torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1511 of 2870

ME(H4DOTC)-53

MECHANICAL

V-belt

2. REAR SIDE BELT

1) Install the belt, and tighten the slider bolt (B) so

as to obtain the specified belt tension.

2) Tighten the lock nut (A).

Tightening torque:

Lock nut (A);

22.6 N

⋅m (2.3 kgf-m, 16.6 ft-lb)

C: INSPECTION

1) Replace the belts, if cracks, fraying or wear is

found.

2) Check the drive belt tension and adjust it if nec-

essary by changing generator installing position

and/or idler pulley installing position.

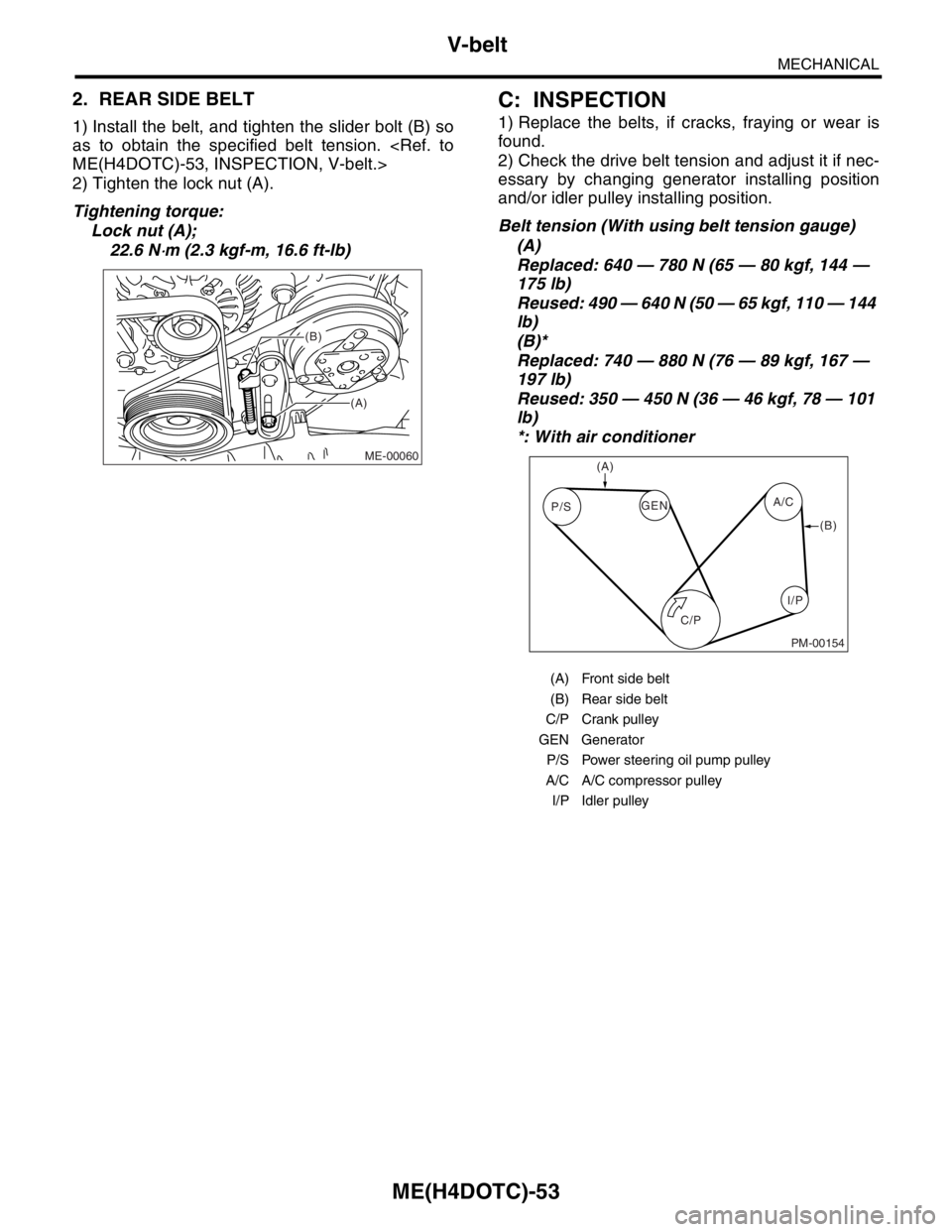

Belt tension (With using belt tension gauge)

(A)

Replaced: 640 — 780 N (65 — 80 kgf, 144 —

175 lb)

Reused: 490 — 640 N (50 — 65 kgf, 110 — 144

lb)

(B)*

Replaced: 740 — 880 N (76 — 89 kgf, 167 —

197 lb)

Reused: 350 — 450 N (36 — 46 kgf, 78 — 101

lb)

*: With air conditioner

(A)

(B)

ME-00060

(A) Front side belt

(B) Rear side belt

C/P Crank pulley

GEN Generator

P/S Power steering oil pump pulley

A/C A/C compressor pulley

I/P Idler pulley

C/P P/SA/C

GEN

(A)

(B)

I/P

PM-00154

Page 1513 of 2870

ME(H4DOTC)-55

MECHANICAL

Crank Pulley

13.Crank Pulley

A: REMOVAL

1) Remove the V-belt.

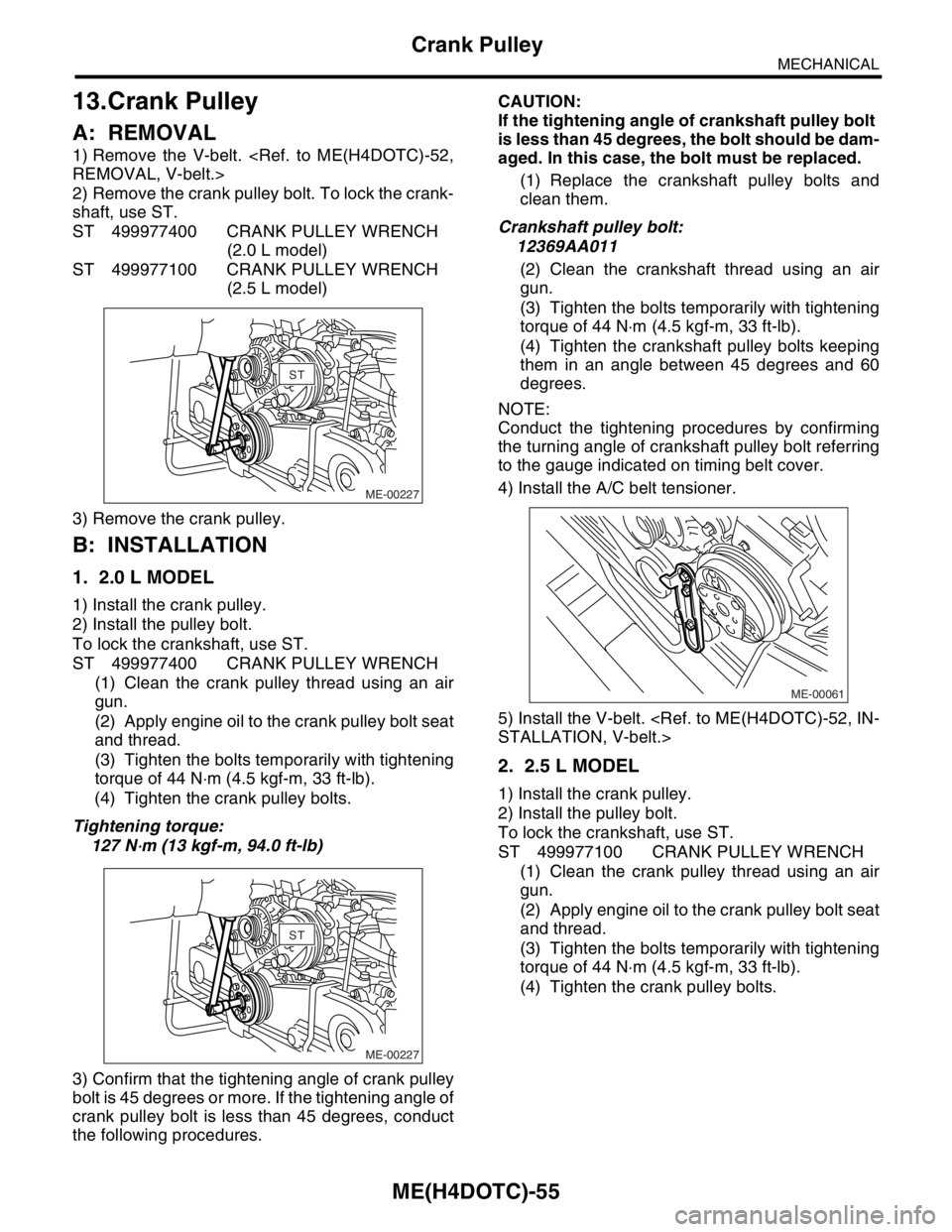

2) Remove the crank pulley bolt. To lock the crank-

shaft, use ST.

ST 499977400 CRANK PULLEY WRENCH

(2.0 L model)

ST 499977100 CRANK PULLEY WRENCH

(2.5 L model)

3) Remove the crank pulley.

B: INSTALLATION

1. 2.0 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

To lock the crankshaft, use ST.

ST 499977400 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

Tightening torque:

127 N

⋅m (13 kgf-m, 94.0 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 45 degrees or more. If the tightening angle of

crank pulley bolt is less than 45 degrees, conduct

the following procedures.CAUTION:

If the tightening angle of crankshaft pulley bolt

is less than 45 degrees, the bolt should be dam-

aged. In this case, the bolt must be replaced.

(1) Replace the crankshaft pulley bolts and

clean them.

Crankshaft pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crankshaft pulley bolts keeping

them in an angle between 45 degrees and 60

degrees.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crankshaft pulley bolt referring

to the gauge indicated on timing belt cover.

4) Install the A/C belt tensioner.

5) Install the V-belt.

2. 2.5 L MODEL

1) Install the crank pulley.

2) Install the pulley bolt.

To lock the crankshaft, use ST.

ST 499977100 CRANK PULLEY WRENCH

(1) Clean the crank pulley thread using an air

gun.

(2) Apply engine oil to the crank pulley bolt seat

and thread.

(3) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(4) Tighten the crank pulley bolts.

ME-00227

STST

ME-00227

STST

ME-00061

Page 1514 of 2870

ME(H4DOTC)-56

MECHANICAL

Crank Pulley

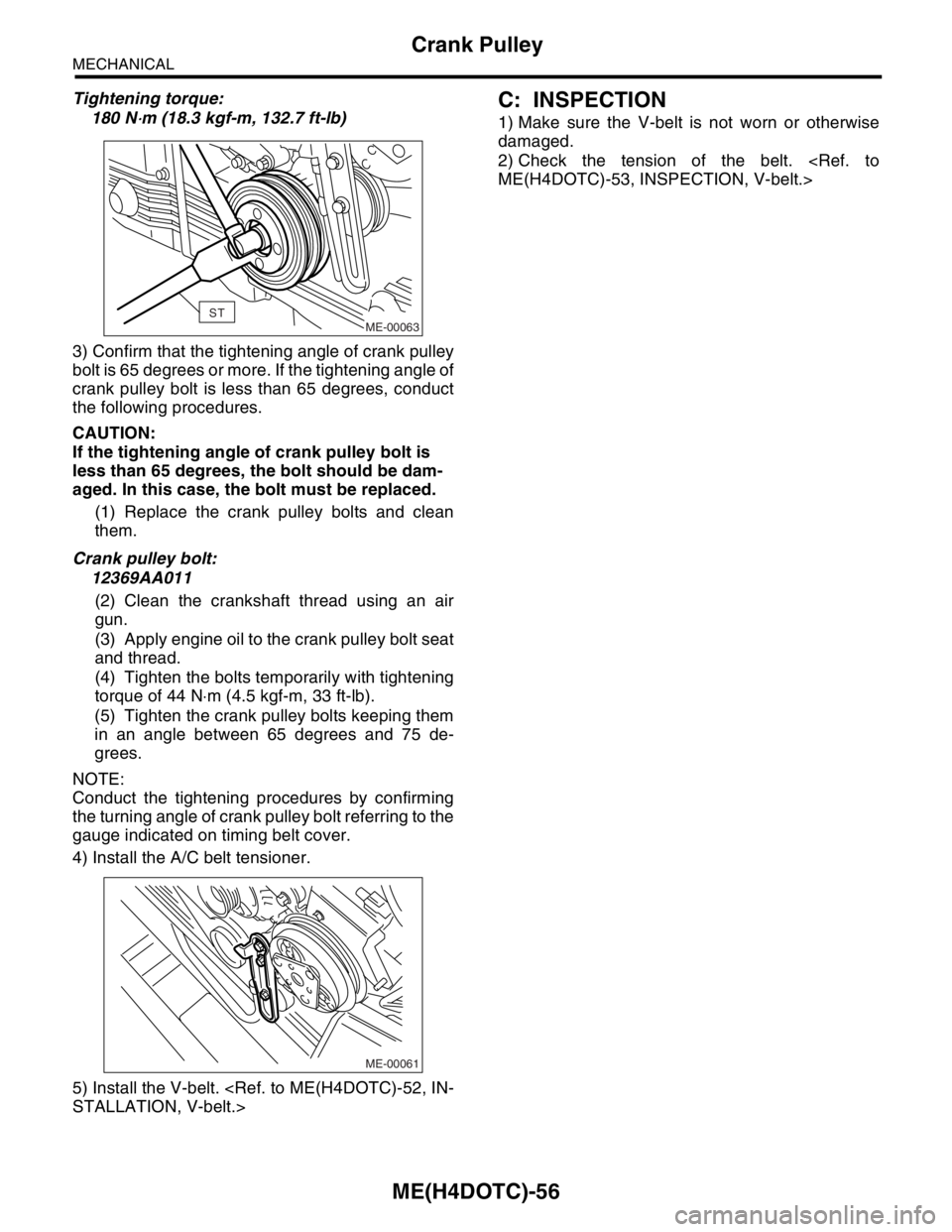

Tightening torque:

180 N

⋅m (18.3 kgf-m, 132.7 ft-lb)

3) Confirm that the tightening angle of crank pulley

bolt is 65 degrees or more. If the tightening angle of

crank pulley bolt is less than 65 degrees, conduct

the following procedures.

CAUTION:

If the tightening angle of crank pulley bolt is

less than 65 degrees, the bolt should be dam-

aged. In this case, the bolt must be replaced.

(1) Replace the crank pulley bolts and clean

them.

Crank pulley bolt:

12369AA011

(2) Clean the crankshaft thread using an air

gun.

(3) Apply engine oil to the crank pulley bolt seat

and thread.

(4) Tighten the bolts temporarily with tightening

torque of 44 N⋅m (4.5 kgf-m, 33 ft-lb).

(5) Tighten the crank pulley bolts keeping them

in an angle between 65 degrees and 75 de-

grees.

NOTE:

Conduct the tightening procedures by confirming

the turning angle of crank pulley bolt referring to the

gauge indicated on timing belt cover.

4) Install the A/C belt tensioner.

5) Install the V-belt.

C: INSPECTION

1) Make sure the V-belt is not worn or otherwise

damaged.

2) Check the tension of the belt.

ME-00063ST

ME-00061

Page 1515 of 2870

ME(H4DOTC)-57

MECHANICAL

Timing Belt Cover

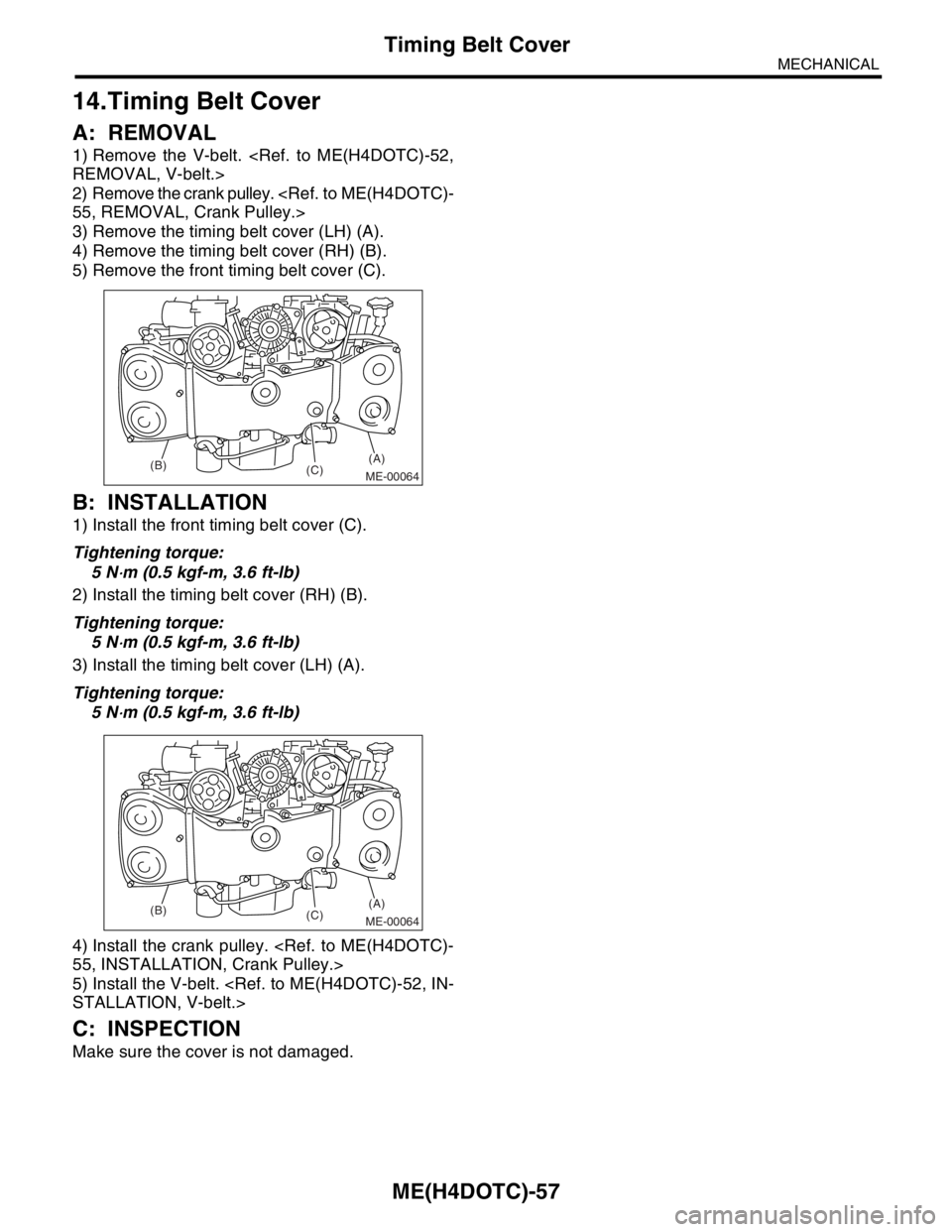

14.Timing Belt Cover

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover (LH) (A).

4) Remove the timing belt cover (RH) (B).

5) Remove the front timing belt cover (C).

B: INSTALLATION

1) Install the front timing belt cover (C).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

2) Install the timing belt cover (RH) (B).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

3) Install the timing belt cover (LH) (A).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

4) Install the crank pulley.

5) Install the V-belt.

C: INSPECTION

Make sure the cover is not damaged.

ME-00064

(A)

(C) (B)

ME-00064

(A)

(C) (B)

Page 1518 of 2870

ME(H4DOTC)-60

MECHANICAL

Timing Belt Assembly

Do not release the press pressure until stopper

pin is completely inserted.

(1) Attach the automatic belt tension adjuster

assembly to the vertical pressing tool.

(2) Slowly move the adjuster rod down with a

pressure of 294 N (30 kgf, 66 lb) until the adjust-

er rod is aligned with the stopper pin hole in the

cylinder.

(3) With a 2 mm (0.08 in) dia. stopper pin or a 2

mm (0.08 in) (nominal) dia. hex bar wrench in-

serted into the stopper pin hole in the cylinder,

secure the adjuster rod.

2) Install the automatic belt tension adjuster as-

sembly.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)3) Install the belt idler No. 2.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

4) Install the belt idler.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

2. TIMING BELT

1) Preparation for installation of automatic belt ten-

sion adjuster assembly.

SEMBLY AND BELT IDLER, INSTALLATION,

Timing Belt Assembly.>

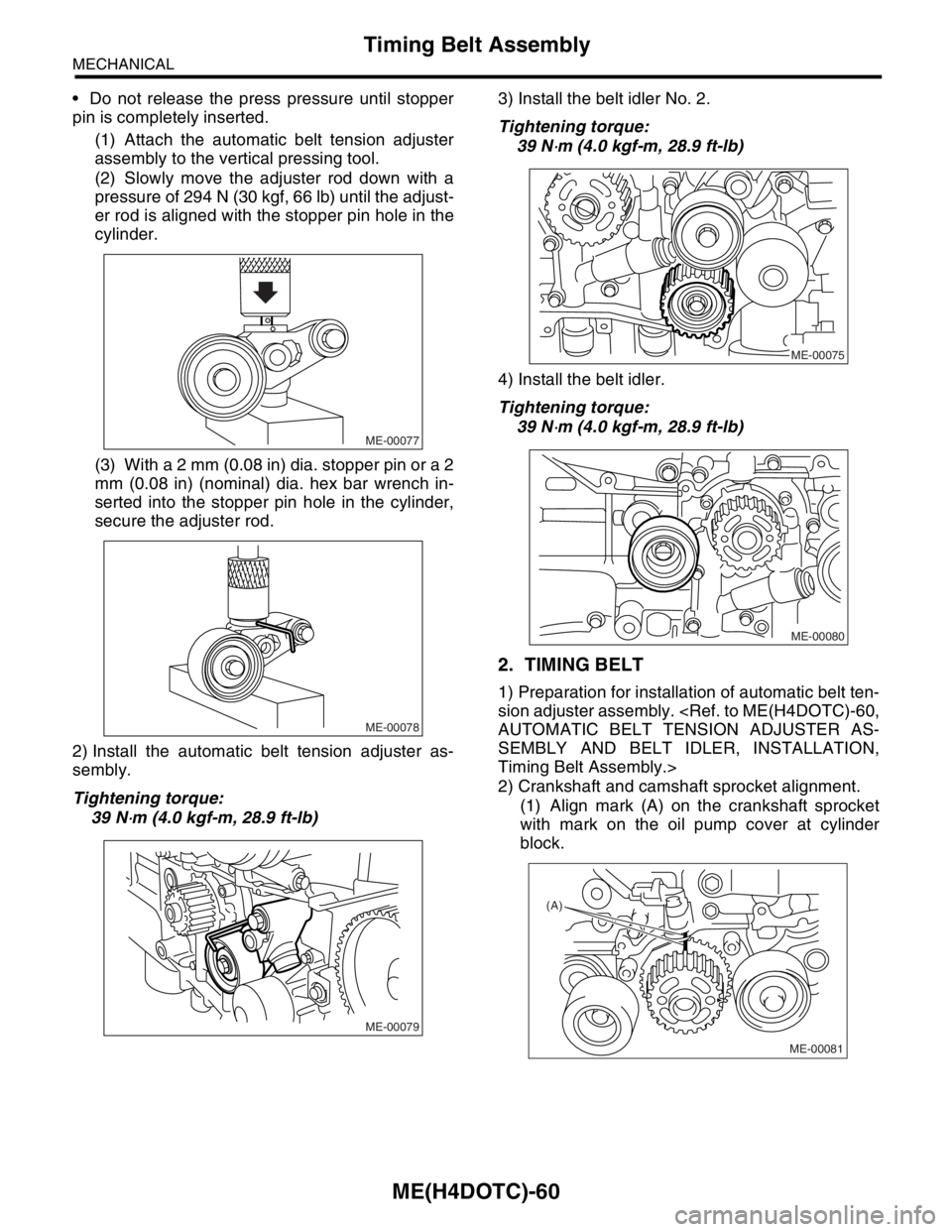

2) Crankshaft and camshaft sprocket alignment.

(1) Align mark (A) on the crankshaft sprocket

with mark on the oil pump cover at cylinder

block.

ME-00077

ME-00078

ME-00079

ME-00075

ME-00080

(A)

ME-00081

Page 1521 of 2870

ME(H4DOTC)-63

MECHANICAL

Timing Belt Assembly

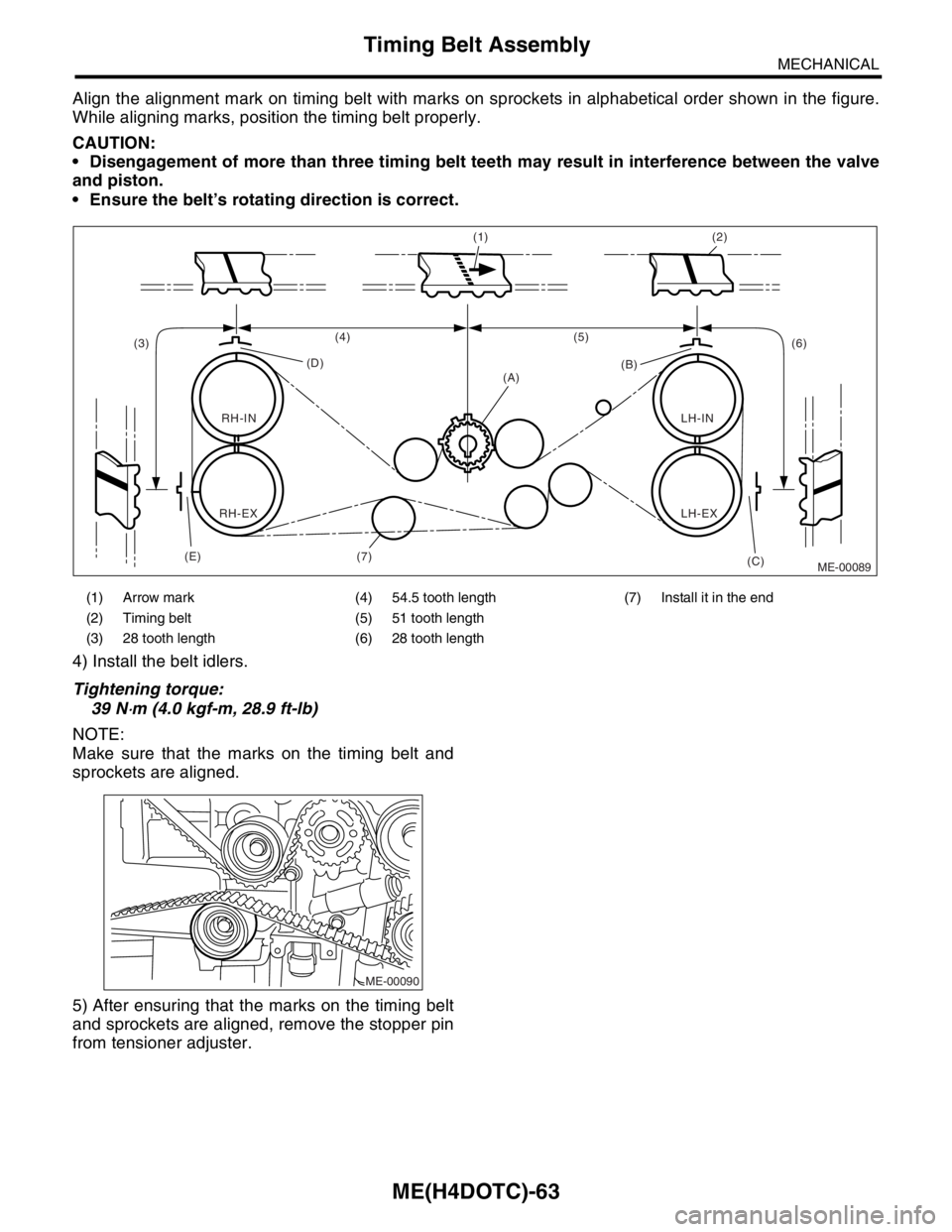

Align the alignment mark on timing belt with marks on sprockets in alphabetical order shown in the figure.

While aligning marks, position the timing belt properly.

CAUTION:

Disengagement of more than three timing belt teeth may result in interference between the valve

and piston.

Ensure the belt’s rotating direction is correct.

4) Install the belt idlers.

Tightening torque:

39 N

⋅m (4.0 kgf-m, 28.9 ft-lb)

NOTE:

Make sure that the marks on the timing belt and

sprockets are aligned.

5) After ensuring that the marks on the timing belt

and sprockets are aligned, remove the stopper pin

from tensioner adjuster.

(1) Arrow mark (4) 54.5 tooth length (7) Install it in the end

(2) Timing belt (5) 51 tooth length

(3) 28 tooth length (6) 28 tooth length

ME-00089 (1) (2)

(5)

(6) (4)

(D)

(A)

(C) (B)

(E) (3)

RH-IN

RH-EXLH-EX LH-IN

(7)

ME-00090

Page 1522 of 2870

ME(H4DOTC)-64

MECHANICAL

Timing Belt Assembly

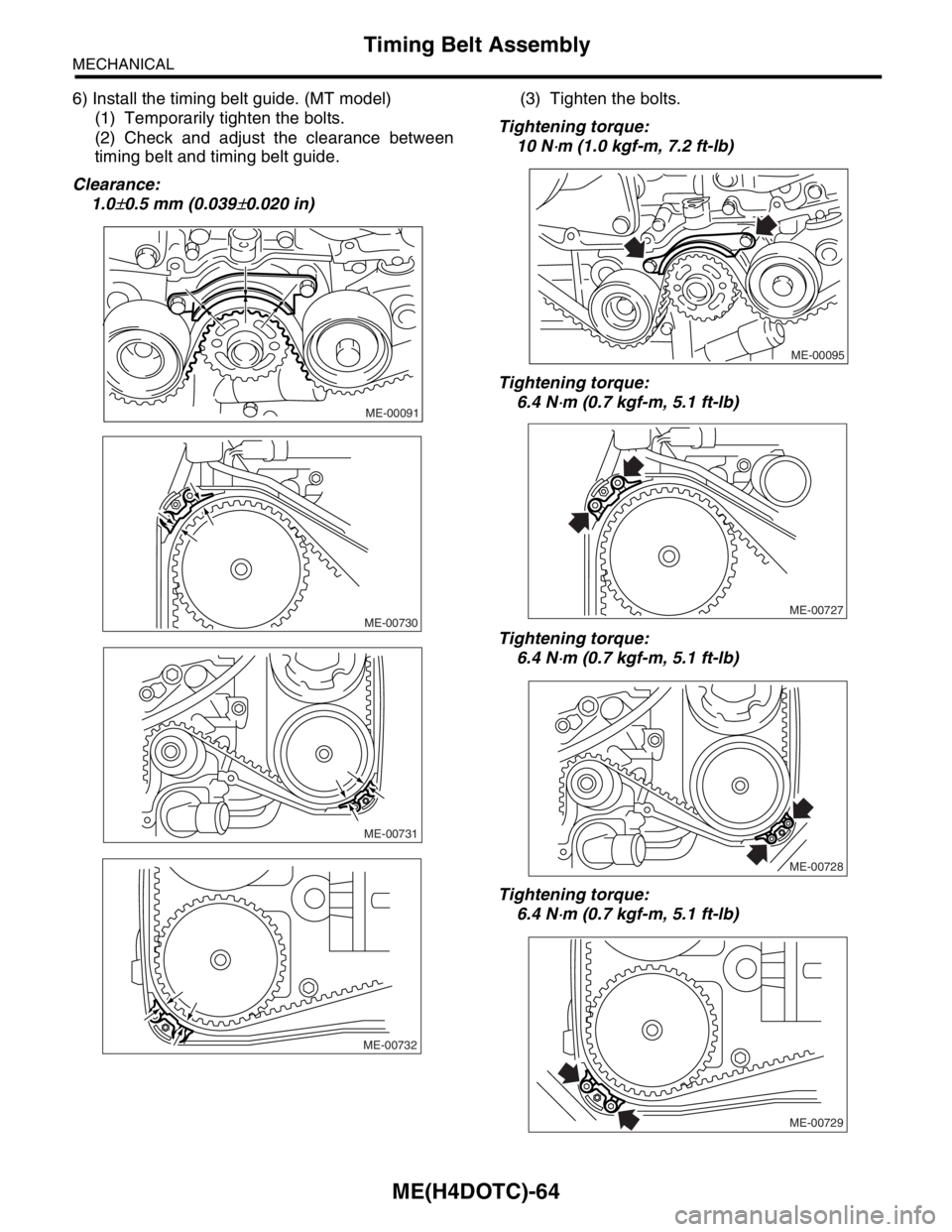

6) Install the timing belt guide. (MT model)

(1) Temporarily tighten the bolts.

(2) Check and adjust the clearance between

timing belt and timing belt guide.

Clearance:

1.0

±0.5 mm (0.039±0.020 in)(3) Tighten the bolts.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

Tightening torque:

6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

Tightening torque:

6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

Tightening torque:

6.4 N

⋅m (0.7 kgf-m, 5.1 ft-lb)

ME-00091

ME-00730

ME-00731

ME-00732

ME-00095

ME-00727

ME-00728

ME-00729

Page 1524 of 2870

ME(H4DOTC)-66

MECHANICAL

Cam Sprocket

16.Cam Sprocket

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt assembly.

bly.>

5) Remove the camshaft position sensor. (2.0 L

model)

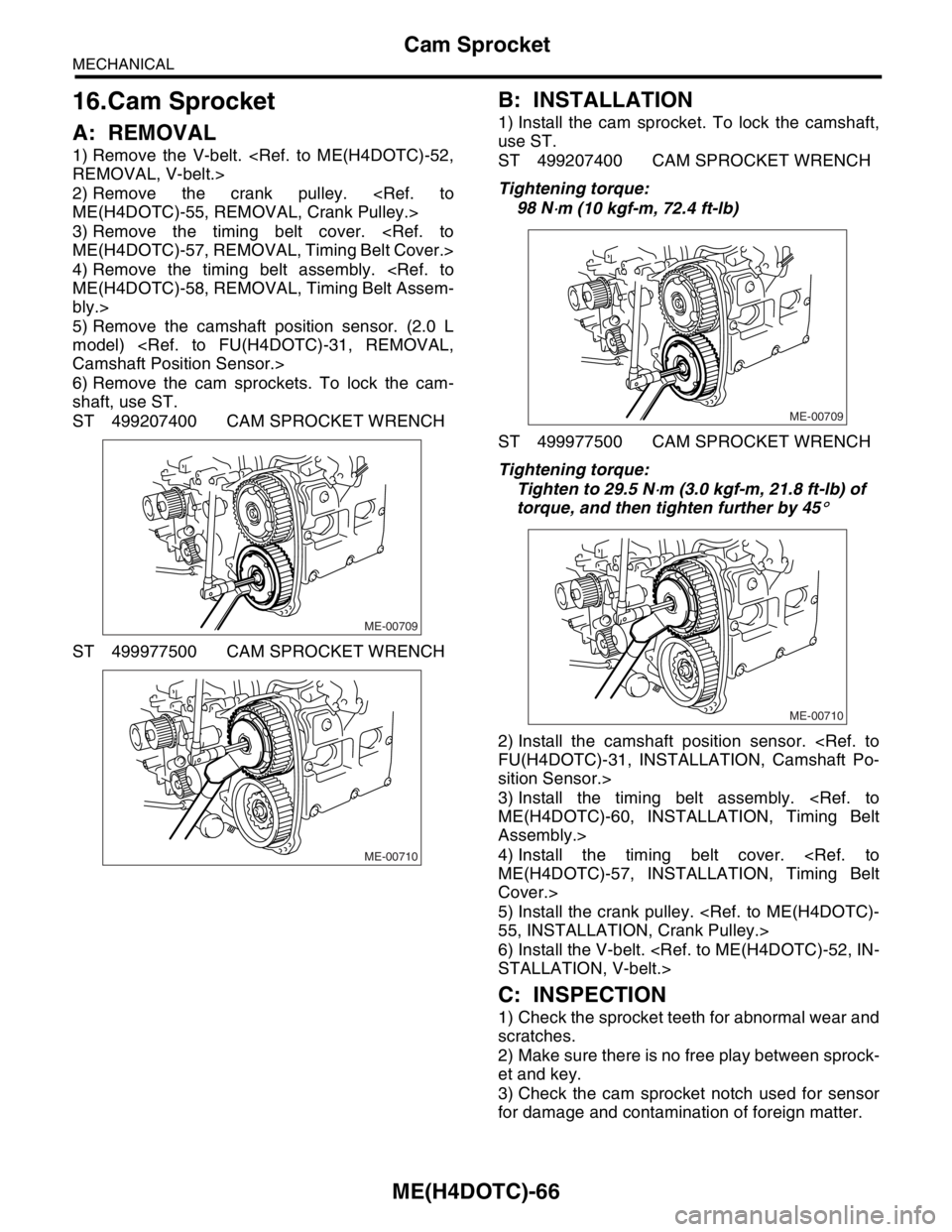

6) Remove the cam sprockets. To lock the cam-

shaft, use ST.

ST 499207400 CAM SPROCKET WRENCH

ST 499977500 CAM SPROCKET WRENCH

B: INSTALLATION

1) Install the cam sprocket. To lock the camshaft,

use ST.

ST 499207400 CAM SPROCKET WRENCH

Tightening torque:

98 N

⋅m (10 kgf-m, 72.4 ft-lb)

ST 499977500 CAM SPROCKET WRENCH

Tightening torque:

Tighten to 29.5 N

⋅m (3.0 kgf-m, 21.8 ft-lb) of

torque, and then tighten further by 45

°

2) Install the camshaft position sensor.

sition Sensor.>

3) Install the timing belt assembly.

Assembly.>

4) Install the timing belt cover.

Cover.>

5) Install the crank pulley.

6) Install the V-belt.

C: INSPECTION

1) Check the sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between sprock-

et and key.

3) Check the cam sprocket notch used for sensor

for damage and contamination of foreign matter.

ME-00709

ME-00710

ME-00709

ME-00710

Page 1528 of 2870

ME(H4DOTC)-70

MECHANICAL

Camshaft

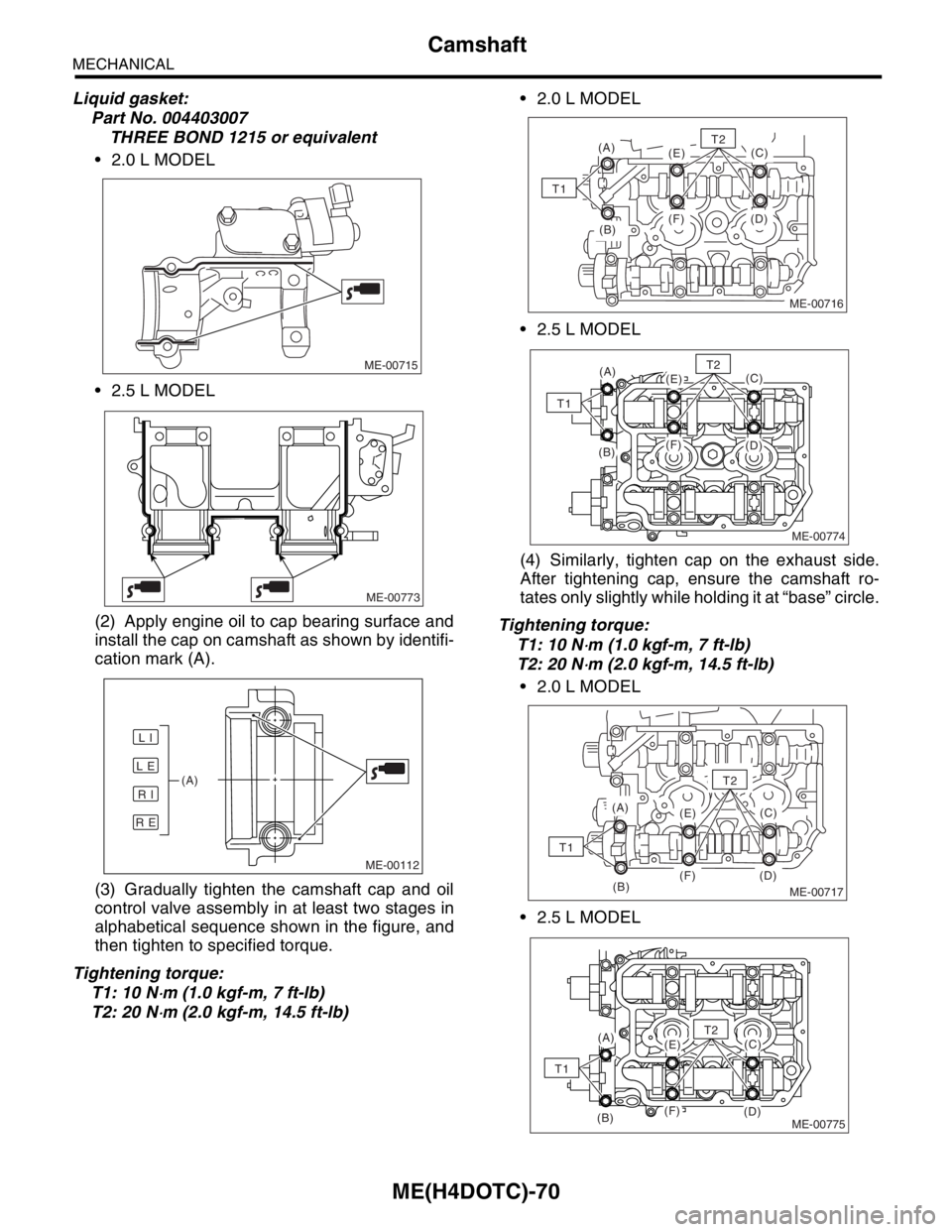

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

2.0 L MODEL

2.5 L MODEL

(2) Apply engine oil to cap bearing surface and

install the cap on camshaft as shown by identifi-

cation mark (A).

(3) Gradually tighten the camshaft cap and oil

control valve assembly in at least two stages in

alphabetical sequence shown in the figure, and

then tighten to specified torque.

Tightening torque:

T1: 10 N

⋅m (1.0 kgf-m, 7 ft-lb)

T2: 20 N

⋅m (2.0 kgf-m, 14.5 ft-lb) 2.0 L MODEL

2.5 L MODEL

(4) Similarly, tighten cap on the exhaust side.

After tightening cap, ensure the camshaft ro-

tates only slightly while holding it at “base” circle.

Tightening torque:

T1: 10 N

⋅m (1.0 kgf-m, 7 ft-lb)

T2: 20 N

⋅m (2.0 kgf-m, 14.5 ft-lb)

2.0 L MODEL

2.5 L MODEL

ME-00715

ME-00773

ME-00112

L E

R E

R I

L I

(A)

(B)

(A)

(E)

(F) (D)(C)

T1

ME-00716

T2

ME-00774

(A)(E)

(F)(B)(D)

(C)T2

T1

ME-00717(B)

(A)

(E)

(F) (D)(C)

T2

T1

ME-00775

(A)(E)

(F)(B)(D)

(C)T2

T1

Page 1529 of 2870

ME(H4DOTC)-71

MECHANICAL

Camshaft

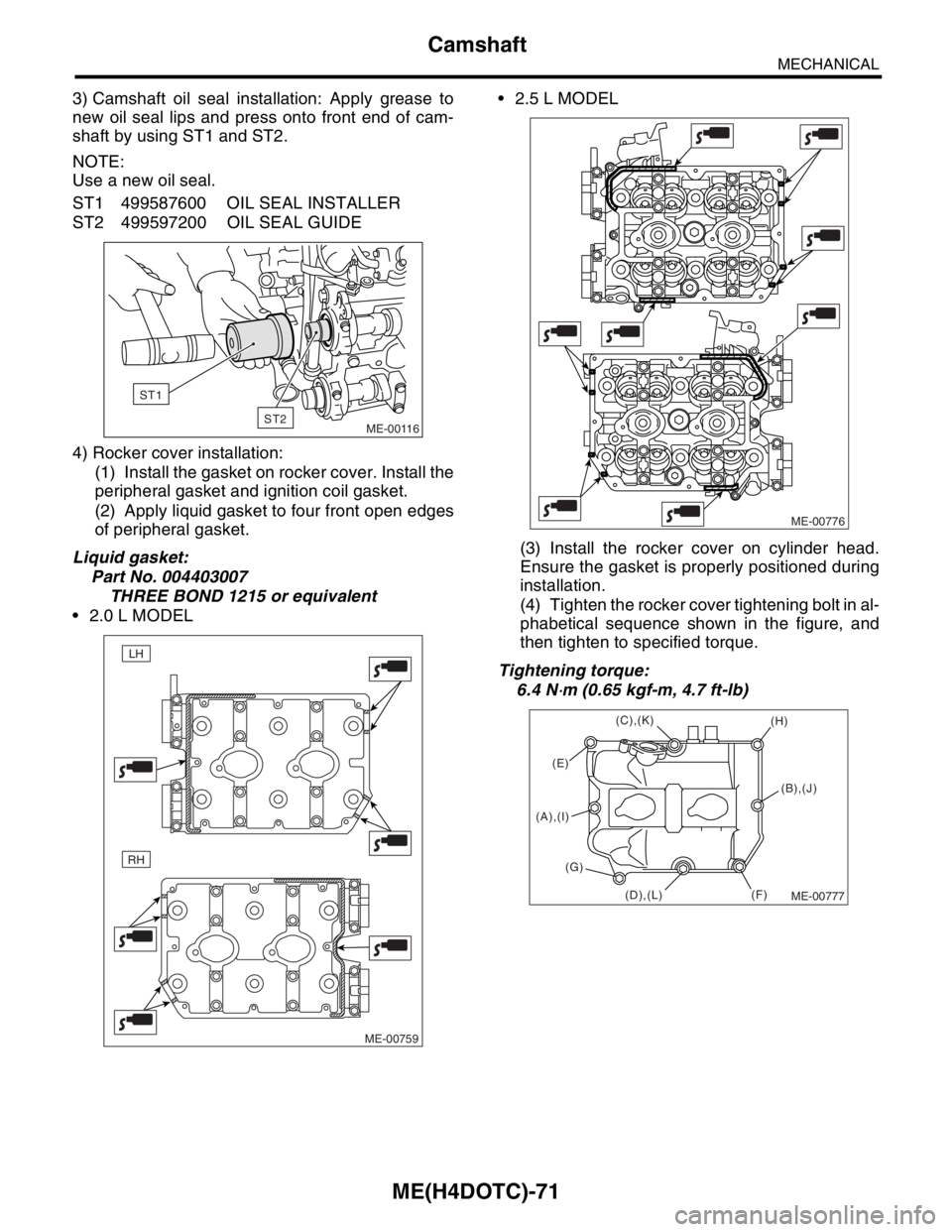

3) Camshaft oil seal installation: Apply grease to

new oil seal lips and press onto front end of cam-

shaft by using ST1 and ST2.

NOTE:

Use a new oil seal.

ST1 499587600 OIL SEAL INSTALLER

ST2 499597200 OIL SEAL GUIDE

4) Rocker cover installation:

(1) Install the gasket on rocker cover. Install the

peripheral gasket and ignition coil gasket.

(2) Apply liquid gasket to four front open edges

of peripheral gasket.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

2.0 L MODEL 2.5 L MODEL

(3) Install the rocker cover on cylinder head.

Ensure the gasket is properly positioned during

installation.

(4) Tighten the rocker cover tightening bolt in al-

phabetical sequence shown in the figure, and

then tighten to specified torque.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

ME-00116

ST1

ST2

ME-00759

RH

LH

ME-00776

ME-00777

(E)

(F)(H)

(G)

(D),(L) (A),(I)(C),(K)

(B),(J)