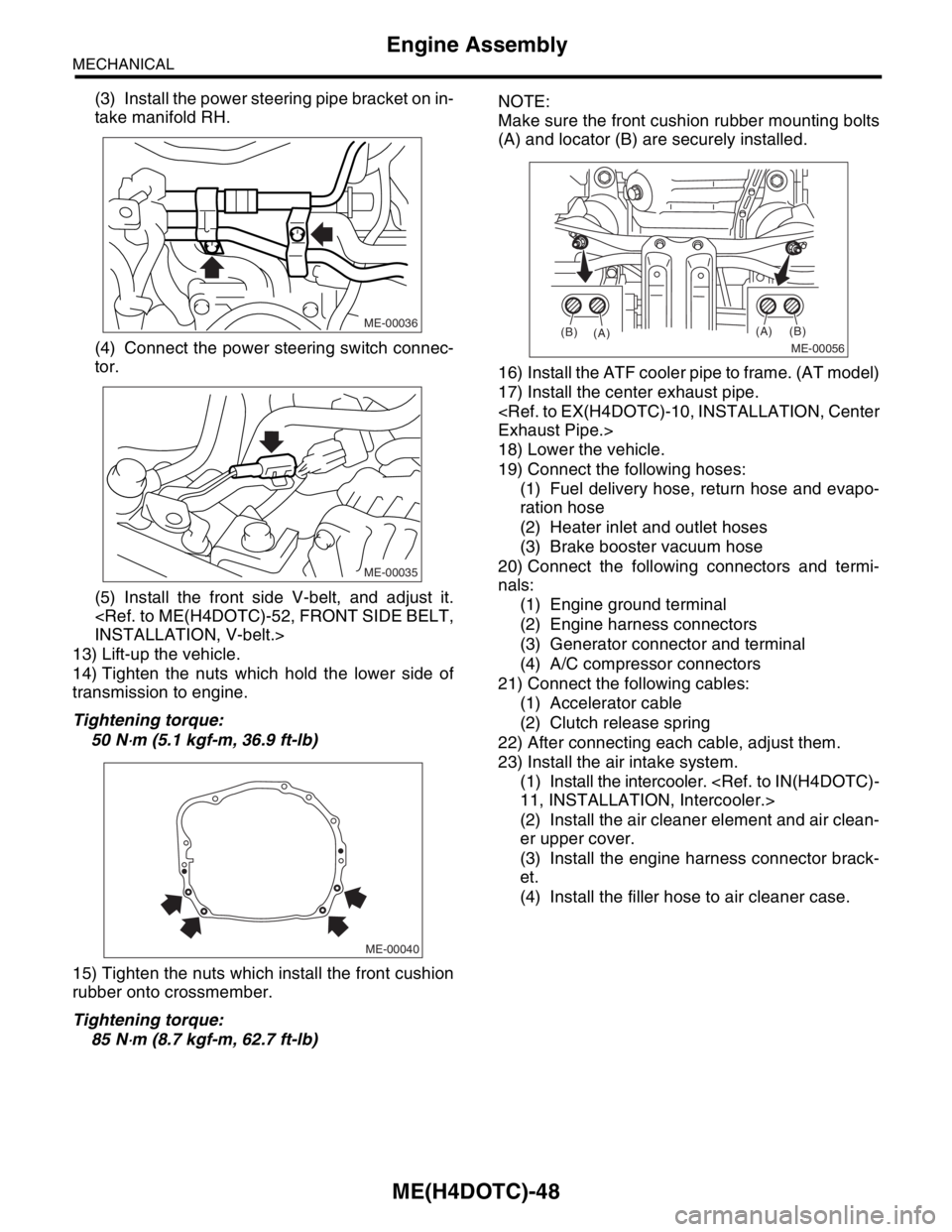

ST 499977300 CRANK PULLEY WRENCHTightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(3) Clog the service hole with plug.

11) Install the fuel filter and bracket.

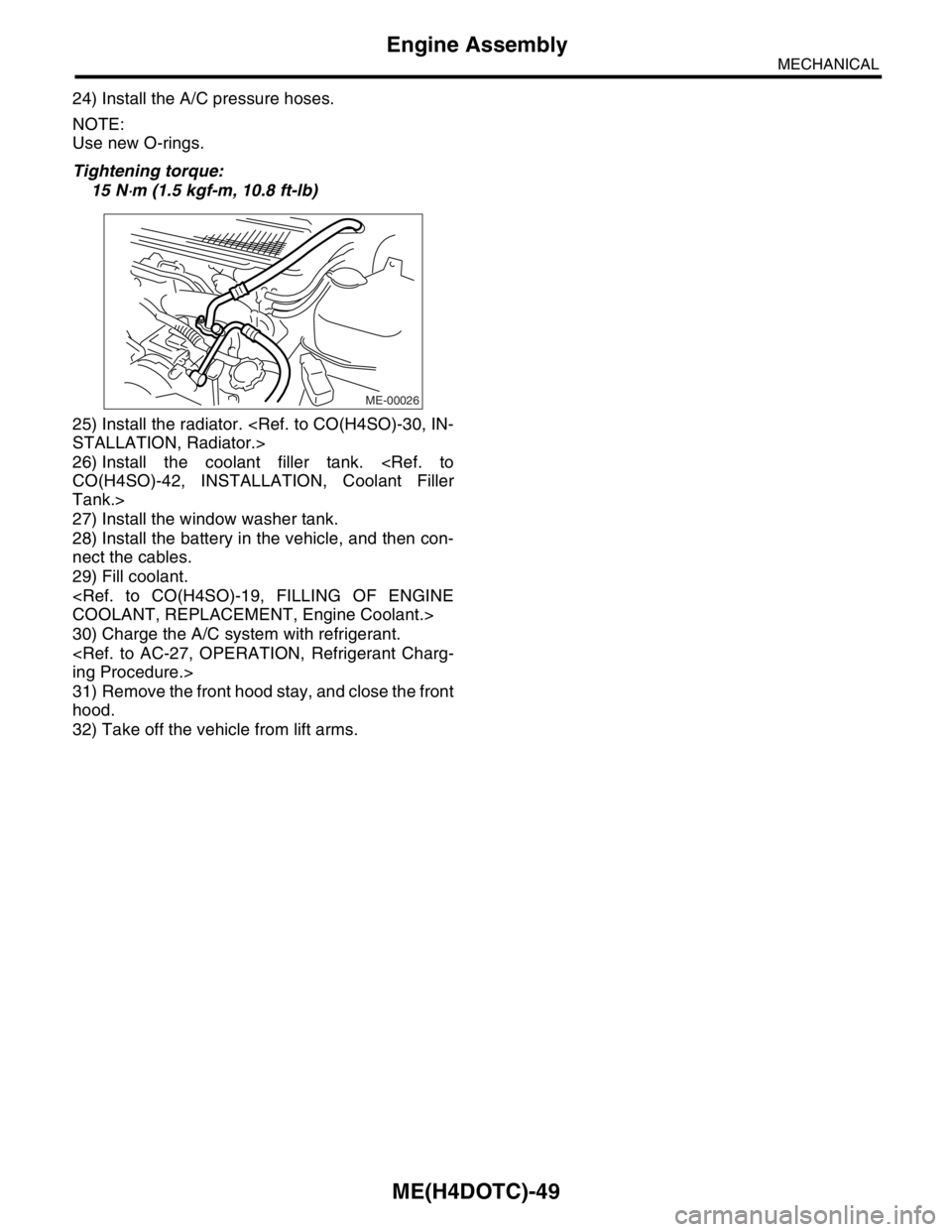

12) Install the power steering pump on bracket.

(1) Install the reservoir tank on bracket.

(2) Install the power steering pump.

Tightening torque:

20.1 N

⋅m (2.05 kgf-m, 14.8 ft-lb)

ME-00047

T1

T2

MT-00085ME-00044

ME-00046

ME-00038

ME-00037

Page 1506 of 2870

ME(H4DOTC)-48

MECHANICAL

Engine Assembly

(3) Install the power steering pipe bracket on in-

take manifold RH.

(4) Connect the power steering switch connec-

tor.

(5) Install the front side V-belt, and adjust it.

13) Lift-up the vehicle.

14) Tighten the nuts which hold the lower side of

transmission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

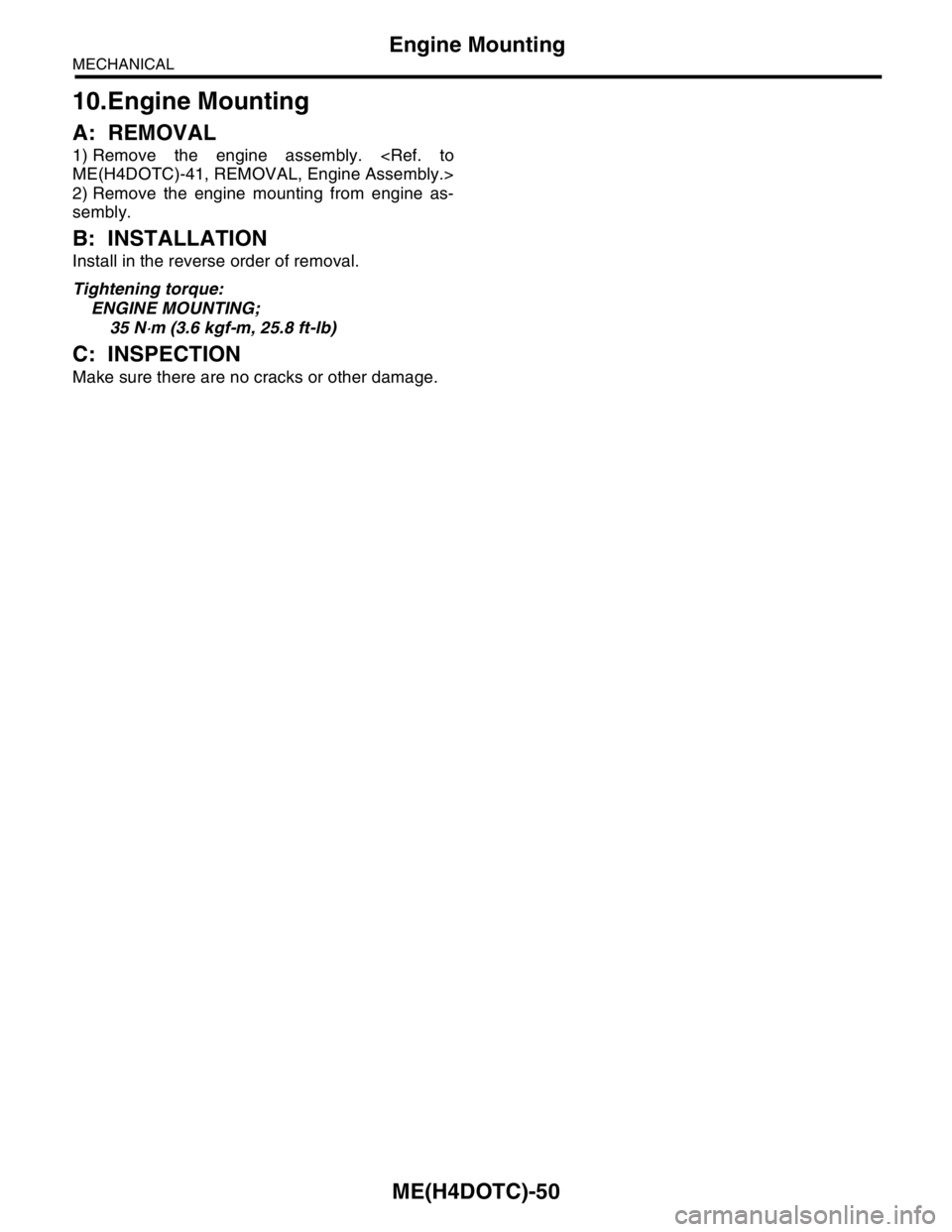

15) Tighten the nuts which install the front cushion

rubber onto crossmember.

Tightening torque:

85 N

⋅m (8.7 kgf-m, 62.7 ft-lb)NOTE:

Make sure the front cushion rubber mounting bolts

(A) and locator (B) are securely installed.

16) Install the ATF cooler pipe to frame. (AT model)

17) Install the center exhaust pipe.

18) Lower the vehicle.

19) Connect the following hoses:

(1) Fuel delivery hose, return hose and evapo-

ration hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

20) Connect the following connectors and termi-

nals:

(1) Engine ground terminal

(2) Engine harness connectors

(3) Generator connector and terminal

(4) A/C compressor connectors

21) Connect the following cables:

(1) Accelerator cable

(2) Clutch release spring

22) After connecting each cable, adjust them.

23) Install the air intake system.

(1) Install the intercooler.

(2) Install the air cleaner element and air clean-

er upper cover.

(3) Install the engine harness connector brack-

et.

(4) Install the filler hose to air cleaner case.

ME-00036

ME-00035

ME-00040

ME-00056

(A)

(A)(B)

(B)

Page 1507 of 2870

ME(H4DOTC)-49

MECHANICAL

Engine Assembly

24) Install the A/C pressure hoses.

NOTE:

Use new O-rings.

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

25) Install the radiator.

26) Install the coolant filler tank.

Tank.>

27) Install the window washer tank.

28) Install the battery in the vehicle, and then con-

nect the cables.

29) Fill coolant.

30) Charge the A/C system with refrigerant.

31) Remove the front hood stay, and close the front

hood.

32) Take off the vehicle from lift arms.

ME-00026

Page 1508 of 2870

ME(H4DOTC)-50

MECHANICAL

Engine Mounting

10.Engine Mounting

A: REMOVAL

1) Remove the engine assembly.

2) Remove the engine mounting from engine as-

sembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

ENGINE MOUNTING;

35 N

⋅m (3.6 kgf-m, 25.8 ft-lb)

C: INSPECTION

Make sure there are no cracks or other damage.

Page 1510 of 2870

ME(H4DOTC)-52

MECHANICAL

V-belt

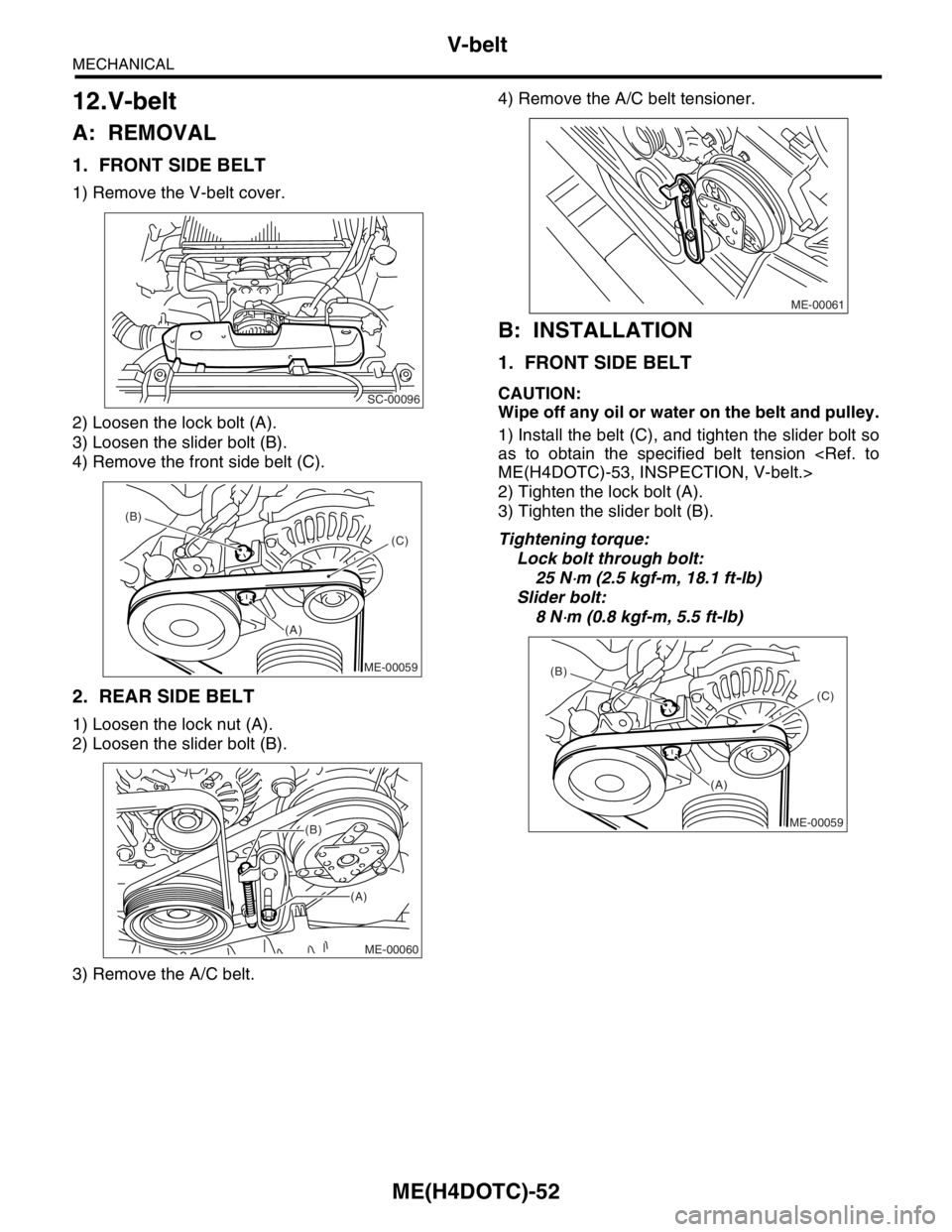

12.V-belt

A: REMOVAL

1. FRONT SIDE BELT

1) Remove the V-belt cover.

2) Loosen the lock bolt (A).

3) Loosen the slider bolt (B).

4) Remove the front side belt (C).

2. REAR SIDE BELT

1) Loosen the lock nut (A).

2) Loosen the slider bolt (B).

3) Remove the A/C belt.4) Remove the A/C belt tensioner.

B: INSTALLATION

1. FRONT SIDE BELT

CAUTION:

Wipe off any oil or water on the belt and pulley.

1) Install the belt (C), and tighten the slider bolt so

as to obtain the specified belt tension

2) Tighten the lock bolt (A).

3) Tighten the slider bolt (B).

Tightening torque:

Lock bolt through bolt:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

Slider bolt:

8 N

⋅m (0.8 kgf-m, 5.5 ft-lb)

SC-00096

(A)

(C) (B)

ME-00059

(A)

(B)

ME-00060

ME-00061

(A)

(C) (B)

ME-00059